/

TABLE OF COTETS

I. Important safety precautions ............................. 2

II. Warranty, lia ility waiver, and return policy .... 2

III. Specifications .................................................... 3

IV. Special features .................................................. 3

V. Parts List ............................................................ 4

VI. Assem ly instructions ................................. 4

VII. Setup and adjustments ............................... 11

VIII. Preflight checks ......................................... 11

I. IMPORTAT SAFETY PRECAUTIOS TO PROTECT YOUR MODEL, YOURSELF & OTHERS:

1. This product should not e considered a toy, ut rather a sophisticated, working model that functions much like

a full-scale airplane. Because of its performance capa ilities, this product, if not assem led and operated cor-

rectly, could cause injury to you or spectators and damage to property. Maxford USA provides you with a high-

quality, thoroughly tested model airplane kit with assem ly instructions. However, the quality and capa ilities

of your finished model airplane depend on how you uild it, and your safety depends on how you use and fly it.

Any testing or flying of this model airplane is done entirely at your own risk.

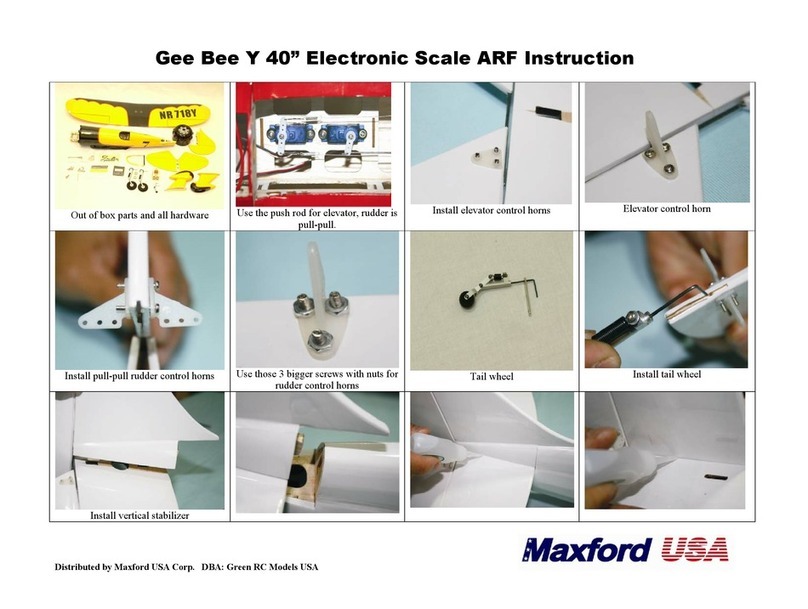

2. Assem le the model airplane according to these instructions. We recommend that you do not alter or modify the

model eyond the assem ly options covered in these instructions, as doing so may result in an unsafe or un-

worka le model. In a few cases the instructions may differ slightly from the photos; in those instances the writ-

ten instructions should e considered as correct. If you have any question or concern a out these instructions,

efore you proceed with assem ly of this product, contact us at 562-529-3988 (Monday through Friday, except

national holidays, etween 9 AM to 5 PM Pacific time).

3. It is your responsi ility to install the R/C system and other components in such a way that this model airplane

passes all applica le safety/range tests and that the power system and controls operate correctly and smoothly.

4. Recheck the operation of this model airplane efore every flight to ensure that all equipment is still operating

correctly and that the model has remained structurally sound. Also, efore every flight check all electrical

and/or structural connections; do not fly without replacing any that you find damaged or worn.

5. If you are not an experienced R/C pilot or have not flown this type of model efore, we strongly recommend

that you get the assistance of an experienced R/C pilot.

6. Throughout the lifetime of this model, use only the Maxford USA-recommended or same-sized motor and a

new or well-maintained R/C radio system and atteries recommended y the maker of the motor and radio sys-

tem.

7. While this kit has een flight-tested to meet or exceed our rigid performance and relia ility standards in normal

use, if you plan to perform any extremely high-stress flying, such as racing or advanced aero atics, or if you

plan to install a larger power system than specified, you (the uyer or user of this product) are solely responsi le

for taking any and all necessary steps to reinforce the high-stress points and/or su stitute hardware that is more

suita le for such increased stresses.

II. WARRATY, LIABILITY WAIVER, AD RETUR POLICY:

Maxford USA guarantees this kit to e free from defects in material and workmanship at the time of purchase.

All of our products have een inspected in our factory and are checked again when shipped from our ware-

house.

However, Maxford USA cannot directly control the materials you may use nor your final assem ly process.

Therefore, Maxford USA can NOT in any way guarantee the performance of your finished model airplane. Fur-

thermore, in purchasing this product, you (the uyer or user of this product) exempt, waive, and relieve Max-

ford USA from all current or future lia ility for any personal injury, property damage, or wrongful death, and if

you (the uyer or user of this product) are involved in any claim or suit, you will not sue Maxford USA or any

of its representatives.

If you do not fully accept the a ove lia ility and waiver, you may request a return merchandise authorization

num er (RMA#) as explained in item 2 on the following page.

If you think there is a missing, damaged or unsatisfactory part, please read our after-sales service and return

policy on the following page.

Page 2 of 12 S101118 Copyright 2010