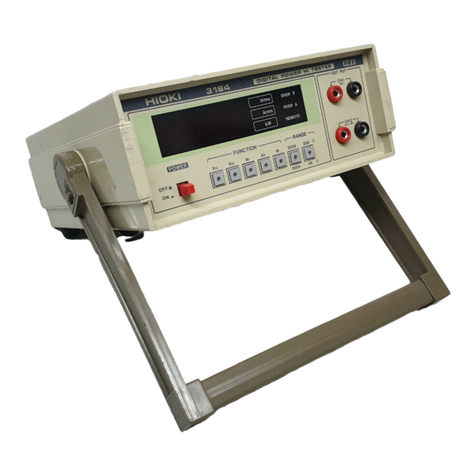

Step 4. Viewing Instantaneous Data

View instantaneous measurement conditions.

(Refreshed approx. every second.)

Press the key to hold the display.

(Press again to disable hold.)

Display Hold Display Hold disabled

Step 5. Viewing Recorded Measurement Data

(recorded measurement data is backed up even when the instrument's power is turned off)

Viewing measurement process and results

Updating the screen

Compressing internal memory

The time series graph displays within the screen at all times

each measurement result from recording start.

Event Recording Status Indicator

Step 6. Viewing Recorded Data (Measurement Data, Screen Image) on a Computer

Screen image 3197 Applications (Install from the supplied CD.)

Measurement data (TIME PLOT data)

<Automatic data recording compression function>

This function begins recording at one-second intervals and automatically lengthens the

recording interval to up to an hour as internal memory fills. This function helps to ensure

that suitable data quantities are acquired for analysis, whether the overall measurement

period is short or long. This function supports continuous measurement sessions of up to

about 125 days.

Measurement data (EVENT data)

<Recordable Number of Events>

The number of events that can be recorded is as follows regardless of whether internal

memory is partitioned.

USB connection procedure

Screen Display Description

VIEW

[WAVEFORM ] Displays instantaneous mea

surement values.

Measurement data can be

viewed at any time regardless

of recording start or stop state

[VECTOR]

[ HARMONICS]

[DMM]

Changes

magnification

rate for

waveform

display

WAVEFORM VECTOR HARMONICS DMM

Displays voltage

and

current waveforms.

Displays a voltage

and

current vector diagram.

Displays the results of harmonic wave-

form measurements of voltage, current,

and active power to the 50th order.

Displays the instantaneous voltage,

current, and power values for each

measurement channel.

Switches

phase

angle

display

Switches

between bar

graph and

numerical

value list

Switches

channels

Screen Display Description

TIME

PLOT

[RMS] Displays data at each mea

surement interval as a time

series graph.

Shows fluctuations that occu

between recording start and

stop.

[DIP/SWELL]

[DEMAND]

[ENERGY]

Graph fills screen Graph is compressed

Internal memory full Internal memory

compressed

RMS DIP/SWELL DEMAND ENERGY

Various calculated rms values are

displayed in a time series graph with

maximum, minimum, and average

values during every interval.

Displays calculated rms

voltage for one waveform

shifted by one-half cycle. Displays demand values for

each specified demand period.

Energy consumption values of

active power [kWh] or reactive

power [kvarh] are displayed.

Changes

displayed

parameters

DisplaysU1,

U2, U3

voltage

fluctuation Maximum/

average

value within

the period

Energy value

within the

period

Displayed Parameter

Freq, U1, I1, U2, I2, U3, I3, I4, U1peak+,

U1peak-, I1peak+, I1peak-, U2peak+,

U2peak-, I2peak+, I2peak-, U3peak+,

U3peak-, I3peak+, I3peak-, Uave, Iave,

Psum, Qsum, Ssum, PFsum, DPFsum,

THD1, THD2, THD3, Uunb

Selects cursor operation

Changes displayed parameters

Displayed Parameter Content

Pdem+ Active Power Demand

(consumption only)

Pdem- Active Power Demand

(regenerated only)

QdemLAG Reactive Power Demand

(lagging only)

QdemLEAD Reactive Power Demand

(leading only)

Displayed Parameter Content

WP+ Active Power

(consumption only)

WP- Active Power

(regenerated only)

WQLAG Reactive Power

(lagging only)

WQLEAD Reactive Power

(leading only)

Changes

displayed

parameters

Screen Display Description

EVENT

[WAVEFORM] Displays the results of event

detection.

Shows the contents of events

detected between recording

start and stop.

[DETAIL]

[RMS WAVE]

[INRUSH]

Event

onitor

Even

list

Transient SWELL DIP Interruption Other

Indicates that six events have been recorded

Indicates that 46 events have been recorded

WAVEFORM DETAIL RMS WAVE INRUSH

Displays voltage waveforms and

current waveforms at event

detection alternately. Displays list and details at

event detection. Displays a graph showing rms

voltage fluctuations at event

detection.

Displays a graph showing

inrush current fluctuations at

event detection.

Displayed

when

INRUSH

exists

Details of

selected

event

Switches

between

voltage

waveform

and

current

waveform

Selects

cursor

event

Displayed

when DIP,

SWELL, or

INTER.

exists.

Press the key to store the displayed screen.

Approximately 30 to 40 screen images can be stored in

internal memory.

CHECK!

BMP data saved.

Data number : 4

Remaining volume [kB] :671

Press ESC to close window.

< Save screen image > Sample Message

3197 Computer

Operate the instrument remotely.

(observation, control and screen

capture)

Download screen images and

measurement data from the

instrument's internal memory.

Analyze data recorded by the

instrument

USB Cable

You can also analyze recorded

measurement data with the 9624-

50. (Available soon)

3197 Communicator

• Remote operation

• Download

3197DataViewer

• Recorded measurement

data analysis

Event Recordable Qty. Description

Event data Total 50 Event List, details, voltage/current wave-

forms

Event voltage fluctuation graph

data Total 20 Event voltage fluctuation graph for 4

seconds

Inrush current fluctuation graph

data 1Inrush current fluctuation graph for 30

seconds

2With attention to connector

orientation, insert the USB cable

plug into the port.

Remove the dust

cap from the USB

port

(The cap bends along

the dotted line shown

in the illustration on

the right and remains

attached to the unit.)

1

Dust Cap

Flip open