Copyright © 2018 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer.

Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative

for current technical data and instructions.

www.mccrometer.com

3255 WEST STETSON AVENUE • HEMET, CALIFORNIA 92545 USA Printed In The U.S.A.

TEL: 951-652-6811 • 800-220-2279 • FAX: 951-652-3078 Lit. # 30122-46, Rev. 1.2 / 5-31-18

Contents

SAFETY.....................................................................................1

1.0 BATTERY POWERED CONVERTER OVERVIEW ............................................2

1.1 Serial Numbers....................................................................................3

1.2 Compatible Products ..............................................................................3

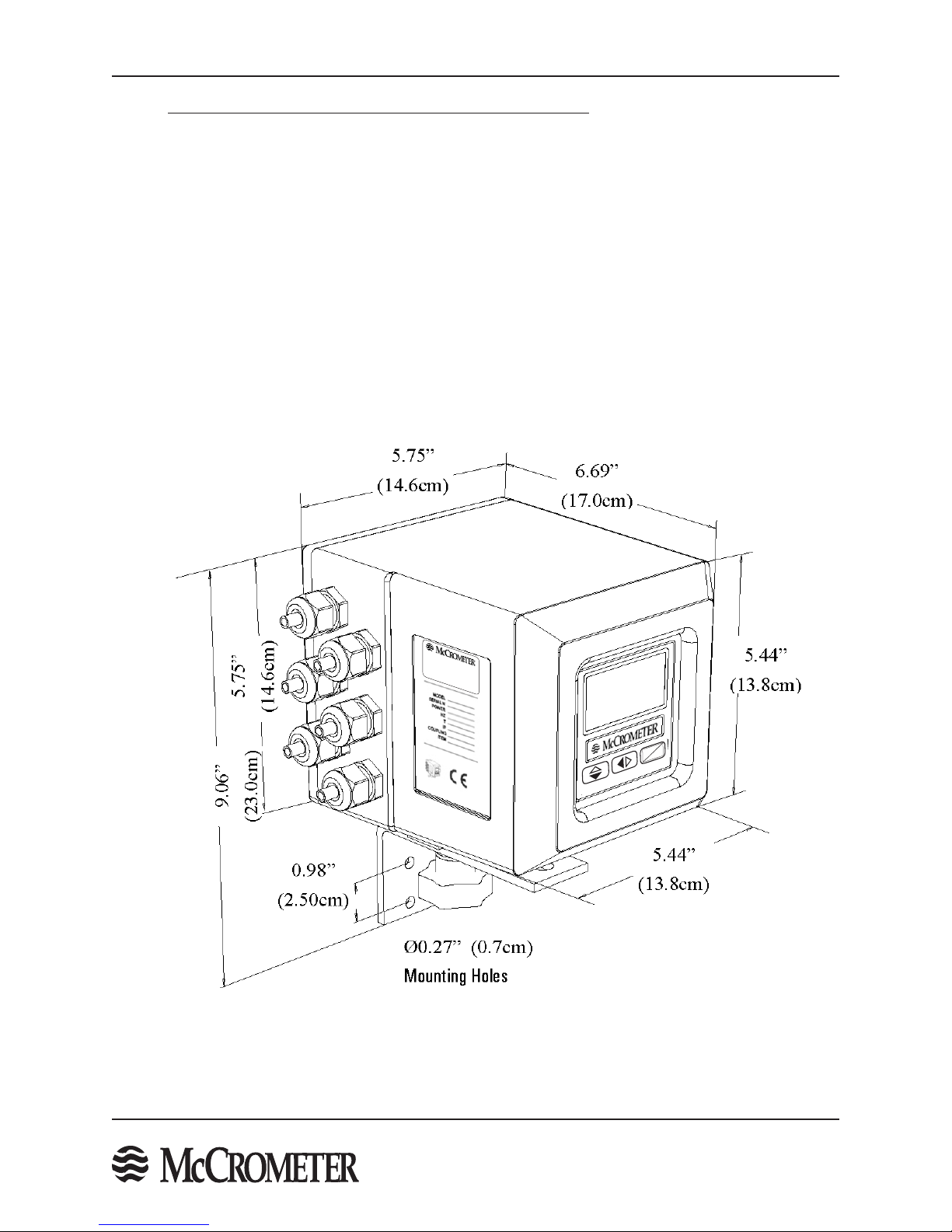

2.0 CONVERTER INSTALLATION ............................................................4

2.1 Mounting The Converter ..........................................................................4

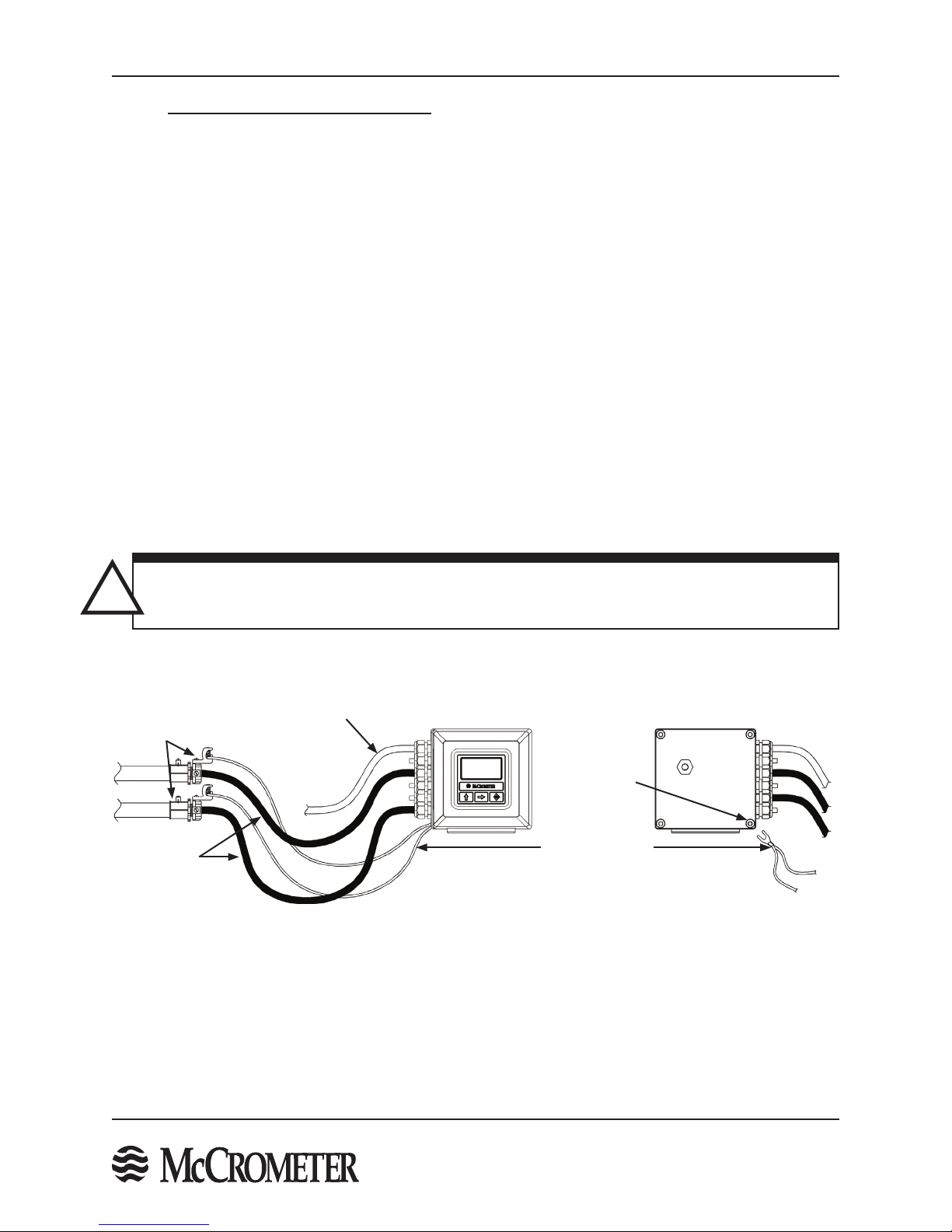

2.2 Installing Cables To Converter And Service Loop ...................................................4

2.3 Pulling Sensor Cable Through Electrical Conduit....................................................5

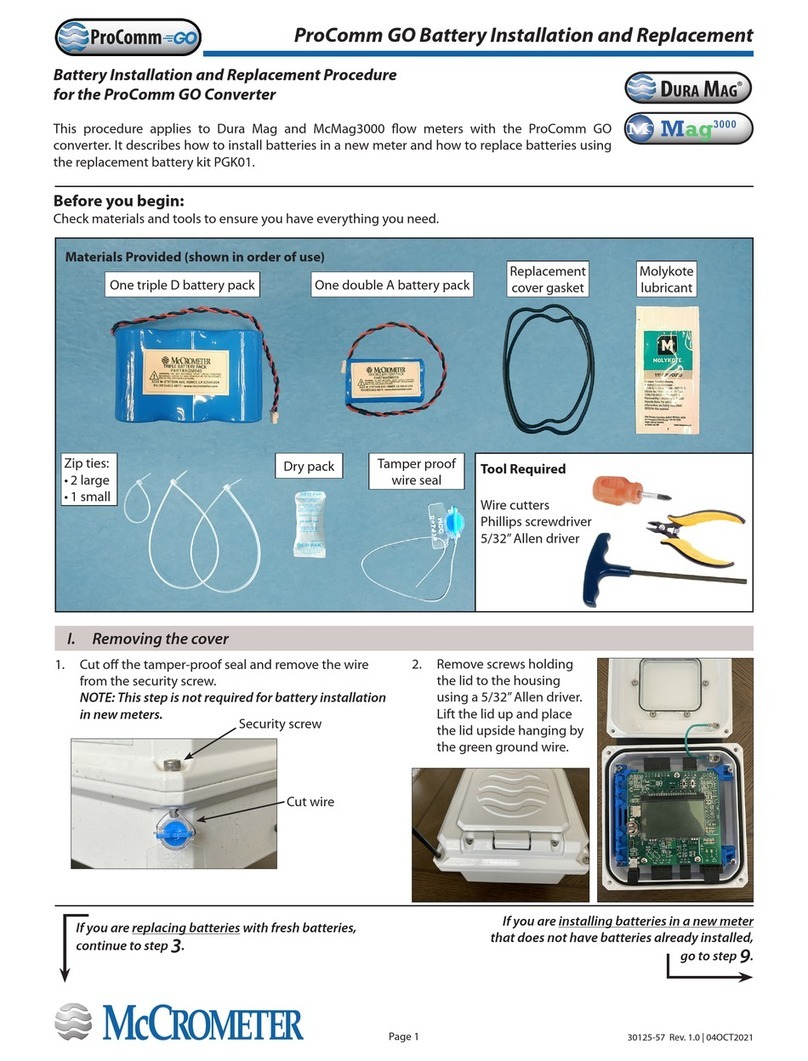

3.0 BATTERY INSTALLATION AND SYSTEM START-UP ........................................6

3.1 Battery Life .......................................................................................6

3.2 Installing Batteries and Starting Up ................................................................6

3.3 Setting the Time and Date .........................................................................6

3.4 Replacing Batteries................................................................................7

3.5 Powering-Down and Powering-Up the System .....................................................8

