Contents

McQuay and MicroTech II are registered trademarks of McQuay International.

Microsoft is a registered trademark of Microsoft Corporation.

Windows is a trademark of Microsoft Corporation.

Copyright © 2004 McQuay International. All rights reserved throughout the world.

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

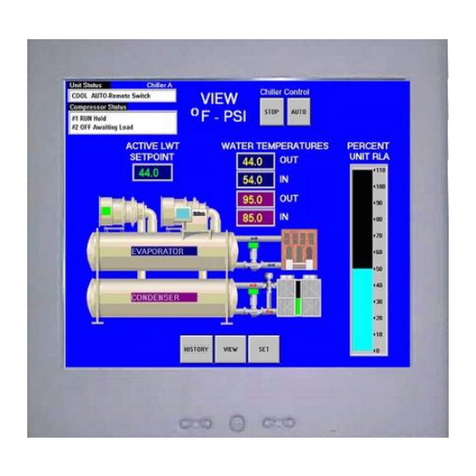

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Component Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Main Control Board (MCB) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Analog inputs terminal blocks . . . . . . . . . . . . . . . . . . . . . 4

Binary Inputs Terminal Blocks . . . . . . . . . . . . . . . . . . . . . 4

Binary Outputs Terminal Blocks . . . . . . . . . . . . . . . . . . . 4

RS-485 Communications Terminal Block . . . . . . . . . . . . 4

Power Supply Terminals . . . . . . . . . . . . . . . . . . . . . . . . . 4

Keypad/LCD Display Connection . . . . . . . . . . . . . . . . . . 4

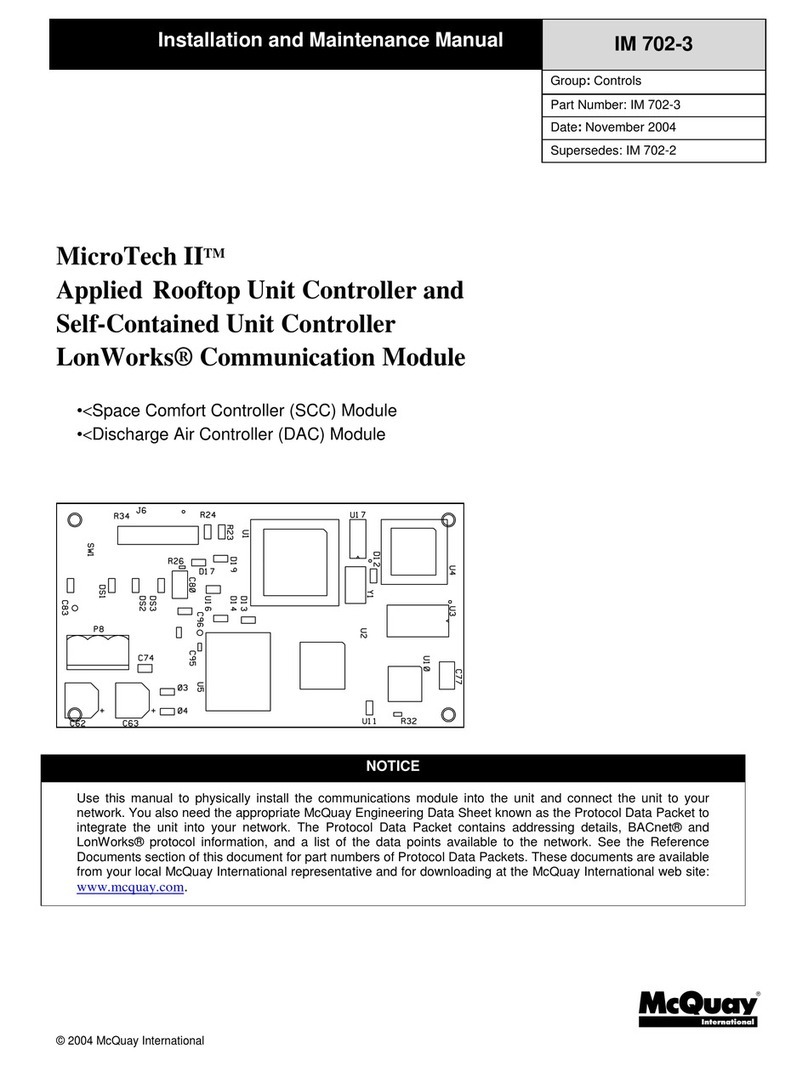

Communication Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Plug-in BACnet/IP Communications Module . . . . . . . . . . 4

