Evaluates: MAX3286/MAX3296

MAX3296 Longwave (Common Anode)

Evaluation Kit

2 _______________________________________________________________________________________

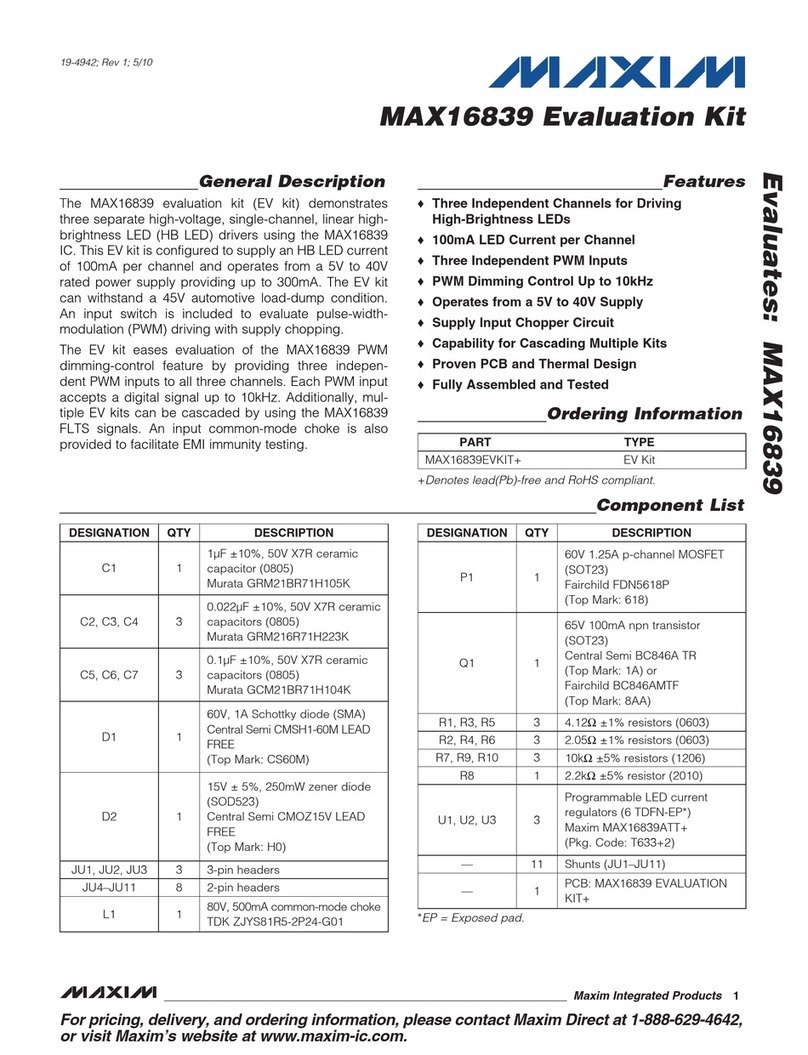

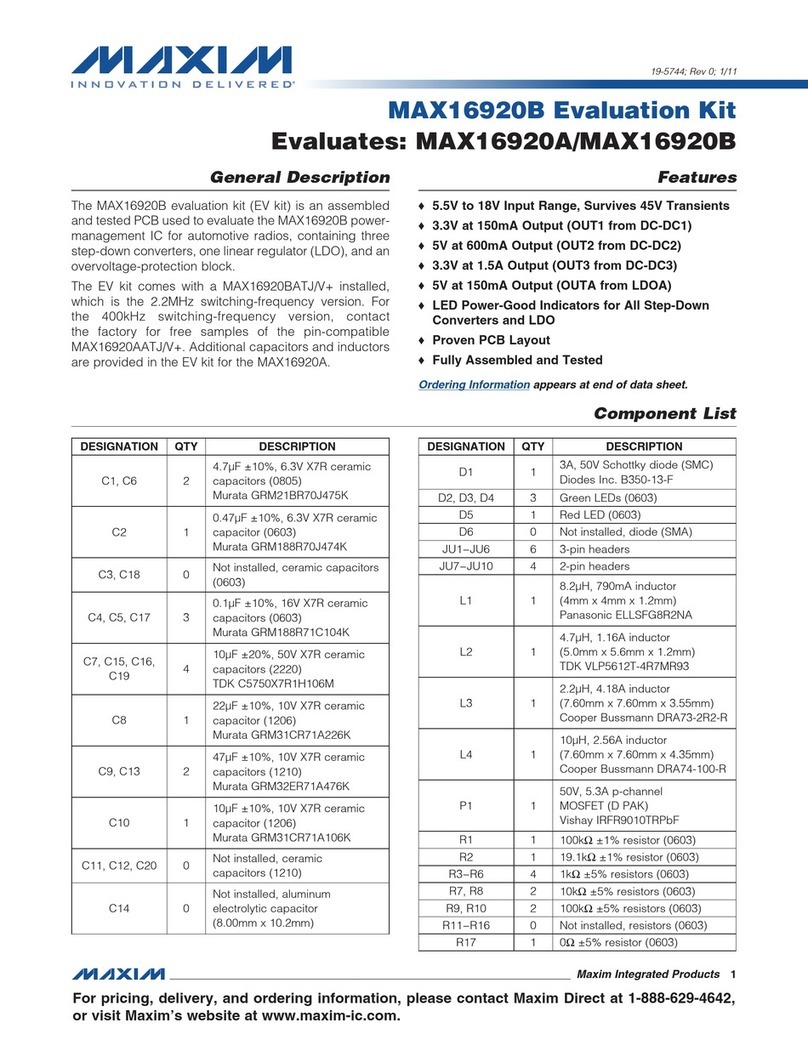

