NSTALLATION REC!UREMENTS

PLEASEREAD All Installation Instructions and Requirements Before Installing Power Cord.

IT IS RECOMMENDED THAT A QUALIRED ELECTRkDryers installed in manufactured (mobile) homes must be

ClAN ORSERVICETECHNICIAN INSTALLYOUR DRYER. connected with 4 conductor type SRD or SRDT cord to a 3

pole, 4 wire grounding type receptacle; by metal-clad cable;

or suitable conductorsenclosed in flexible metal conduit. If

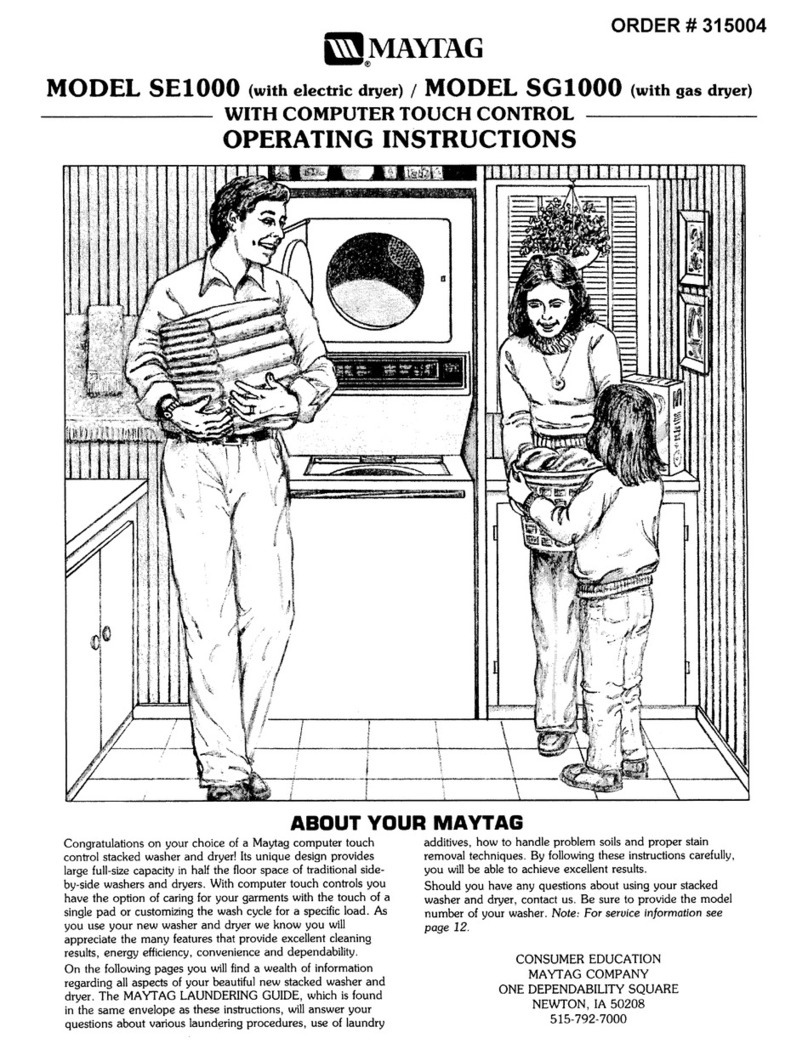

LOCATIONusing metal-clad cable or flexible conduit, leave at least 3

This clothes dryer is designed so that it can be feet free to permit moving the dryer.

installed in most locations in the home. The dryer may

even be installed in an unheated indoor location,such Where permitted by local codes, a flexible power cord (pig-

as a utility room or building. However, with models hav- tail) may be connected to the dryer. A receptacle should be

ing automatic dry cycles, the TIME DRY SETTING installed in a separate circuit connected tothe main service

SHOULD BE USED WHEN THE ROOM TEMPERA- entrance panel for this type of installation. See Figure #3.

TURE DROPS BELOW 50 DEGREES FAHRENHEIT Use onlya 3 or 4 wire power cord kit,includingstrainrelief,

OR (10 DEGREES C.), AS THE AUTOMATIC CYCLE listed byU.L.foruse withdryers.Thepower cordmusthave

MAYNOT SHUT OFF. a ratingof30 amperes, 120/240voltsAC minimumand be

terminatedinclosed looporopenspade lugs withupturned

DO NOT INSTALL THE DRYER ON A CARPETED ends.The attachmentplugofthe powercordandtherecep-

FLOOR. tacleto whichit willbeconnectedmusthaveaminimum cur-

DO NOT INSTALLOR STORE THE DRYER WHERE rent rating of30 amps andhave matchingconfigurations.

