McConnel ROBOCUT2 RC40 User manual

Publication 992

January 2021

Part No. 24214.92

Revision: 24.06.22

REMOTE CONTROLLED TRACTOR UNIT

Operator Manual

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

Dealer Warranty Information & Registration Verification

It is imperative that the selling dealer registers this machine with McConnel Limited before

delivery to the end user –failure to do so may affect the validity of the machine warranty.

To register machines; log onto https://my.mcconnel.com and select ‘Machine Registration’

which can be found in the ‘Warranty’section of the site. Confirm to the customer that

the machine has been registered by completing the verification form below.

Registration Verification

Dealer Name:

……………………..……………………………………………………………..

Dealer Address:

…….…………………………………………………………………………..

Customer Name:

……………………..…………………………………………………………

Date of Warranty Registration:

……/……/...… Dealer Signature: ………………..………

Note to Customer / Owner

Please ensure the section above has been completed and signed by the dealer to verify

your machine has been registered with McConnel Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s responsibility

to regularly inspect all nuts, bolts and hose connections for tightness and re-tighten if required. New

hydraulic connections occasionally weep small amounts of oil as the seals and joints settle in –where

this occurs it can be cured by re-tightening the connection –refer to torque settings chart below. The

tasks stated above should be performed on an hourly basis during the first day of work and at least

daily thereafter as part of the machine’s general maintenance procedure.

CAUTION: DO NOT OVER TORQUE HYDRAULIC FITTINGS AND HOSES

Torque Settings for Hydraulic Fittings

Hydraulic Hose Ends

Port Adaptors with Bonded Seals

BSP

Setting

Metric

BSP

Setting

Metric

1/4”

18 Nm

19 mm

1/4”

34 Nm

19 mm

3/8”

31 Nm

22 mm

3/8”

47 Nm

22 mm

1/2”

49 Nm

27 mm

1/2”

102 Nm

27 mm

5/8”

60 Nm

30 mm

5/8”

122 Nm

30 mm

3/4”

80 Nm

32 mm

3/4”

149 Nm

32 mm

1”

125 Nm

41 mm

1”

203 Nm

41 mm

1.1/4”

190 Nm

50 mm

1.1/4”

305 Nm

50 mm

1.1/2”

250 Nm

55 mm

1.1/2”

305 Nm

55 mm

2”

420 Nm

70 mm

2”

400 Nm

70 mm

Serial No.

Warranty Policy (page 1 of 3)

WARRANTY POLICY

WARRANTY REGISTRATION

All machines must be registered, by the selling dealer with McConnel Ltd, before delivery to the end user.

On receipt of the goods it is the buyer’s responsibility to check that the Verification of Warranty

Registration in the Operator’s Manual has been completed by the selling dealer.

1. LIMITED WARRANTIES

1.01. All mounted machines supplied by McConnel Ltd are warranted to be free from defects in material

and workmanship from the date of sale to the original purchaser for a period of 12 months, unless a

different period is specified.

All Self Propelled Machines supplied by McConnel Ltd are warranted to be free from defects in

material and workmanship from the date of sale to the original purchaser for a period of 12 months

or 1500 hours. Engine warranty will be specific to the Manufacturer of that unit.

1.02. All spare parts supplied by McConnel Ltd and purchased by the end user are warranted to be free from

defects in material and workmanship from the date of sale to the original purchaser for a period of 6

months. All parts warranty claims must be supported by a copy of the failed part invoice to the end

user. We cannot consider claims for which sales invoices are not available.

1.03. The warranty offered by McConnel Ltd is limited to the making good by repair or replacement for the

purchaser any part or parts found, upon examination at its factory, to be defective under normal use

and service due to defects in material or workmanship. Returned parts must be complete and

unexamined. Pack the component(s) carefully so that any transit damage is avoided. All ports on

hydraulic items should be drained of oil and securely plugged to prevent seepage and foreign body

ingress. Certain other components, electrical items for example, may require particular care when

packing to avoid damage in transit.

1.04. This warranty does not extend to any product from which McConnel Ltd’s serial number plate has

been removed or altered.

1.05. The warranty policy is valid for machines registered in line with the terms and conditions detailed and

on the basis that the machines do not extend a period of 24 months or greater since their original

purchase date, that is the original invoice date from McConnel Limited.

Machines that are held in stock for more than 24 months cannot be registered for warranty.

