Contents

Page 2

Table of Contents

1About this Operating Manual...................................................................................................................3

2Safety.........................................................................................................................................................4

2.1 Intended Use..............................................................................................................................................4

2.2 Qualification of Personnel...........................................................................................................................4

2.3 General Safety Instructions ........................................................................................................................5

2.4 Special Safety Instructions .........................................................................................................................6

2.5 Basic Rules.................................................................................................................................................7

3Task and Application ...............................................................................................................................7

4Delivery and Shipment.............................................................................................................................8

5Installation.................................................................................................................................................8

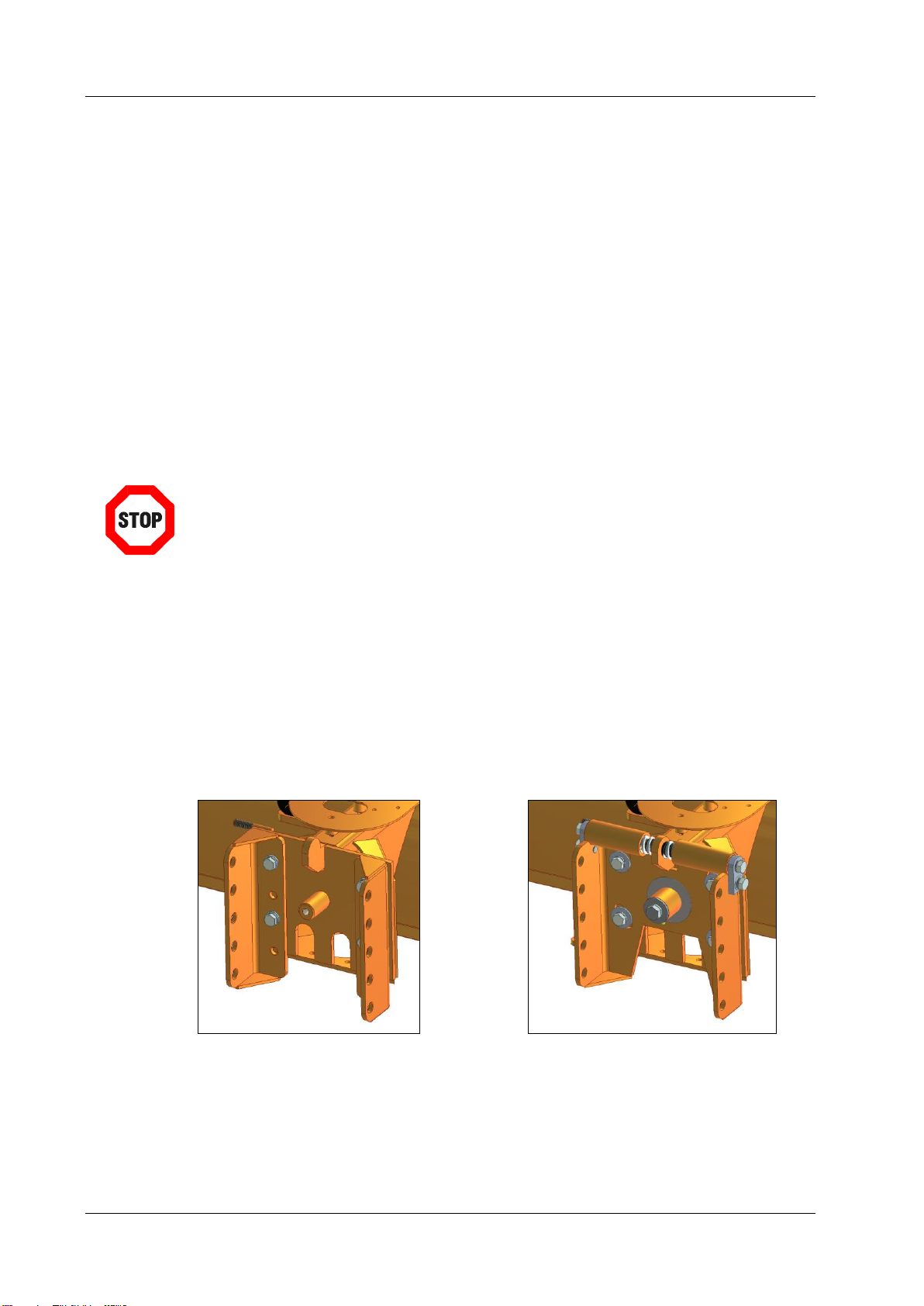

5.1 Install Adapter Extension............................................................................................................................8

5.2 Mount Extension Cat or Extension JD........................................................................................................9

