Table of Contents

SAFETY.....................................................................................1

Safety Symbols ................................................................................... 1

Safety Warnings .................................................................................. 1

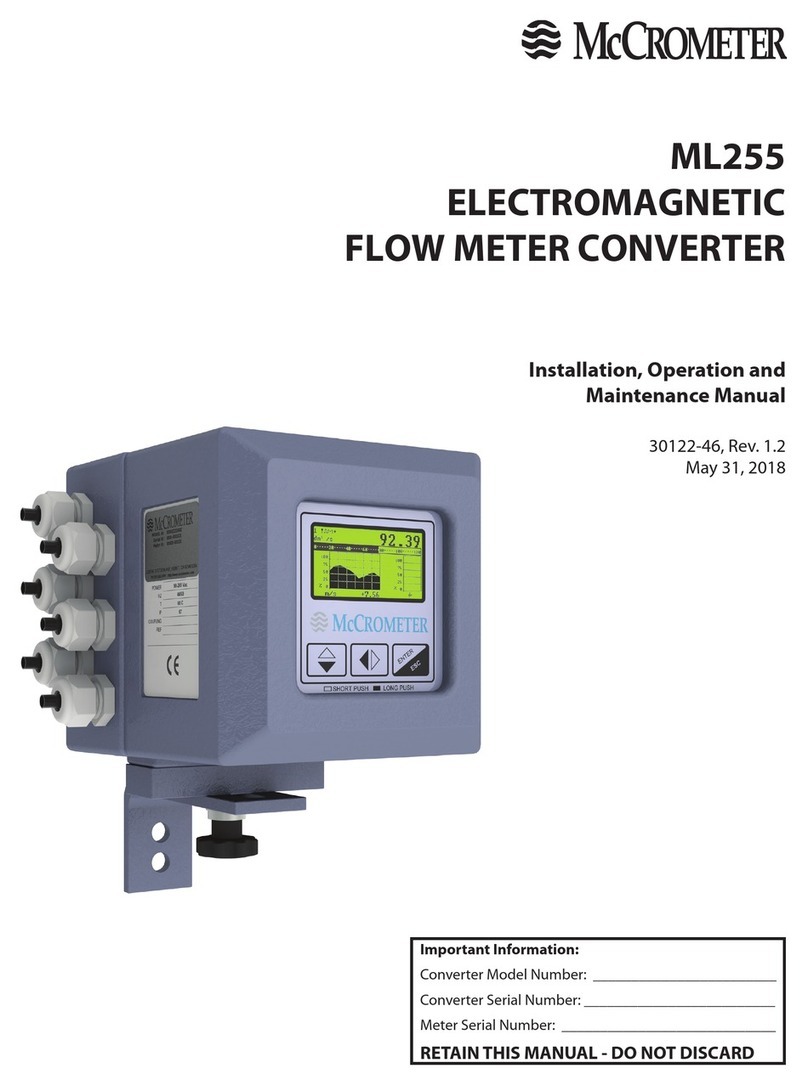

1.0 CONVERTER DESCRIPTION .............................................................2

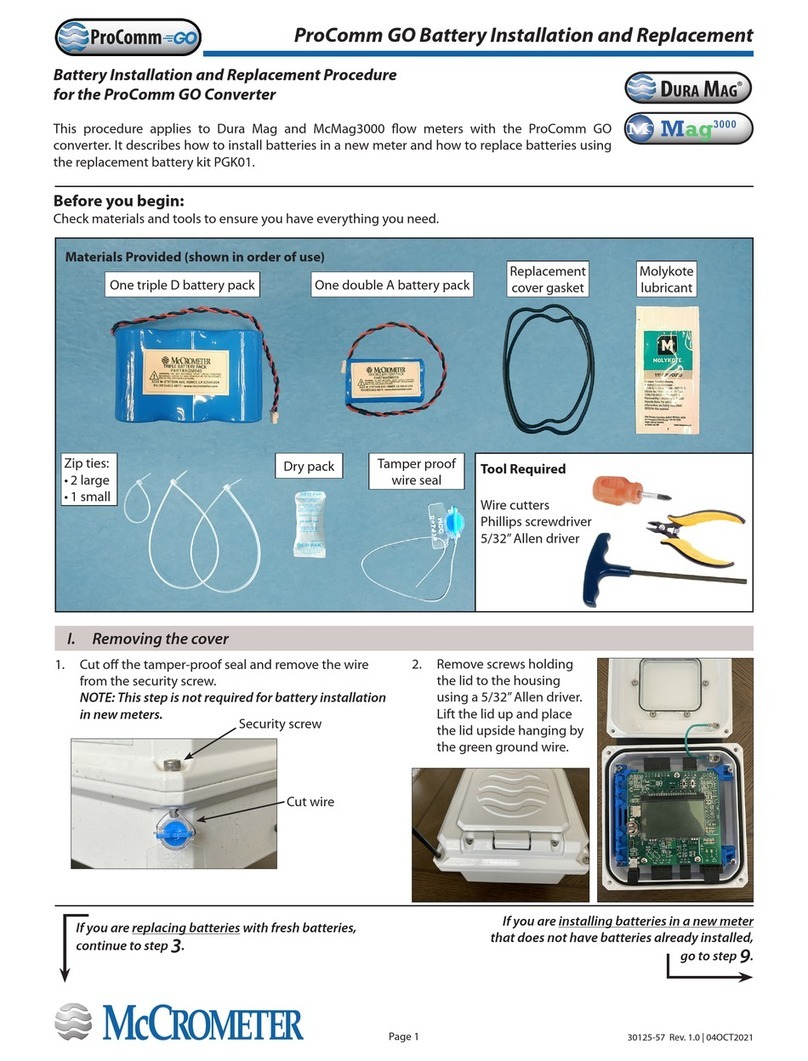

2.0 INSTALLING THE CONVERTER AND CABLES .............................................2

2.1 Verify Serial Numbers .................................................................... 2

2.2 Mounting the Converter .................................................................. 3

2.3 Installing Cables through Cable Glands and Conduit ....................................... 4

2.4 Cable Gland Assignment for Wiring Harnesses ............................................. 5

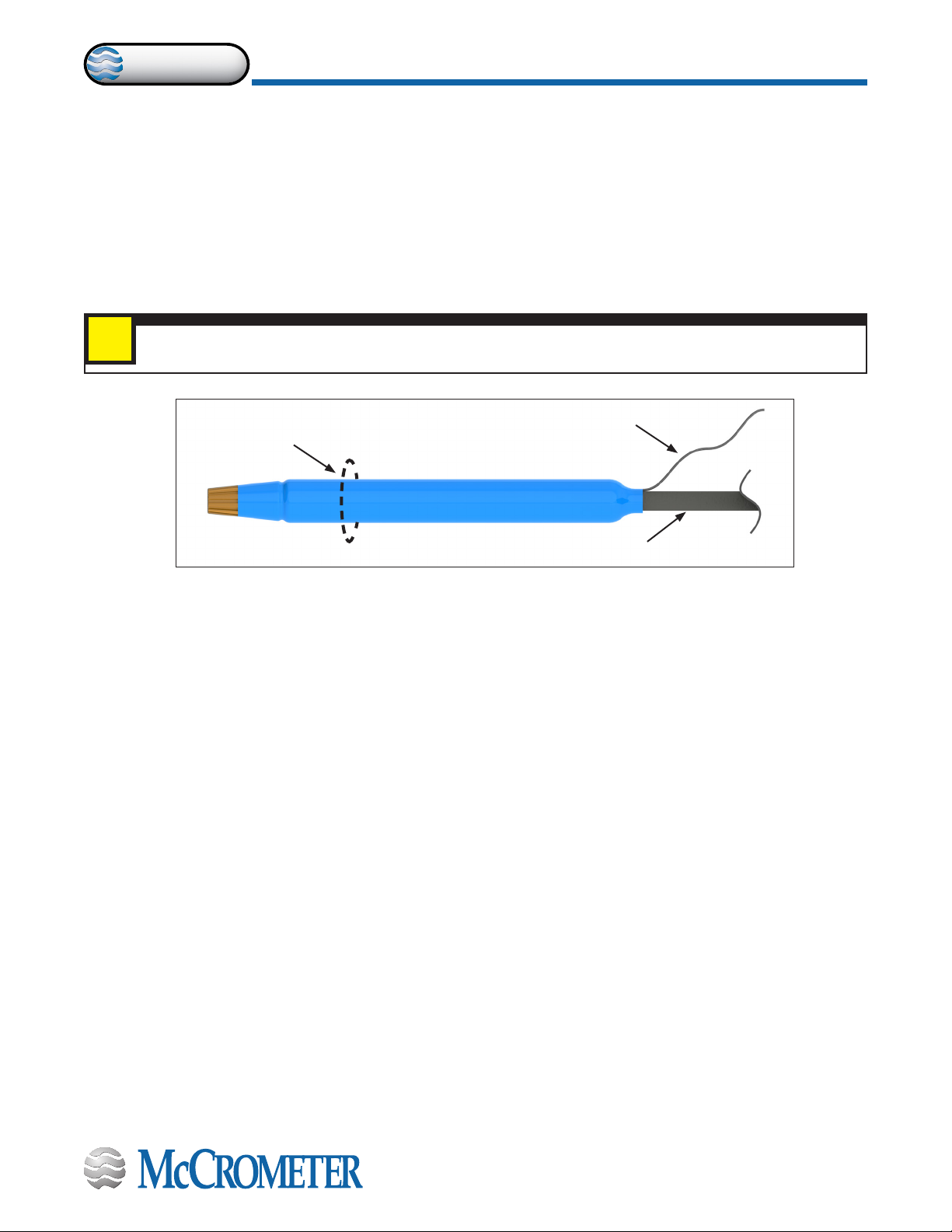

2.5 Pulling Sensor Cable Through Electrical Conduit ........................................... 6

3.0 CONNECTING WIRES TO TERMINALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Terminal Block Diagram .................................................................. 7

3.2 Wiring Diagrams ......................................................................... 8

3.3 4-20mA Hook-Up ........................................................................ 9

3.4 Opto-Isolated Pulse Output Hook-Up ....................................................10

3.5 Opto-Isolated Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Optional Smart Output Hook Up .........................................................11