1.06. This warranty does not apply to any part of the goods, which has been subjected to improper or

abnormal use, negligence, alteration, modification, fitment of non-genuine parts, accident damage,

or damage resulting from contact with overhead power lines, damage caused by foreign objects (e.g.

stones, iron, material other than vegetation), failure due to lack of maintenance, use of incorrect oil or

lubricants, contamination of the oil, or which has served its normal life. This warranty does not apply

to any expendable items such as blades, belts, clutch linings, filter elements, flails, flap kits, skids, soil

engaging parts, shields, guards, wear pads, pneumatic tyres or tracks.

1.07. Temporary repairs and consequential loss - i.e. oil, downtime and associated parts are specifically

excluded from the warranty.

1.08. Warranty on hoses is limited to 12 months and does not include hoses which have suffered external

damage. Only complete hoses may be returned under warranty, any which have been cut or repaired

will be rejected.

1.09. Machines must be repaired immediately a problem arises. Continued use of the machine after a

problem has occurred can result in further component failures, for which McConnel Ltd cannot be held

liable, and may have safety implications.

1.10. If in exceptional circumstances a non McConnel Ltd part is used to effect a repair, warranty

reimbursement will be at no more than McConnel Ltd’s standard dealer cost for the genuine part.

Warranty Policy (page 2 of 3)

1.11. Except as provided herein, no employee, agent, dealer or other person is authorised to give any

warranties of any nature on behalf of McConnel Ltd.

1.12. For machine warranty periods in excess of 12 months the following additional exclusions shall apply:

1.12.1. Hoses, exposed pipes and hydraulic tank breathers.

1.12.2. Filters.

1.12.3. Rubber mountings.

1.12.4. External electric wiring.

1.12.5. Bearings and seals

1.12.6. External Cables, Linkages

1.12.7. Loose/Corroded Connections, Light Units, LED’s

1.12.8. Comfort items such as Operator Seat, Ventilation, Audio Equipment

1.13. All service work, particularly filter changes, must be carried out in accordance with the manufacturer’s

service schedule. Failure to comply will invalidate the warranty. In the event of a claim, proof of the

service work being carried out may be required.

1.14. Repeat or additional repairs resulting from incorrect diagnosis or poor quality previous repair work

are excluded from warranty.

NB Warranty cover will be invalid if any non-genuine parts have been fitted or used. Use of non-genuine

parts may seriously affect the machine’s performance and safety. McConnel Ltd cannot be held

responsible for any failures or safety implications that arise due to the use of non-genuine parts.

2. REMEDIES AND PROCEDURES

2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the McConnel web

site and confirms the registration to the purchaser by completing the confirmation form in the

operator’s manual.

2.02. Any fault must be reported to an authorised McConnel Ltd dealer as soon as it occurs. Continued use

of a machine, after a fault has occurred, can result in further component failure for which McConnel

Ltd cannot be held liable.

2.03. Repairs should be undertaken within two days of the failure. Claims submitted for repairs undertaken

more than 2 weeks after a failure has occurred, or 2 days after the parts were supplied will be

rejected, unless the delay has been authorised by McConnel Ltd. Please note that failure by the

customer to release the machine for repair will not be accepted as a reason for delay in repair or

submitting warranty claims.

2.04. All claims must be submitted, by an authorised McConnel Ltd Service Dealer, within 30 days of the

date of repair.

2.05. Following examination of the claim and parts, McConnel Ltd will pay, at their discretion, for any valid

claim the invoiced cost of any parts supplied by McConnel Ltd and appropriate labour and mileage

allowances if applicable.

2.06. The submission of a claim is not a guarantee of payment.

2.07. Any decision reached by McConnel Ltd. is final.

3. LIMITATION OF LIABILITY

3.01. McConnel Ltd disclaims any express (except as set forth herein) and implied warranties with respect to

the goods including, but not limited to, merchantability and fitness for a particular purpose.

3.02. McConnel Ltd makes no warranty as to the design, capability, capacity or suitability for use of the

goods.

3.03. Except as provided herein, McConnel Ltd shall have no liability or responsibility to the purchaser or

any other person or entity with respect to any liability, loss, or damage caused or alleged to be caused

directly or indirectly by the goods including, but not limited to, any indirect, special, consequential, or

incidental damages resulting from the use or operation of the goods or any breach of this warranty.

Notwithstanding the above limitations and warranties, the manufacturer’s liability hereunder for

damages incurred by the purchaser or others shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this warranty may

be brought more than one (1) year after the cause of the action has occurred.

Warranty Policy (page 3 of 3)

4. MISCELLANEOUS

4.01. McConnel Ltd may waive compliance with any of the terms of this limited warranty, but no waiver of

any terms shall be deemed to be a waiver of any other term.

4.02. If any provision of this limited warranty shall violate any applicable law and is held to be

unenforceable, then the invalidity of such provision shall not invalidate any other provisions herein.

