2

Tape Technology

Figure 1

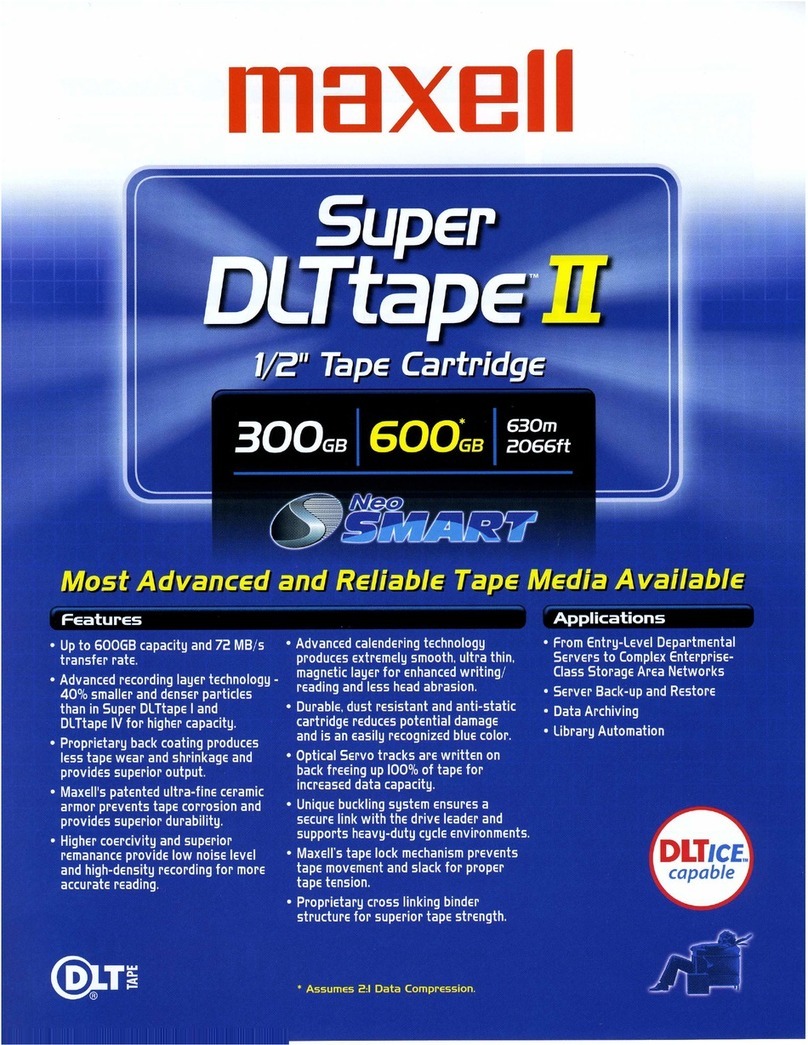

Features such as factory written servo tracks (see

figure 1), keep heads aligned for precise data

reading/writing to ensure proper tracking for all

128, 256, or 384 tracks for the entire length of the

tape. Because linear serpentine recording

technologies require many back-and-forth

traversals of the tape, this shoe shining process

often results in high heat build-up of the record

heads and stress to the tape's coated surface. Under

these extreme conditions, the tape has a life

expectancy that depends on the number of passes

and the speed used to record and playback.

