16027056 2 September 2006

©2006 Maytag Services

Troubleshooting Procedures

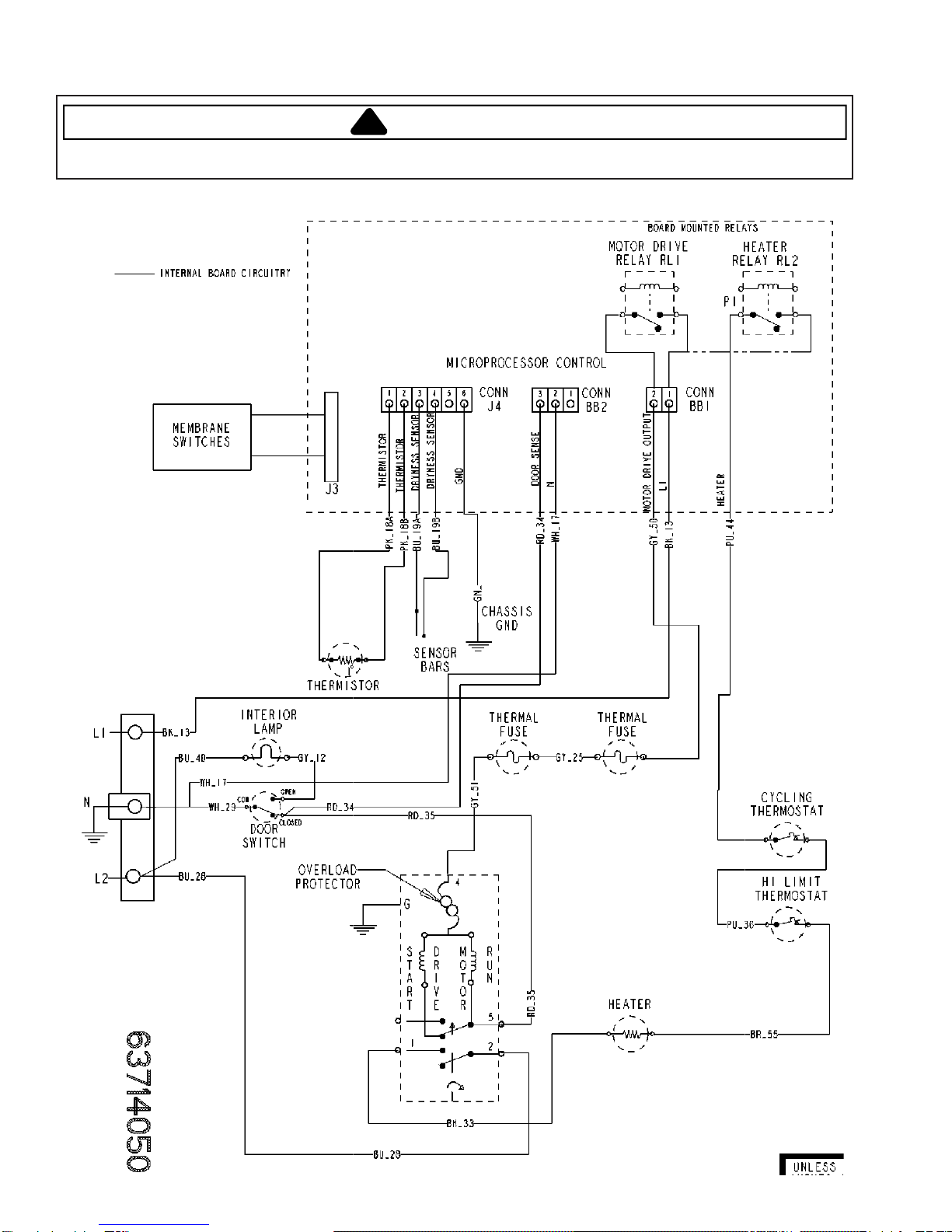

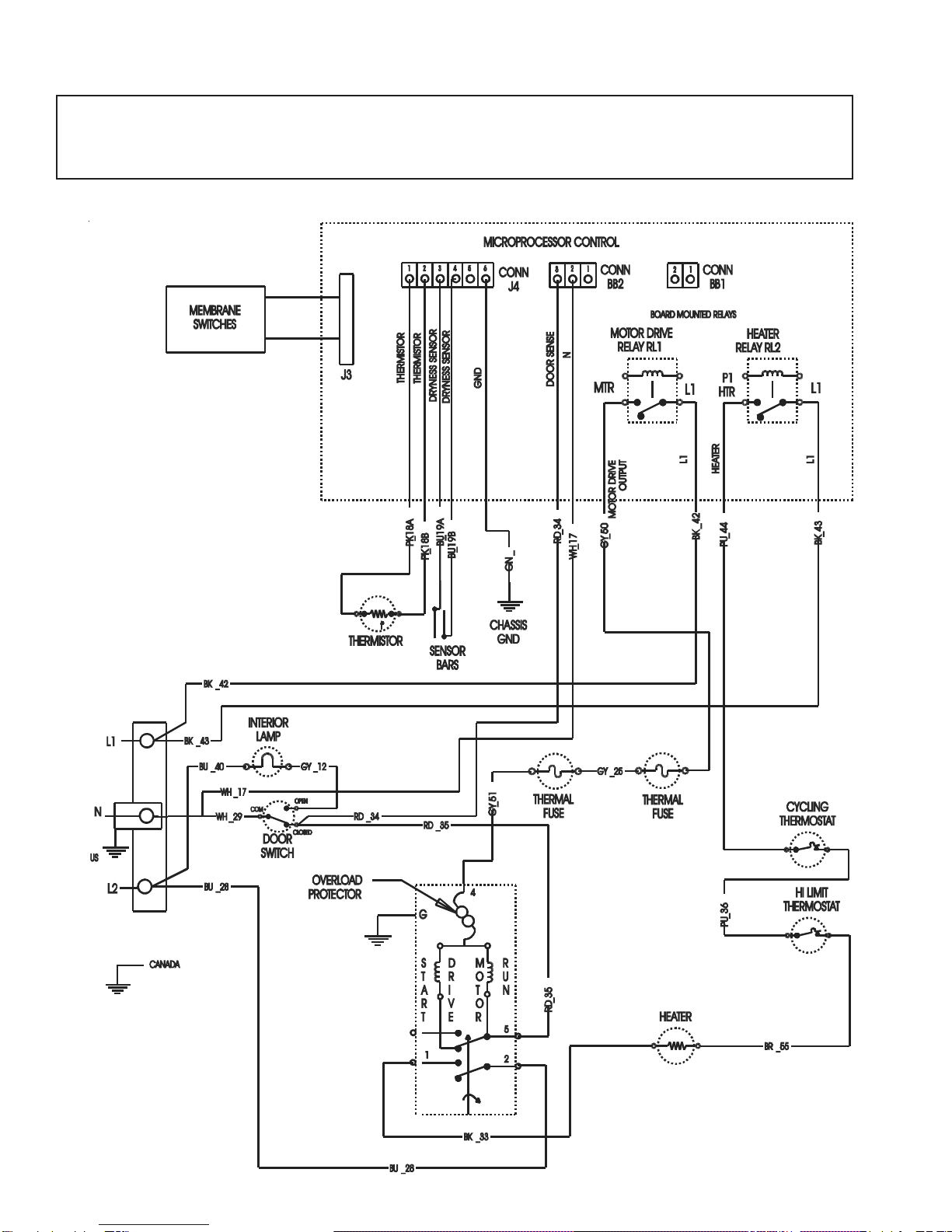

!WARNING

To avoid risk of electrical shock, personal injury or death; disconnect power to dryer before servicing, unless

testingrequirespower.

