Dear Client,

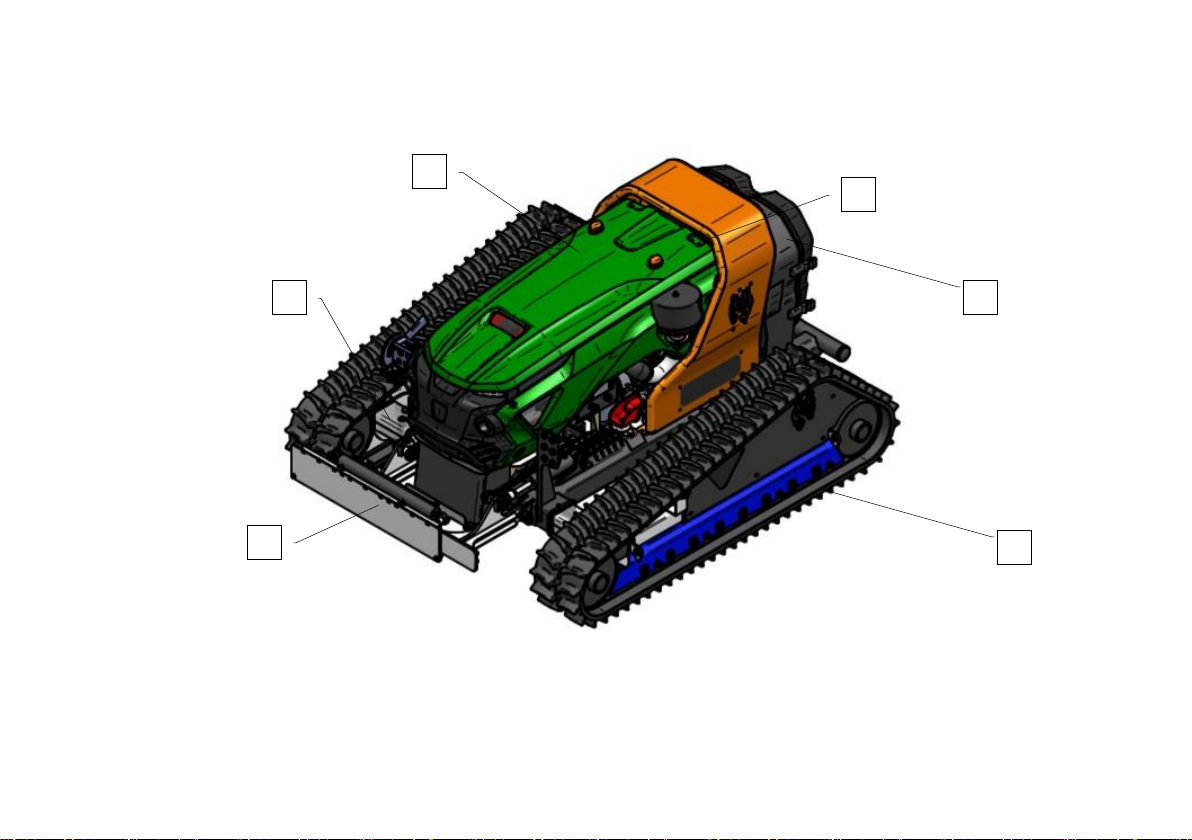

Thank you for having purchased an MDB machine.

This Operations and Maintenance manual will enable you to fully appreciate the qualities of the

machine. Please read the manual entirely before starting to use the machine. The manual contains

important information, advice and warnings regarding the correct use of the machine, also allowing

you to exploit the technology of this MDB machine. The manual includes essential information

regarding the care, maintenance, operational safety, and conservation of the machine over time.

Warnings and indications that require particular attention are called up by the following symbols:

DANGER:

This symbol indicates a situation

of danger which,

if not prohibited, will result in

serious injury or death of the

persons concerned.

WARNING:

This symbol indicates a situation

of potential danger

regarding the integrity of the

machinery which, if not avoided,

may cause damage to the

machinery itself which, indirectly,

could cause serious injury or

death to the persons concerned

PLEASE NOTE:

This symbol indicates particularly

important things to enable to

work in the simplest and safest

way with the machine.

We are sure that the accurate reading of this operations and maintenance manual will allow you to

be in line with the MDB Green Climber LV800.

Pleasant reading.