Measurement Systems International MSI-6260CS User manual

MSI6260cs

RF Digital Crane Scale

Operator’s Manual

Page 2 MSI-6260CS Crane Scale™ • User Guide6260CSCraneScaleRFSCALEINSTRUMENTATIONTABLEOFCONTENTSSECTION 1 – INTRODUCTION & INSTALLATION .......................................3

Introduction ...................................................................................3

Installation ....................................................................................3

Battery LIFE .................................................................................4

Battery Charger .............................................................................4

Battery Removal & Replacement .................................................5

6260CS Battery Well ....................................................................6

Comm Port ....................................................................................7

Model 6260CS Trans-Weigh CS Crane Scale ..............................9

SECTION 2 – RF SCALE COMMUNICATIONS .........................................10

Introduction - The CellScale System ..........................................10

Network Description ...................................................................10

Network Expansion ....................................................................10

2.4 GHZ Interference ..................................................................11

FCC’s MPE Requirements ..........................................................11

FCC Statement ............................................................................11

SECTION 3 – THE EMBEDDED CELLSCALE ..........................................12

Accessing The CellScale ............................................................12

Connection Procedure .................................................................12

Set Points ....................................................................................12

Scale Calibration .........................................................................12

Legal-For-Trade ..........................................................................13

Sealing the MSI-6260CS Crane Scale ........................................13

APPENDIX – SPECIFICATIONS & DIMENSIONS .......................................16

Hardware Overview ....................................................................16

General Features .........................................................................16

General Specifications ................................................................17

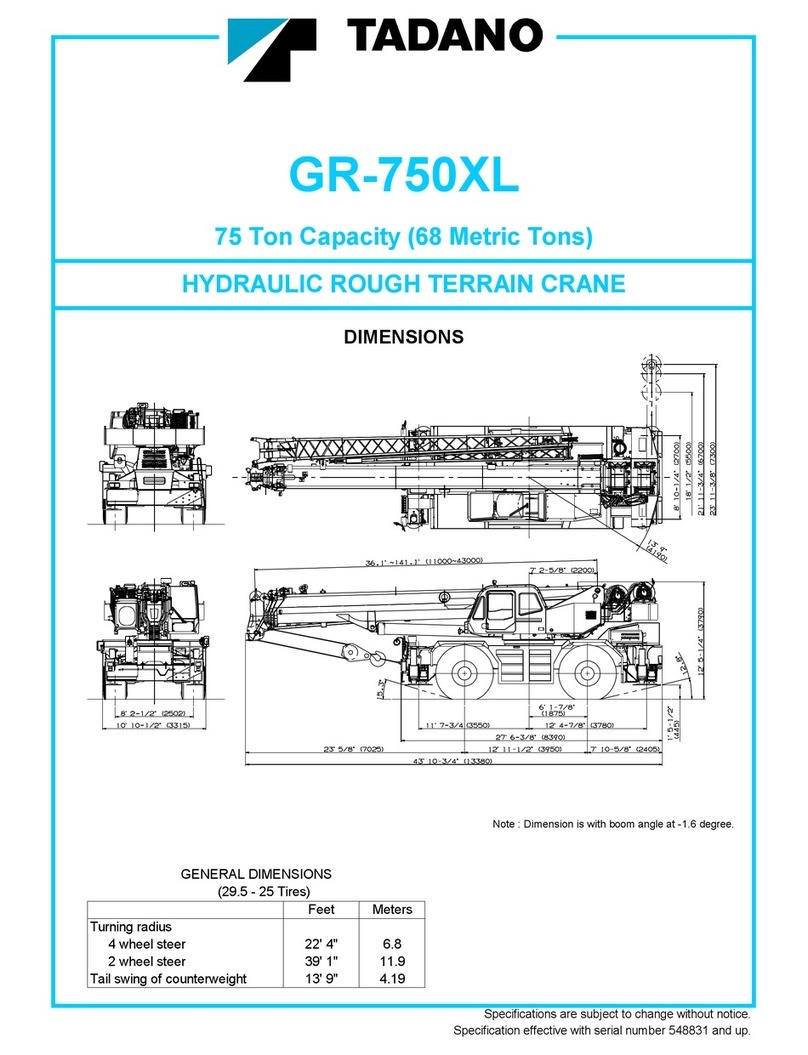

Dimensions and Load Train Specifications ................................18

Options and Accessories .............................................................18

