TABLE OF CONTENTS

i

FORWARD 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MBW SLIPFORM PAVER PURCHASE AWARENESS 2. . . . . . . . . .

SAFETY PRECAUTIONS 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

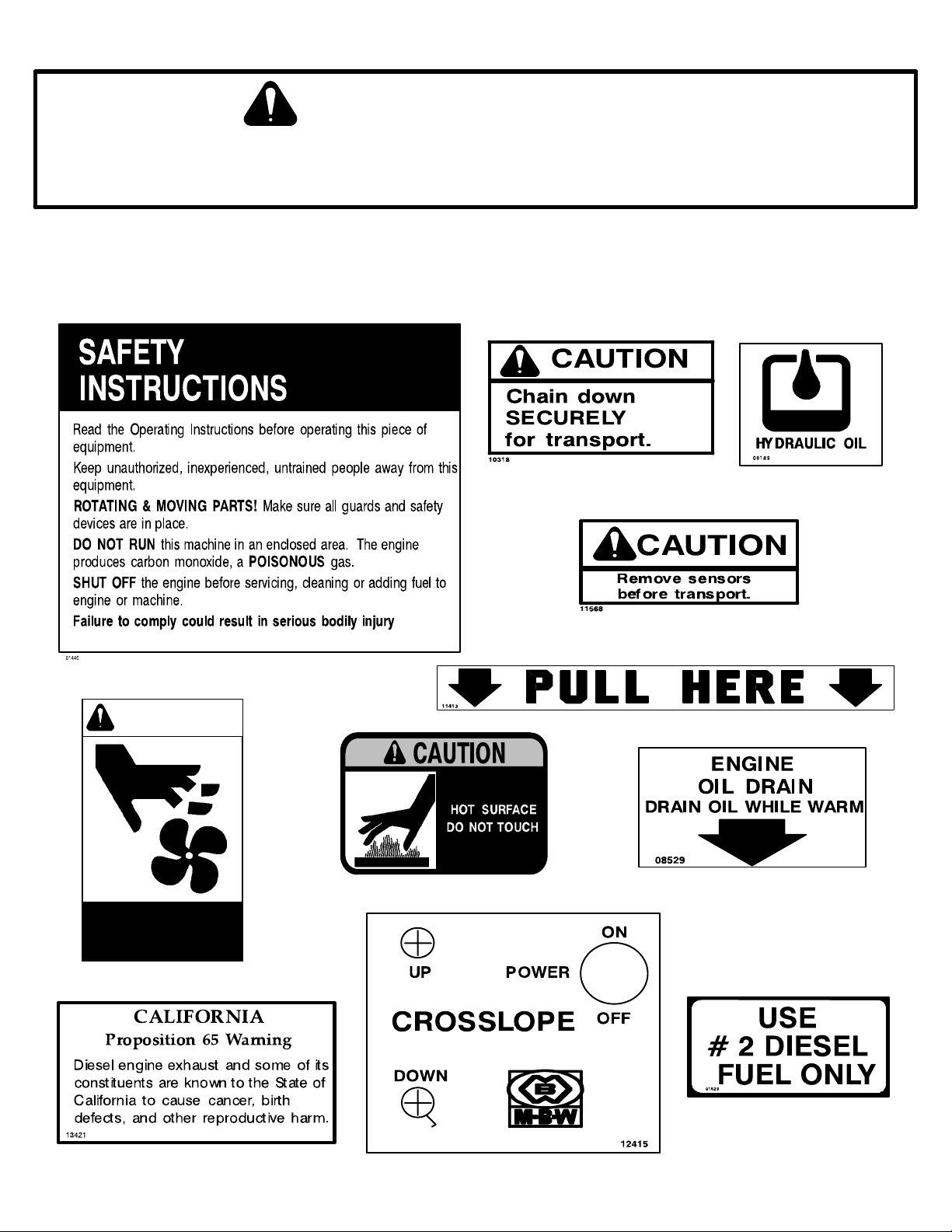

SAFETY NOTICE AND DECALS 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SAFETY DECAL LOCATIONS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARRANTY 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MBW WAREHOUSE LOCATIONS 9. . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFICATIONS 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERIAL # LOCATION 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTROL PANEL DESCRIPTION 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

CONTROL PANEL 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VIBRATOR CONTROLS 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING INSTRUCTIONS 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTING THE ENGINE 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOPPING THE ENGINE 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASSEMBLY INSTRUCTIONS 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATTACHING HOPPER: 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATTACHING MOLDS: 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLING VIBRATORS: 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHANGING HOPPERS IN THE SIDE UNIT: 21. . . . . . . . . . . . . . . . .

INSTALLING SENSORS: 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SET-UP AND POURING INSTRUCTIONS 25. . . . . . . . . . . . . . . . . . .

JOB SITE SET-UP, SIDE DRIVE APPLICATIONS 25. . . . . . . . . . . .

JOB SITE SET-UP, 12" HOPPER, NO SIDE DRIVE 26. . . . . . . . . .

AUTOMATIC SENSOR SET-UP: 27. . . . . . . . . . . . . . . . . . . . . . . . . .

AUTOMATIC STEERING SENSOR ADJUSTMENTS: 28. . . . . . . . .

AUTOMATIC HEIGHT SENSOR ADJUSTMENTS: 30. . . . . . . . . . .

ADJUSTING THE HEIGHT LIMIT SWITCH: 31. . . . . . . . . . . . . . . . .

GRADING WITH THE PAVER BE ORE POURING: 32. . . . . . . . . . .

BEGIN POURING: 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWITCHING STEERING SENSORS: 34. . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS WHILE POURING: 35. . . . . . . . . . . . . . . . . . . . . . . .

ADJUSTMENTS A TER POURING: 35. . . . . . . . . . . . . . . . . . . . . . . .

OPERATING HINTS 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PERIODIC MAINTENANCE 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING ENGINE OIL LEVEL: 38. . . . . . . . . . . . . . . . . . . . . . . . . .

CHANGING ENGINE OIL AND ILTER: 38. . . . . . . . . . . . . . . . . . . .

CLEANING ENGINE AIR ILTER: 39. . . . . . . . . . . . . . . . . . . . . . . . . .

CLEANING/REPLACING UEL ILTER: 39. . . . . . . . . . . . . . . . . . . .

CHECKING ENGINE COOLANT LEVEL: 40. . . . . . . . . . . . . . . . . . .

CHECKING BATTERY: 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING ENGINE AN BELT: 41. . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING HYDRAULIC OIL LEVEL: 41. . . . . . . . . . . . . . . . . . . . . .

CHANGING HYDRAULIC OIL ILTERS: 42. . . . . . . . . . . . . . . . . . . .

CHANGING HYDRAULIC OIL: 42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAINTENANCE & LUBRICATION CHART 43. . . . . . . . . . . . . . . . . . . .

TROUBLE SHOOTING - ENGINE 44. . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLE SHOOTING - PAVER 46. . . . . . . . . . . . . . . . . . . . . . . . . . . .

HYDRAULIC SCHEMATIC DIAGRAM 47. . . . . . . . . . . . . . . . . . . . . . . .

CONTROL PANEL WIRING DIAGRAM 48. . . . . . . . . . . . . . . . . . . . . . .

MACHINE WIRING DIAGRAM 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MOLD ORDERING 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

POURING CONDITIONS 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MBW INC. MOLD ORDER FORM 54. . . . . . . . . . . . . . . . . . . . . . . . . . . .