2202G1JE-DA-M-N_2010.01.

Important Information

Reciprocating Compressor M Series

viii

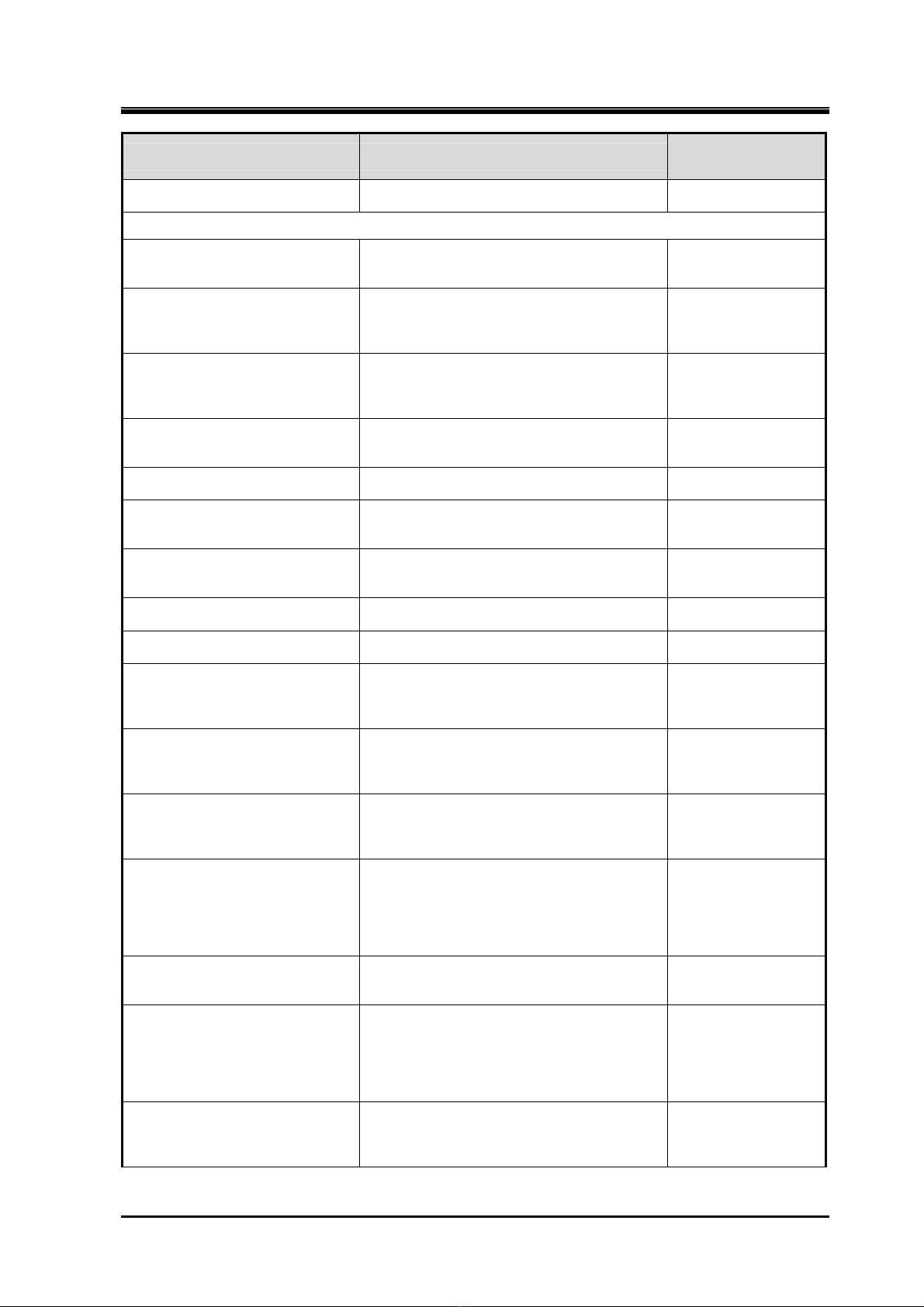

Description Location Telephone and

facsimile No.

MAYEKAWA VIETNAM ONE

MEMBER COMPANY LIMITED

(MAYEKAWA VIETNAM)

ROOM 305, 3FL, TOUI TRE TOWER,

60A HOANG VAN THU, WARD 9,

PHU NHUAN DIST., HO CHI MINH CITY,

VIETNAM

TEL: (84) 8-3997-5284

FAX: (84) 8-3997-5287

MYCOM KOREA CO., LTD.

HEAD OFFICE

JUYEON BUILDING 2F, SEOGYE-DONG 209,

YONGSAN-KU, SEOUL, 140-710,

REP.OF KOREA

TEL: (82) 2-796-1766

FAX: (82) 2-798-7715

MYCOM KOREA CO., LTD.

CHANGWON FACTORY

PALYONG DONG 24-20,

CHANGWON KYUNGSANGNAM-DO 641847,

REP.OF KOREA

TEL: (82) 55-294-8678

FAX: (82) 55-299-7678

MYCOM KOREA CO., LTD.