THE MSI LIMITED WARRANTY ..........................................................19

MSI-6260CS Crane Scale™ • User Guide Page 3

MEASUREMENTSYSTEMSINTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

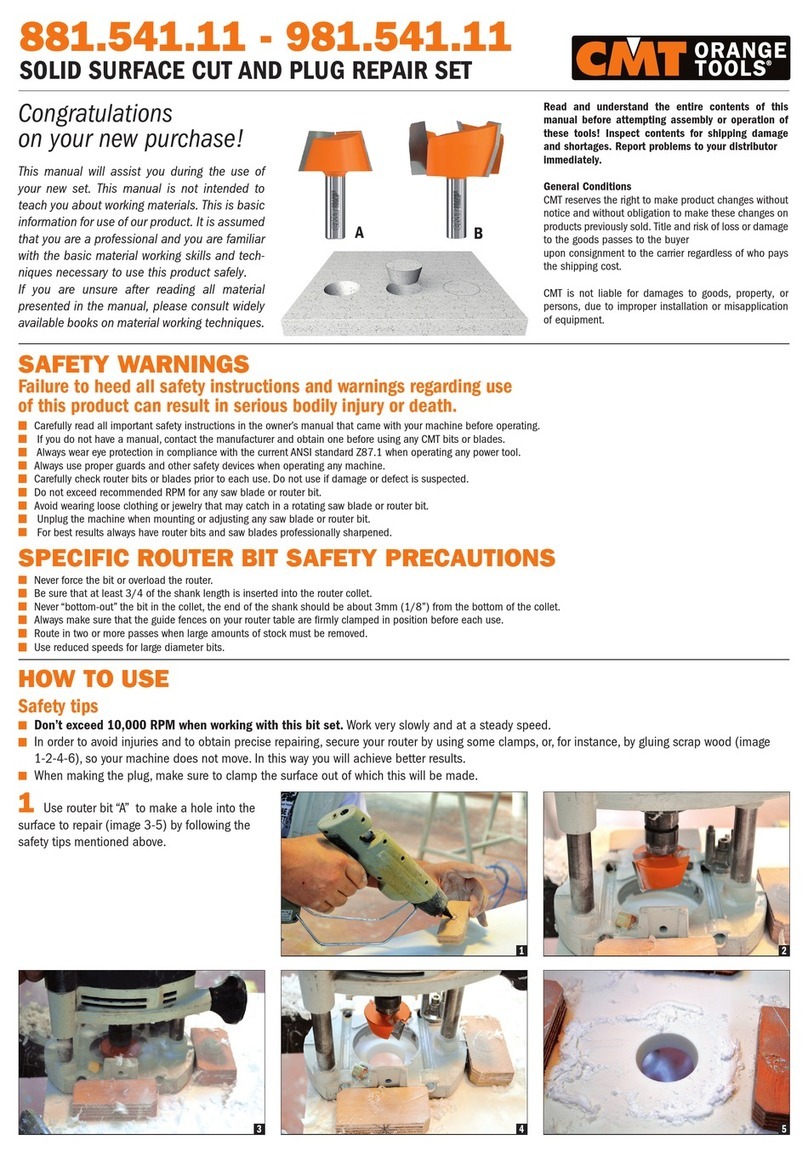

SECTION1–INTRODUCTION&INSTALLATIONINTRODUCTIONThe MSI-6260CS Crane Scale is a member of the Measurement Systems International (MSI) CellScale system.

CellScale™, the system’s central weighing and communication controller, gives you an unprecedented founda-

tion for building your weighing system. For the first time, your weighing system may expand to virtually any

combination of load sensors, weight displays and other data recorders — without requiring cables. In com-

bination with other CellScale equipment and software, the 6260CS can form the basis for intelligent process

control, material inventory systems, and material handling systems.

The 6260CS is available in a wide range of standard weighing capacities from 500 lb (250kg) to 100000 lb

(50000 kg). In addition, MSI has designs for capacities as high as 500 tons as well as custom in-block systems

for any type of crane.

