XR32220 Evaluation Board User’s Manual

2/6

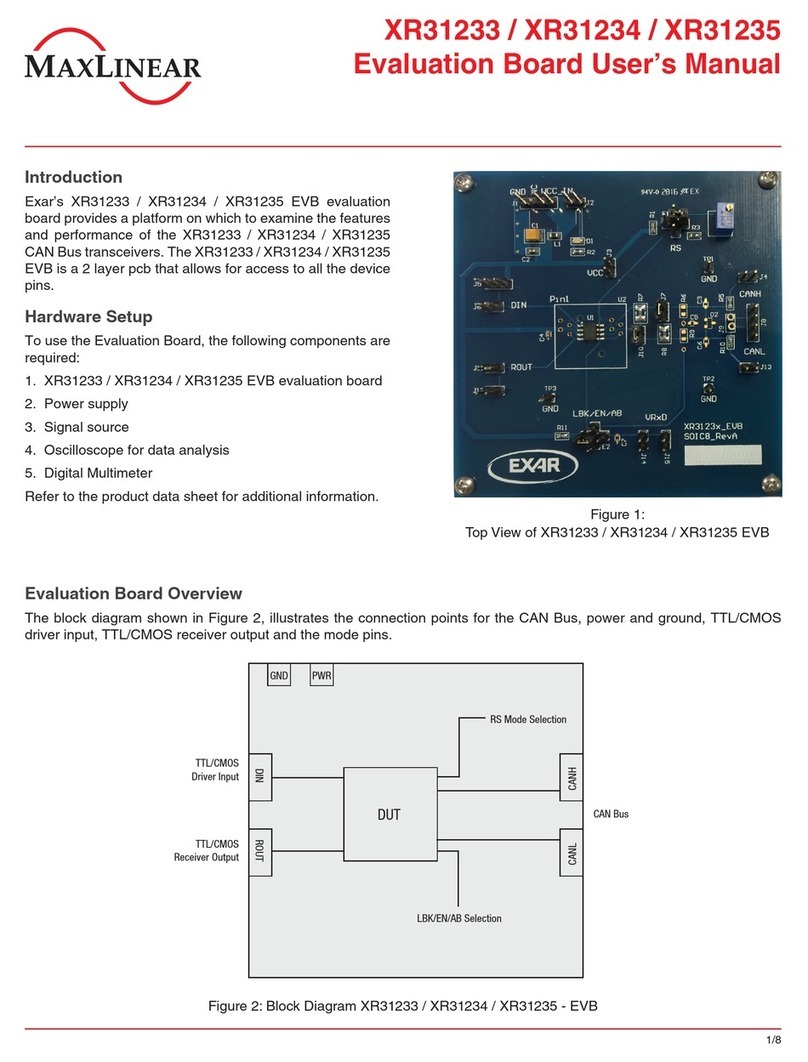

Hardware / System Setup

Jumpers are factory installed per Table 1. Jumper and

testing options are described in the next section.