3.7 Converter Power Wiring Diagram ........................................................11

4.0 CONVERTER OPERATION..............................................................12

4.1 Starting up the Converter ...............................................................12

4.2 Menu Navigation .......................................................................12

4.3 Front Panel Display .....................................................................13

4.4 Menu Structure .........................................................................15

4.5 Factory Set Key Code ....................................................................16

4.6 Converter Access Code ..................................................................16

4.7 Changing Settings on the Quick Start Menu ..............................................17

4.8 Changing Main Menu Settings ...........................................................18

5.0 MENU DESCRIPTIONS ................................................................19

5.1 Menu 1 - Sensor ........................................................................19

5.2 Menu 2 - Units ..........................................................................21

5.3 Menu 3 - Scales .........................................................................22

5.4 Menu 4 - Measure .......................................................................24

5.5 Menu 5 - Alarms ........................................................................26

5.6 Menu 6 - Inputs .........................................................................27

5.7 Menu 7 - Outputs .......................................................................29

5.8 Menu 8 - Communication ................................................................31

5.9 Menu 9 - Display ........................................................................32

5.10 Menu 10 - Data Logger ..................................................................32

5.11 Menu 11 - Functions.....................................................................35

5.12 Menu 12 - Diagnostic....................................................................35

5.13 Menu 13 - System .......................................................................36

6.0 BIV (BUILT-IN VERIFICATION) ..........................................................37

6.1 Functioning ............................................................................37

6.2 Saving Reference Values (Characteristic Parameters) ......................................37

6.3 Criteria and Internal Limits Values........................................................37

6.4 General Notes for the Activation of BIV ...................................................37

6.5 ISOBIV Interface ........................................................................38

7.0 ERROR CODES........................................................................39

8.0 ALARM MESSAGES ...................................................................40

9.0 SPECIFICATIONS .....................................................................42

10.0 DIMENSIONS.........................................................................44

11.0 RETURNING A UNIT FOR REPAIR .......................................................46

12.0 TROUBLESHOOTING GUIDE ...........................................................47

WARRANTY STATEMENT ....................................................................48

30124-60 Rev. 1.2 | 16DEC2019

Page ii