INSTALLATIONThe 6260CS features a heavy duty, cast aluminum enclosure rated at NEMA

4 IP 65. The 6260CS installs easily by hanging it on the crane, using properly

sized shackles. Please refer to MSI’s brochure, “Crane Safety” when install-

ing model 6260CS.

One of the most common installation problems is using an oversize shackle

or too large a hook to interface with the 6260CS. This can cause off center

loading and stress points that will reduce the life of the 6260CS lifting eye

or hook. Use the appropriate interface hardware for the capacity of the scale.

If your interface hardware does not fit properly, MSI can supply the 6260CS

with oversize lifting eyes or shackle interfaces. If the crane hook is too large

to fit in the lifting eye with single point interface, then install the scale using

adaptive rigging.

If multiple attachments are needed, use a shackle or ring to attach the mul-

tiple lines to thus keeping a single point attachment to the scale. Single point

attachments are necessary to ensure the safety and accuracy of the scale

system.

Regular maintenance inspections of the lifting system should be performed to

ensure safety. Pay particular attention for signs of stress on any element in the

load train.

DONOT1.DO NOT PUSH OR PULL ON LOADED SCALE.2.DO NOT PULL LATERALLY ON HOOK WITHSCALE LOADED.DOUSE HARDWARE THAT CREATES SINGLEPOINT ATTACHMENTS AND ALLOWS THESCALE FREEDOM OF ALIGNMENT.DONOTDO NOT INTERFACE HARDWARE(SHACKLES, HOOKS ETC.) THAT AREOVERSIZED AND RESTRICT SINGLE POINTLOADING AND SELF-ALIGNMENT WHICHCAN RESULT IN OFF-AXIS LOADING.DONOTDO NOT USE MULTIPLE ATTACHMENTS.

Page 4 MSI-6260CS Crane Scale™ • User Guide6260CSCraneScaleRFSCALEINSTRUMENTATIONBATTERYLIFEThe 6260CS battery life depends on a number of factors: Brightness of the LED Display and number of

segments lit, the amount of RF activity, and the age and condition of the SLA (sealed lead acid) battery. The

6260CS will automatically turn the scale off when the SLA battery drops to approximately 10.5V. You must

recharge the battery when this happens. Leaving a discharged battery in the scale, which has a maintenance

battery drain, can result in a deep discharged battery which will shorten its service life.

SLA batteries do not suffer from memory effects and actually benefit from frequent rechargings. Recharge

the battery whenever it is convenient even when it still has available life. Due to the maintenance discharge

imposed on the battery by the 6260CS electronics, do not store the 6260CS away with the battery inside.

Remove the battery if the 6260CS will not be used for more than 2 weeks.

Battery Use Guidelines1) Recharge whenever convenient. Do not wait for the scale to shut itself off if your work situation permits.

2) If you need the scale continuously, keep a fully charged spare battery. Replace the drained battery as close

as possible to the low battery warning, or earlier.

3) SLA Batteries that have not been deep discharged should withstand 500 to 1500 charging cycles.

4) The low battery warning will indicate about 2-4 hours of additional use before the 6260CS turns itself off.

5) If the 6260CS is not going to used again soon, remove the SLA battery to prevent deep discharge while the

unit is in storage.

6) Recycle the battery to an authorized recycling center when average life drops to 20 hours or less.

BATTERYCHARGEREach 6260CS is shipped with a battery charger designed to charge and maintain the battery. Exact charging

time will depend on the degree of discharge of the battery. A battery removed when the low battery warning

first appears should take about 4 hours to fully charge.

When the battery is new, it might take significantly longer for the initial charge. MSI recommends charging a new battery for 24 hours. It might take several charge/discharge cycles before full capacity is reached. Deep discharged batteries will also take significantly longer to charge.Using the Charger1) Remove the Battery from the 6260CS. See previous page for removal instructions.

2) Connect the charger assembly to the AC supply (86-260VAC). The Power Status light should be green. If

the power status light fails to illuminate, check your AC power connection and make sure the Vin jack is

fully seated. AC power cords suitable for any world location are available from MSI.

3) Plug in the polarized connector to the jacks on the battery.

4) The Charge Status light should turn ORANGE indicating fast charge.

If the status light remains Green when the battery is first plugged in, the battery may be defective. 5) Charge until the status light turns GREEN.