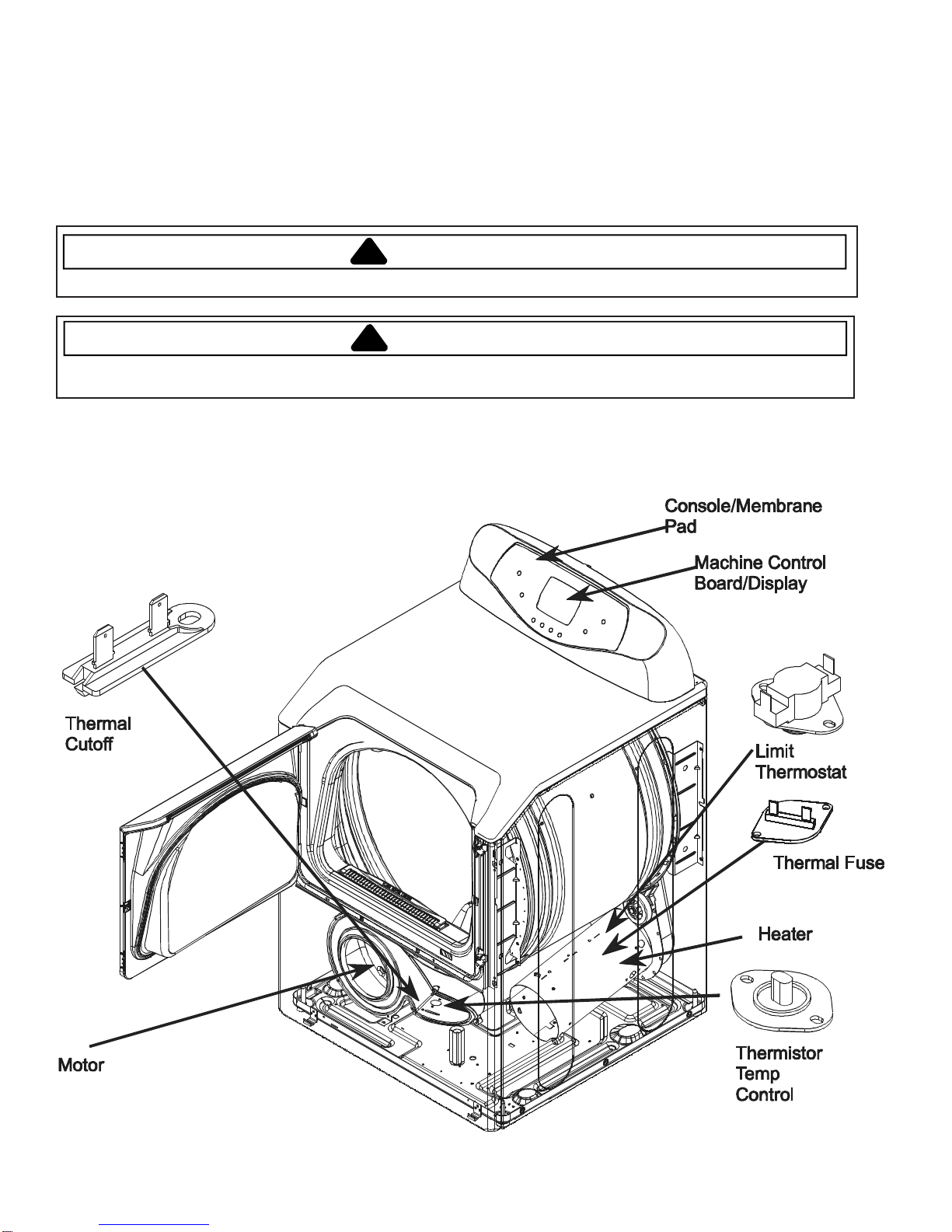

Maytag Dryer MDE6800A, MDE5500B

•Due to possibility of personal injury or property damage, always contact an authorized technician for servicing

or repair of this unit.

Will Not Run

Will not start or run:

• All wires are hooked up to their corresponding

terminals.

• Dryer is plugged in.

• Blown fuse or circuit breaker.

• Door switch functional...door closed.

• Start/Pause switch functional.

• Control Board operational.

• Drive motor functional.

• Blown thermal fuse.

Motor runs/ tumbler will not turn:

• Belt off or broken/damaged.

• Idler tension spring too weak or stretched.

• Idler pulley jammed or stuck.

Runs a few minutes and then stops:

• Lint buildup around drive motor.

• Low voltage present.

• Blower impeller blocked in blower

housing.

• Drive motor - start switch contacts stuck closed.

Blows fuses or trips circuit breaker:

• The amperage readings are at 240 volts. One line

will be 24 amps and the other line will be 21 amps.

The neutral line will be at 3 amps. If the above

amperages are present, then the house wiring,

fuse box or circuit breaker should be suspect.

• Shorted heating element to housing.

• Incorrect wiring or a wire shorting to ground.

• Drive motor winding shorting to ground.

Will Not Dry

Will not heat (motor runs):

• Open heating element.

• Hi-Limit trips easily or is open.

• Regulating thermostat trips easily or is open.

• Membrane switch open.

• Drive motor centrifugal start switch not allowing

voltage to gas valve or heating element.

Improper drying/clothes wrinkled/ rough

texture/long dry time:

• Lint filter is not clean.

• Restriction in exhaust.

• Outside exhaust hood damper door stuck closed.

• Exhaust too long, too many elbows, flex ductwork

installed.

• Poor makeup air available for the dryer.

• Incorrect tumbler speed. Tumbler belt slipping.

• Blower impeller bound; check for foreign material

in blower area.

• Customer overloading dryer.