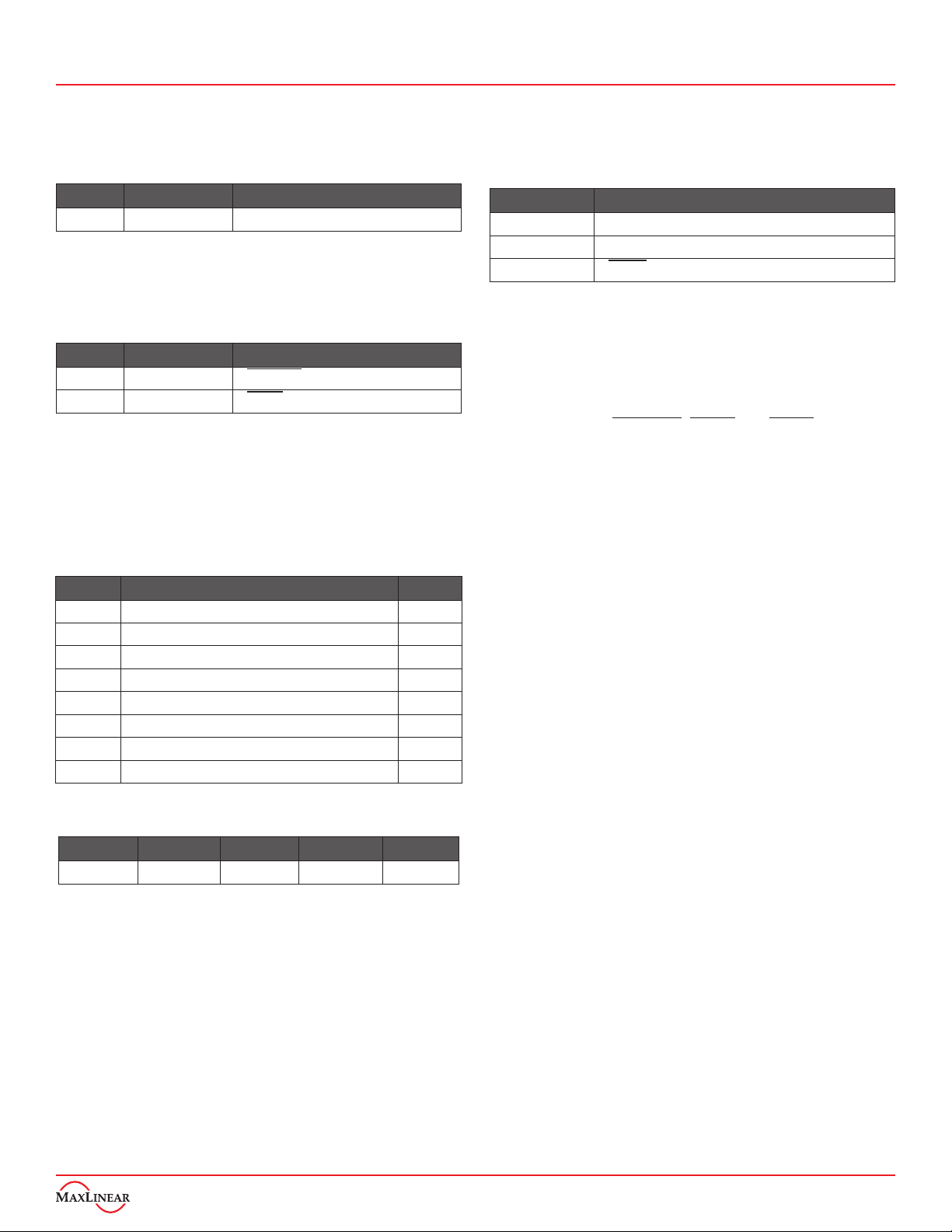

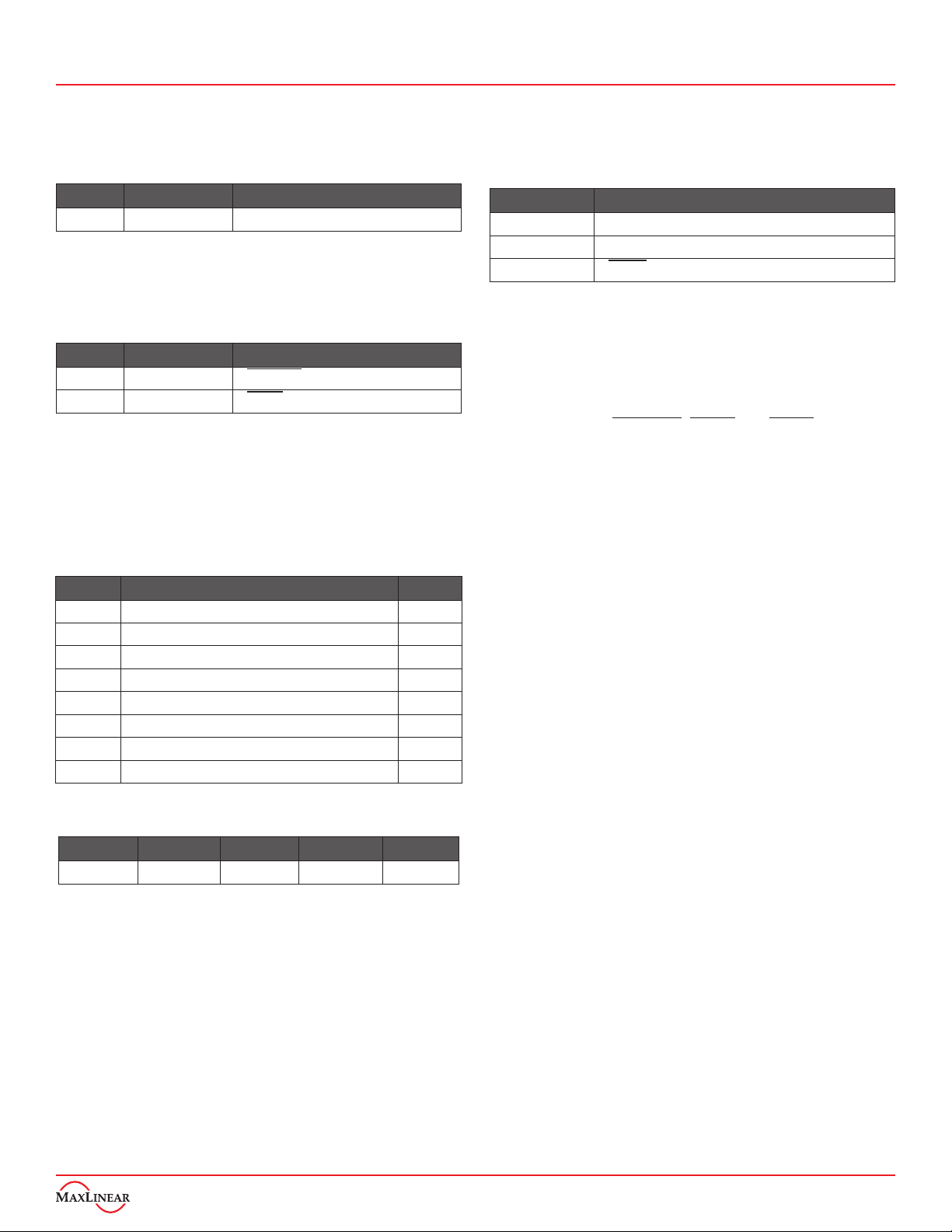

Header Factory Setting Description

J2 Jumper 1-2 Connects VL to VCC

Table 1: Factory Settings

Connect J43 and J45 per Table 2 to configure the EVB for

normal mode operation.

Header Configuration Description

J43 Jumper 2-3 Shutdown = 1 enables normal mode

J45 Jumper 2-3 Online = 1 enables normal mode

Table 2: Normal Mode Configuration

Connect the RS232 drivers and receivers, TTL/CMOS

Driver Inputs and Receiver Outputs per Table 3 and power

and ground per Table 4 for immediate evaluation of the

XR32220 functionality and performance.

Header Connection Pin

J9 RS232 receiver input R1IN

J11 RS232 receiver input R2IN

J19 RS232 driver output T1OUT

J21 RS232 driver output T2OUT

J29 TTL / CMOS driver input T1IN

J27 TTL / CMOS driver input T2IN

J39 TTL / CMOS receiver output R1OUT

J37 TTL / CMOS receiver output R2OUT

Table 3: Input and Output Connections

J1 J1-1 J1-2 J1-3 J1-4

Name GND NC VCC VCC

NOTE:

1. VCC = 3.0V to 5.5V

Table 4: Power and Ground Connections

Pin J1-1 is the ground connection to the XR32220

evaluation board and is a common ground connection to the

entire board. An external 3.3V ±10% or 5.0V ±10% supply,

referenced to J1 pin 1 ground, should be connect to J1 pins

3 & 4.

Use probes summarized in Table 5 to observe operation at

various points. TP1 and TP2 provide GND for probes at 2

different spots.

Header Probe Points

J3, J4, J5, J7 C3, C4, C2 and C1 charge pump capacitors

J6 VCC into XR32220 transceiver

J42 Status output

Table 5: Monitoring Probes

Jumper and Testing Options

TTL / CMOS Logic Supply, VL - J2

The XR32220 has a separate logic supply pin, VL, which

controls the logic levels for the following pins: T1IN, T2IN,

