RF-SHK-319-NN Wireless TOTAL Window Sensor

I-RF-SHK-319 Rev.3 Oct. 2020 For updated Installation Manual Revision go to MaxoutTech.com and select Documentation page

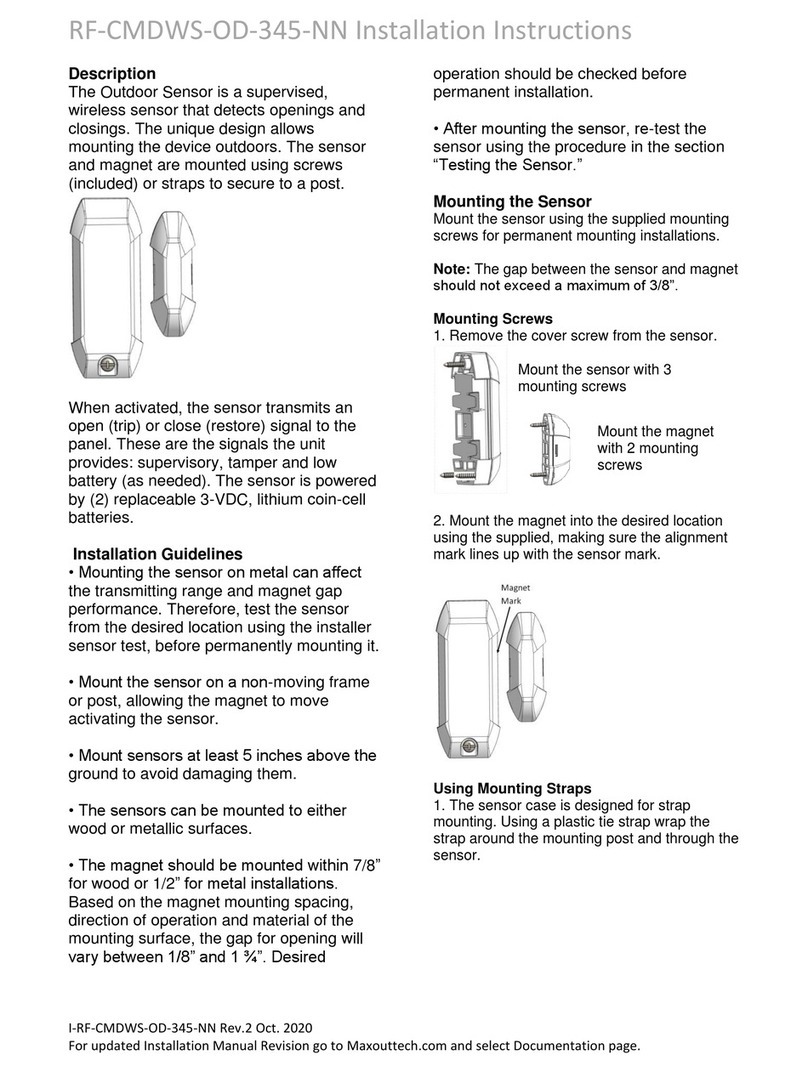

2.

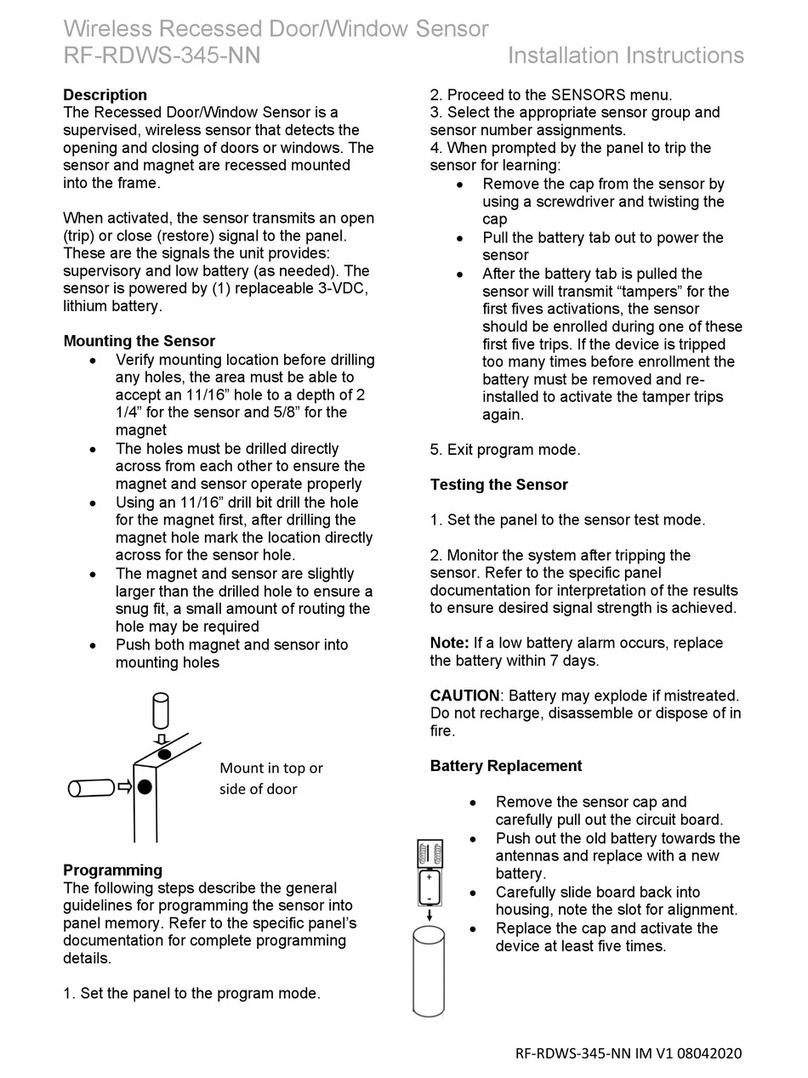

Apply double-sided tape to the bottom of

the sensor and the magnet. Mount the

sensor and magnet at the desired locations,

ensuring the alignment marks line up with

each other.