PUSAN BRANCH

TONG YOUNG SU SAN 6F,

763-20 KAMCHEON-DONG, SAHA-KU,

PUSAN 604-806, REP.OF KOREA

TEL: (82) 51-242-3737

FAX: (82) 51-243-8542

MYCOM KOREA CO., LTD.

GWANGJU BRANCH

970-6 WOLCHUL-DONG PUK-KU GWANGJU

500-460, REP. OF KOREA

TEL: (82) 62-973-8471

FAX: (82) 62-973-8475

LATIN AMERICA

MAYEKAWA ARGENTINA S.A.

(BUENOS AIRES OFFICE)

AV. VELEZ SARSFIELD 670/74 C1282

AFT-CAPITAL FEDERAL BUENOS AIRES,

REPUBLICA ARGENTINA

TEL: (54) 11-4302-2791

FAX: (54) 11-4304-3015

MAYEKAWA ARGENTINA S.A.

(PUERTO MADRYN OFFICE)

OFICINA PTO. MADRYN LEOPOLDO

LUGONES 45 (U9129KDA)-PUERTO MADRYN

PCIA DE CHUBUT REPUBLICA ARGENTINA

TEL: (54) 2965-475414

FAX: (54) 2965-475414

MYCOM PERU S.A.C. CALLE LUIS PASTEUR 1490,

LINCE, LIMA, PERU

TEL: (51) 1-441-8552

FAX: (51) 1-222-1543

MAYEKAWA CHILE S.A.C.el.

(SANTIAGO OFFICE)

CORDILLERA No.331, MODULO D14,

FLEX CENTER, PUERTO VESPUCIO,

QUILICURA, SANTIAGO, CHILE

TEL: (56) 2-739-0202

FAX: (56) 2-739-2700

MAYEKAWA CHILE S.A.C.el.

(CONCEPCION OFFICE)

ANIBAL PINTO No.215, OFICINA 403,

CONCEPCION, CHILE

TEL: (56) 41-223547

FAX: (56) 41-212443

MAYEKAWA CHILE S.A.C.el.

(PUERTO MONTT OFFICE)

BERNARDINO 1057 MODULO 6,

PARQUE INDUSTRIAL SAN ANDRES

PUERTO MONTT, CHILE

TEL: (56) 65-257570

FAX: (56) 65-288073

ANREC LTDA TRANSVERSAL 93 NO.53-48 INTERIOR 37,

PAQUE INDUSTRIAL EL DORADO, BOGOTO,

COLOMBIA

TEL: (57) 1-224-3028

FAX: (57) 1-224-3203

MAYEKAWA DO BRASIL REF.

LTDA.

RUA LICATEM 250, JARDIM FAZENDA

RINCAO POLO INDUSTRIAL DE ARUJA-SP,

CEP 07400-000, BRASIL

TEL: (55) 11-4654-8000

FAX: (55) 11-4654-8002

MAYEKAWA DO BRASIL LTDA.

(BAHIA BRANCH)

RUA DR. JOSE PEROBA, 275 - SALA 902

EDIFICIO METROPOLIS - BAIRRO STIEPE,

SALVADOR-BA, CEP 41770-2325, BRASIL

TEL: (55) 71-3341-0737

FAX: —

MAYEKAWA DO BRASIL LTDA.

(BELO HORIZONTE BRANCH)

AV. BARAO HOMEM DE MELLO,

4386 – S 401 ED.EMYR SOARES - BAIRRO

ESTORIL BELO HORIZONTE-MG,

CEP 30450-250, BRASIL

TEL: (55) 31-3297-6166

FAX: —

MAYEKAWA DO BRASIL LTDA.

(CHAPECO BRANCH)

RUA FERNANDO MECHADO,

593 D-S 201 CHAPECO-SC

CAIXA POSTAL 177, CEP 89801-973, BRASIL

TEL: (55) 49-3322-4241

FAX: (55) 49-3322-4241

MAYEKAWA DO BRASIL LTDA.

(CUIABA BRANCH)

AVENIDA ISSAC POVOAS, 586 – SALA 405

EDIFICIO WALL STREET - CENTRO

CUIABA-MT, CEP 78055-560, BRASIL

TEL: (55) 65-3023-7559

FAX: —

MAYEKAWA DO BRASIL LTDA.

(CURITIBA BRANCH)

RUA ISABEL A. REDENTORA, 1826 – SALA 8

CENTRO - SAO JOSE DOS PINHAIS-PR,

CEP 83095-980, BRASIL

TEL: (55) 41-3383-1518

FAX: —

MAYEKAWA DO BRASIL LTDA.

(CAMPO GRANDE BRANCH)

RUA JOSE ANTONIO PEREIRA, 2200 – S 02

CONDOMINIO COSTA D’OURO CAMPO

GRANDE-MS, CEP 79010-190, BRASIL

TEL: (55) 67-3042-7200

FAX: —

MAYEKAWA DO BRASIL LTDA.

(GOIANIA BRANCH)

RUA C, 255 – QUADRA 588 – LOTE 4/8 SALA

1004 – CENTRO EMPRESARIAL SEBBA

GOIANIA-GO, CEP 74280-010, BRASIL

TEL: (55) 62-3093-5062

FAX: —