OperatingManual

Operating Manual Page 1-2

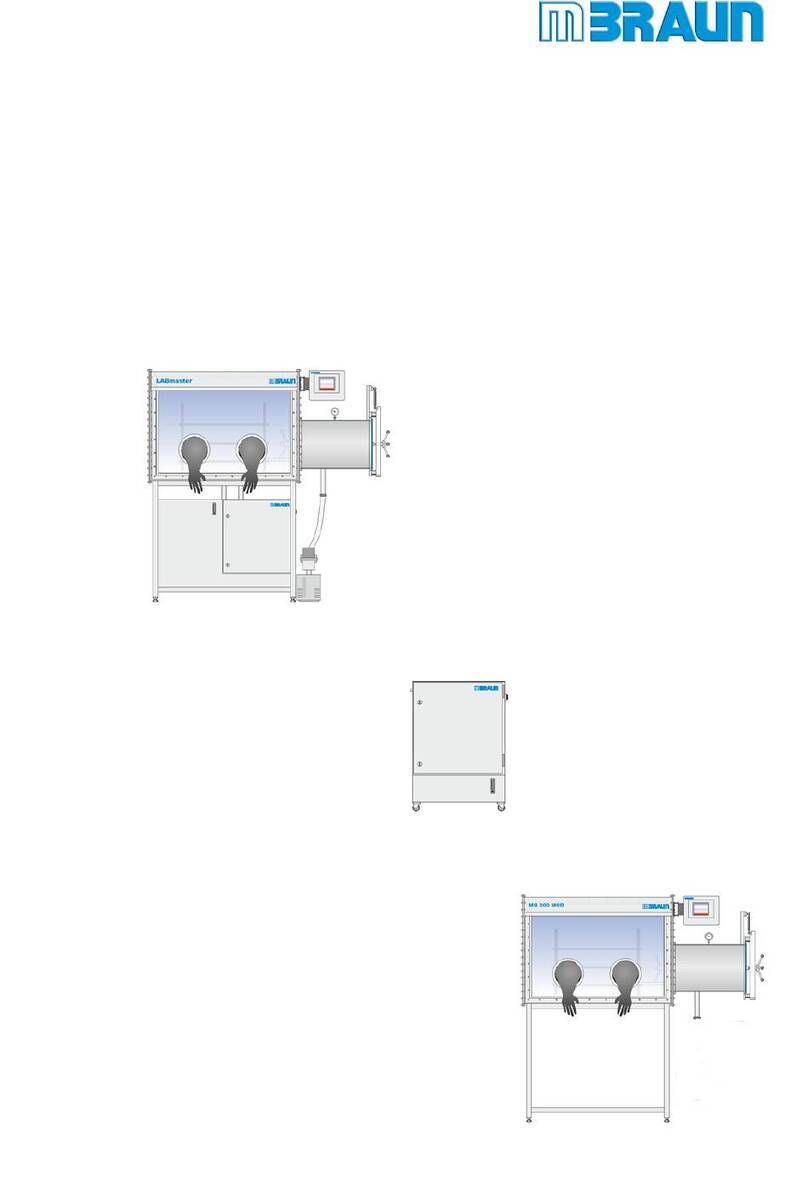

Operating Manual Glove Box Systems

© GmbH – 01/2016 –- Version 3.0

1. General Information

1.1 General Information

This technical documentation is not liable to any obligations on the part of the manufacturer.

The manufacturer M. Braun Inertgas-Systeme Shanghai Co.,Ltd reserves the right for

technical and optical modifications as well as functional modifications on the systems or

system’s components described therein. Any duplication of this documentation, even in form

of excerpts, is only permitted after having obtained the manufacturer’s information and

concession.

Title:..................................................................................................... MBRAUN Glove Box

Systems

Standard operating Manual

Edition: ....................................................................................................................................

01/2016

see type plate for details

Copyright: ................................................. © 2016 M. Braun Inertgas-Systeme (shanghai)

Co,. Ltd. (MBRAUN)

1.2 Entries Referring to the System

We guarantee the equipment as stated in the order/contract.

This documentation is part of the system:

Designation / Type: .........................................................................................

Serial number (s): .........................................................................................

Person(s) in charge .........................................................................................

of the system:

Space left for notes on system settings, instructions for maintenance etc.

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................

....................................................................................................................................................