4.03. Applicable law may provide rights and benefits to the purchaser in addition to those provided herein.

McConnel Limited

For Safety and Performance…

ALWAYS READ THE BOOK FIRST

In line with our policy of constant improvement, this publication will be periodically updated; to ensure you

have access to the latest version of this manual please visit the manuals library on our website where an

‘up-to-date’ version can be referenced online or downloaded.

https://my.mcconnel.com/service/pdf-manuals/pdf-operator-manuals/remote-control-technology-manuals/

McCONNEL LIMITED

Temeside Works

Ludlow

Shropshire

England

Telephone: +44 (0)1584 873131

www.mcconnel.com

1

McCONNEL

TABLE OF CONTENTS

1.1 - PRELIMINARY INFORMATION 5

1.2 - TRAINING REQUIRED FROM THE OPERATOR 6

1.3 - WARNINGS ON USE AND STORAGE 6

1.4 - INTRODUCTION 7

1.4.1 - UPDATING THE MANUAL 7

1.4.2 - COPYRIGHT 7

1.5 - WARRANTIES 7

1.6 - RESPONSIBILITIES 8

1.7 - PERMITTED USES 8

1.8 - IMPROPER OR PROHIBITED USES 9

1.9 - RUNNING-IN AND TESTINGTHE MACHINE 10

2.1 - MACHINE DESCRIPTION 11

2.2 - RULES APPLIED 12

2.3 - MACHINE IDENTIFICATION 13

2.3.1 - MACHINE DIRECTIONS 13

2.4 - NOISE LEVEL 14

3.1 - GENERAL SAFETY RULES 15

3.1.1 - GETTING TO KNOW THE MACHINE THOROUGHLY 15

3.1.2 - WEAR PROTECTIVE CLOTHING 16

3.1.3 - USE SAFETY EQUIPMENT 16

3.1.4 - WARNINGS FOR CHECKS AND MAINTENANCE 17

3.1.5 - CHECKING THE MACHINE 17

3.2 - GENERAL PRECAUTIONS 18

3.2.1 - SAFETY WARNINGS 18

3.2.2 - OPERATIONAL SAFETY 19

3.2.3 - SAFETY WHEN USING GRASS MOWING EQUIPMENT 19

3.2.4 - SAFETY REQUIREMENTS FOR THE HYDRAULIC SYSTEM 20

3.2.5 - LOCATION OF THE SAFETY SIGNS 21

3.2.6 - DESCRIPTION OF THE SAFETY SIGNS 22

3.2.7 - PRECAUTIONS REGARDING THE EQUIPMENT 24

3.3 - GENERAL SAFETY RULES 24

3.3.1 - CARE AND MAINTENANCE 24

3.3.2 - SAFETY DURING REFUELLING ANDTOPPING UP 25

3.4 - MAINTENANCE PRECAUTIONS 25

3.4.1 - WARNING SIGNS 25

3.4.2 - TOOLS 25

3.4.3 - PERSONNEL 26

3.4.4 - WORKING UNDER THE MACHINE 26

3.4.5 - KEEPING THE MACHINE CLEAN 26

3.4.6 - PERIODICAL REPLACEMENT OF THE MAINSAFETY COMPONENTS 27

3.4.7 - HYDRAULIC SYSTEM 27

1 - GENERAL DESCRIPTION

5

2 - MACHINE SPECIFICATIONS

11

3 - SAFETY REQUIREMENTS

15

2

McCONNEL

4.1 - TECHNICAL SPECIFICATIONS 28

4.2 - MACHINE NAME 31

5.1 - DEFINITION OF THE TERMS USED 33

6.1 - PRELIMINARY CHECKS 34

6.2 - CHECKS TO BE PERFORMED ATTHE START OF EACH WORKING DAY 34

6.2.1 - CHECKING THE CHROME-PLATED PARTS 34

6.2.2 - DESCRIPTION OF RECEIVER UNIT 35

6.2.3 - TRANSMITTER DESCRIPTION 36

6.3 - TRANSMITTER USE 37

6.3.1 - CONNECTION BETWEEN MACHINE AND TRANSMITTER 38

6.3.2 - STARTING THE ENGINE 39

6.3.3 - STOPPING THE ENGINE 41

6.3.4 - STOPPING THE ENGINE INAN EMERGENCY 42

6.3.5 - ENGINE RPM CHECK 43

6.3.6 - SLOW/FAST TRAVEL SWITCH 43

6.3.7 - TRAVEL SPEED POTENTIOMETER 44

6.3.8 - MOVING THE MACHINE FORWARDSAND BACKWARDS 44

6.3.9 - STEERING THE MACHINE 45

6.3.10 - STEERING BIAS CONTROL 45

6.3.11 - LIFTING DEVICE 46

6.3.12 - HOW TO HITCH UPA TOOL 47

6.3.13 - OPERATING THE TOOL 49

6.3.14 - STOPPING THE TOOL 50

6.3.15 - AUXILIARY FUNCTION(AUX 1) 50

6.3.16 - AUXILIARY FUNCTION(AUX 2) 51

6.3.17 - AUXILIARY FUNCTION(AUX 3) 51

6.3.18 - TRANSMITTER/RECEIVER CONNECTION BUTTON / HORN 52

6.3.19 - REVERSIBLE FAN 53

6.3.20 - REMOTE CONTROL DISPLAY 54

6.3.21 - STATUS LED 54

