03

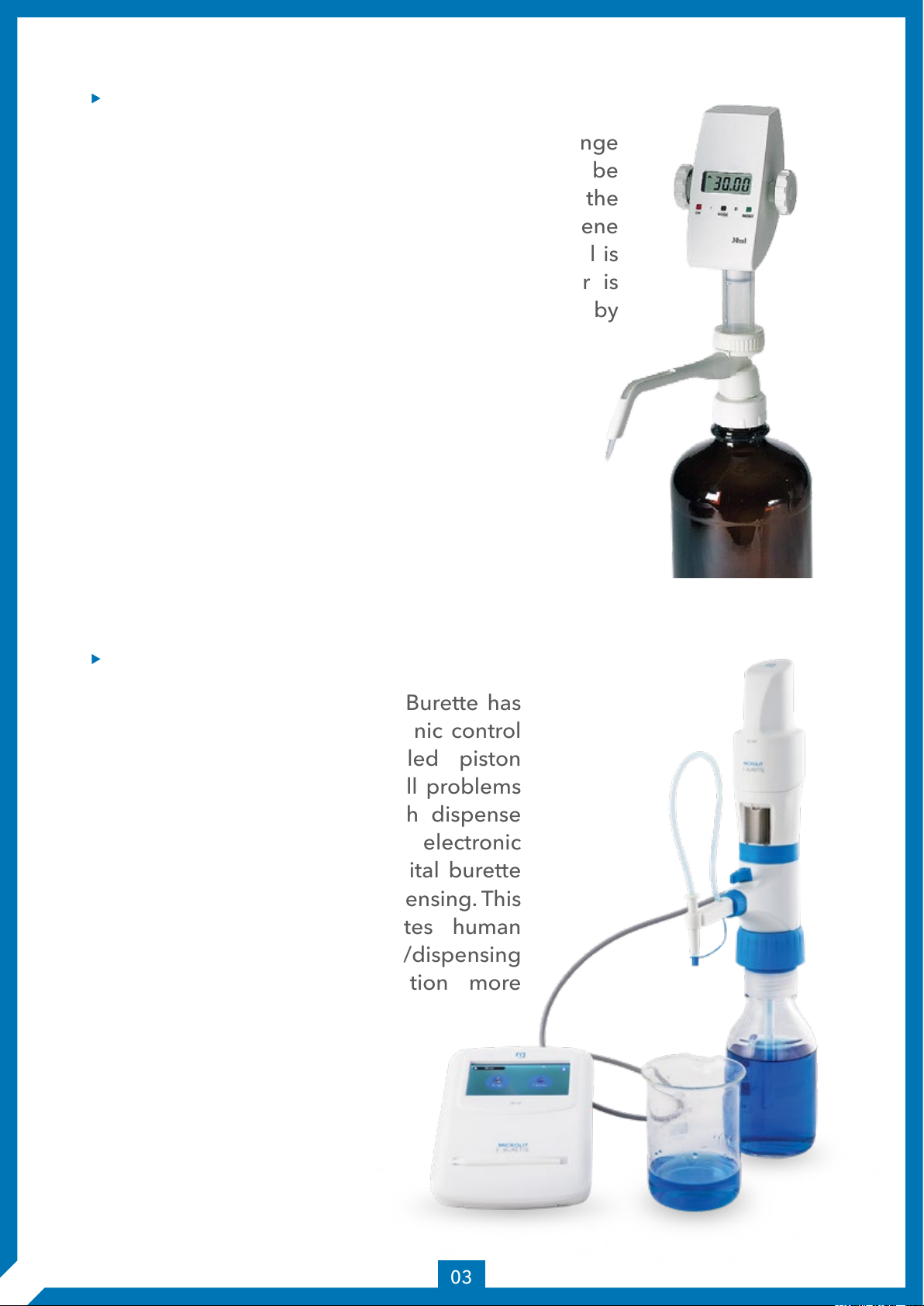

PISTON OR DIGITAL BURETTE:

A piston or digital burette is based on a syringe

design wherein the barrel and plunger can be

made of glass or plastic. For alkali solutions, the

barrel and plunger may be made of polyethylene

or another resistant plastic material. The barrel is

placed in a fixed position and the plunger is

moved incrementally by rotating the wheel by

hand or by means of a step motor.