3.6 Power Options ....................................................................................8

3.7 Sampling Frequencies.............................................................................9

4.0 SOLAR PANEL OPTION................................................................10

4.1 Description ......................................................................................10

5.0 ELECTRICAL CABLE CONNECTIONS ....................................................11

5.1 Converter Electrical Cable Connections ...........................................................11

5.2 Terminal Board...................................................................................11

5.3 FPI Mag 395L Forward Only Cable Connections ...................................................13

5.4 SPI Mag 282L Cable Connection ..................................................................14

5.5 Ultra Mag Sensor Cable ..........................................................................15

5.6 Converter Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.7 Opto-Isolated Pulse Output Hook-Up .............................................................18

5.8 Opto-Isolated Pulse Input ........................................................................18

5.9 Converter Power Hook-Up........................................................................19

6.0 CONVERTER START-UP - ALL SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6.1 Menu Navigation.................................................................................20

6.2 Front Panel Visualization Pages ...................................................................21

6.3 Factory Set Key Code .............................................................................22

6.4 Menu Structure ..................................................................................22

7.0 PROGRAMMING EXAMPLE ............................................................25

8.0 MENU 0 - QUICK START ...............................................................26

9.0 MAIN MENU DESCRIPTIONS...........................................................26

9.1 Menu 1 - Sensor .................................................................................26

9.2 Menu 2 - Scales ..................................................................................28

9.3 Menu 3 - Measure ................................................................................31

9.4 Menu 4 - Alarms..................................................................................31

9.5 Menu 5 - Inputs ..................................................................................32

9.6 Menu 6 - Outputs ................................................................................32

9.7 Menu 7 - Communication ........................................................................34

9.8 Menu 8 - Display .................................................................................34

9.9 Menu 9 - Data Logger ............................................................................35

9.10 Menu 10 - Diagnostic.............................................................................35

9.11 Menu 11 - Internal Data ..........................................................................37

10.0 ALARM MESSAGES ...................................................................38

11.0 SPECIFICATIONS .....................................................................42

12.0 TROUBLESHOOTING GUIDE ...........................................................44

APPENDIX 1.0 UNITS OF MEASURE ..........................................................45

APPENDIX 2.0 CONVERSION TABLES.........................................................46

WARRANTY STATEMENT ....................................................................47