6.4 - CONTROL PANEL 55

6.4.1 - LCD DISPLAY 55

6.4.2 - WARNING LIGHTS 57

6.4.3 - MACHINE HOURS COUNTER / MAINTENANCE SCREEN 58

6.4.4 - ALARMS SCREEN 59

6.4.5 - INCLINOMETER SCREEN (OPTIONAL) 59

6.4.6 - CHANGE OPERATION MODE SCREEN (OPTIONAL) 60

6.4.7 - REGENERATION SCREEN 60

6.4.8 - FUSES AND RELAYS 61

6.4.9 - FUSES AND RELAYS OF THE CENTRALCONTROL UNIT 61

6.5 - EXHAUST GAS POST TREATMENT SYSTEM 63

6.5.1 - DPF OVERVIEW (PARTICULATE FILTER) 63

6.5.2 - MAINTENANCE AND ASSISTANCE FOR THEPARTICULATE FILTER 64

6.5.3 - RESET REGENERATION 65

6.5.4 - STATIONARY REGENERATION 65

4 - TECHNICAL DATA

28

5 - TERMINOLOGY

33

6 - USE OF THE MACHINE

34

3

McCONNEL

6.5.5 - FORCED STATIONARY REGENERATION 66

7.1 - FAULTS 68

7.1.1 - DIESEL ENGINE 68

7.1.2 - TROUBLESHOOTING CONTROL UNIT LE70 69

7.1.3 - ELECTRICAL CIRCUIT 72

7.1.4 - HYDRAULIC SYSTEM 72

7.1.5 –DRIVE MOTORS 73

7.2 - WORKING WITH THE MACHINE 74

7.3 - CONTROL STATION –OPERATOR WORK AREA 76

7.1 - LOADING AND UNLOADING OPERATIONS FOR ROAD TRAVEL 77

7.1.1 - IF THE MACHINE BREAKS DOWN 78

7.2 - USING THE MANUAL CONTROL 79

7.2.1 - MANUAL CONTROL FUNCTIONS 79

7.3 - STARTING THE ENGINE USING ANAUXILIARY BATTERY 80

8.1 - DISMANTLING, DECOMMISSIONING 81

9.1 - INTRODUCTION 82

9.2 - GENERAL INSTRUCTIONS 82

9.3 - EXTRAORDINARY INTERVENTIONS 83

9.4 - FLUIDS AND GREASES 83

9.4.1 - TABLE 83

9.4.2 - COOLANT 84

9.4.3 - FUEL 84

9.5 - ENGINE MAINTENANCE 85

9.5.1 - ENGINE OIL LEVEL CHECK 85

9.5.2 - FILTER AND ENGINE OIL CHANGE 86

9.5.3 - COOLANT LEVEL CHECK 88

9.5.4 - COOLANT REPLACEMENT 89

9.5.5 - FUEL LEVEL CHECK 92

9.5.6 - DRAINING AND BLEEDING THEFUEL SEPARATOR 93

9.5.7 –PRIMARY FUEL FILTER REPLACEMENT 94

9.5.8 - REPLACING THE FUEL FILTER 96

9.5.9 - CLEANING OR REPLACINGAIR FILTERS 98

9.5.10 - CLEANING THE RADIATOR CASING ANDTHE RADIATOR 100

9.6 - HYDRAULIC SYSTEM MAINTENANCE 101

9.6.1 - HYDRAULIC OIL LEVEL CHECK 101

9.6.2 - CHANGING THE HYDRAULIC OIL FILTER 102

9.6.3 - CHANGING THE HYDRAULIC OIL FILTER 103

9.7 - MAINTENANCE OF THE HYDRAULIC MOTORS ANDHYDRAULIC VALVES 104

9.8 - CHECKING AND MAINTAINING THEELECTRICAL SYSTEM 104

9.8.1 - V-BELT INSPECTION/TENSIONING 105

9.8.2 - REPLACING THE V-BELT 106

9.8.3 - CHECKING THE BATTERY CHARGE 108

9.9 - PERIODICAL REPLACEMENT OF THESAFETY COMPONENTS 109

7 - TRANSPORTATION AND HANDLING

77

8 - STORAGE

81

9 - MAINTENANCE

82

4

McCONNEL

9.10 - WHEEL DRIVE MAINTENANCE 110

9.10.1 - CHECKING THE TIGHTNESS OF THE SCREWS 110

9.11 - TRACK MAINTENANCE 111

9.11.1 - CHECKING THE TRACK TENSION PRESSURE 111

9.11.2 - REPLACING THE TRACK 113

9.11.3 - ROLLER WEAR 114

9.12 - GREASING THE LIFTING DEVICE 114

9.12.1 - CHECKING THE CHROME-PLATED PARTS 114

9.13 - MAINTENANCE OPERATIONS 115

9.13.1 - MAINTENANCE FREQUENCY 115

10.1 - FIRE 116

10.2 - ASSISTING THE OPERATOR IN CASEOF ILLNESS 116

11.1 - SCREW TIGHTENING TABLE 117

11.2 - FITTINGS TIGHTENING TABLE 117

10 - INSTRUCTIONS FOR EMERGENCY SITUATIONS

116

11 - TIGHTENING TABLES

117

12 - NOTES

118

5

1.1 - PRELIMINARY INFORMATION

This is the machine use and maintenance instruction manual and is compliant under:

• Directive Machine 2006/42/EC and subsequent amendments and additions.

• Statutory instruments 2008 No. 1597.

Do not destroy or modify it and only supplement it with additional files.

Publication: 992