R1OUT, R2OUT, Shutdown, Online and Status.

With a jumper placed across J2 the logic supply is tied to

VCC. To drive the VL logic supply to a lower voltage than

VCC, simply remove the jumper across J2 and connect

the separate external logic supply to pin 2 of J2. The logic

supply voltage, VL, must always be less than or equal to

VCC.

Power LED - J12

Connect Jumper J12 1-2 to illuminate the D1 LED when

power is connected if desired.

RS232 Receiver Inputs - J9 and J11 (J8 and J10)

Pin 2 on both the J9 and J11 connectors is the RS232

receiver input and pin 1 is ground. There is a 3 pin jumper

next to each of the test points, J8 and J10, to allow the

receiver inputs to be tied to VCC or ground if desired.

Normally the RS232 signal is applied to Pin 2 of J9 and J11

and J8 and J10 are unused.

RS232 Driver Outputs - J19 and J21 (J18 and J20)

Pin 2 on both the J19 and J21 connectors is the RS232

driver output and pin 1 is ground. There is a 2 pin jumper

next to each of these test points, J18 and J20, to allow for

any external loads to be applied if desired.

TTL/CMOS Driver Inputs - J27 and J29 (J26 and J28)

Pin 2 on both the J27 and J29 connectors is the TTL/CMOS

driver input and pin 1 is ground. There is a 3 pin jumper

next to each of the test points, J28 and J26 to allow the

driver inputs to be tied to VL or ground if desired. Normally

the signal generator would be applied to Pin 2 of J29 and/or

J27 and J28 and J26 would not be used.

TTL/CMOS Receiver Outputs - J37 and J39 (J36 and J38)

Pin 2 on both connectors is the TTL/CMOS receiver output

and pin 1 is ground. There is a 2 pin jumper next to each

of these test points, J38 and J36, to allow for any external

loads to be applied if desired.