Plug-in BACnet MS/TP Communications Module . . . . . . 4

LonWorks® Communication Modules . . . . . . . . . . . . . . . 5

RS-232 Connection Port . . . . . . . . . . . . . . . . . . . . . . . . . 5

15 VDC Supply Connection . . . . . . . . . . . . . . . . . . . . . . . 5

Main Control Board LEDs . . . . . . . . . . . . . . . . . . . . . . . . 6

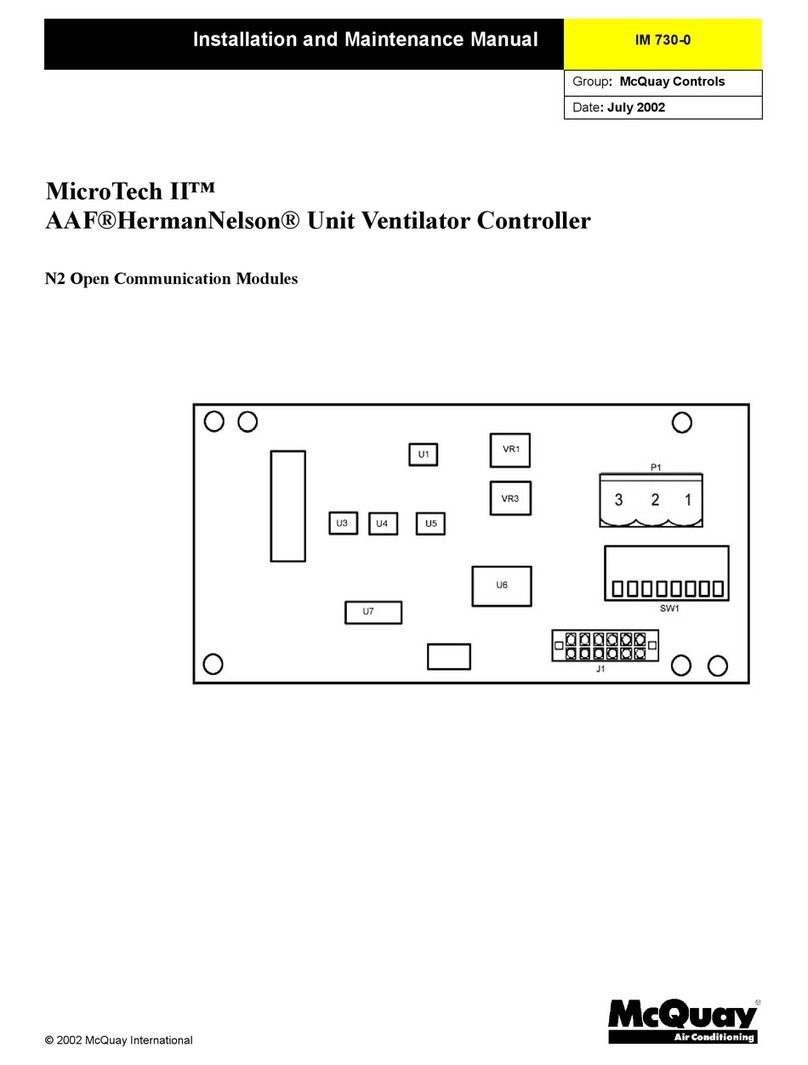

Auxiliary Control Boards (CCB1and CCB2) . . . . . . . . . . . . . . 6

Analog Inputs Terminal Block (J8) . . . . . . . . . . . . . . . . . 7

Binary Inputs Terminal Blocks (J9 and J10) . . . . . . . . . . 7

Binary Outputs Terminal Block . . . . . . . . . . . . . . . . . . . . 8

RS-485 Communications Module . . . . . . . . . . . . . . . . . . 8

Power Supply Terminals (J1) . . . . . . . . . . . . . . . . . . . . . 8

J7 Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

J2 Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Main Control Board (MCB) Output Relays and Triacs . . . . . . 8