Part No.: 24214.92

Issued: 01/2021

Machine type: Remote-controlled, self-propelled machine

Model: RC40

The manual is valid from serial number: M2165985

McConnel Limited, Temeside Works, Ludlow, Shropshire, SY8 1JL, UK

Tel: +44 (0)1584 873131 Email: sales@mcconnel.com Website: www.mcconnel.com

AS SUPPLIED (Hood Ram Spacer)

The flail head is fitted with a hydraulic ram to allow movement of the hinged hood. The movement of this

ram is restricted with an internal spacer. This is to stop operators inadvertently opening the hood when

cutting alongside the highway. This reduces the risk to passing traffic from being hit by objects ejected

at speed from the working flail head. It should be noted that with the hinged hood opened objects could

be thrown a considerable distance. Being struck by a thrown object could result in injury or death.

If the machine is being used away from the highway, other vehicles and bystanders are not normally in

the vicinity then the spacer can be removed provided the general safety information and specific

following conditions are met;

A detailed work area and bystander risk assessment is undertaken before work begins.

The operator has been trained in the safe use of the Robocut, including safe retrieval of the unit from

any situation where it could become stuck or trapped.

The hydraulic ram is returned to the approved version after usage away from the highway and before

the re-sale to another party.

1

-

GE

NE

RAL

DESCRIPTION

.DANGER.

Machines are supplied pre-fitted with an internal ram spacer to

prevent inadvertent opening of the hood when working in the vicinity

of highways and public areas – the ram spacer must be fitted at all

times when operating the machine in these types of areas.

6

McCONNEL

1.2 - TRAINING REQUIRED FROM THE OPERATOR

Reading this manual thoroughly:

•All machine maintenance personnel must read this entire manual thoroughly and pay maximum

attention to its requirements.

•The employer has an obligation to ensure that the operator possesses the required abilities to

operate the machine, and that they have read this manual.

1.3 - WARNINGS ON USE AND STORAGE

The operating instructions contained in this manual are valid exclusively for the McConnel RC40.

This instruction manual must be read and used as follows:

•Carefully read the instruction manual and consider it an integral part of the machine;

•The instruction manual must be readily accessible by the personnel assigned to operate it and to

perform maintenance on it;

•This manual should be kept for the entire service life of the machine;

•Make sure that any received update is incorporated into the text;

•Pass on the manual to any other user or subsequent owner of the machine;

•Use the manual in such a way as not to damage it;

•Do not remove, tear, or rewrite any parts of the manual for any reason;

•Keep the manual in a place protected from moisture and heat;

•If the manual is lost or partially damaged and it is no longer possible to read its contents either

partially/completely, it is advisable to request a new manual from themanufacturer.

Pay maximum attention to the following symbols and to their meanings. They serve to highlight

particular information such as:

WARNING

With reference to additions or suggestions for the correct use of the machine.