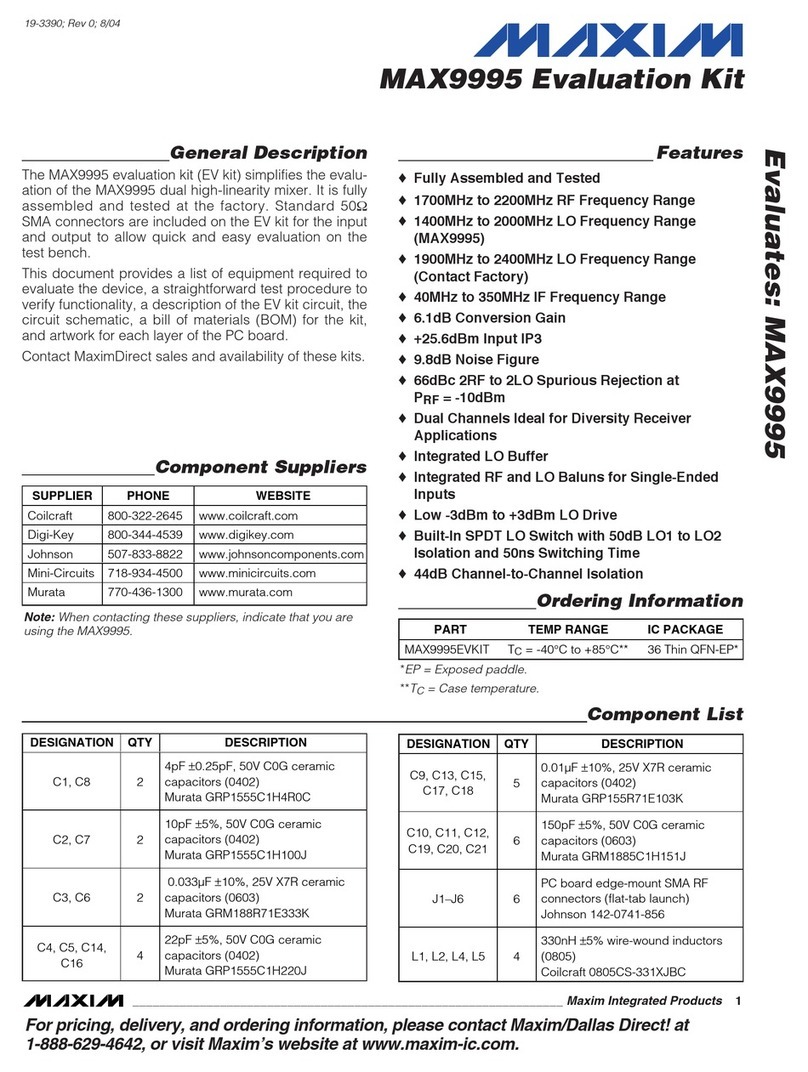

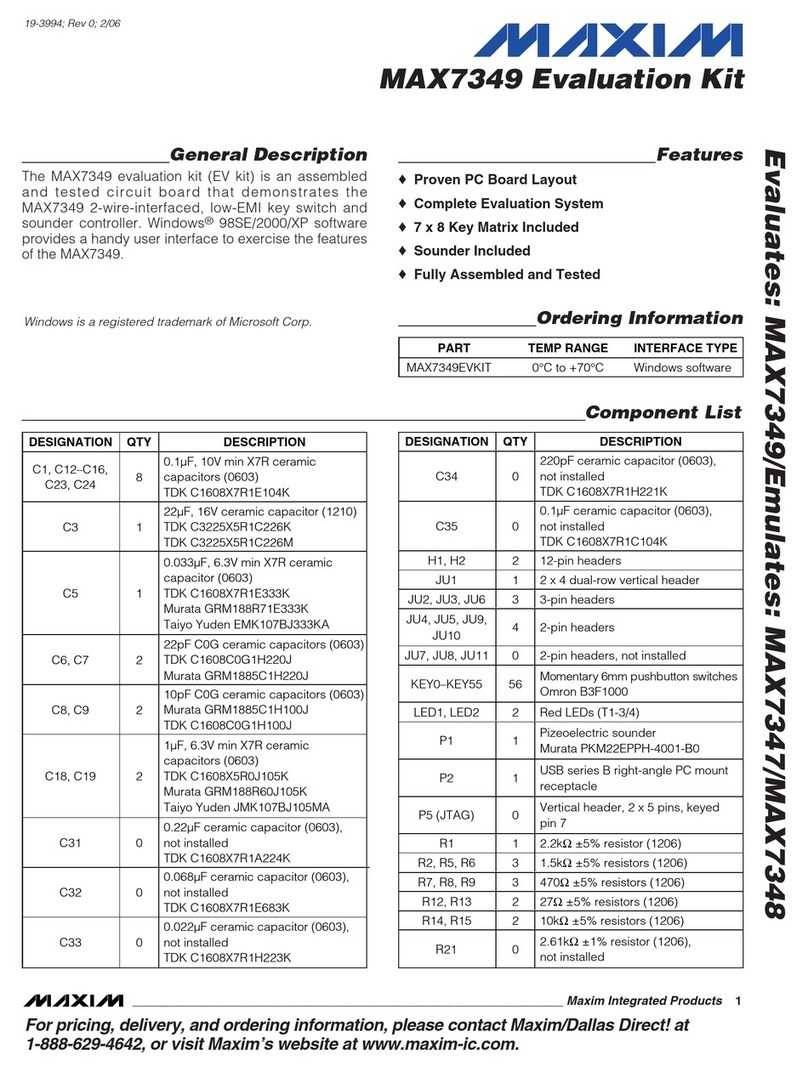

Component List (continued)

*These components are part of the compensation network, which

reduces overshoot and ringing. Parasitic series inductance intro-

duces a zero into the laser’s frequency response.

R17 and C18 add a pole to cancel this zero. The optimal values

depend upon the laser used. Maxim recommends R17 = 24.9Ω

and C18 = 2pF as a starting point.

