TORQUE

1/4”

Body color : Black, Red, Blue or Green

Body Graduation Scales

Driver 1/4” Main Scales Knob

BEFORE STARTING

CONTENTS

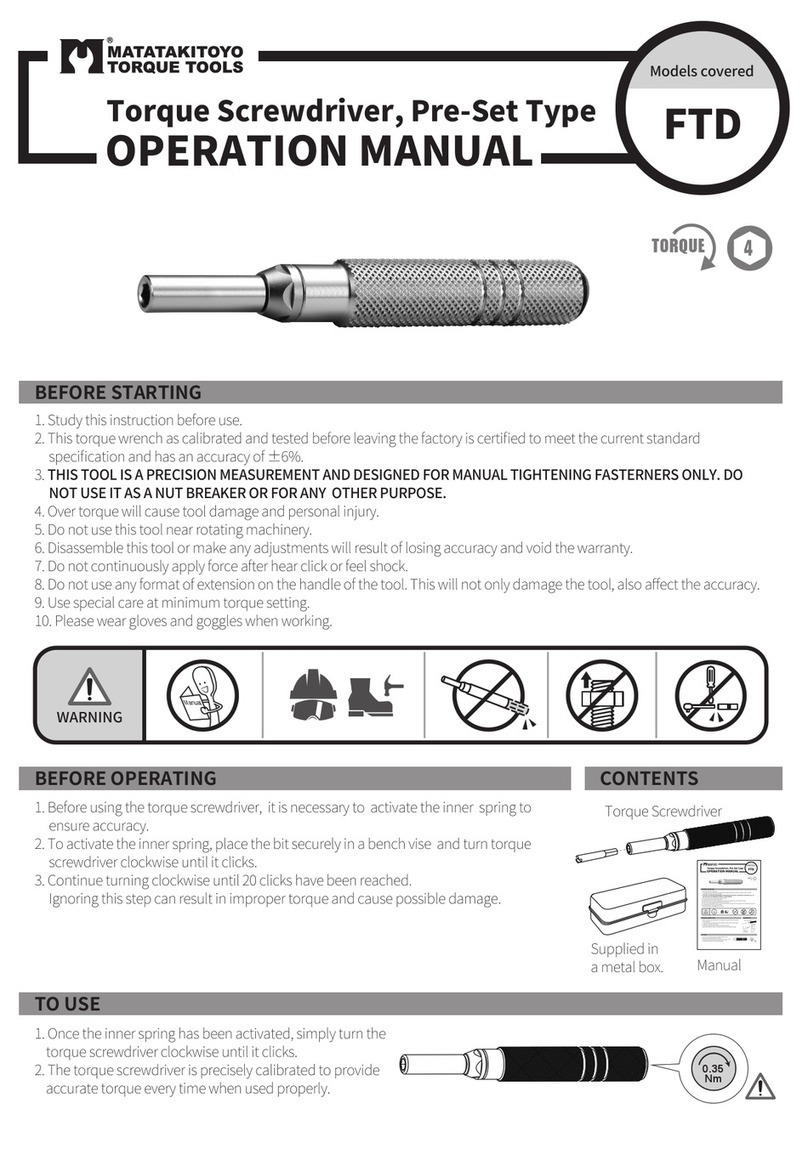

HOW TO SET TORQUE VALUE

1. Study this instruction before use.

2. This torque wrench as calibrated and tested before leaving the factory is certified to meet the current standard

specification and has an accuracy of ±6%.

3. THIS TOOL IS A PRECISION MEASUREMENT AND DESIGNED FOR MANUAL TIGHTENING FASTERNERS ONLY. DO

NOT USE IT AS A NUT BREAKER OR FOR ANY OTHER PURPOSE.

4. Over torque will cause tool damage and personal injury.

5. Do not use this tool near rotating machinery.

6. Disassemble this tool or make any adjustments will result of losing accuracy and void the warranty.

7. Do not continuously apply force after hear click or feel shock.

8. Do not use any format of extension on the handle of the tool. This will not only damage the tool, also affect the accuracy.

9. Use special care at minimum torque setting.

10. Please wear gloves and goggles when working.

Pull to unlock and turn it to set the target torque.

Then push it back to lock.

1 2 3

Set LockUnlock

For example, ITEM NO. MTD6-1405N target torque is 3.5 Nm.