ATTENTION

With reference to dangerous situations that can occur when using the machine and

which could cause severe injury to people or damage to property.

DANGER

With reference to dangerous situations that can occur when using the machine and

which could cause severe injury or death if not avoided.

7

McCONNEL

1.4 - INTRODUCTION

The service instructions outlined in this manual are an integral part of the machine supply contract.

These instructions are also addressed to operators already specifically trained to operate this kind

of machinery and contain all the information necessary and essential for safe operation and for the

correct/optimal use of the machine. Hurried and incomplete preparations may lead to improvisation

and this is the cause of many accidents;

Before starting work, carefully read and thoroughly observe the following advice:

•Become familiar confident with all permissible operations and operating positions before startingto

operate the machine;

•The operator must always have the instruction manual available at all times;

•Plan each intervention carefully;

•Obtain all the information necessary for machine road transport, such as distance, itinerary, height

of level crossings, height of bridges, etc.;

•Be knowledgeable about where and how the machine should be operated: ground bearing weight,

necessary outreach, mobility limitation due to the presence of buildings, power lines and similar;

•Before starting to work, make sure that the safety devices are working properly and there is no

uncertainty regarding their operation; if this is not the case, do not use the machine under any

circumstances;

•When travelling by road, respect all the regulations and requirements in force on road traffic

circulation;

•Carefully read the warnings relating to special hazards contained in this manual;

•Constant and thorough preventive maintenance always guarantees high operational safety of

the machine. Never put off necessary repairs and ensure they are performed exclusively by

specialised personnel, using only original spare parts.

1.4.1 - UPDATING THE MANUAL

The information, descriptions and illustrations contained in this manual reflect the state of the art

at the time the machine was marketed.

The manufacturer reserves the right to make changes to the machines at any time for technical

or commercial reasons. In the event that such changes are made, the manufacturer has no

obligation (for safety reasons) to modify the other machines sold up to that point or to send

updates for the manual. Moreover, this publication shall not be considered inadequate. Any

additions that the manufacturer deems appropriate to provide as a result of the changes made

must be kept with the manual and considered an integral part thereof.

1.4.2 - COPYRIGHT

The copyright of this manual belongs to the machine's manufacturer. This manualcontains

technical texts, drawings and illustrations which may not be divulged or transmitted to third

parties, in whole or in part, without the written authorisation of the machine manufacturer.

1.5 - WARRANTIES

The parts supplied by McConnel are covered by a 12-month warranty, that becomes valid upon

commissioning, proven by the documentation delivered to the customer. In any case, refer to the

machine order confirmation or to any specific agreements entered into during the sale.

McConnel shall repair or replace parts recognised as defective during the warranty period (see

attached service log).

8

McCONNEL

By replacing the defective part, McConnel shall consider itself free from any other expenses borne by the

Dealer and the Dealer's Customer, for instance alleged damage, either present or future, such as lost

earnings, conventional penalties, etc.

Ordinary and extraordinary maintenance must be performed in accordance with the instructions contained in

this manual. For all cases not included and for every type of assistance, contact McConnel directly by

registered letter or fax, even in the case of agreements made by telephone. McConnel shall not be held

responsible for any delays or missed interventions. McConnel shall not be held responsible for any damage

or malfunctions due to technical operations carried out on the machine by unauthorised personnel.

1.6 - RESPONSIBILITIES

McConnel considers itself exempted from all liability and obligations for accidents involving personal injuries

or damage to property which may occur due to:

•Failure to observe the instructions given in this manual to run, operate and perform maintenance on the

machine;

•Abrupt actions or incorrect manoeuvres when operating or performing maintenance on the machine;

•modifications made to the machine without prior written authorisation from McConnel;

•Any other events that cannot be considered normal and correct use of the machine.

In any case, whenever the user blames the accident on a defect of the machine, it is necessary to

prove that the consequent damage was a main and direct consequence of such defect.

Any tampering or the use of non-original spare parts will create the conditions for voiding the warranty

and put the operator's safety at risk.

ATTENTION

•For repairs or maintenance always make exclusive use of original spareparts.

•McConnel declines all liability for any damage that may be caused as a result of non-

compliance with the above.

•The machine is guaranteed according to the contractual agreements entered into

upon sale.

•The warranty, however, will not apply if the rules and instructions of use contained

in this manual have not been complied with.

1.7 - PERMITTED USES

RC40 is a machine manufactured to be used by professional personnel. The machine is a self- propelled

radio-controlled vehicle that can be used in the agricultural sector, with the possibility of attaching different

tools to the front lifting equipment, as well as in the forestry sector.