Auxiliary Control Boards (CCB1 and CCB2) Output Relays . . 8

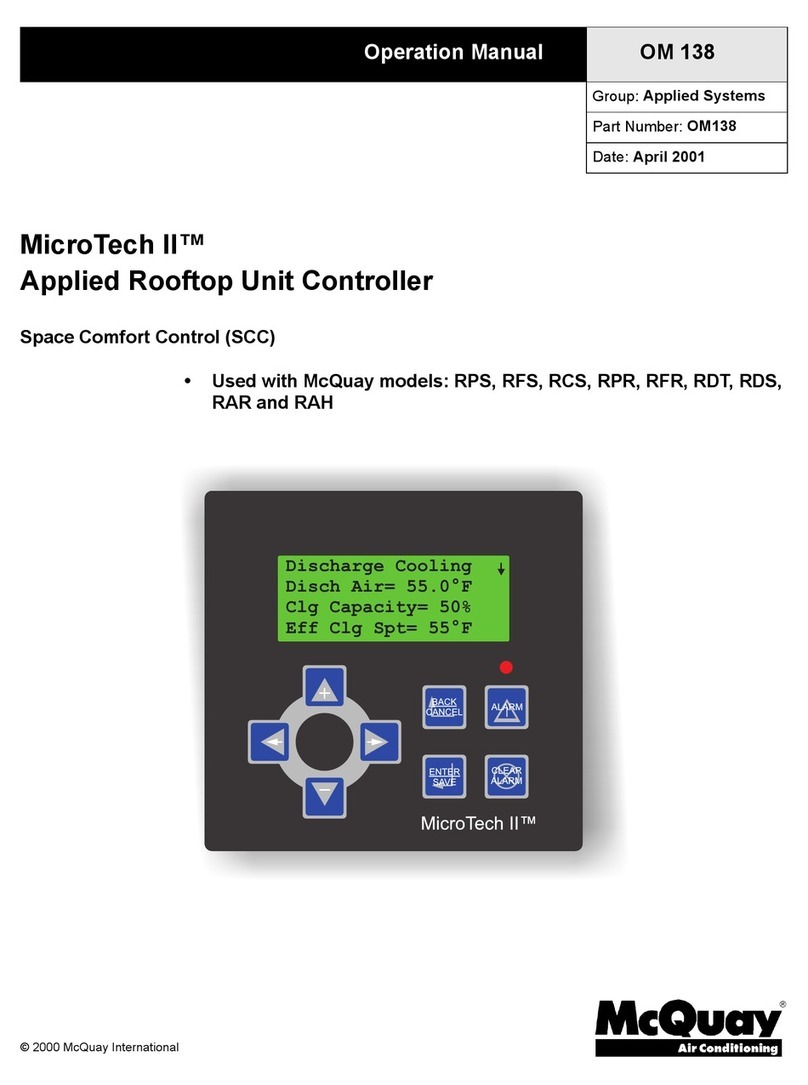

Keypad/Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Temperature Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pressure Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Humidity Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Adjustable Frequency Drives (AFDs) . . . . . . . . . . . . . . . . . . . 9

Field Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Field Output Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Outside Air Damper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fan Operation Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Remote Alarm Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

VAV Box Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cooling-Only Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Cooling-Only Units With Field Supplied Heat . . . . . . . . 11

Units With Staged Heat . . . . . . . . . . . . . . . . . . . . . . . . . 11

Units With Modulating Heat . . . . . . . . . . . . . . . . . . . . . . 12

Pump Start Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Field Analog Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Zone Temperature Sensor Packages . . . . . . . . . . . . . . . . . . 12

Zone Sensor Without Remote Setpoint Adjustment . . . 12

Zone Sensor With Remote Setpoint Adjustment . . . . . . 12

Tenant Override (Timed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

External Discharge Air Reset Signal . . . . . . . . . . . . . . . . . . . 13

Field Actuator Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Field 100% OA Damper Actuator . . . . . . . . . . . . . . . . . . . . . 14

Humidity Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Humidity sensor—discharge air control (DAC) unit . . . . 15

Field Binary Input Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Manual Cooling And Heating Enable . . . . . . . . . . . . . . . . . . 16

Cooling Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Heating Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Manual Unit Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

External Time Clock Or Tenant Override . . . . . . . . . . . . . . . . 16

Miscellaneous Output Signals . . . . . . . . . . . . . . . . . . . . . . . . 16

Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Controller Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Analog Inputs—Main Control Board (MCB) . . . . . . . . . . . . . . 17

Analog inputs—Auxiliary Control Boards (CCB1 and CCB2) 19

Binary Inputs—Main Control Board (MCB) . . . . . . . . . . . . . . 19

Binary Inputs—Auxiliary Control Boards (CCB1 and CCB2) . 19

CCB1 and CCB2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Controller Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Binary Outputs—Main Control Board (MCB) . . . . . . . . . . . . . 21

Binary Outputs—Auxiliary Control Boards (CCB1 and CCB2) .

22

CCB1 & CCB2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2 Compressors—2 Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Compressors—3 Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Compressors—4 Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3 Small Compressors & 1 Large Compressor—5 Stages . . . 23

2 Small Compressors & 2 Large Compressors—6 Stages . . 23

6 Compressors—6 Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Software Identification and Configuration . . . . . . . . 25

Main Control Board (MCB) Configuration . . . . . . . . . . . . . . . . . . . 25

Main Control Board (MCB) Data Archiving . . . . . . . . . . . . . . . . . . 26

Keypad/Display Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Typical Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . 27

Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Troubleshooting Main Control Board (MCB) . . . . . . . . . . . . . 35

MCB Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

MCB Data Archiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

MCB “Cold” Reboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

MCB LED Power-Up Sequence . . . . . . . . . . . . . . . . . . . 36

MCB LED Startup Error Codes . . . . . . . . . . . . . . . . . . . 37

Battery Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Flash CRC Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

SRAM Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Communication Port Tests . . . . . . . . . . . . . . . . . . . . . . . 39

IP Register Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Troubleshooting Auxiliary Control Boards (CCB1and CCB2) 39

Hardware Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

RS-485 Communication Module Status LEDs . . . . . . . . 39

Troubleshooting Keypad/Display . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Keypad/Display Power Up Initialization . . . . . . . . . . . . . 40

Troubleshooting Temperature Sensors . . . . . . . . . . . . . . . . . 41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Troubleshooting Communications Cards . . . . . . . . . . . . . . . . 41

BACnet/IP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

BACnet MS/TP Module . . . . . . . . . . . . . . . . . . . . . . . . . 42

LonMark Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Troubleshooting Static Pressure Transducers . . . . . . . . . . . . 42

Troubleshooting Refrigerant Pressure Transducers . . . . . . . 44

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45