Table of Contents

Document number: 2611275-EN Sales number: 1501101 ... 1501132 (LABmaster), 1500111 (MB-20-G), 1500114

(MB-200G-W), 1500050 ...1500092 (MOD Box)

MB-20-G/MB-200G-W_MB-LABmaster_MB-200 MOD_TP700

Operating Manual - V5.0 - 04/2018 - STD

Page

1

Table of Contents

1 General information ...................................................................... 1- 1

1.1 Entries referring to the system .................................................... 1- 1

1.2 Scope of delivery .......................................................................... 1- 1

1.3 Type plate ...................................................................................... 1- 2

1.4 Liability........................................................................................... 1- 3

1.5 Warranty......................................................................................... 1- 4

1.6 Modifications ................................................................................. 1- 4

1.7 Service address............................................................................. 1- 4

1.8 Included description of optional features................................... 1- 5

1.9 About this operating manual ....................................................... 1- 6

1.9.1 General............................................................................1- 6

1.9.2 Availability of instructions ................................................1- 6

1.9.3 Safety warnings in this manual........................................1- 6

1.9.4 Conventions used in this manual ....................................1- 7

1.9.5 Units used........................................................................1- 8

1.9.6 Terms used......................................................................1- 8

1.9.7 Abbreviations...................................................................1- 9

1.9.8 Glossary ........................................................................1- 10

1.9.9 Disclaimer......................................................................1- 11

2 Inert gas technology ..................................................................... 2- 1

2.1 Overview ........................................................................................ 2- 1

