Note

Strictly ensure to read!!!

Forward all safety instructions on to other users!

2.1 Intended use

•The implement is designed exclusively for conventional use in agricultural and

forestry, green area and park care applications, as well as for winter service.

•Any use extending beyond the intended use cited above is considered non-

intended use. The manufacturer bears no liability whatsoever for resulting dam-

age; the risk associated with non-intended use is born solely by the operator.

•Intended use also includes compliance with the operating, service, and mainte-

nance conditions prescribed by the manufacturer.

•The implement should only be used, maintained, and repaired by persons who

are familiar with these tasks and who have been instructed in the hazards.

•The applicable accident prevention regulations as well as other recognized occu-

pational health and safety rules must be complied with.

•Unauthorized modifications to the machine result in exclusion of liability of manu-

facturer for the resulting damage. Non-intended use causes:

•Health hazards for the operator or for third parties

•Damage to the tractor and the attachments

•Environmental damage

2.2 General safety and accident prevention regulations

•In addition to the instructions in this operating manual also comply with the gen-

erally valid safety and accident prevention regulations! People under the age of

18 should not operate the device!

•Comply with the respective regulations for use on public traffic routes!

•Prior to starting work familiarize yourself with all fixtures and activation elements

and the function of these fixtures and elements. Ensure that all protective devices

are properly attached. It is too late to do this during work implementation!

•The user is responsible for third persons in the work area!

•It is prohibited for anyone to be in the danger zone of the machine.

•Prior to starting up the machine check the area around the machine (watch for

children). Ensure that you have an adequate view.

2.3 Special safety instructions

•Escaping fluids (hydraulic oil) can penetrate the skin and cause severe injuries!

Consequently seek medical attention immediately if such injuries have occurred –

danger of infection!

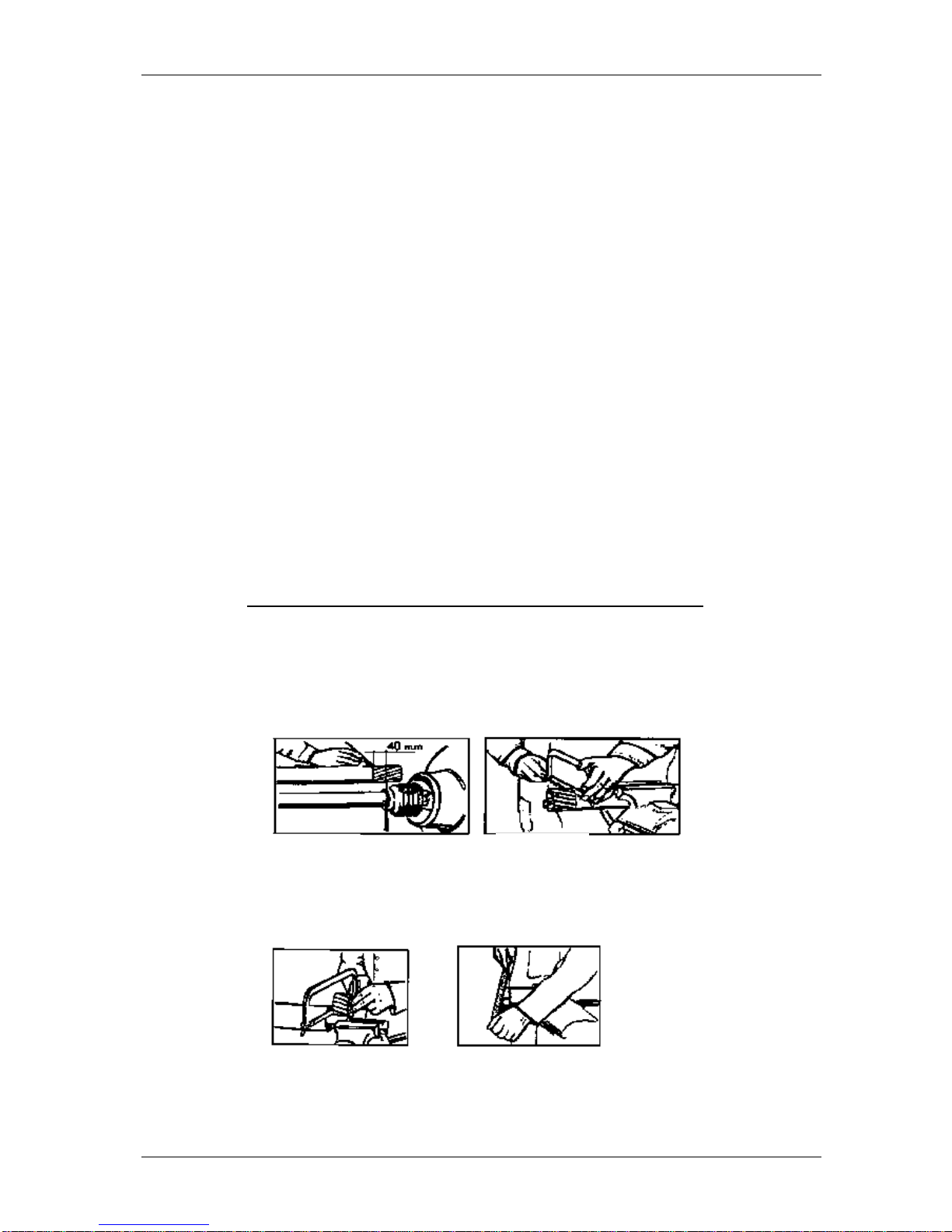

•Repair, maintenance and cleaning tasks, as well as correcting malfunctions

should always be performed with the drive switched off and the engine at a

standstill. Remove the ignition key! After executing these tasks re-attach all pro-

tective devices!

•For maintenance tasks performed on the lifted device always use suitable support

elements as safeguards!