When the charge cycle is complete you can (and should) leave the battery on the charger until it is needed. The

charger keeps a maintenance float charge on the battery to ensure the best possible operation times. For scales

that are in high usage, MSI recommends obtaining a spare battery so one can always be on the charger.

MSI-6260CS Crane Scale™ • User Guide Page 5

MEASUREMENTSYSTEMSINTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

BATTERYREMOVAL&REPLACEMENT1) Turn the 6260CS Off.

2) With one hand, hold the battery access cover.

3) Release the two latches holding the battery access cover.

4) Carefully lower the cover and when possible, hold the battery in place. The battery might be loose and

subject to falling.

5) Remove the battery by pulling straight back.

6) Install a fully charged battery by plugging it in to the exposed battery jacks. The 6260CS may or may not

turn on once the new battery is installed.

7) Reseat the access panel.

8) Reset the latches. Make sure the latches are completely latched and the plate is firmly in place.

The charger is a universal input type and is rated for 100-240VAC, 50-60Hz. AC power cords suitable for any

world location are available from MSI.

Charge Indicator Light

Amber = Charging

Green = Float

Page 6 MSI-6260CS Crane Scale™ • User Guide6260CSCraneScaleRFSCALEINSTRUMENTATION6260CSBATTERYWELLPeriodically, inspect the battery latches for fit. Adjust the screw latch to maintain a tight seat on the battery O-

ring.

The Sealed Lead Acid Battery can be a dangerous falling hazard. When opening the battery hatch, be sure to hold the battery to prevent it from falling. These batteries contain Lead and should be recycled when it has reached its end of life.Downloaded from www.Manualslib.com manuals search engine

MSI-6260CS Crane Scale™ • User Guide Page 7

MEASUREMENTSYSTEMSINTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

COMMPORTThe 6260CS has a single Comm Port allowing access to the embedded CellScale through the Terminal Access

Mode. The Terminal Access Mode is used for setup and calibration of the 6260CS by providing an interface

to the embedded CellScale. This Comm Port is not intended for output use as it is usually impractical to use

a cable connected port on a Crane Scale. However, in fixed scale applications, the Comm Port can be used to

drive printers, scoreboards, and any other serial peripheral.

CommPortCablesThe 6260CS comes standard with one Comm Port Cable wired for RS-232 (MSI P/N 501705-0001) following

the AT standard for 9 pin serial cables (DCE). An unterminated cable is available (MSI P/N 12023) if you wish

to wire your own serial cable for RS-232 or RS-422 or RS-485.

CommPortCableColorCodeRS-232Brown – Transmit output from CellScale, connect to receive of DTE.

Black – Receive input to CellScale, connect to transmit of DTE.

Grey – CTS Input to CellScale. Connect to RTS or RTR output of DTE.

White – RTS/RTR output from CellScale. Connect to CTS input of DTE.

Blue – Signal Ground

Drain Wire – Connect to metal shell.

CellScaleCOMMPORTPin1-TD+Pin2-TD-Pin3-GNDPin4-RD+Pin5-RD-TD+TD-RD+RD-GNDCHASSISGND485TerminationResistor.120Ω1/4WFinalreceiveronly.485TerminationResistor.120Ω1/4WFinalreceiveronly.TerminateShieldatonlyoneend.GroundReferenceResistor.100Ω1/2WAtallreceivers.ShieldShieldRS-485/422FullDuplexConnectionRemoteDeviceUpto1000metersBRNWHTBLUEBLKGREY

RS-422/485OperationRS-422 and RS-485 serial connections are used when long wire runs are necessary. The 485 spec covers cable

runs up to 4000’. 422 and 485 are differential transmissions and require twisted pair wiring to achieve common

and normal mode rejection. Although short runs of 422/485 cabling is often just two wires, a ground reference

is required. Usually the ground reference is connected through resistors to prevent ground differential cur-

12345678(NC)9Brown(TD)Black(RD)Blue(GND)Grey(CTS)White(RTS)Jumper1-6-4RS-232DCE9-PinFemale‘D’SolderCupViewStandardwiringfordirect9000toComputerconnection

123456789(NC)Brown(TD)Black(RD)Blue(GND)Grey(CTS)White(RTS)Jumper1-6-4RS-232DTE9-PinMale‘D’SolderCupViewWiringfordirect9000toPrinter/Scoreboardconnection

Page 8 MSI-6260CS Crane Scale™ • User Guide6260CSCraneScaleRFSCALEINSTRUMENTATIONrent flow. RS422/485 connections require a termination resistor to reduce reflections. See wiring diagrams for

details.

