ASPIRAMAX 25L

5

IT

EN

GB

Product:

Suction unit for wet and dry substances

Typ ASPIRAMAX 25L

Unitconstruct-

ion type

Complies

with the

following rele-

vant provisions

Applicable

harmonised

standards

Applicable

national

standards andtechnical

specifications

Vacuum cleanersfrom classes Mand Hhave been suc-

cessfully tested in accordance with

IFATest Certificate

–GS–BIA–MO2 (07/02),

–DIN EN 60335–2–69 (including)Appendix AA,

–DIN 60335–2–69/A1 (11/05).

We declareinour own sole responsibilitythat this pro-

ductcomplies with the EU directives ansdefinitivestan-

dards:machinery and amending Directive 2006/42/EG

with amendments,electromagnetic compatibility directive

2004/108/EG with amendments.

Electricaltool vacuum unit

vg

e

IP24

●Warning!

●ASPIRAMAX 25L-vacuum devices are

notsuitable foraspiration/clearingoftoxicdusts.

●Class Mvacuum devices are suitable for aspira-

tion/clearing of dry,non-combustibledusts, non-com-

bustibleliquids,wood dusts and hazardous dusts with

workplacelimit values of ≥0.1mg/m³.

●Class Hvacuum devices are suitable for aspira-

tion/clearing of dry,non-combustible dusts,carcinoge-

nic and pathogenicparticles as wellasnon-combusti-

ble liquids,wood dusts and toxicdustswith workplace

limit values of <0.1 mg/m³.

●Warning!

●Persons (including children)who are,due to theirphy-

sical,sensory or intellectual abilities or lackofexpe-

rience or knowledge,unabletosafelyuse thevacuum

device shouldnot useitwithoutsupervision or instruc-

tion by aresponsible person.

●Particular caution is advised with children,elderly or infirm

persons.

●Do not point nozzle,tube or hose at peopleoranimals.

●Danger!

●Do not operate the vacuum device where there is dan-

ger of explosions.

●Keep away the vacuum device from inflammablegases

and substances.

●Danger!

●Do not aspirate any combustibleorexplosive solvents,

materialssoaked in solvents,explosive dusts,liquids

suchaspetrol,oil,alcohol, diluents or materials hotter

then 60 °C (140 °F).

●Otherwisethere will be danger of fire and explosions!

●Danger!

●Use the socket of the vacuum device onlyfor the pur-

posesdefined in the instruction manual.

●In case of any inappropriate usage,improper operation

or repair, the producer shallbeexempt from liability.

●Do notuse anydamagedextension lines.

●If the connector line of thevacuum device has been dama-

ged,itmust be replaced with aspecial connector line which

is available from the producer or their service.

