1

Calder Brothers Corp

V1.0

Serial Number Range:

848-S-56TCG9Y2*03848 to ________________

Page 1

Model: 1560 Paver

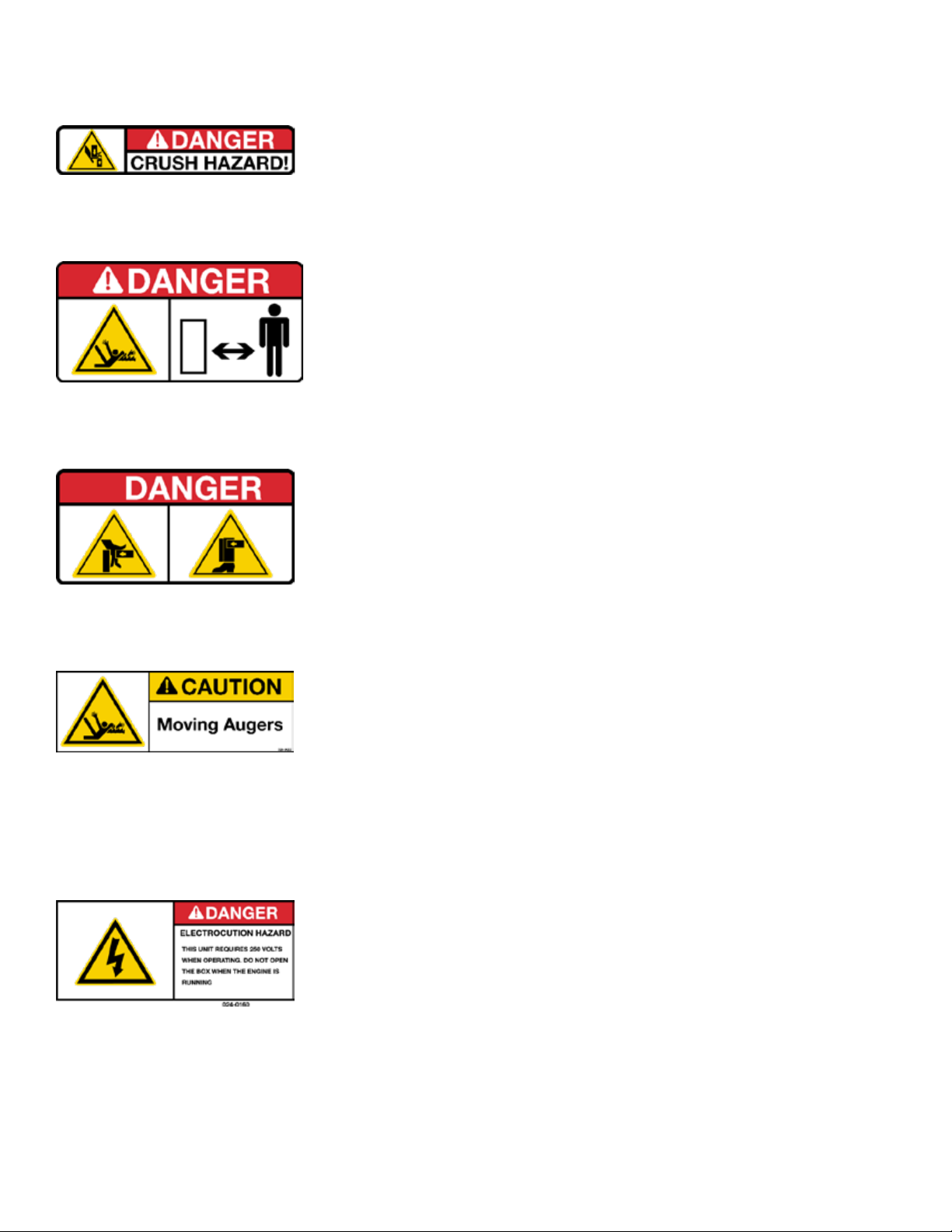

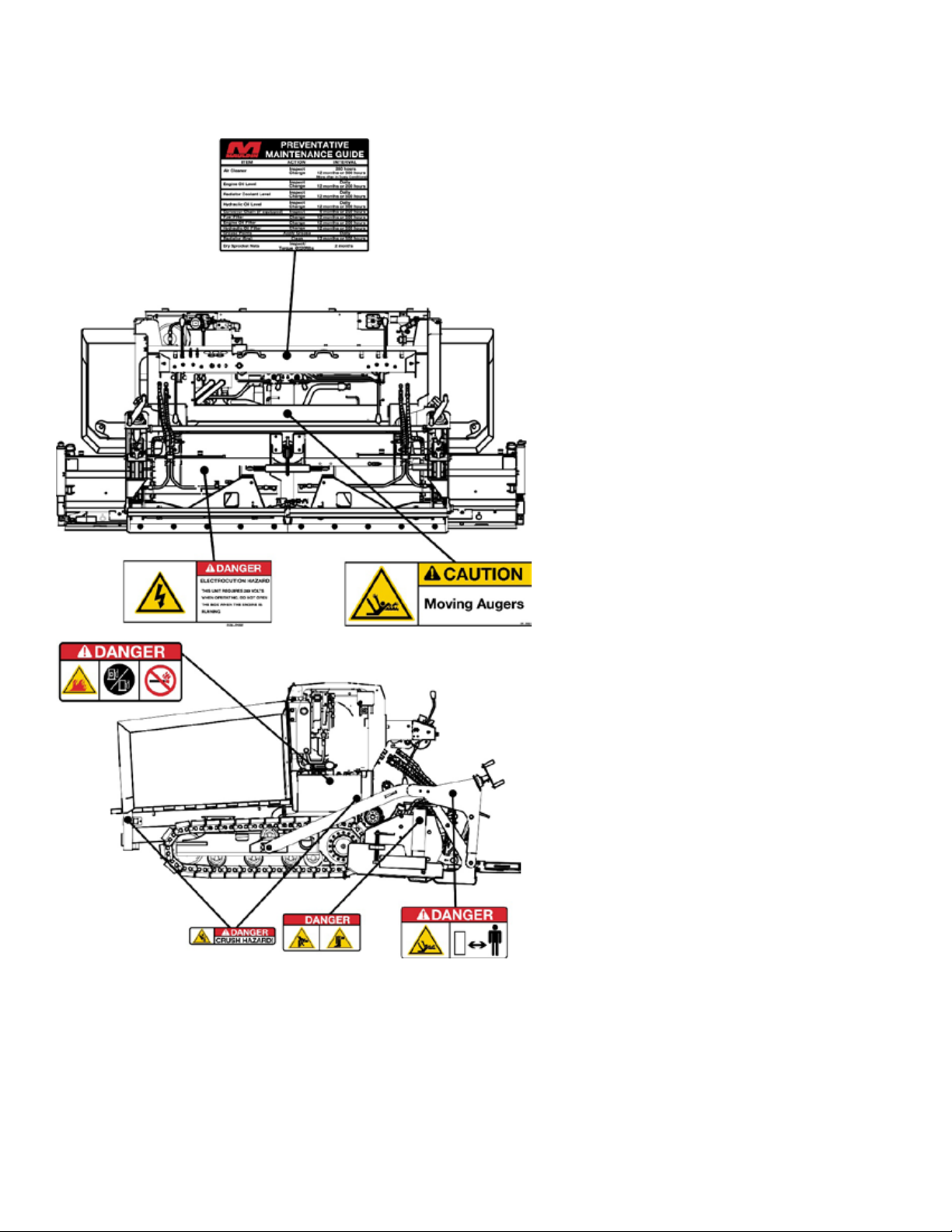

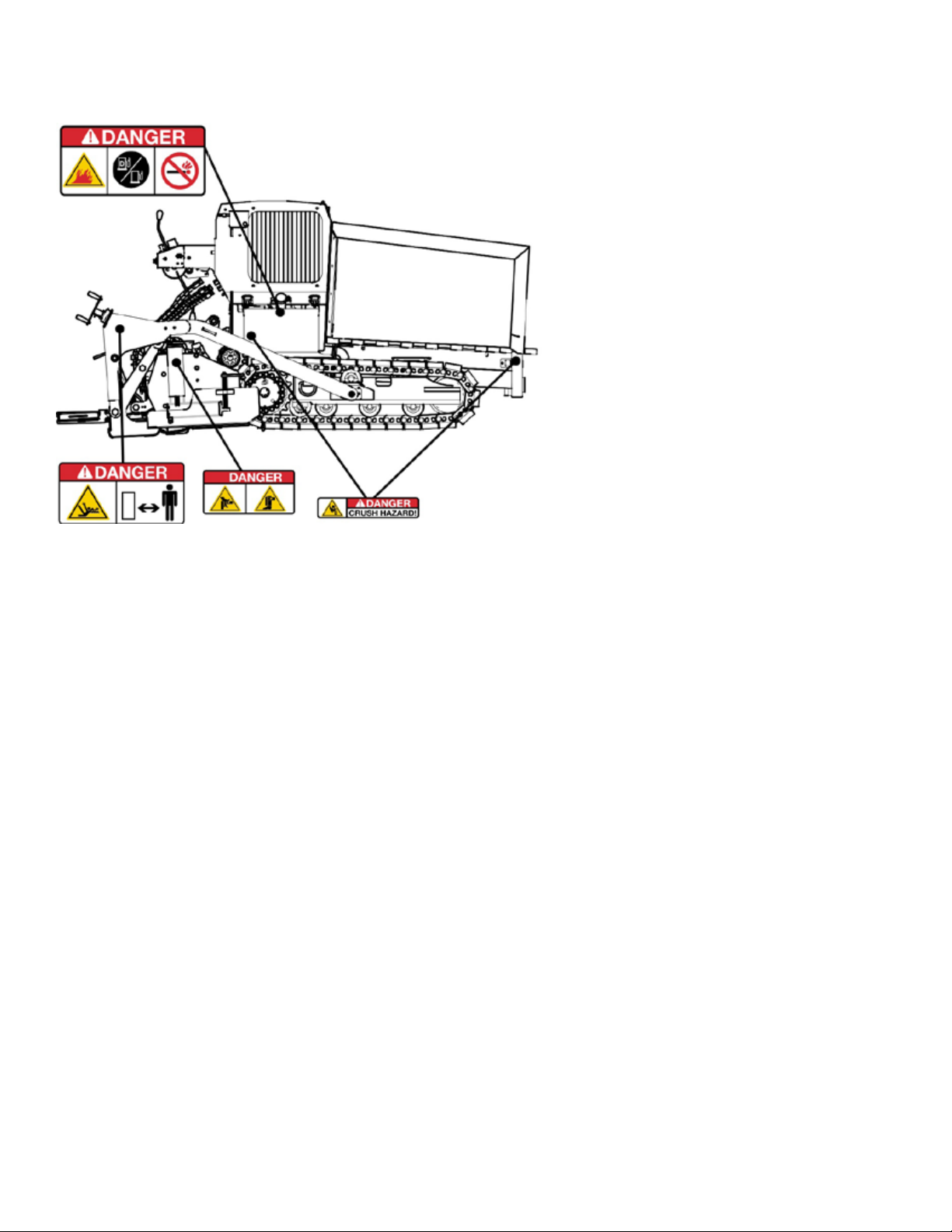

Safety

IMPORTANT SAFETY INFORMATION

Most accidents involving paver maintenance are caused by failure to observe basic safety

rules or precautions.

An accident can often be avoided by recognizing potentially hazardous situations before

an accident occurs.

Read and understand all safety precautions and warnings, before operating or performing

lubrication and maintenance on this paver.

WARNING: IMPROPER OPERATION, LUBRICATION OR MAINTENANCE OF THIS PAV-

ER CAN BE DANGEROUS AND COULD RESULT IN INJURY OR DEATH.

WARNING: DO NOT OPERATE THIS PAVER UNTIL YOU READ AND UNDERSTAND

THE INSTRUCTIONS IN THE OPERATION SECTION OF THIS MANUAL.

WARNING: DO NOT PERFORM ANY LUBRICATION AND MAINTENANCE ON THIS

PAVER UNTIL YOU READ AND UNDERSTAND THE INSTRUCTIONS IN THE MAINTE-

NANCE SECTION OF THIS MANUAL.

DANGER: RELEASE, RESTRAIN, OR OTHERWISE RENDER SAFE ALL POTENTIAL

HAZARDOUS STORED OR RESIDUAL ENERGY. IF A POSSIBILITY EXISTS FOR RE-

ACCUMULATION OF HAZARDOUS ENERGY, REGULARLY VERIFY DURING THE

SERVICE AND MAINTENANCE THAT SUCH ENERGY HAS NOT REACCUMULATED

TO HAZARDOUS LEVELS.