4

Cartridge filtration is an eective trouble-free proven method of filtration. Pool water

enters the filter and passes through a polyester single element cartridge. Suspended

particles are trapped and the water is returned to the pool. As the build-up of dirt in the

element increases, so the water pressure rises and the flow decreases. When the pressure

reaches an unacceptable level, the element must be removed and cleaned (spray washing

with a common garden hose is generally sucient).

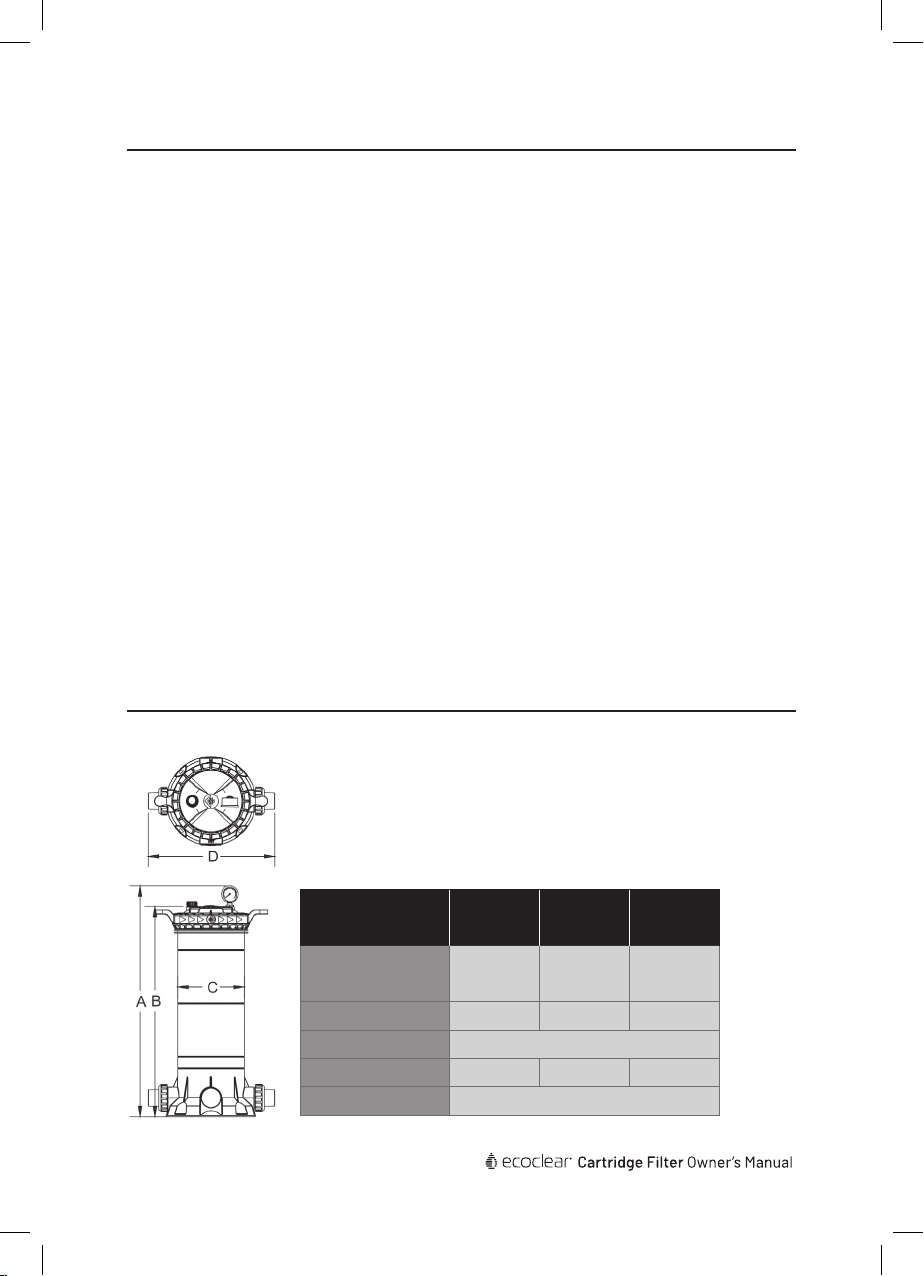

LOCATION

The filter should be placed in its permanent location , preferably as close to the pool or spa as

practical. Position the filter tank and pump on a level concrete slab or similar base. Allow suf-

ficient space around the filter for routine maintenance and provide for adequate ventilation

and drainage. Place the pump in position on the slab and locate the filter alongside with the

appropriate pump inlet connection orientated towards the pump. Refer to the ‘Specifications’

section for the minimum clearance measurements required for each model.

WEATHER PROTECTION

Ecoclear® cartridge filters are constructed of corrosion resistant materials. However,to ensure

years of reliable performance, it is recommended that the filtration system be adequately

protected from the weather.

ASSEMBLY

Assemble the pressure gauge to the filter lid using Teflon tape on the male thread.

Do not over tighten!

PIPE CONNECTIONS

Piping should be supported independently and not impose heavy loads on the filter or pump.