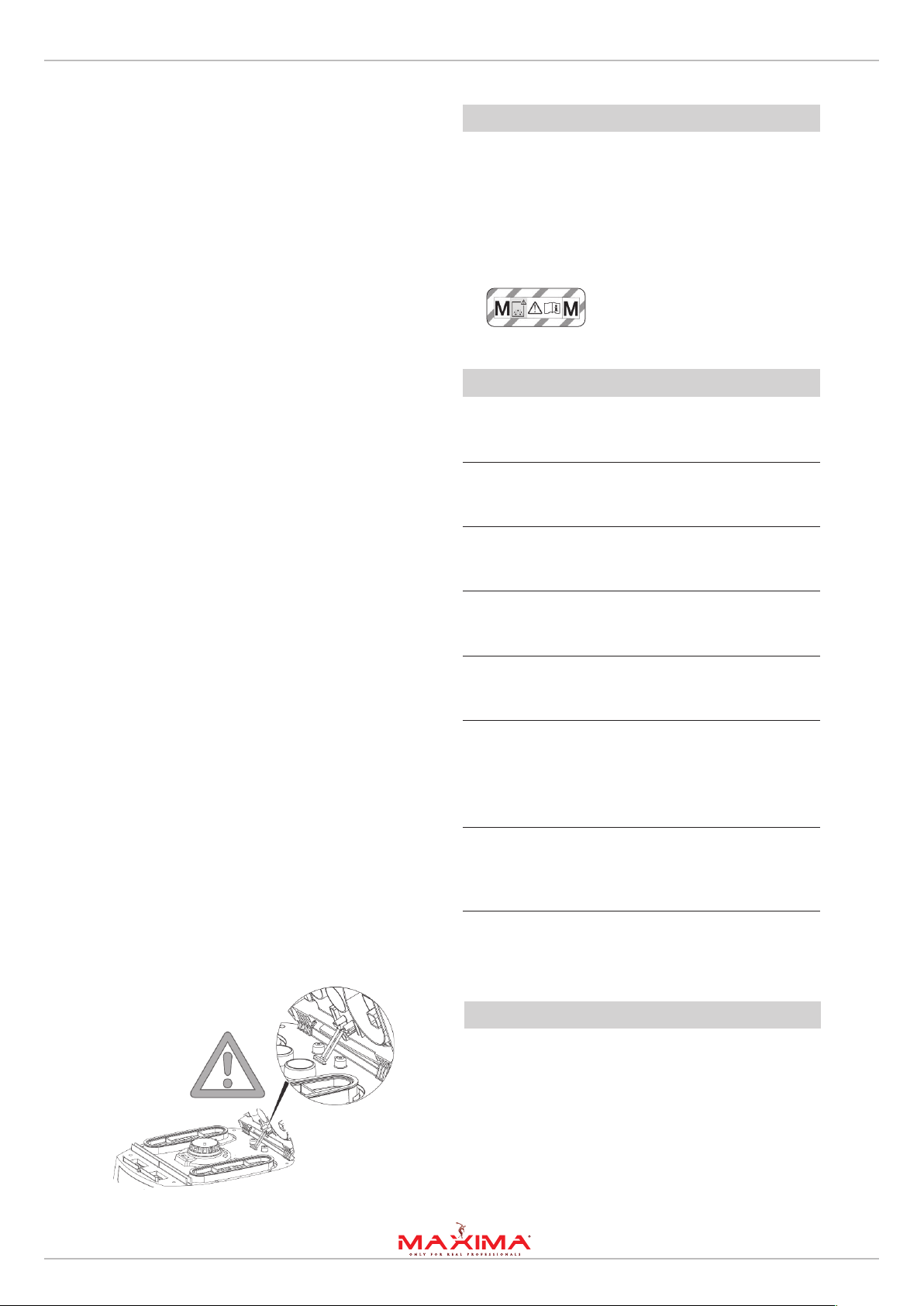

●Electric brushes:Donot allow the rotating brushestoget

intocontact with the powerconnection line.

●Thevoltage on the type sign must correspondtothe grid

voltage.

●After everyuse andbefore any maintenance,switchoff

thevacuum device and pullthe power plug.

●Pullonthe plug only,not on the line.

●Neverplug or pull thepower plug with wet hands.

●Thesocket must be secured viaahousehold fuse with a

suitable current rating.

EC Machinery Directive 2006/42/EU

EMCDirective 2004/108/EC

EN 12100-1, EN-12100-2,

EN 60335-1, EN 60335-2-69,

EN 55014-1,EN55014-2,

EN 61000-3-2

DIN EN 60335–1,

DIN EN 60335–2–69

When unpacking,checkthat the unitiscomplete and shows

no signs of transportdamage.

Read all theinformation carefully. They containimportant

advice about how to use the unit,safety,maintenance and

care.Please keep these operating instructionssomewhere

safe and passontoany subsequent owners.Wereservethe

right to make design and equipment changes.

1. Safety Advice.

●Thevacuum device is designed for industrial use. Ideal in

combination with an electrictool,onbuilding sites, in

workshops, etc.

Presidente

Dall’Olio Dott. Mirco

Maxima SpA - Via Matteotti, 6

42028 Poviglio (Re) Italia