/

I. SAFETY PRECAUTIONS & ASSEMBLY TIPS:

(IMPORTANT –READ THIS SECTION BEFORE YOU BEGIN ASSEMBLY)

1. This product should not be considered a toy, but rather a sophisticated, working model that functions much

like a full-scale airplane. Because of its performance capabilities, this product, if not assembled and operated

correctly, could cause injury to you or spectators and damage to property. Maxford USA provides you with a

high-quality, thoroughly tested model airplane kit with assembly instructions. However, the quality and

capabilities of your finished model airplane depend on how you assemble it, and your safety depends on how

you use and fly it. Any testing or flying of this model airplane is done entirely at your own risk.

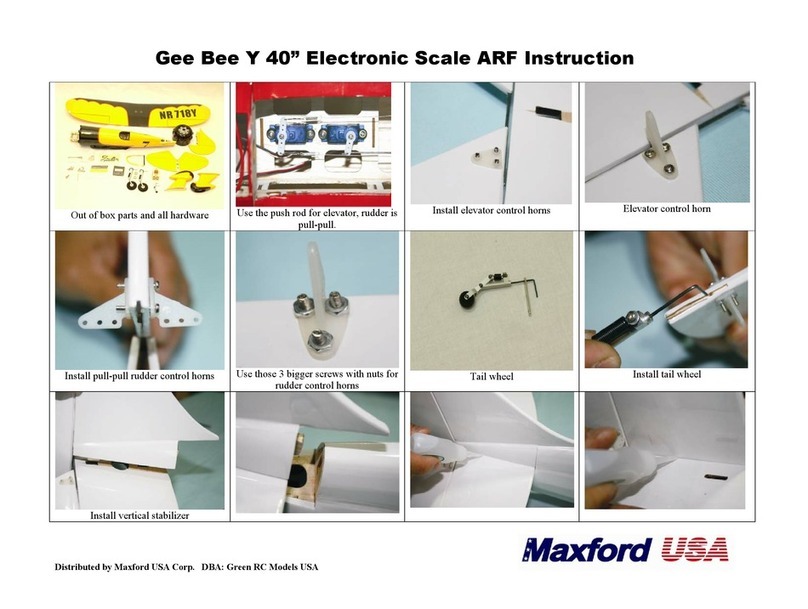

2. Assemble this model airplane according to these instructions. Do not alter or modify the model beyond the

assembly and power system options covered in these instructions, as doing so may result in an unsafe or

unworkable model. In a few cases the instructions may differ slightly from the photos; in those instances the

written instructions should be considered as correct. If you have any question or concern about these

instructions, before you proceed with assembly of this product, contact your dealer, or speak to a Maxford

USA customer service representative at 562-529-3988 (Monday through Friday, except national holidays,

9 AM to 5 PM Pacific time).

3. While this kit has been flight-tested to meet or exceed our rigid performance and reliability standards in

normal use, if you elect to perform any extremely high-stress flying, such as racing or advanced aerobatics,

or if you install a larger power system than specified, you (the buyer or user of this product) are solely

responsible for taking any and all necessary steps to reinforce the high-stress points and/or substitute

hardware that is more suitable for such increased stresses.

4. Throughout the lifetime of this model, use only the Maxford USA-supplied or a same-sized motor and a new

or well-maintained radio control system and batteries recommended by Maxford USA or your radio system.

5. It is your responsibility to install the receiver and connect the R/C components in such a way that this model

airplane passes all applicable safety/range tests and that the power system and controls operate correctly and

smoothly.

6. Recheck the operation of this model airplane before every flight to ensure that all equipment is still operating

correctly and that the model has remained structurally sound. Also before every flight, check all electrical,

control and structural connections; do not fly without replacing any that you find damaged or worn.

7. Before you begin assembly of this model airplane, read all instructions and test-fit each part to ensure you

fully understand the instructions and that no parts are missing, damaged or unsatisfactory.

(Note: Temperature and/or humidity differences between the factory, our warehouse and your home or

workshop may indicate the need for slight adjustments to the wing saddle, cabane struts and/or the horizontal

stabilizer‟s mounting platform to ensure the wing is parallel to the horizontal stabilizer; however, we

recommend you contact us before you attempt any such adjustments.)

8. If you are not an experienced R/C pilot or have not flown this type of model

before, we strongly urge you to get assistance from an experienced R/C pilot.

9. To help ensure the security of your servo connections, we recommend use of

optional Maxford USA servo extension safety clips. (This JN-4 includes two

preinstalled servo safety clips, one for each aileron servo extender cable).

10. You may apply 30-minute epoxy to permanently attach critical parts (such as where the horizontal and

vertical stabilizer attach at the end of the fuselage) and apply a thread-lock compound to secure the motor‟s

mounting hardware from vibration.

11. If you have concern about the security of any factory fabrication procedure(s), you may apply 30-minute

epoxy around the perimeter of such part(s) as an extra safety precaution.

12. This model includes some plastic, fiberglass and/or carbon-fiber reinforced parts. If you drill, grind or sand

such a part, always wear safety goggles, a particle mask and rubber gloves to guard yourself from eye, skin

and respiratory-tract irritation and never blow into the part (the dust may blow back into your face).

13. Check the Mylar covering material‟s joints and surfaces; if necessary, carefully use a dedicated covering-

material iron (do NOT set the iron‟s temperature too high) to secure the edges and to tighten any loosened

areas. Recheck and retighten from time to time.