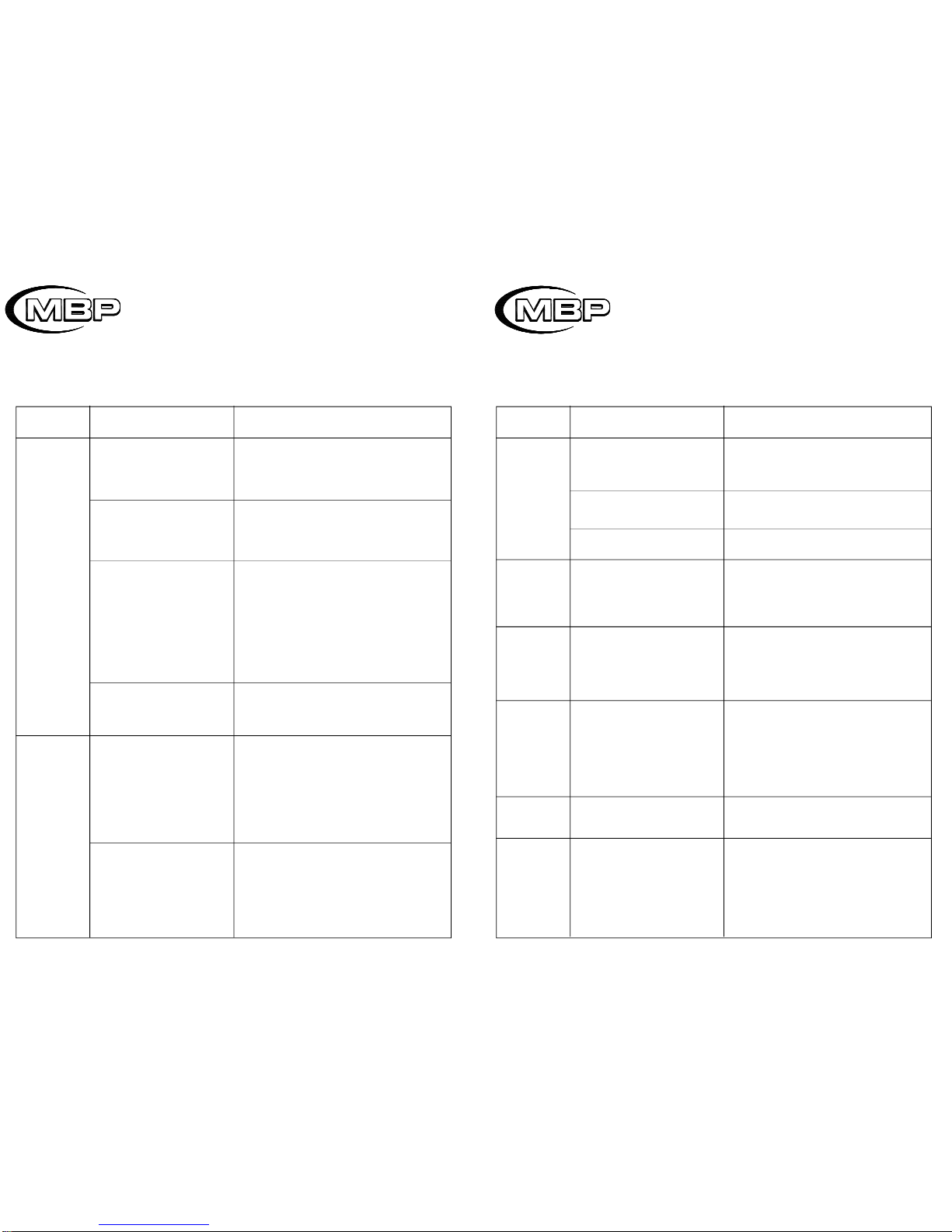

7

SOLUTION

Remove siphon tube and feel lower ball check

to be sure it isfree to move offit is seat. Place

full cup of paint thinner over end of fluid

section and turn on pump.

Remove and clean.

Hold gun trigger in open position and run unit

about 10 seconds until air is purged. Check

for siphon tube leak.

Replace.

Prime pump withcompatiblesolvent. Bringup

to pressure, carefully remove pump from

solvent container and immerse inlet tube into

heavy material to be sprayed. With nozzle tip

removed trigger gun until heavy material

appears at gun.

Replace nozzle tip and you are readyto spray.

Remove and clean.

Check connection and seal.

Relieve pressure, remove tip and clean.

Adjust to increase pressure.

Cleanortemporalyremove.

Replace or clean.

Hold gun trigger in open position and run

about 10 seconds until airs is purged.

Replace.

Replace.

With gun trigger closed, allow unit to pump

up to pressure and shut off if pump

momentarily starts, internal leak is indicated

and fluid section rebuild is necesary.

CAUSE

Dried out piston packings.

Stuck valve balls.

Pump inlet screen plugged.

Air in pump or hose

Packings worn.

Fluid too viscous.

Siphon tube clogged.

Siphon tube air leak.

Clogged tip.

Pressure adjusting knob not

properly set.

Pump inlet strainer dirty.

Valve balls or seats worn or

dirty.

Air in pump or hose.

Packings worn.

Worn spray tip.

Internal leakage.

TROUBLE

Unitwillnot

prime

Unitwillnot

build or

maintain

pressure.

TROUBLESHOOTING CHART

8

CAUSE

Fuid leak.

Fluid too viscous.

Too large a spray tip.

Worn packing.

Upper packings worn.

Piston rod worn.

Too large a tip size.

Pressure adjustment wrong.

Insufficient fluid delivery.

Fuid too viscous.

Pressure adjustment low.

Improper voltage supply.

Excessive pressure.

Excesive extention cord length

or improper wire gauge.

TROUBLE

Unitwillnot

build or

maintain

pressure.

Fuid leakage

out relief hole

at pressure

control.

Fluid leakage

at upper end

offluid

section.

Bad spray

pattern.

Unit lacks

power.

Blown fuses

at pump.

SOLUTION

Checkforexternalleaksincludinghydraulic

fittings attached to pressure control

housing.

Consultmanufacturersrecommendationson

paint container label.

Change tip.

Repack or replace transducer.

Relieve pressure and tighten packing take

up nut or replace packings.

Replace.

Change to asmaller tip size.

Adjust pressure control knob.

Clean all straines and filters in system.

Add solvent to fluid according to

manufacturer’s recommendations.

Increase.

Reconnect input voltage accordingly.

HaveService Center recalibratethepressure

control.

Use 3x1,5 mm. section wire or larger up to

maximumof50meters. Foradditionallenght,

more airless hose may be used.