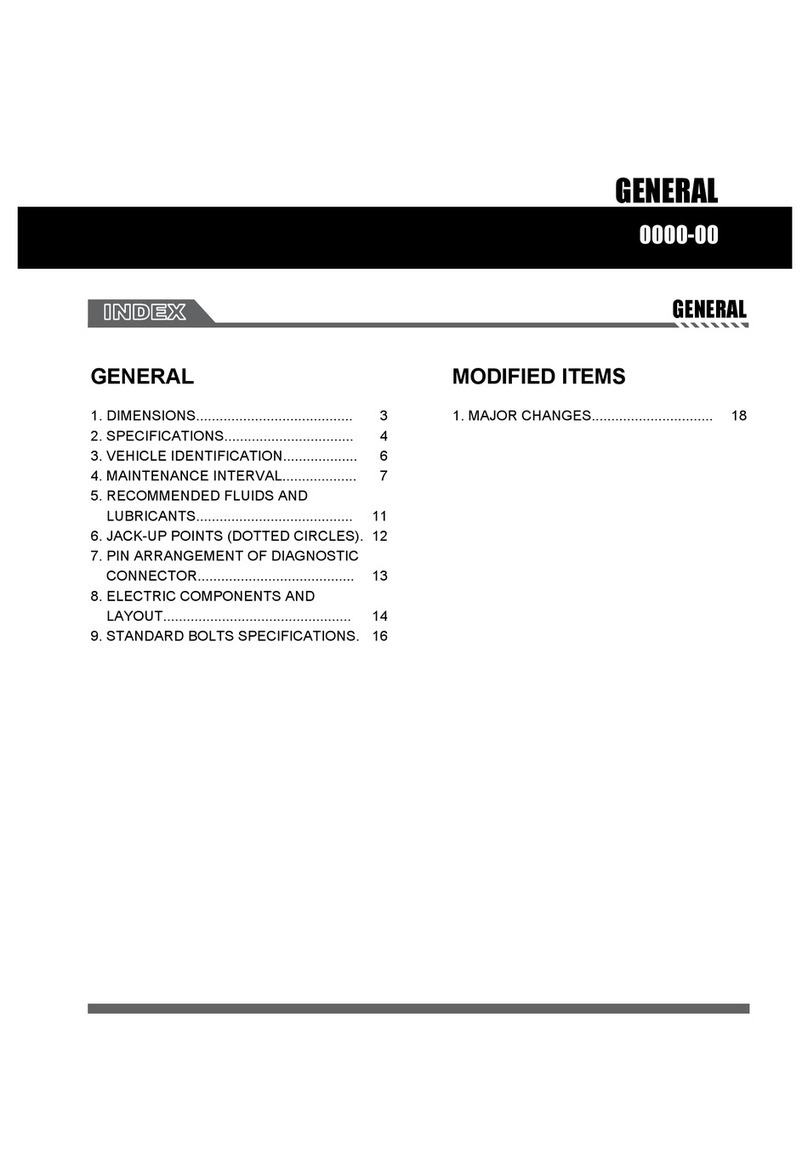

GI

IMPORTANT INFORMATION

IMPORTANT INFORMATION

BASIC ASSUMPTIONS

This workshop manual assumes that you have certain special tools that are necessary for the safe and effi-

cient performance of service operations

on

Mazda vehicles and that you know how to use them properly.

It

also assumes that you are familiar with automobile systems and basic service and repair procedures. You

should not attempt to use this manual unless these assumptions are correct and you understand the conse-

quences described below.

SAFETY RISK

This manual contains certain notes, warnings, and other precautionary information that you should carefully

read and follow to reduce the risk

of

personal injury to yourself or others and the risk of improper service

that may damage the vehicle or render

it

unsafe.

If

there

is

no such information

in

regard to any specific

service method, this does not mean there

is

no possibility that personal safety or vehicle safety will be

jeopardized by the use of incorrect methods or tools.

POSSIBLE LOSS OF WARRANTY

The manufacturer's warranty on Mazda vehicles and engines can be voided

if

improper service or repairs

are performed by persons other than those

at

an Authorized Mazda Dealer.

WARNING ON LUBRICANTS AND GREASES

Avoid

all

prolonged and repeated contact with mineral oils, especially used oils. Used oils contaminated

during service (e.g., engine sump oils) are more irritating and more likely to cause serious effects, including

skin cancer,

in

the event of gross and prolonged skin contact.

Wash skin thoroughly after work involving oil.

Protective hand cleaners may be of value provided they can be removed from the skin with water. Do not

use gasoline, paraffin, or other solvents to remove

oil

from the skin.

Lubricants and greases may be slightly irritating to the eyes.

Repeated or prolonged skin contact should be avoided by wearing protective clothing. Particular care should

be taken with used oils and greases containing lead. Do not allow work clothing to be contaminated with

oil. Dry clean or launder such clothing

at

regular intervals.

05UGIX-002

GI-2

-

-