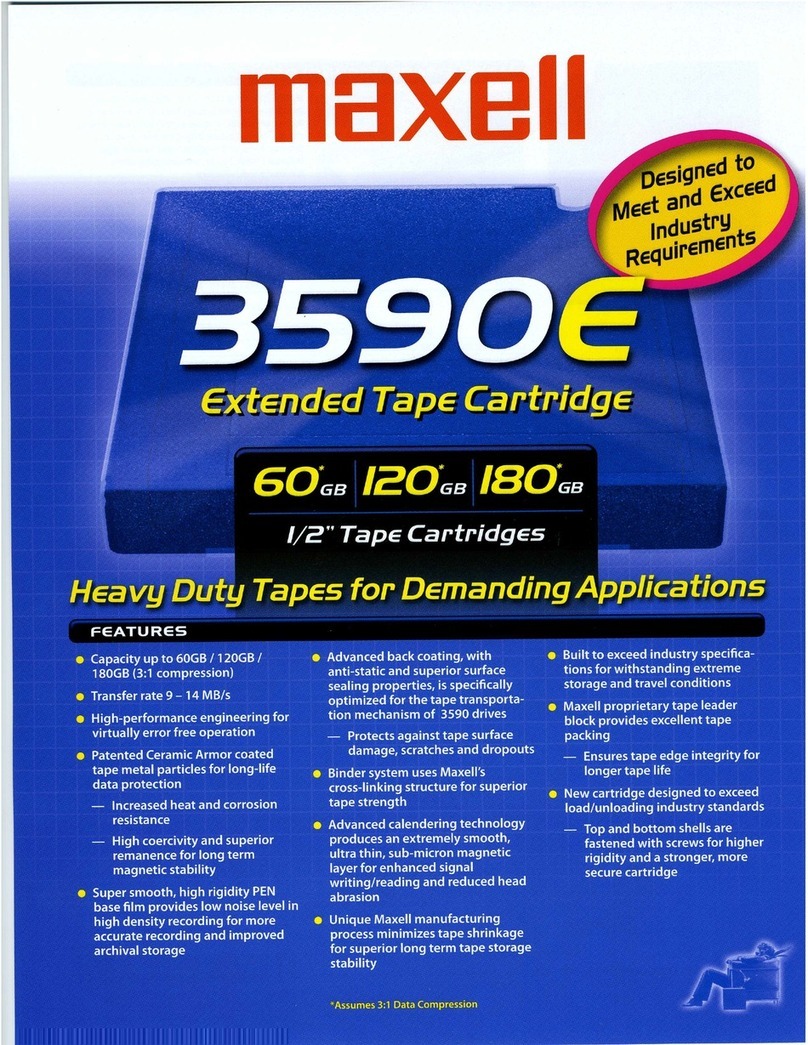

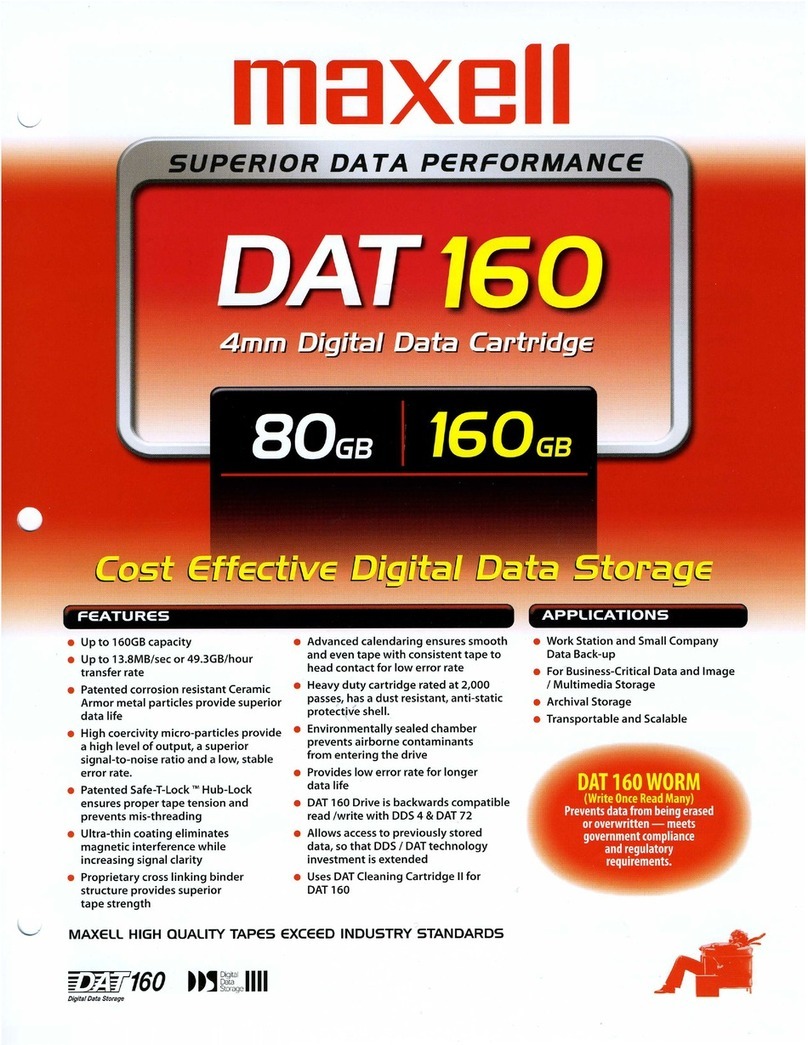

Maxell Enterprise tape is manufactured with an

additional layer (optimized back coat) to control

friction and static charges during the tape running

mode (figure 2). This optimized back coat also

serves to protect the base film against mechanical

tape transport scratches by improving the tape's

runability and reliability.

Additionally, the back-coating of the tape has anti-

static and surface sealing properties that protects the

recording side from dropouts and reduces errors and

damage to the tape caused by dirt and dust.

Figure 2

Maxell Enterprise cartridges are not only designed to perform error free but also have an archival life in excess

of 30 years to preserve valuable data for the long term.

Low Error Rate

The Maxell Enterprise media employs our proprietary Ceramic Armor Metal magnetic particles. Combining it

with Maxell’s unique multi-orientation technology to effectively utilize its high magnetic energy, Maxell has

achieved a remarkable high output low noise tape. Low error rate is also reached by achieving superior low

noise characteristics.

As figure 3 (below) illustrates, Maxell's tape media cartridges are designed to be error free even when used up

to 40,000 read-forward cycles. Thanks to the superior, reliable and resilient qualities of the Ceramic Armor

Metal Particle formulation, Maxell's media is proven to contain fewer Read Permanent and Read ECC Errors

than the competition.