RC40 (hereinafter referred to as “machine”) and the tools are not toys, but a PROFESSIONAL MACHINE.

Always respect the conditions of use specified by the producers of the machine. The machine is suitable for

performing flail mowing operations at a speed of up to 4-5 km/h, depending on the conditions of the ground

and the type and condition of material to be cut (length, whether dry or wet, density etc.) and on slopes

having a maximum inclination of 55°.

This machine is generally used during daylight hours. If, under exceptional circumstances, it has to be used

at night or in conditions of reduced visibility, an auxiliary lighting system must be used. Operate in daylight

or with artificial lights which guarantee a visibility of at least 100 metres.

9

McCONNEL

1.8 - IMPROPER OR PROHIBITED USES

ATTENTION

With reference to dangerous situations that can occur when using the machine and

which could cause severe injury to people or damage to property.

WARNING

This paragraph indicates some of the improper or unauthorised uses; as it is

impossible to foresee all possible improper uses, if there are particular occasions of

use of the machine not contemplated among those permitted, consult McConnel before

carrying out the work.

The following uses must always be strictly avoided:

•Use of the machine by minors, inexperienced, untrained, or unlicensedpersons;

•Using the machine to lift people or objects;

•Using the flail mower head as a piledriver;

•Using the machine to tow damaged vehicles;

•It must not be used on surfaces contaminated by glass, loose stones, pieces of iron or other extraneous

bodies that could be kicked up by the blades of the tool;

•Lifting or pulling tilted loads;

•Placing accessories or equipment classified as dangerous due to their chemical or physical properties

(e.g. flammable, toxic, explosive materials etc.) on the machine;

•Overloading the machine beyond its permitted limits;

•Increasing the working length with booms without the authorisation of McConnel;

•Using the machine with equipment not authorised by McConnel;

•Making changes to the machine (hydraulic, electrical, or mechanical);

•The machine must not be used on public roads.

DANGER

If the machine is used in the ways specified above, there will be the risk of overturning

or structural breakage of the same, with the consequent risk of injury or death of the

operator.

Range of action means an area that should be free of people, as it could be hazardous. Tothis end,

also consider what is indicated in the manuals of the individual pieces of equipment and the different

operating modes used.

10

McCONNEL

1.9 - RUNNING-IN AND TESTING THE MACHINE

Each machine is carefully adjusted and tested before delivery.

A new machine must however be used with caution for the first 100 hours for the purpose of the efficient

running-in of the various components.

If the machine is subjected to an excessive work load during the initial phase of operation, its potential

performance will be prematurely compromised, and its functionality reduced in a short period of time.

During the running-in period, pay close attention to the following points:

•After start-up, let the engine run at a low speed for 5-6 minutes;

•Avoid running the machine at the maximum speed for the first 100 hours of operation.Avoid sudden

accelerations or decelerations.

Refer to the service booklet attached for the various types of maintenance to be carried out. Also refer to

the engine manual and to the equipment manual for any type of work that has to be carried out.

ATTENTION

When replacing oil and diesel filters, inspect them internally to check if there are any

deposits. If there are, check for possible causes before restarting the machine.