2.2 Components .................................................................................. 2- 2

2.2.1 Glovebox .........................................................................2- 2

2.2.2 Antechamber ...................................................................2- 6

2.2.3 Gas purifier......................................................................2- 9

2.2.4 System control...............................................................2- 11

2.2.5 Vacuum pump ...............................................................2- 13

2.3 Functional description................................................................ 2- 14

2.3.1 Gas flow general............................................................2- 14

2.3.2 Single reactor systems (sp)...........................................2- 16

2.3.3 Optional: double purifier (dp).........................................2- 17

2.3.4 Optional: solvent filter....................................................2- 17

2.3.5 Box pressure control......................................................2- 19

2.3.6 Vacuum antechamber ...................................................2- 22

2.4 MBRAUN standard platforms..................................................... 2- 25

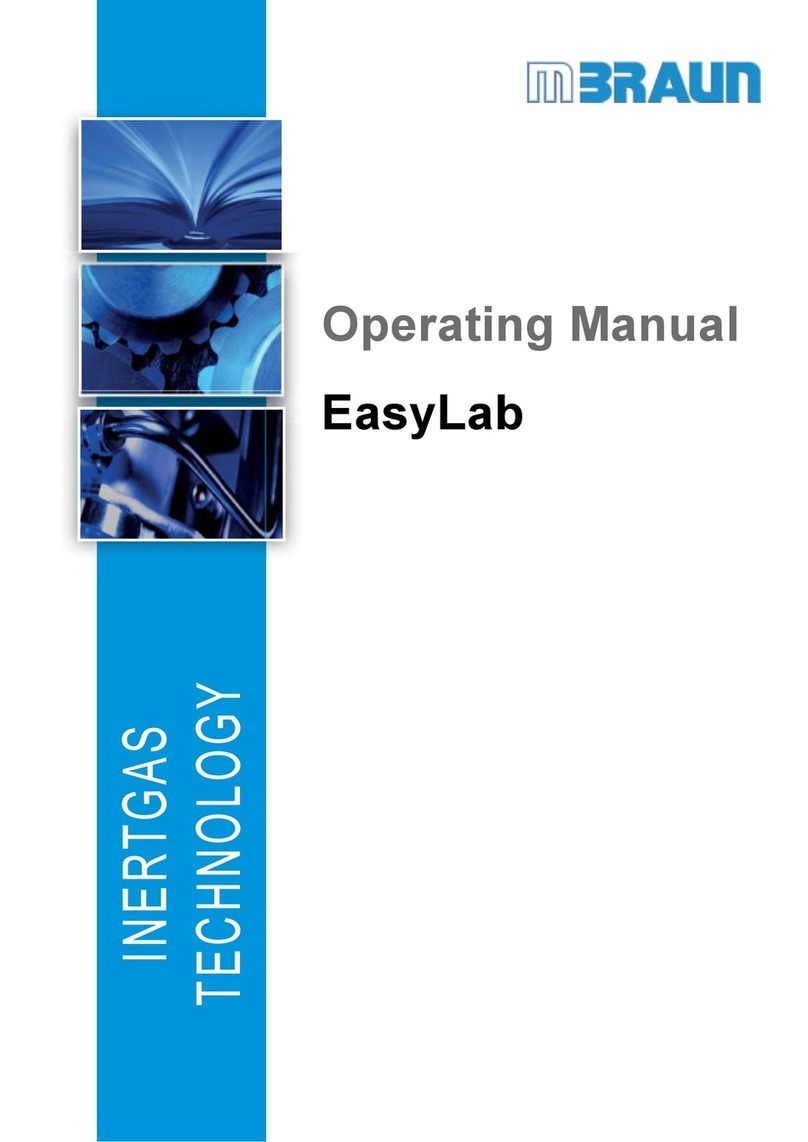

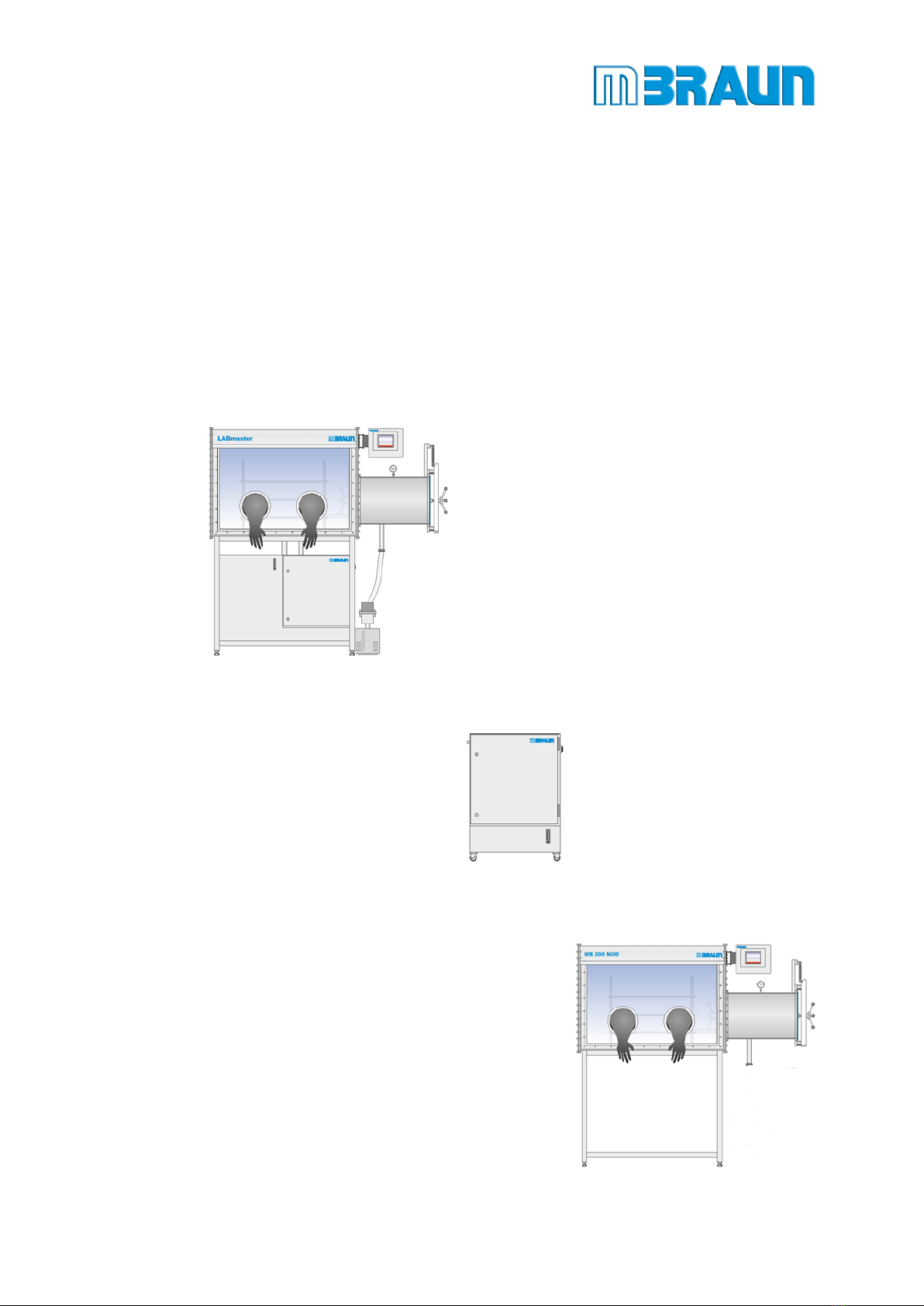

2.4.1 MB-20-G and MB-200G-W............................................2- 25

2.4.2 LABmaster pro workstation ...........................................2- 25

2.4.3 MOD box systems .........................................................2- 26

2.4.4 Technical data ...............................................................2- 26

2.4.5 Noise level.....................................................................2- 28

2.4.6 On-site conditions..........................................................2- 28

3 Safety ............................................................................................. 3- 1

3.1 Intended use .................................................................................. 3- 1

3.2 Improper use ................................................................................. 3- 2

3.3 Statement of the manufacturer .................................................... 3- 3