Red line of main scale reach 3 Nm (see A) and adjust

graduation scale to 0.5 Nm (see B), Then 3+0.5=3.5 Nm (see C)

Manual

WARNING

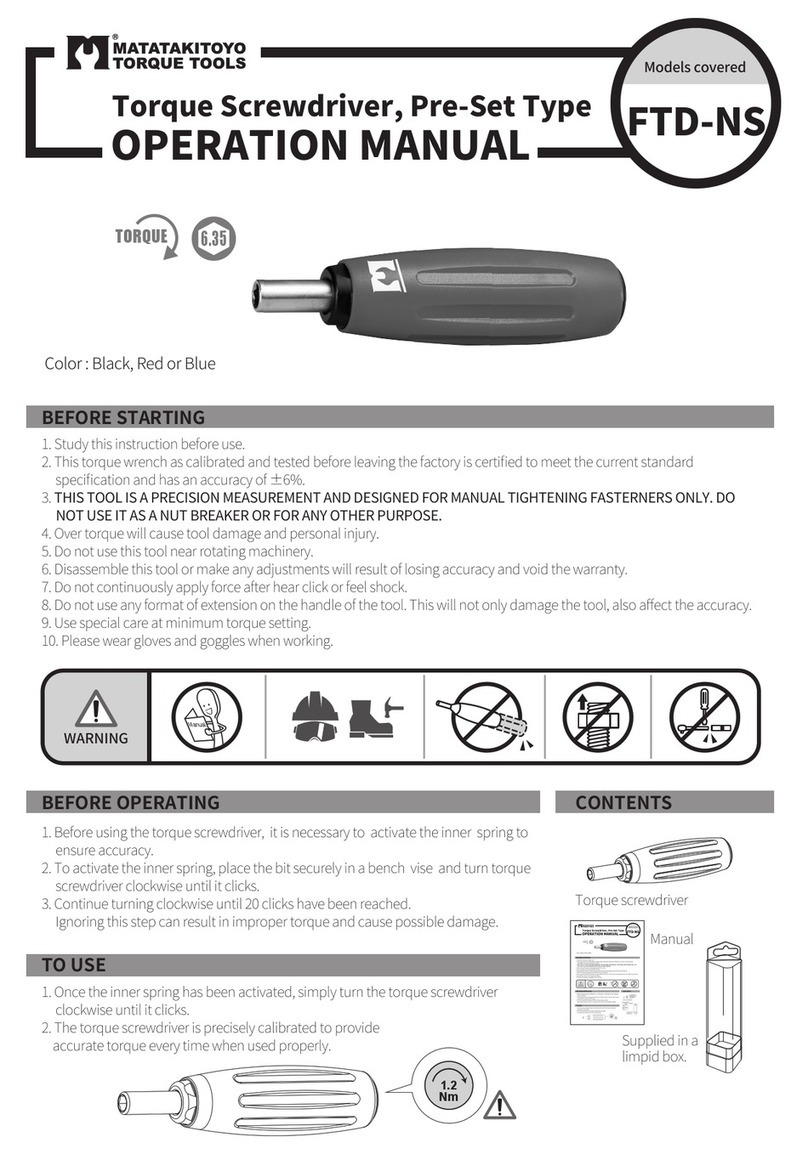

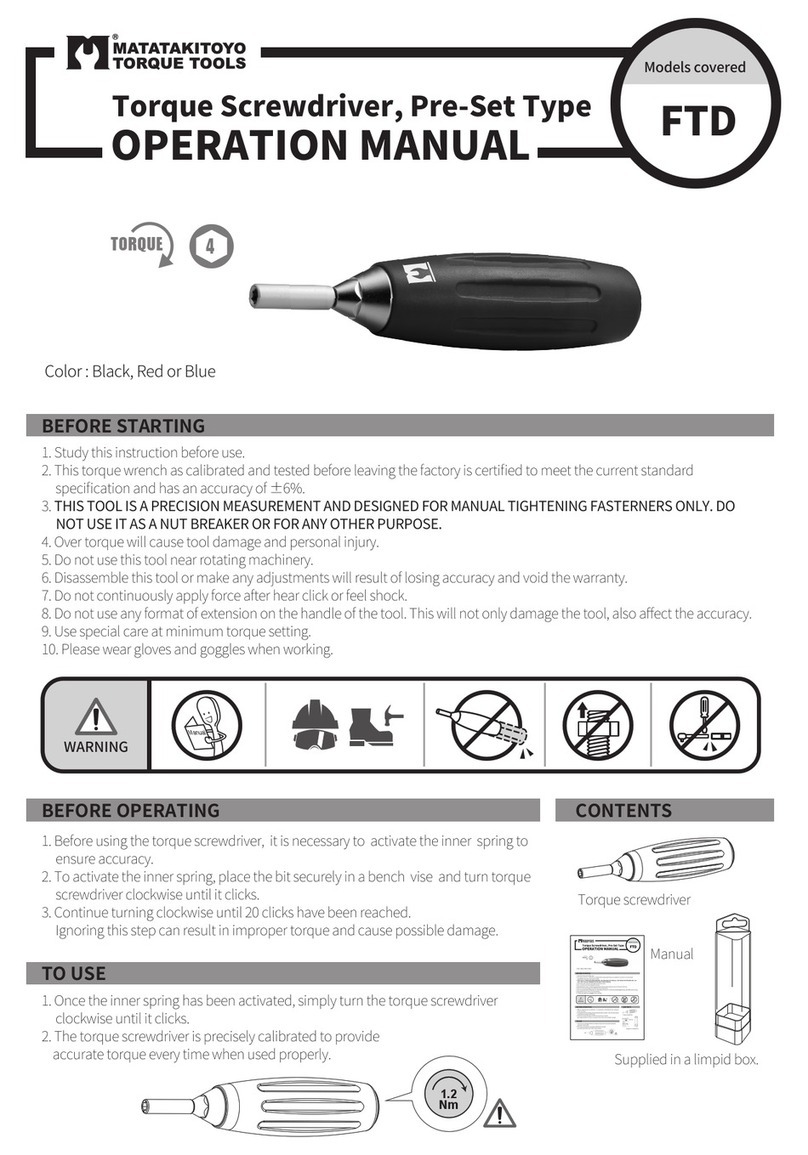

Torque screwdriver