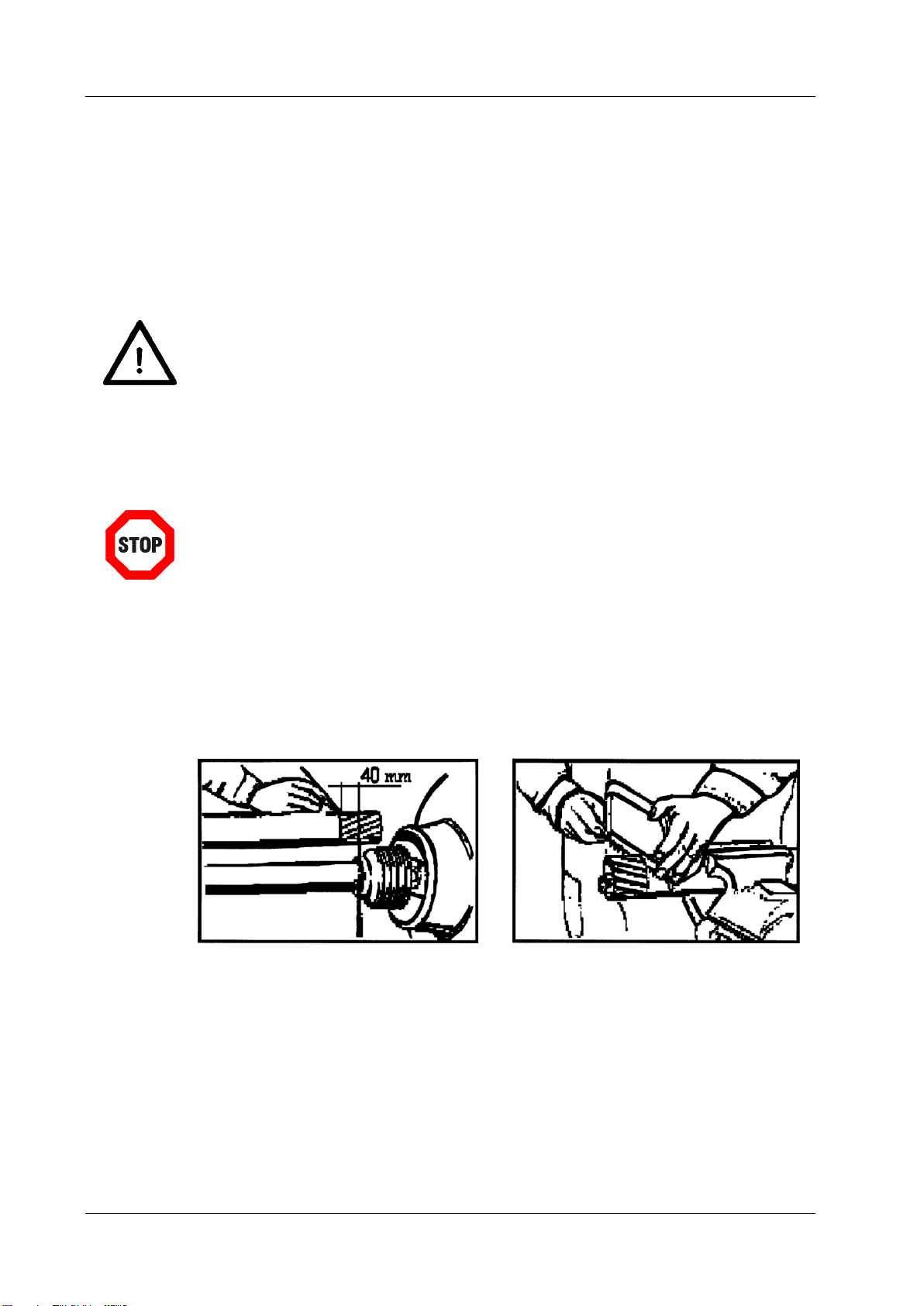

5.3 Assembly of the Drive Shaft for Sweepers with Mechanical Drive............................................................10

5.3.1 Adjusting the drive shaft ...........................................................................................................................10

5.3.2 Installing the drive shaft............................................................................................................................11

5.3.3 Drive shaft angled sharply........................................................................................................................12

5.4 Connect hydraulic connections of the sweeper to the tractor...................................................................12

5.5 Install the Dirt Catcher..............................................................................................................................13

5.6 Mount Splash Guard and Splash Plate.....................................................................................................16

5.7 Mechanically Assemble the Side Brush....................................................................................................17

5.8 Hydraulically Assemble the Side Brush....................................................................................................18

5.9 Installing the Irrigation Sprinkler ...............................................................................................................18

5.10 Electro-Magnetic Switching Valve ............................................................................................................19

5.11 Hydraulic Add-on Kit for Side Brush.........................................................................................................20

6Operation.................................................................................................................................................23

6.1 Adjust the sweeper...................................................................................................................................24

6.2 Parking the sweeper.................................................................................................................................26

6.3 Working with the Front Sweeper...............................................................................................................27

6.4 Exchange Sweeping Roller Edging ..........................................................................................................27

6.5 Rotation Speed.........................................................................................................................................28

6.6 Side Brush Mechanical and Hydraulic......................................................................................................29

6.6.1 Shift the support foot ................................................................................................................................29

6.6.2 Lift up side brush......................................................................................................................................29

7Maintenance............................................................................................................................................30

7.1 General Information..................................................................................................................................30

7.2 Maintenance.............................................................................................................................................30

7.2.1 Maintenance schedule..............................................................................................................................31

7.2.2 Lubrication schedule.................................................................................................................................31

7.2.3 Change sweeping roller............................................................................................................................32

7.3 Errors........................................................................................................................................................33

7.4 Repairs.....................................................................................................................................................33

8Disposal ..................................................................................................................................................33

9Guarantee................................................................................................................................................34

10 Technical data, Extension units and add-on kits.................................................................................34

10.1 SWE-H/M 12-45 .......................................................................................................................................34

10.2 SWE-H/M 14-45 .......................................................................................................................................34

10.3 SWE-H/M 16-45 .......................................................................................................................................34

10.4 Extension Units and Additional Equipment...............................................................................................35

11 Table of Figures......................................................................................................................................36

12 EC –Declaration of Conformity.............................................................................................................37