11

McCONNEL

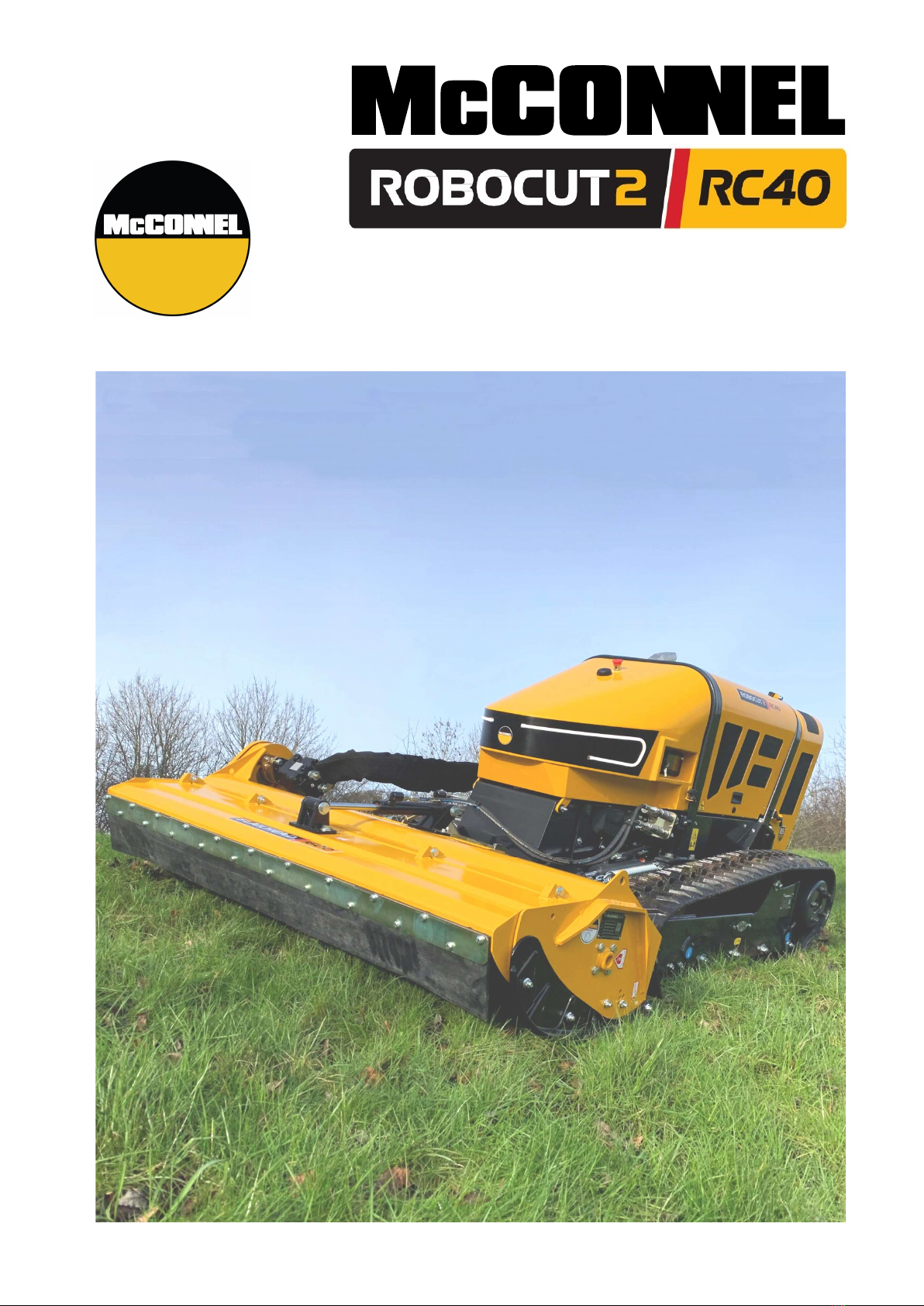

2.1 - MACHINE DESCRIPTION

Multi-purpose operating machine, specific for grass mowing, shrubs, grass maintenance of roadsides,

embankments, etc.

Equipped with hydraulic attachments with quick screw couplings

which allow the replacement of various equipment depending on

the operational needs.

The machine has a multi-purpose lifter that allows all the

equipment allowed by McConnel to be connected.

PERMITTED EQUIPMENT

All the equipment validated by McConnel and listed here, does not alter the stability of the vehicle,

including the equipment, up to the permitted gradient (both for equipment with and without ballast).

McConnel declines all responsibility for damage of any kind caused by improper use or use other than

that described above.

The approved equipment enables the machine to remain stable at the maximum permitted gradients.

CUTTING HEAD

MOWER BAR

ROTARY MOWER

TRENCHER

ROTARY HARROW

ROTARY TILLER

RAKE

LAND BLADE

SNOW BLADE

WINCH

Ballast weights should be applied when using the following equipment:

FORESTRY HEAD (rotary hammers)

BIO-SHREDDER;

FRONT LOADER BUCKET;

BUCKET

FORKS

GRAPPLE BUCKET

SNOW BLOWER

TREE SHAKER

FORESTRY WINCH

2 - MACHINE SPECIFICATIONS

Table of contents

Other McConnel Farm Equipment manuals

Popular Farm Equipment manuals by other brands

Farmet

Farmet FALCON PRO Operating instruction

AGCO

AGCO FENDT 700 Vario SCR Stage 3B Workshop service manual

Tume

Tume NOVA COMBI 3000 instruction manual

Agria

Agria Cyclone 5900 Translation of the original operating instructions

Farmet

Farmet DUOLENT DX 380 NS operating manual

Land Pride

Land Pride LR3784 Operator's manual

Amazone

Amazone ZG-TS 7501 Truck operating manual

Powerfix Profi

Powerfix Profi 76607 translation of original operation manual

WIL-RICH

WIL-RICH 2550 Operator's manual

HighLine

HighLine NT Rockpicker NT60E Operator's manual

DALBO

DALBO FRONTFLEX 450 manual

New Leader

New Leader L5034 G4 Assembly/operators/parts manual