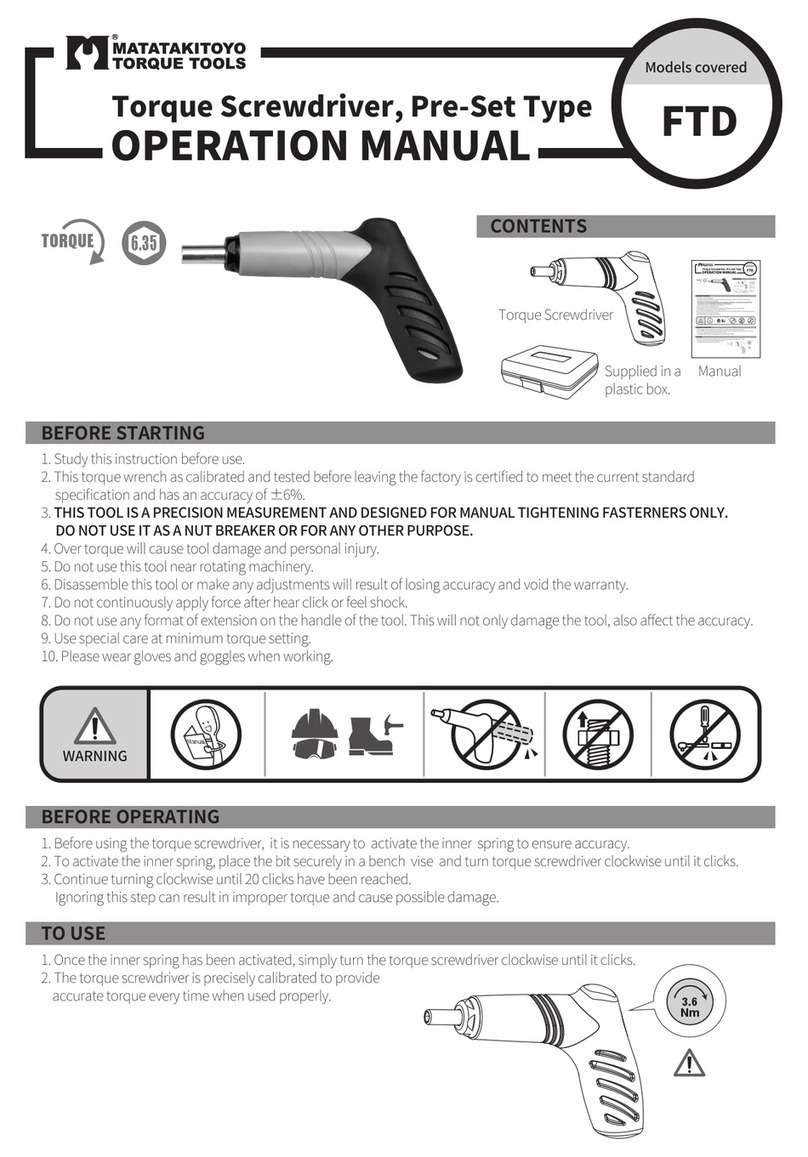

Above MTD6-1405N & 1450I with

sliding T-Handle for more convenient use.

Manual

Supplied in a plastic box.

Only MTD6-1402N & 1420I

in a limpid box.

A B C

OPERATION MANUAL

Adjustable Torque Screwdriver MTD6

Models covered