CONTENTS

INTRODUCTION ……………………………………………………………………… 4

Audience …………………………………………………………………………….….. 4

Getting Started ……………………………………………………………….…………. 4

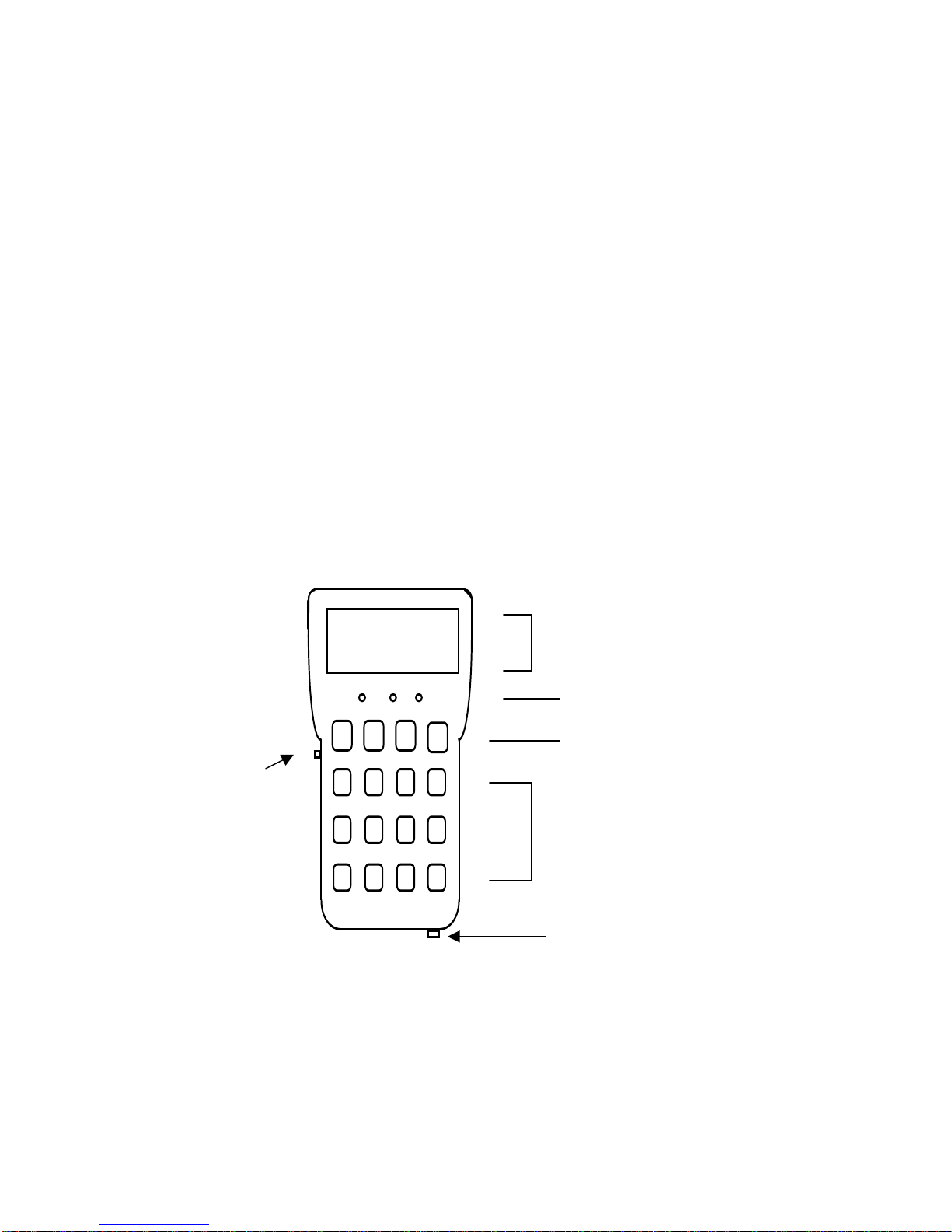

LCD Display ……………………………………………………………………………. 5

LED Indicators ………………………………………………………………………….. 5

Soft Keys …………………………………………………………………………….….. 5

Categorized Function Keys …………………………………………………………...... 6

Categorized Function Key Descriptions ………………………………………………... 6

The FRAME Key ……………………………………………………………………...… 6

The CODE Key …………………………………………………...……………………... 6

The PATTERN Key ……………………………………………………………………... 6

The TEST PERIOD Key ………………………………………………………….…….. 7

The ERROR Key ………………………………………………...…….……………….. 7

The INPUT Key .................................................................………………………….…... 7

LIU...........................................................…………………………………………….….. 7

CLOCK ..............................................................................……………………………… 8

The LOOP Key ..................................................................……………………………… 8

The AUTO Key ..................................................................……………………………… 9

The ADV. Key ...................................................................…………………..………… 10

ALARM enable/disable ......................................................…………………….……… 10

POWER conservation enable/disable .................................……………………….…… 10

Nx64 (Fractional E1)..........................................................………………………..…… 10

Additional Bits Manipulation ............................................……………………….…… 11

IDLE Code Define .............................................................………………………..…… 11

DATA Pattern Received .....................................................……………………….…… 11

SIG (Signaling Bits) ..........................................................…………………….……..… 11

CLEAR ................................................................................…………………………… 11

S/N ........................................................................................……………...…………… 11

The HELP Key .....................................................................…………………………… 11

APPENDIX A FACTORY DEFAULT SETTINGS.............……………………...…… 12

APPENDIX B ABBREVIATIONS USED ..........................…………………….…….. 13

APPENDIX C SPECIFICATIONS......................................…………………...…….… 14

3