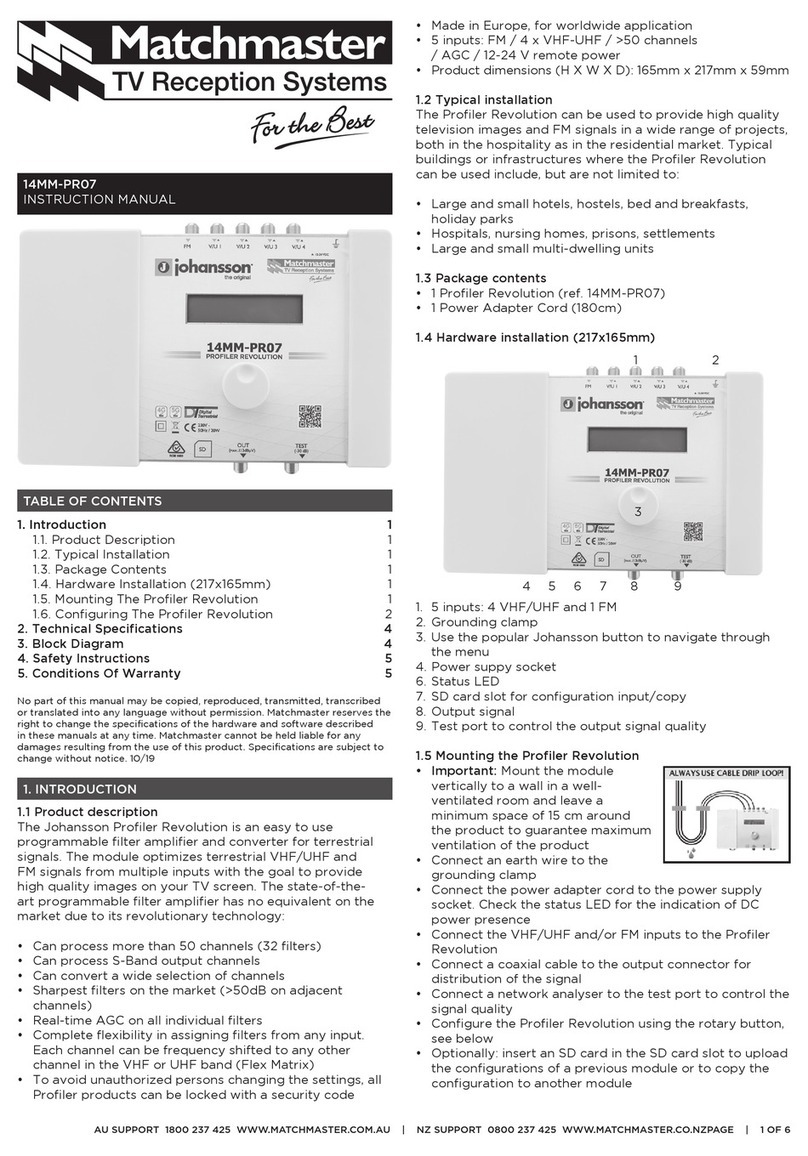

PAGE 1 OF 2 | AU SUPPORT 1800 237 425 WWW.MATCHMASTER.COM.AU

55MM-SM18 INSTRUCTION MANUAL

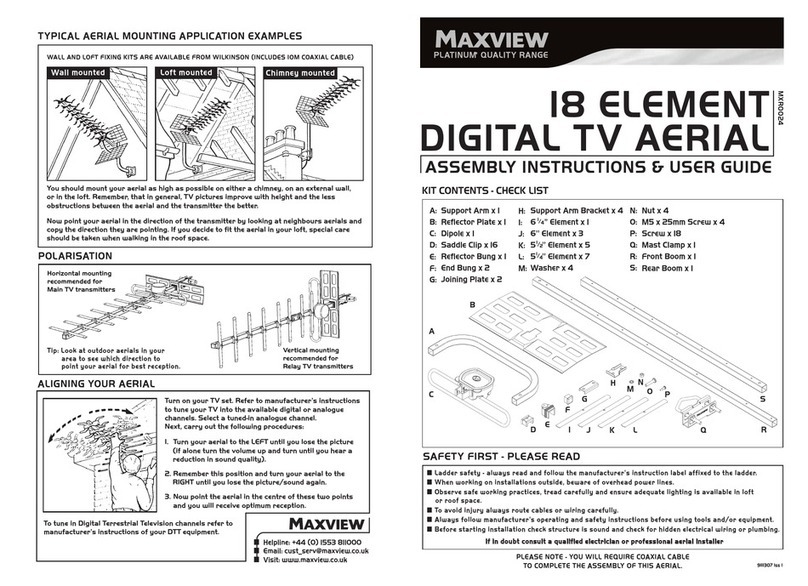

Installation Site

Installer must carefully inspect the selected roof installation

location to ensure it is structurally sound and in good repair

before installation. Please also ensure the roof location

chosen is suitable for optimal signal and accepted by the

customer before installation.

Warning

The SM18 relies upon the strength of the purlin-rafter joint to

transfer the wind load to the building structure. Therefore,

the installer must inspect joints near the mast to ensure they

are suitable and structurally sound.

Safety Warning

Dangerous live electrical cables may be present behind

roof sheets/building cladding. Please make sure to use an

earth leakage protection safety device when drilling into

any surfaces.

Note: You can adjust the attened

ends of the stay bars to suit the

installation angle by simply bending

them with an appropriate tool like a

vice grip or adjustable wrench.

Installation Limitations

You can install the SM18 to a maximum height of 8.5m above

ground level. The roof must not exceed 30 degrees slope

and have cladding rib heights between 16 and 30mm.

Rafter and batten spacings must be between 900mm

minimum and 1200mm maximum.

The SM18 mount is suitable for use on standard corrugated

cladding proles like CUSTOM ORB®, and different proles

such as TRIMDEK®or SPANDEK®, a cyclonic metal batten

kit can be used for additional strength if required at the

anchor locations (sold separately) All anchor screws must

be through the ridge of the sheeting.

The SM18 is unsuitable for tiled roofs and light gauge metal

frame roofs.

Mast and Stay Arms

The SM18 mast is 1.8m in height.

The design of the stay bars

allows them to run down the

roof from the main mast and

have a maximum allowable

length of 2200mm. The minimum

permissible overlap of the inner

and outer stay bar tubes is

150mm. See Figure 1.