Both RS-422 and RS-485 are multi-drop capable. The CellScale can drive up to 32 receivers on one twisted

pair. Although the CellScale uses standard RS-485 drivers, the standard software does not have a full duplex

protocol. Contact MSI for custom solutions for networking with RS-485.

CommPortCableColorCodeRS-422/485Brown – TD+ (Y)

White – TD- (Z)

Black – RD+ (A)

Grey – RD- (B)

Blue – Signal Ground

Drain Wire – Connect to metal shell.

If the CellScale is the final device in a chain, connect a 1/4W 120Ω resistor from RD+ to RD-. Terminating T

connectors are available, contact MSI for details.

9000CellScale485Receiver485Receiver485Receiver485Receiver

BROWNWHITEBLUE

ShieldDrainGroundReferenceResistor.100Ω1/2WAtallreceivers.485TerminationResistor.120Ω1/4WFinalreceiveronly.TerminateShieldatonlyoneend.Multi-dropOutput+–+–+–GNDTD+TD–

SERVICINGTHE6260CSMSI’s Dealer Network provides both on-site and depot servicing of 6260CS Crane Scales. Please contact your

local dealer. MSI also operates a service center for all our products. Contact MSI Service at 1-206-433-0199

to obtain an RMA (returned material authorization). Due to the weight and size of many of our products, it is

not always necessary to return the whole scale. If the electronics are at fault, you can often return just the front

casting section. See the following illustration. MSI cannot guarantee that calibration will be restored if you

choose to return just the electronics. If you are able to perform an on-site calibration, then this might not be a

consideration. Always inspect the load train for stress and fatigue wear before returning the scale to use.

There are no user servicable parts inside the 6260CS. Depot repair is performed with module and harness

swaps.

MSI-6260CS Crane Scale™ • User Guide Page 9

MEASUREMENTSYSTEMSINTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

REMOVINGTHEELECTRONICSCASTINGDownloaded from www.Manualslib.com manuals search engine

Page 10 MSI-6260CS Crane Scale™ • User Guide6260CSCraneScaleRFSCALEINSTRUMENTATIONSECTION2–RFSCALECOMMUNICATIONSINTRODUCTION-THECELLSCALESYSTEMThe 6260CS is a key component of the MSI CellScale™ System. The CellScale system uses frequency hopping

spread-spectrum RF Modem technology transmitting in the 2.4 GHz ISM band.

RF Modems have been problematic as the RF bands are very hostile, corrupted by noise, path loss and inter-

fering transmission from other radios. Even in a pure interference-free environment, radio performance faces

serious degradation through a phenomenon known as multipath fading, a problem particularly prevalent for

indoor installations. Multipath fading results when two or more reflected rays of the transmitted signal arrive

at the receiving antenna with opposing phase, thereby partially or completely cancelling the desired signal.

Spread spectrum reduces the vulnerability of a radio system to both interference from jammers and multipath

fading by distributing the transmitted signal over a larger region of the frequency band than would otherwise

be necessary to send the information. This allows the signal to be reconstructed even though part of it may be

lost or corrupted in transit.

Spectrum has been set aside at 2.4GHz in most countries for the purpose of allowing compliant spread spec-

trum systems to operate freely without the requirement of a site license. In the USA, there are absolutely no

site licensing requirements. The CellScale system is also programmable for use in most European countries.

Please contact MSI for worldwide compliance information.

NETWORKDESCRIPTIONThe CellScale system uses frequency hopping which is produced by transmitting the data signal as usual, but

varying the carrier frequency rapidly according to a pseudo-random pattern over a broad range of channels, in

this case 86 discreet frequencies. These 86 frequencies are combined in different “hopping patterns” to provide

64 separate networks. The CellScale network uses a ‘Star’ network topology. One unit, usually the CellScale,

is designated a ‘Master’. The Master transmits a sync pulse on a regular basis, providing synchronization of all

remotes in the designated Network. Thus it forms the center of a cell. MSI provides four products capable of

being the master unit: the CellScale Model 9000, the 9300 Crane Scale, the 9260 Ruggedized Crane Scale, or

the 6260CS Crane Scale. Up to 16 remotes can access the master unit. Current MSI provided remote devices

include the 3750CS Indicator, the 9750A Handheld Indicator, the 9850 Indicator, and the 9020 CellModem.