• Check clothing labels for fabric content and cycle

selected.

• Clothes too wet due to insufficient spin out by

washer.

Will Not Shut Off

Short in Sensor Circuit.

Check Membrane Pad.

Check Electronic Control Board.

Troubleshooting the electronic

control circuit:

• Check for miswiring of the electrical connector at

the electronic control board.

• Does not shut off, then the problem is in the

electronic control unit. Disconnect the sensor wire

from the sensor bar. If the dryer runs for about 20

minutes, then shuts down or the timer advances,

then the electronic control unit is good and the

problem lies in the sensor bar.

• Check sensor for continuity. If found, replace

sensor bar or clean with alcohol. Some fabric

softener sheets will coat the sensor bars.

Noisy and/Or Vibration

• Thumping Check for loose tumbler baffle, rear

tumbler roller(s) worn or misaligned, out-of-round

tumbler or high weld seam on tumbler.

• Ticking Check for loose wire harness or object

caught in blower wheel area.

• Scraping Check for front or rear bulkhead felt seal

out of position or worn tumbler front bearings.

• Roaring Check for blower wheel rubbing on blower

housing or bad motor bearings.

• Popping or squealing sound.Check for a sticky

or frayed belt.

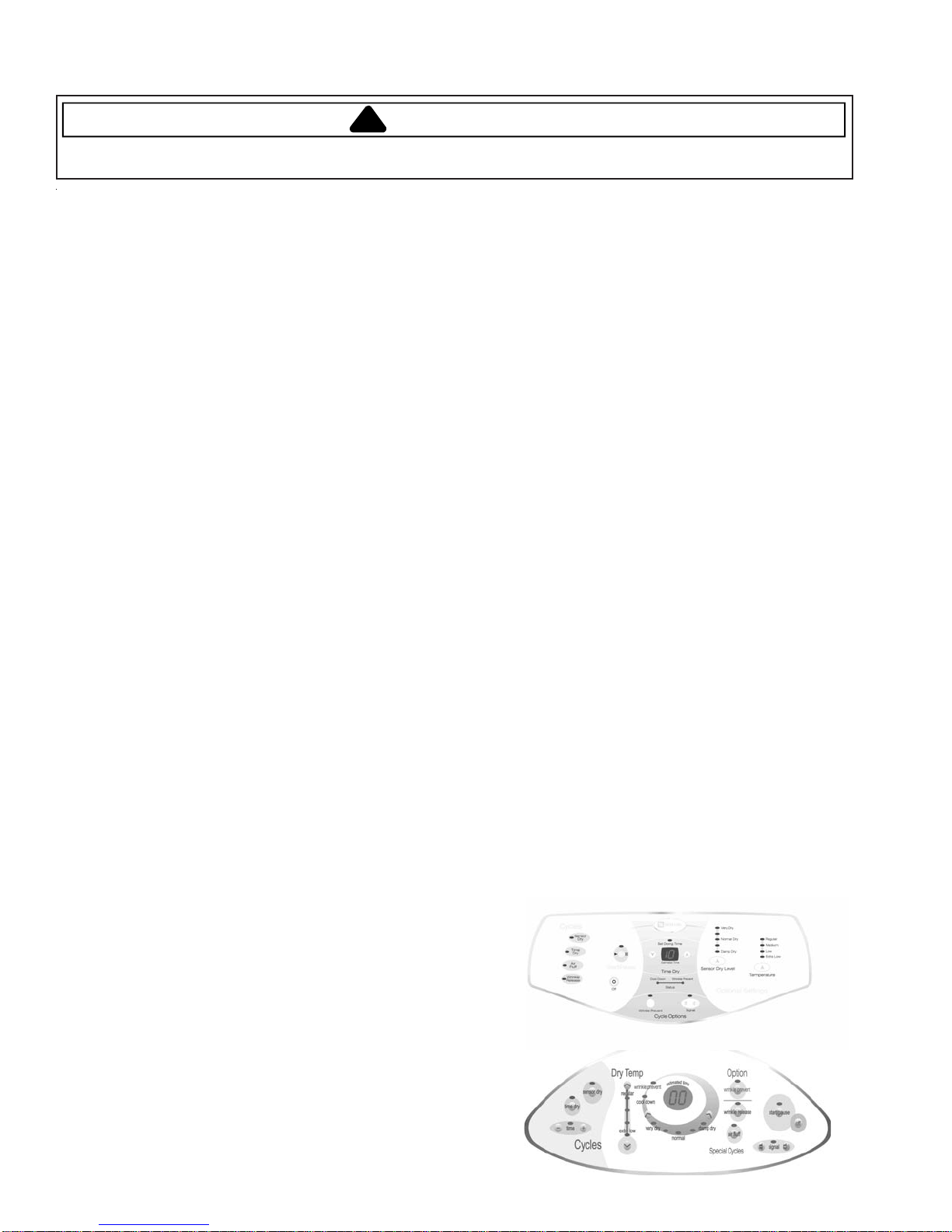

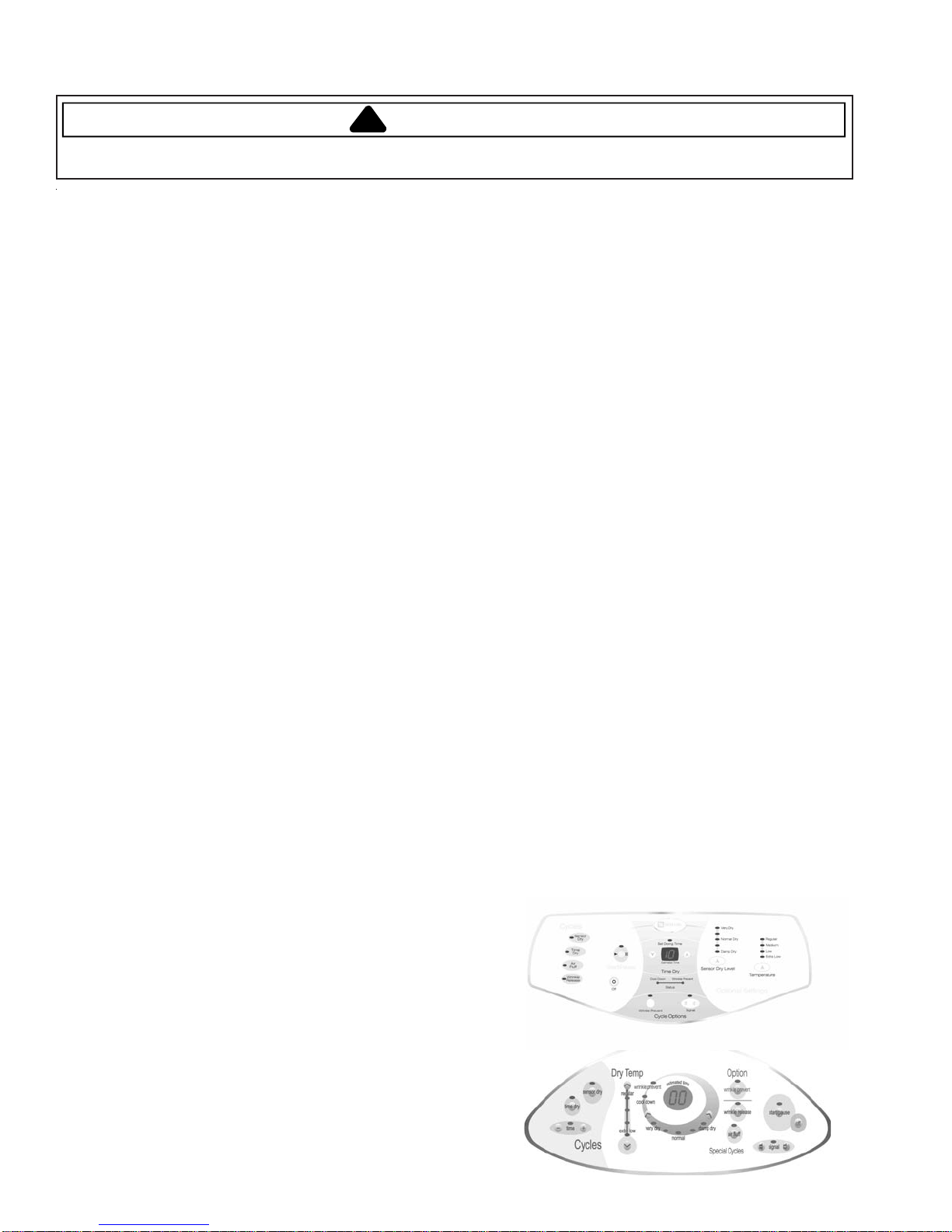

Control Configuration

This Trouble Shooting guide illustrates how the

software works with the 13 and 15 key membrane

switches. The section on Accessing Diagnostic Codes

includes instruction for use with older control boards.

13 Key Membrane

15 Key Membrane