IT MAY BE EXPOSED TO THE WEATHER OR DRIP-Typical30 ampereconfigurations are illustratedin figure#3.

PING WATER. IF IT IS EVER EXPOSED TO WATER,

HAVE A QUALIFIED TECHNICIAN CHECK IT GROUNDINGINSTRUCTIONS

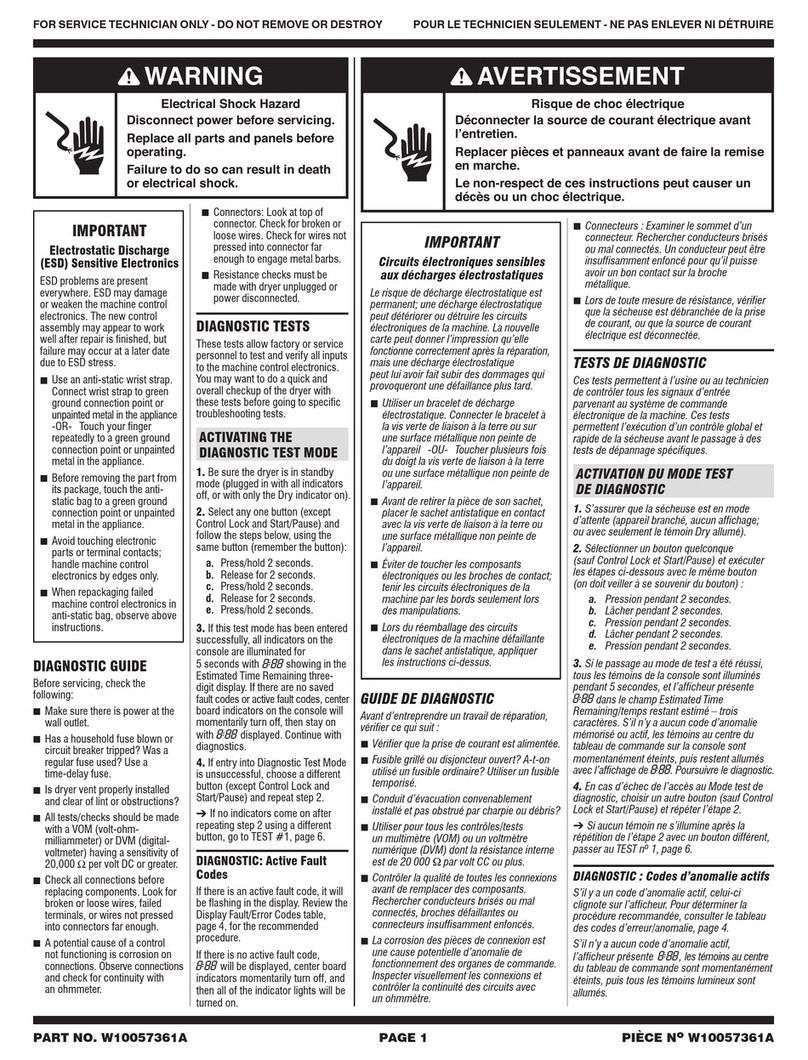

BEFORE USING.This appliance MUST BECONNECTED TO A GROUNDED

THE INSTALLATION MUST BE MADE WITH ADEQUATE METAL PERMANENTWIRING SYSTEM; oran equipment-

CLEARANCE TO PERMIT SERVICING. groundingconductormust berunwiththe circuitconductors

and connected to the equipment-grounding terminal or lead

Inordinary installations enough air will be available for prop- on the appliance.