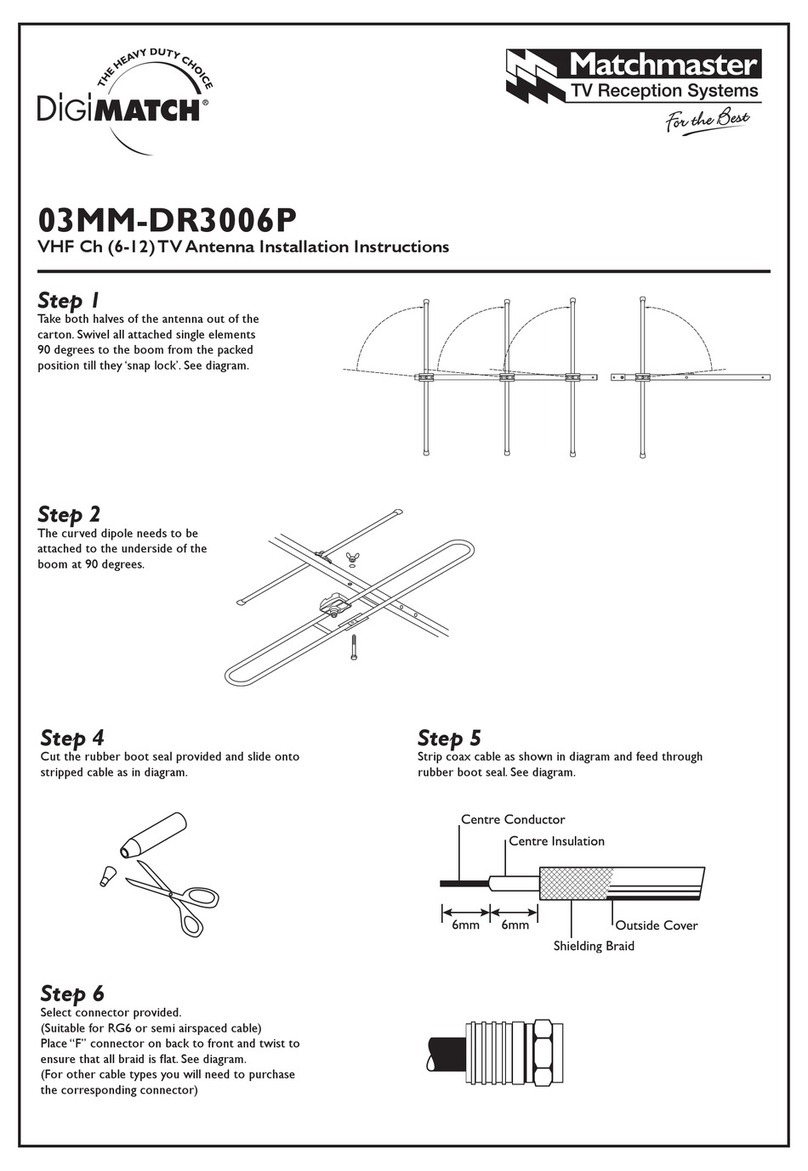

Installation Guide

Step 1: After selecting a suitable

roof position and conrming

with your client, fasten the

supplied cleat bracket to the

foot of the mast using the

supplied M8 x 30mm carriage

bolt, washers and nut. Refer to

Figure 2.

Fix the two stay bars to the

mast (450-550mm down from

the mast top) using the collar

clamp assembly with two

supplied spacers and M8 x

50mm bolt, washers and nut.

Refer to Figure 3.

Figure 1

Figure 2

Figure 3

Figure 4 Figure 4a

Step 2: Place the mast foot cleat bracket onto the roof or

ridge capping. Place some roong silicone sealant

underneath the bottom face of the mast base where the

two screws fasten and then fasten to the roof using two

Type 17, 65mm wood screws with cyclone and rubber

washers supplied. Next, extend out and attach the attened

ends of the telescoping stay tubes to the roof ridges,

rst placing some roong silicone sealant underneath the

bottom face. Again, use the Type 17, 65mm wood screws

and cyclone and rubber washers supplied.

See Figures 4 and 4a.

Step 3: The mount is nearly

complete and should look as

shown in Figure 1. Using a

spirit level (magnetic levels

make the job easier), adjust

the mast by pushing it into

place until it is plumb, now

secure in place the two stay

bars by using the supplied

10g x 16mm TEK®screws and

drilling into the pilot holes of

the stay bar overlap.

See Figure 5

Mast

Spacers

Inner Stay

Inner Stay

Outer Stay

Cleat Bracket

Cleat Bracket

M8 Bolt

M8 Bolt

M8 Nut

M8 Nut Cyclone & Rubber

Washer with

Silicone Sealant

Underneath

Cyclone & Rubber

Washer with

Silicone Sealant

Underneath

M8 Washers

M8 Washers

Adjustable

Outer Stays

M8 Bolt

M8 Washers

& Nut

Outer Stays

Warning: If xing to metal batten roofs (0.42-1.5mm

thick), use either duo cleats (55MM-DUOCLEAT) or the

cyclonic metal batten kit (sold separately) and fasten

replacing all Type 17, 65mm wood screws with Buildex®

M6.5-12 x 55 Roof Zips®screw fasteners.

*Also sold separately 55MM-BK01 Universal Batten Kit for

Metal Roofs

Figure 5

Outer

Stay

Inner

Stay

10g x 16mm

Tek Screw

(Pilot Hole)

T17 x 65mm

T17 x 65mm