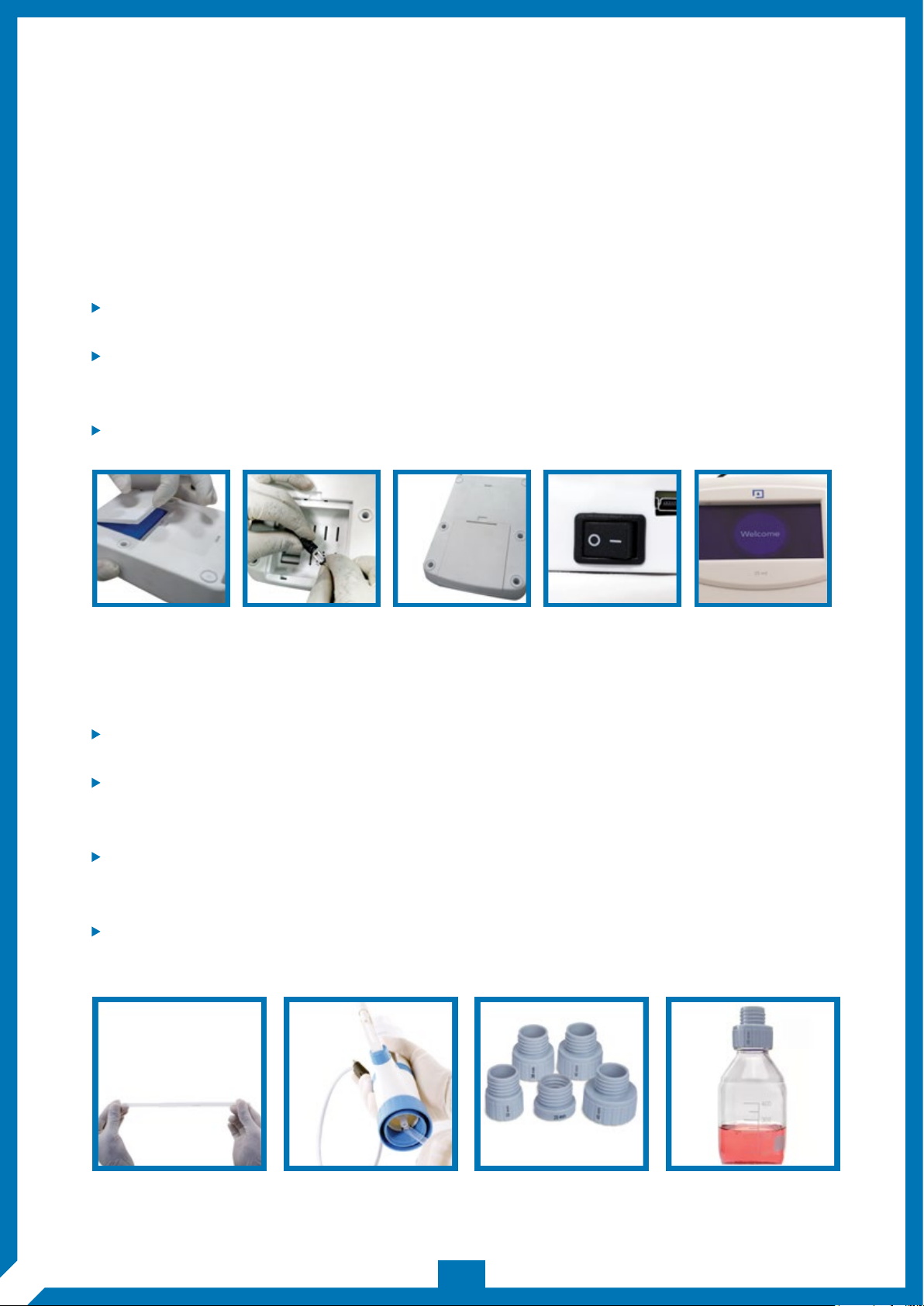

The Electronic Burette or E-Burette has

an electronic display, electronic control

panel and motor controlled piston

movements that eliminate all problems

of the digital burette which dispense

manually. The accuracy of electronic

burette is higher than a digital burette

due to motor controlled dispensing. This

motorized system eliminates human

errors in the titration/dispensing

process, making the titration more

precise.

The volume is shown on a digital

display given at the top of the

burette. A high-precision syringe can

be used to deliver a very precise

amount of liquid. A motorized digital

burette can be controlled by a

computer.

ELECTRONIC BURETTE