160GR Natural Gas Booster Instruction Manual

Mayekawa all rights reserved. Subject to change without notice. Lat revised in October 2007 p.2

Contents

1. Introduction..........................................................................................................................................4

2. Capacity Control Procedures...............................................................................................................4

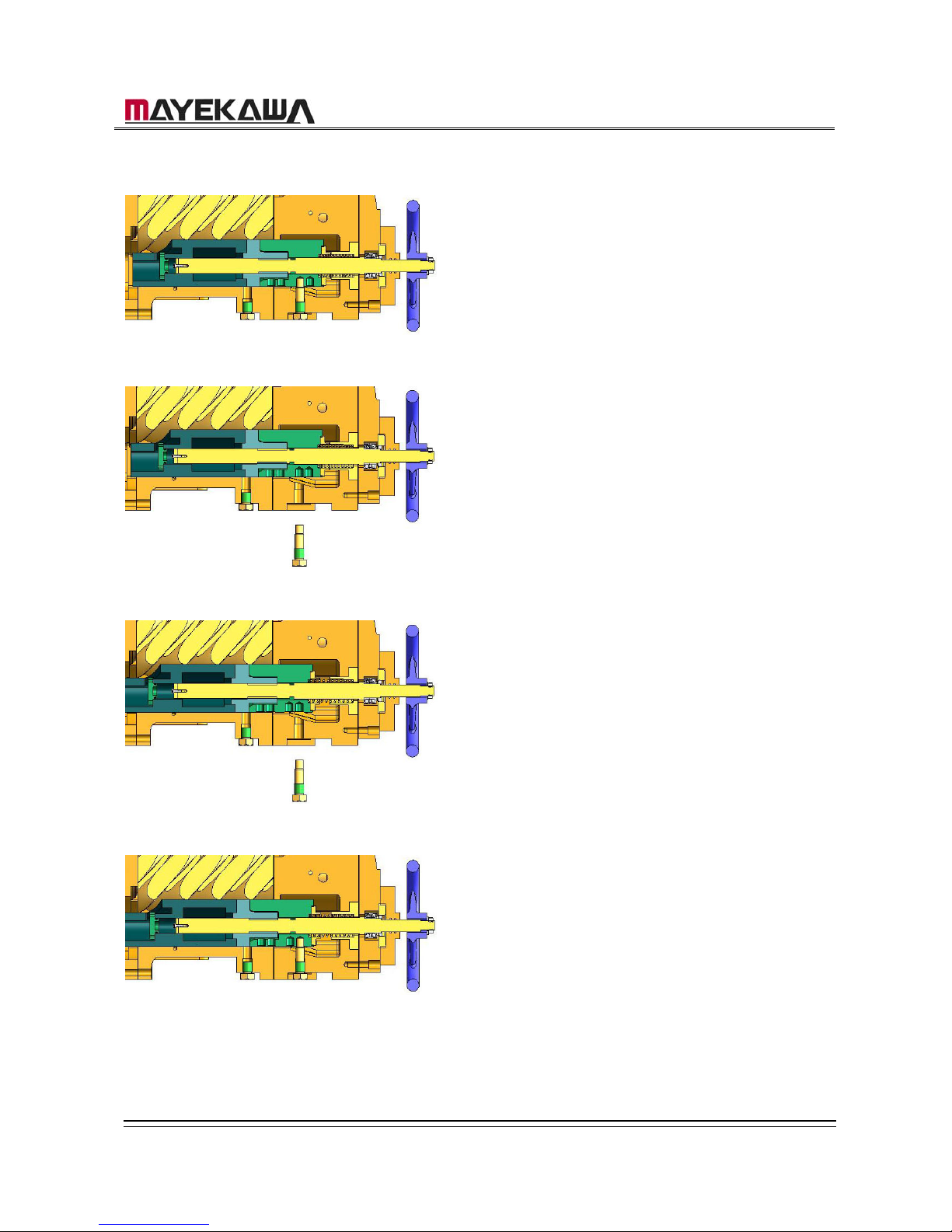

3. Variable Vi Structure ............................................................................................................................4

3.1.1 When the position of the current port is known......................................................................5

3.1.2 When the Current Port is not known ....................................................................................10

4. Parts Expanded View ........................................................................................................................13

4-1 160GR Standard .................................................................................................................13

4-2 160GR with Integral Pump ..................................................................................................14

4-3 Parts Structure Diagram......................................................................................................15

5. Parts List............................................................................................................................................17

6. Outer Dimension................................................................................................................................19

7. Disassembly ......................................................................................................................................20

Removing the Compressor..............................................................................................................20

7.1 Interior Gas Recovery ....................................................................................................20

7.2 Removing the connecting parts......................................................................................20

7.3 Suspending and Transferring the Compressor...............................................................20

7.4.1 Mechanical Shaft Seal....................................................................................................22

7.4.2 Unloader Cover ..............................................................................................................24

7.4.3 Unloader Thrust Bearing ................................................................................................25

7.4.4 Balance Piston Cover.....................................................................................................27

7.4.5 Unloader Spring Retainer...............................................................................................27

7.4.6 Balance Piston, Balance Piston Sleeve..........................................................................28

7.4.7 Speed up Gear Casing Cover ........................................................................................29

7.4.8 Speed up gear casing ....................................................................................................30

7.4.9 Disassembly of speed up gear parts on the driving side ................................................31

7.4.10 Spindle Roller Bearing....................................................................................................33

7.4.11 Disassembly of the speed up gear on the driven side ....................................................33

7.4.12 Thrust Bearing................................................................................................................34

7.4.12 Suction Cover.................................................................................................................36

7.4.13 Rotor, Rotor Casing, Variable Vi Slide Valve ..................................................................37

7.4.14 Bearing Head and Main Bearing ....................................................................................39

8. Re-assembly......................................................................................................................................40

8.1 Bearing Head and Main Bearing .........................................................................................40

8.2 Rotor Casing, Unloader Slide Valve, Variable Vi Slide Valve, Bearing Head.......................40

8.3 Rotor Casing, Rotor ............................................................................................................41

8.4 Suction Cover......................................................................................................................41

8.5 Thrust Bearings...................................................................................................................41

8.5 Installation of the driven side speed up gear .......................................................................42

8.6 Spindle Roller Bearings.......................................................................................................43

8.7 Building the Driving Side speed up Gear ............................................................................43

8.8 Installation of speed up Gear Casing ..................................................................................43