Programming

The following steps describe the general

guidelines for programming the sensor into

panel memory. Refer to the specific panel’s

documentation for complete programming

details.

The internal magnetic reed switch and

shock zones use separate ID’s

Concord Control Panel – both ID’s are enrolled

at the same time

•Enter system programming

•Sensors

•Learn Sensor

•Trip Sensor

•Activate sensor tamper – the panel will

enroll (2) zones

•First zone enrolled is shock

•Second zone enrolled is reed switch

Simon/Zerowire – each ID is enrolled separately

•Enter system programming

•Sensors

•Trip Sensor

•Activate sensor tamper to enroll shock

•For next zone number, remove sensor

batteries, while holding the tamper re-

insert batteries, this will enroll the reed

switch

Qolsys - each ID is enrolled separately

•Enter system programming

•Sensors

•Trip Sensor

•Activate sensor tamper to enroll shock

•For next zone number, remove sensor

batteries, while holding the tamper re-

insert batteries, this will enroll the reed

switch

Note: Panel model numbers variations may

cause a ‘sensor already learned-in’ message

inhibiting the shock sensor for learning in. If this

is the case, learn in the reed switch using a

magnet to trip the reed, and learn-in the shock

zone by tapping on device to activate it.

Exit program mode.

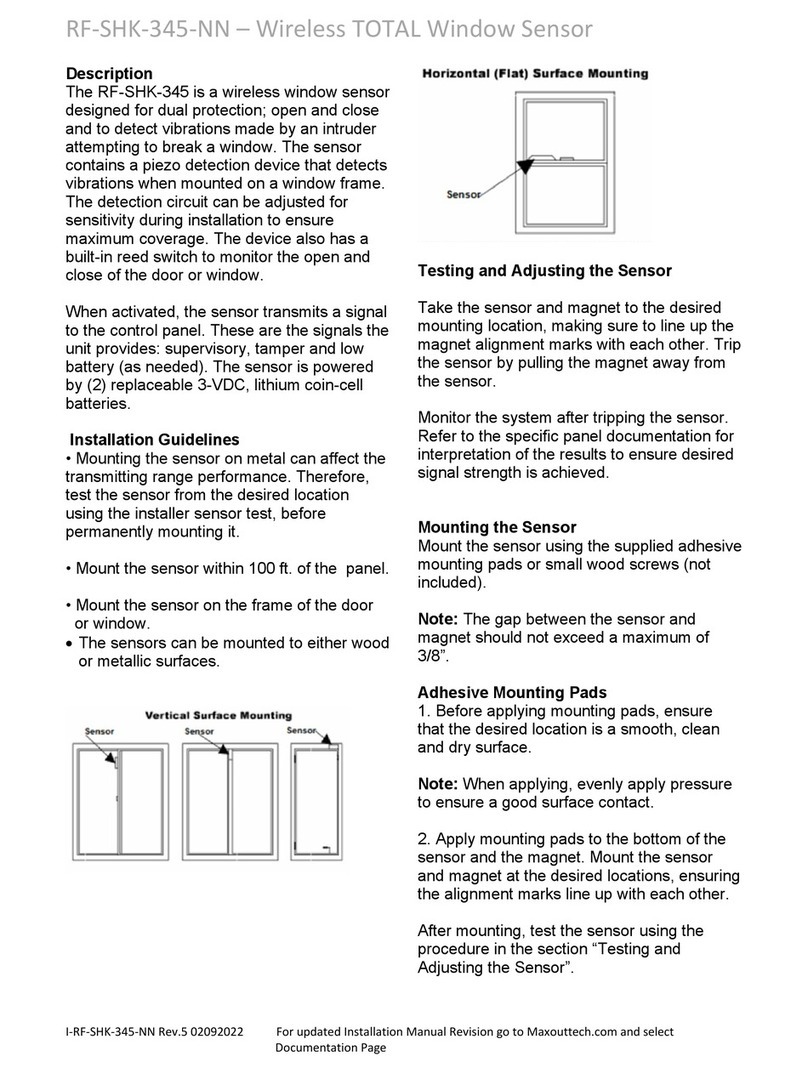

Testing and adjusting the Sensor

1.

Set the panel to the sensor test mode.

2.

Take the sensor and magnet to the

desired mounting location, making sure to

line up their alignment marks with each

other. Trip the sensor by pulling the magnet

away from the sensor.

3.

Monitor the system after tripping the

sensor. Refer to the specific panel

documentation for interpretation of the

results to ensure desired signal strength is

achieved.

Shock LED Functionality

LED is functional only in test mode. Test

mode is entered automatically when

batteries are inserted. LED activates on

shock activation and goes out upon shock

restoral.

Test mode stays on as long as the cover is

removed.

Batteries must be removed and re-installed

to initiate test mode after expiration.

Low battery detect. LED flashes until battery

is replaced. Device sends low battery

signal to control panel.

Shock sensor sensitivity setting

An LED test mode (see above) is included

to aide in setting sensitivity to desired level

1.

Mount sensor in intended location

and tap mounting surface with

desired level of activation impact

2.

Adjust potentiometer until correct

sensitivity is obtained

The potentiometer adjusts shock sensitivity

from minimum Low (CCW) to maximum Hi