6

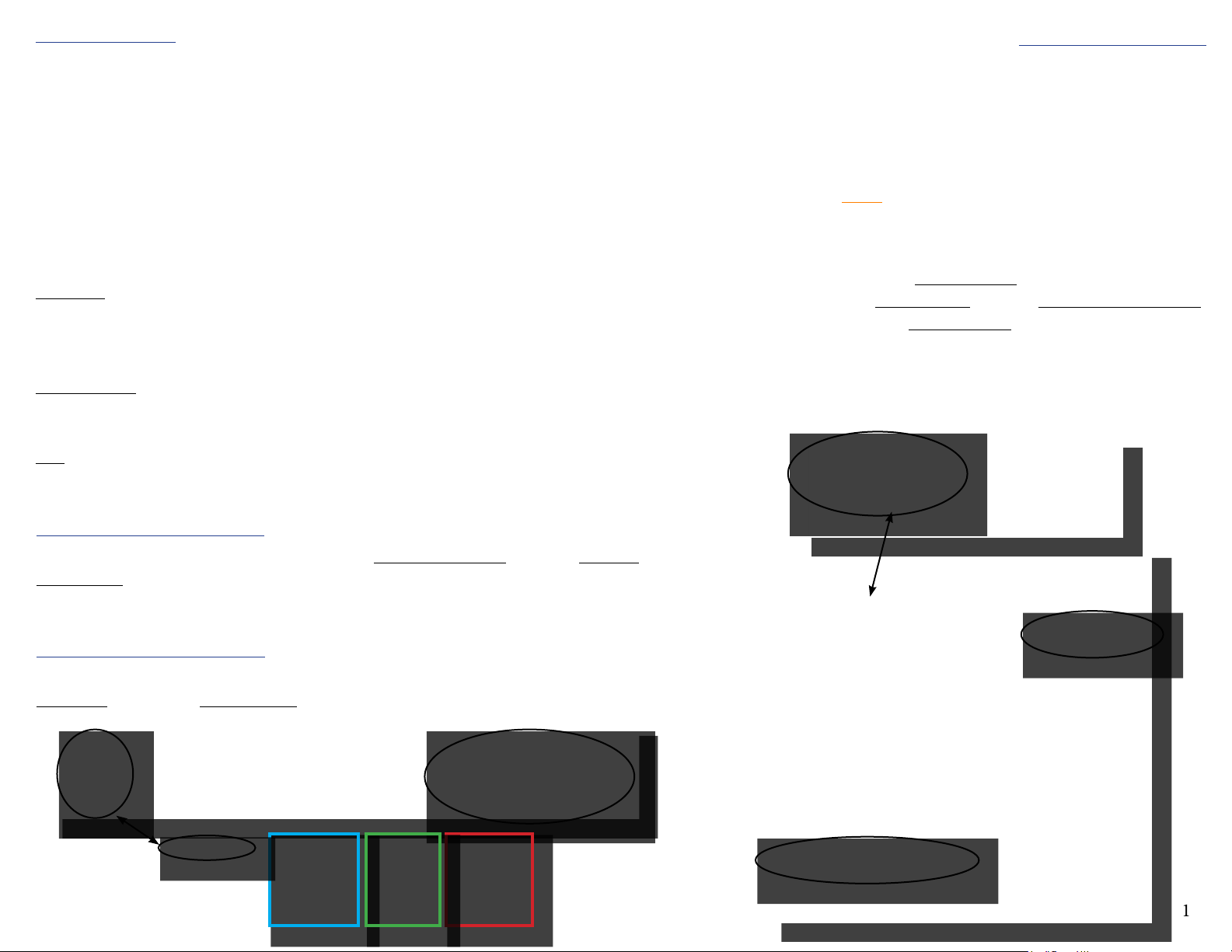

linetype'

continuous'

Black

RGB

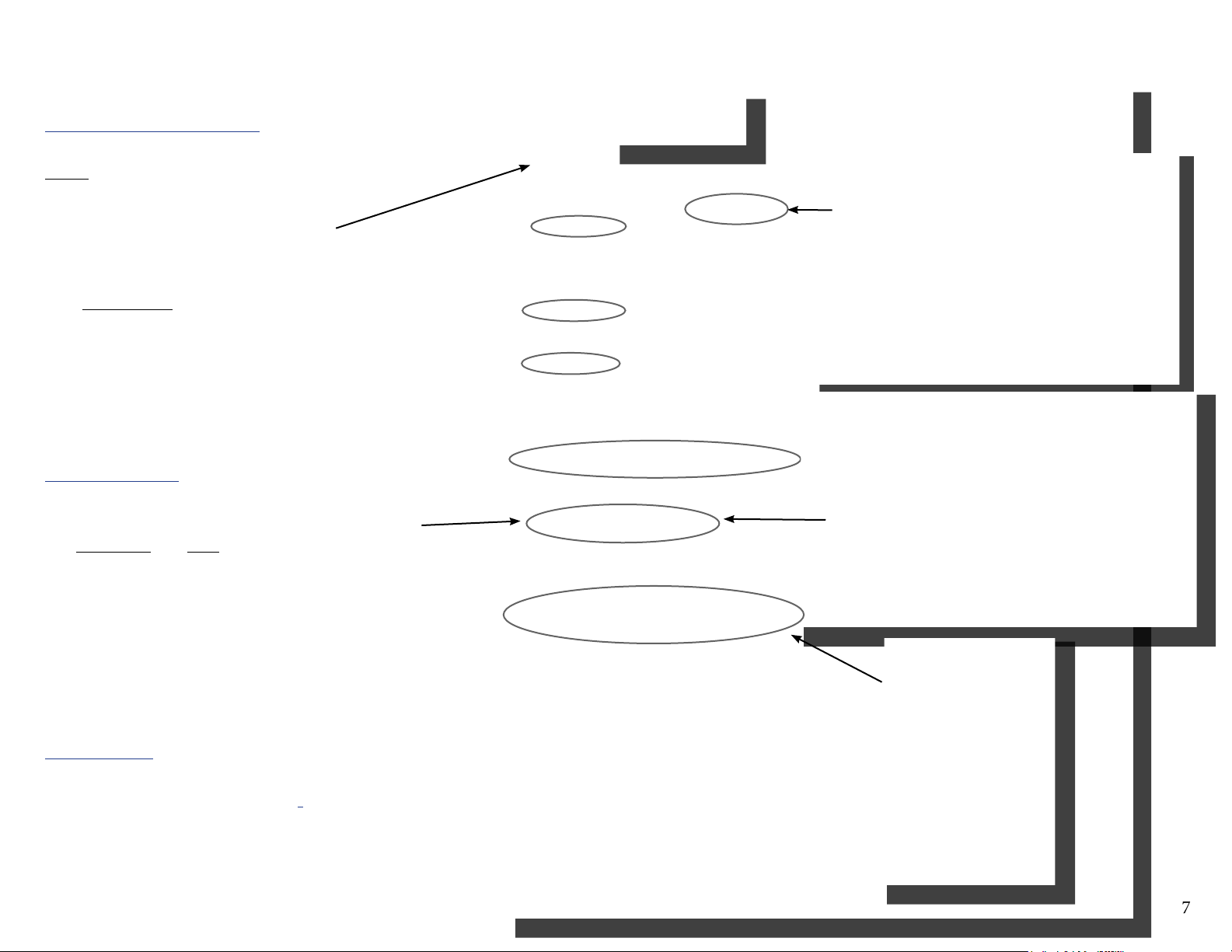

'cutting',

scoring/marking' and 'engraving'

'hatch'

colour, linetype print width

.

hairline'.