er operation of the dryer. However, if the dryer is installed in

a mobile home, a closet or atightly sealed room, provisions CONNECTINGTHEDRYER

should be made for at least 18 square inches ofventilation I I

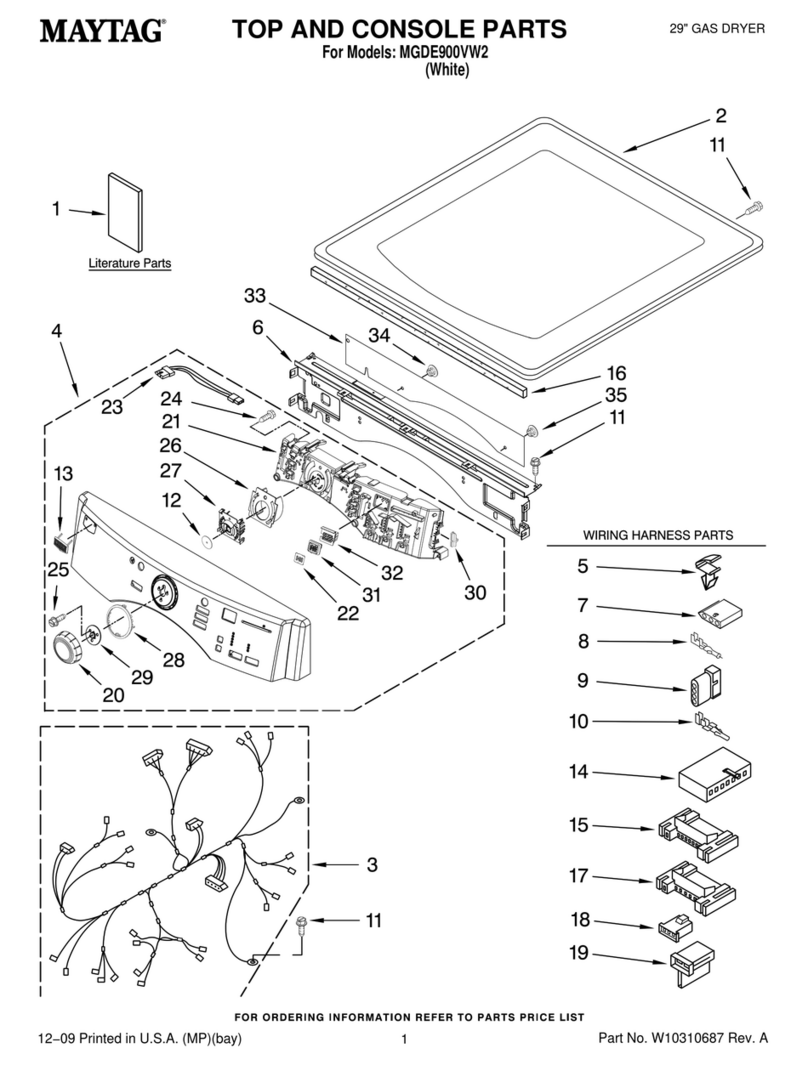

area.Air openings measuring a minimum 3 in.by 3 in.should I FIG.#1-3 WIRE HOTWIREROUTED

_ABOVE BRASS STRAP

++o++++++0+0++o,,+++,+ I I

Ordinarily, Iouvered doors will satisfy the ventilation require- LINE

ments. Dryers installed in a bedroom, bathroom,or closet (BLACI<

must beexhausted outdoors. I-._..11"-/.CRASSSTRAP/-- STRAIN |

I

ELECTRICAL REQUIREMENTS CLAMP I

ml "'"// [/,_-_._/'/(_._:'-_POWER

This phase of the installation should be done by a qualified NEUTRAl r{l_ll__-_-"-{/// _#//_CORD

service technician or electrician in accordance with the (WRITE _ _.-;___,_

++++++++++°++++d°++I

Aseparate circuit must be provided from themain service

entrance panel (fuse box)to the dryer.The circuit must be a 3

or 4 wire, 120/240 volt, 60 Hz, single phase, AC circuit. Each LINE2

(RED)

ofthe120 volt line wires (line t and2)of this circuitmust be I

protected by 30 ampere time delay fuses or circuit breakers.IWJ 'NEUTRALWIRE

Do not fuse the neutral line or the ground line (if provided). HOTWIREROUTED _--_J ROUTEDBELOW

BELOW BRASS STRAP BRASS STRAP

All wires (including neutral and ground if provided) of the I

dryer circuit must be No. 10 gauge copper wirefor up to 40

ft. lengths and No. 8 gauge copper wire for up to 60 ft.THENATIONALELECTRICAL CODEAND ALL

Lengths.NEVER USE A TWO WIRE CABLE WITH AN LOCAL CODES AND ORDINANCES MUST BE

UNINSULATED GROUND WIRE TO CONNECT THEOBSERVED WHEN CONNECTING THIS DRYER.

DRYER.

The NationalElectric Code requires that a means to discon- 1. To gain access to the terminalblock, remove the supply

nect all ungrounded conductors (line 1 and line 2) to the cord cover plate attached to the rear of the dryer.

dryer beprovided forservice. If a powercord andreceptacle

are provided this requirement is met. If other means are 2. Installa suitable strain relief clamp or connector in the

used a suitable switch or circuit breaker must be installed strain relief hole located adjacent to the terminal block.

withinsight of thedryer. 2