Use 40mm or 50mm PVC pipe for pump and pool return lines. 50mm should always be used

if length of piping is over 15m. Ecoclear® cartridge filters are supplied with quick connect barrel

unions suitable for 40mm and 50mm PVC pipe. If the pump and filter are located below pool

water level, it is necessary to fit isolating valves in the pipe between the pump and the pool,

and in the return line from the filter to the pool.

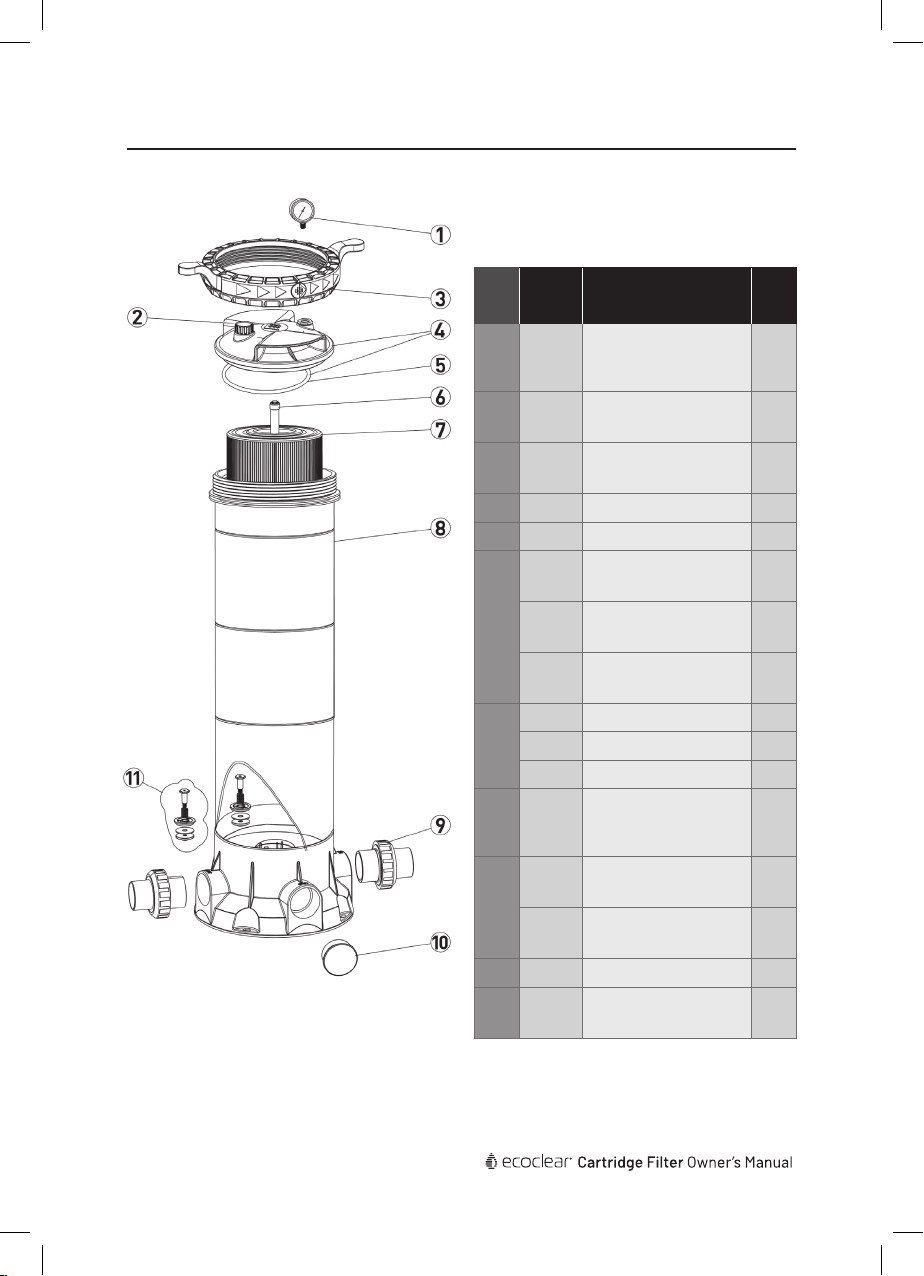

1. Pump to filter

Ecoclear® cartridge filters are equipped with two inlet ports marked ‘INLET’. Select the

inlet port most suitable for the installation and plug the other inlet port with blanking cap

provided. Using the supplied barrel unions, connect the pool pump delivery piping to the

selected inlet port couplings, connect the pool pump delivery piping to the selected inlet

port. Use only `P` type plumbing glue. Tighten unions by hand only.

2. Filter to pool Return

Using the supplied barrel unions, connect the pool return piping to the filter fitting marked

‘OUTLET’, the other outlet should be blocked with the blocking cap provided. Tighten

the fitting by hand only. Ensure the o-ring on the fitting is clean, lubricated with o-ring

lubricant and in the correct position.

The filter base is provided with four mounting holes to enable it to be secured, if required.

THE SPARKLING CLEAR WATER DIFFERENCE

INSTALLATION AND OPERATION INSTRUCTIONS