ConSep 2000®-125HP

Tornos MultiDECO / MultiAlpha / MultiSigma

Rev. 0

MAYFRAN INTERNATIONAL - P.B. 31032- 6370 AA LANDGRAAF - THE NETHERLANDS

: (31) 45 5329 292

Internet: www.mayfran.eu

E-mail: Info@mayfran-europe.com

File name:

T74600.010.00 - T74600.011.00_Tornos Multi Spindle Series_Rev.

0_English.doc

Page: 1

TECHNICAL DOCUMENTATION

COMMISSIONING/ SERVICE/ MAINTENANCE

Table of

Contents

1

REVISION LIST ..........................................................................................................................................2

2

DECLARATION BY THE MANUFACTURER ............................................................................................3

3

GENERAL INFORMATION ........................................................................................................................3

3.1

Mayfran quality statement ..............................................................................................................3

3.2

Mayfran privacy statement .............................................................................................................3

4

UNPACKING AND TRANSPORT ..............................................................................................................4

4.1

Unpacking ......................................................................................................................................4

4.2

Transport........................................................................................................................................4

5

GENERAL WARNINGS AND SAFETY INSTRUCTIONS..........................................................................5

6

GENERAL INSTRUCTIONS FOR REPAIR, MAINTENANCE AND MALFUNCTIONS. ...........................6

7

GENERAL PRODUCT / FUNCTION DESCRIPTION ................................................................................7

7.1

Use of the Consep 2000 ................................................................................................................7

7.2

Important instruction.......................................................................................................................7

7.3

When requesting information or ordering spare parts....................................................................7

7.4

The way in which the system works ...............................................................................................7

7.5

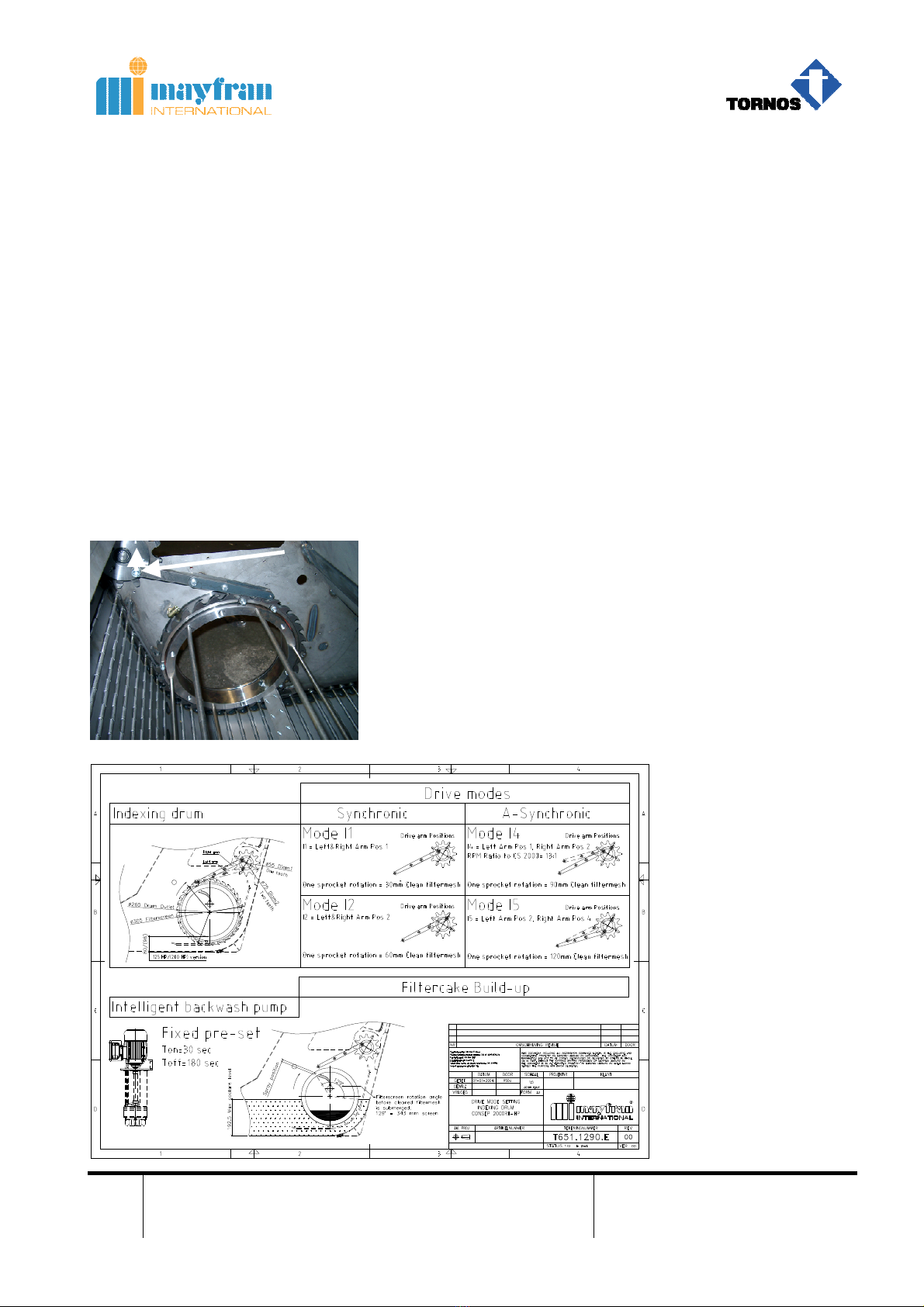

Indexing filter drum.........................................................................................................................8

7.5.1

Filter drum cleaning circuit.................................................................................................9

8

COMMISSIONING THE CONSEP 2000 SYSTEM...................................................................................10

9

STARTING UP THE CONSEP 2000 SYSTEM ........................................................................................11

9.1

Initial start-up procedure...............................................................................................................11

9.2

E-control box ................................................................................................................................11

9.3

How to start the system................................................................................................................11

9.3.1

Conveyors........................................................................................................................11

9.3.2

Pumps..............................................................................................................................12

9.3.3

Pressure switches HP pumps..........................................................................................12

9.3.4

Level indicators additional coolant tank ...........................................................................12

9.3.5

Adjustement of automatic secondary system filter: .........................................................12

9.4

How to stop the system: ...............................................................................................................13

9.5

System malfunction......................................................................................................................13

10

PREVENTIVE MAINTENANCE ACTIONS...............................................................................................15

10.1

General issues .............................................................................................................................15

10.2

Maintenance actions mayfran components..................................................................................15

10.2.1

Driving unit steel belt conveyor / scraper conveyor........................................................15

10.2.2

Filter screen check.........................................................................................................16

10.2.3

Filter screen change procedure .....................................................................................16

10.2.4

Take-up adjustment steel belt conveyor / scraper conveyor .........................................17

10.2.5

Check items ...................................................................................................................18

11

FLOW DIAGRAM .....................................................................................................................................19

11.1

Flow diagram ConSep 2000-125 “L-Series”.................................................................................19

11.2

Flow diagram ConSep 2000-125 “Regular” .................................................................................20

12

REPLACEMENT PARTS LISTS ..............................................................................................................21

12.1

Part list ConSep 2000-125 “L-Series” ..........................................................................................21

12.2

Part list ConSep 2000-125 “Regular” ...........................................................................................22