**The MAX3296/MAX3286CHJ parts are included with the

MAX3296EV-KIT-LW. The MAX3296/MAX3286CGI parts are

included with the MAX3296CGIL.

Electrical Quick Start

Electrical Quick Start with

Simulated Photodiode Feedback

1) Short shunts SP1 and SP2 to use the photodiode

emulator circuitry (see Emulating a Photodiode

During Electrical Evaluation).

2) Make sure nothing is installed in the laser socket

(Figure 1).

3) Confirm that R27 is installed.

4) Make sure L5 is not installed.

5) Confirm that C18 is open. Since the laser is not

installed, no compensation network is required.

6) Set potentiometer R14 (RSET) to midscale by turn-

ing the screw clockwise until a faint click is felt,

then counterclockwise for 15 full revolutions (30 full

revolutions in the 0Ωto 100kΩrange of the multi-

turn potentiometer). This sets the regulation point

for the simulated photodiode current to 1.7V / 50kΩ

= 34µA. The photodiode emulator circuit regulates

the DC bias current into Q6 to 28 ·34µA ≅1mA.

7) Set potentiometer R8 (RMOD) to maximum resis-

tance by turning the screw counterclockwise until a

faint click is felt (30 full revolutions in the 0Ωto

50kΩrange of the multiturn potentiometer). This

minimizes the modulation current.

8) Set potentiometer R7 (RTC) to maximum resistance

by turning the screw counterclockwise until a faint

click is felt (30 full revolutions in the 0Ωto 100kΩ

range of the multiturn potentiometer). This mini-

mizes the temperature coefficient (tempco) of the

modulation current.

9) Place jumpers across JU7 (EN), JU8 (EN), and JU9

(PORDLY).

10) If you intend to power the board from a +5V supply,

place a jumper across JU6 (LV). Do not apply

power yet.

11) Make sure there is no jumper on JU10 (FLTDLY).

This enables the safety circuitry.

12) Attach a cable with 50Ωcharacteristic impedance

between the J6 SMA output connector and the

input of the oscilloscope. Make sure the oscillo-

scope input is 50Ωterminated.

13) Attach differential sources to SMA connectors J3

and J4. Each source should have a peak-to-peak

amplitude between 100mV and 830mV.

14) Apply either +3.3V or +5V power to the board at the

J9 (VCC) and J10 (GND) test points. Set the current

limit to 300mA.

15) While monitoring the voltage between TP17 and

TP18, adjust R14 (RSET) until the desired DC bias

current is obtained. Turning the R14 potentiometer

screw counterclockwise increases the DC bias cur-

rent.

16) While monitoring the J6 SMA connector output on

the oscilloscope, adjust R8 (RMOD) until the desired

modulation current is obtained. Turning the R8

potentiometer screw clockwise increases the modu-

lation current.

Emulating a Photodiode During

Electrical Evaluation

When evaluating the MAX3286/MAX3296 without a laser,

the MAX3286/MAX3296 DC bias circuitry operates using

a photodiode emulator circuit. When shunts SP1 and

SP2 are shorted, U4 (MAX4322), Q5 (FMMT591A), and

R28 form a current-controlled current source that emu-

lates the behavior of the photodiode in the laser assem-

bly. R29 takes the place of the laser diode, and the pho-

todiode emulator circuitry sources a current from the col-

lector of Q5 that is a fraction of the current through R29.

This simulates the behavior of a laser diode and photodi-

ode assembly where a fraction of the laser light reflects

onto the photodiode, which then outputs a small current

proportional to the light emitted.

Optical Quick Start

Optical Quick Start with

Photodiode Feedback

1) Make sure SP1 and SP2 are open. This confirms

that the photodiode emulator circuitry is not con-

nected.

2) Remove R27.

3) Install L5.

4) Connect a laser to the board (Figure 1).

5) Set potentiometer R14 (RSET) to midscale by turn-

ing the screw clockwise until a faint click is felt,

then counterclockwise for 15 full revolutions (30 full

revolutions in the 0Ωto 100kΩrange of the multi-