Multiple remotes can coexist on one network, or can be easily switched to other networks as required.

The CellScale system uses TDMA (Time Division Multiple Access) to arbitrate between multiple remotes.

Each remote is assigned a specific time slot thus guaranteeing data throughput.

NETWORKEXPANSIONYou can expand your system with virtually unlimited combinations of additional CellScales™, CellModems,

and CellScale Indicators (3750CS, 9750A, and 9850).

You can also expand your system with any component that features an RS-232/422/485 input/output (I/O) port:

desktop/laptop computers, printers, scoreboards, relay boards and many others.

There are three ways to connect additional components to your cellular weighing network.

1) Via MSI-3750CS, 9750A, or 9850 Indicators:

RS-232 components can be linked directly to the Indicator Comm Ports with a cable. The 9850 offers two

available Comm ports, one of which is software configurable to RS232/422 or 485. The 3750CS offers 1

RS-232 port.

2) Via CellModem, MSI-9020:

Components can be linked to a remote radio modem, the MSI-9020 CellModem. It enables wireless cel-

lular communication with CellScales™ and the rest of your cellular weighing network. CellModems are

linked via RS-232/422 to peripheral equipment. If necessary, a USB to serial converter can be used for

Computers not equipped with RS-232 serial ports. MSI recommends Keyspan™ products such as the

USA-19HS for this purpose.

In conjunction with the 9020, MSI offers an advanced software solution to interface with the 6260CS,

“CVM”. CVM provides a virtual meter interface for multiple scales and provides datalogging and other

advanced features for computer/scale systems.

MSI-6260CS Crane Scale™ • User Guide Page 11

MEASUREMENTSYSTEMSINTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

3) Via CellScale™:

Each CellScale™ provides an I/O to connect directly to other system components. CellScales™ are linked

via RS-232/422/485 to peripheral equipment. Generate printed and electronic reports automatically for

numerous load sensors; send weighment data automatically from numerous load sensors to a computer

database; cross reference shipments with inventory; track product flow; monitor shelf life; and unlimited

others.

2.4GHZINTERFERENCECo-Existing with 802.11b Networks

In some cases, if a CellScale network is located in close proximity to an 802.11b network, the CellScale net-

work can interfere with the 802.11b network. To avoid causing this interference, the CellScale radio supports a

selection of hopping patterns that avoid the various 802.11b direct sequence channels. These limited band hop-

ping patterns allow CellScale networks to be used with 802.11b networks without impacting the performance

of the 802.11b networks. Settings for 802.11b avoidance are found in the embedded CellScale Comm Port 2

modem menus. See the 9000 User Guide for details.

FCC’SMPEREQUIREMENTSInformation to user/installer regarding FCC’s Maximum Permissible Exposure (MPE) limits.

The field strength radiated by the 6260CS antenna may exceed FCC mandated RF exposure limits. FCC rules

require professional installation of the scale in such a way that the general public will not be closer than 20

cm from the radiating aperture of the antenna (6260CS front casting). End users of these systems must also be

informed that RF exposure limits may be exceeded if personnel come closer than 20 cm to the aperture of this

antenna.

FCCSTATEMENTFCCID:HSW-2450MNote:ThisunithasbeentestedandfoundtocomplywiththelimitsforaClassAdigitaldevice,pursuanttopart15oftheFCCRules.Theselimitsaredesignedtoprovidereasonableprotectionagainstharmfulinterferencewhentheequipmentisoperatedinacommercialenvi-ronment.Thisequipmentgenerates,uses,andcanradiateradiofrequencyenergyand,ifnotinstalledandusedinaccordancewiththeinstructionmanual,maycauseharmfulinterferencetoradiocommunications.Operationofthisequipmentinaresidentialareaislikelytocauseharmfulinterferenceinwhichcasetheuserwillberequiredtocorrecttheinterferenceattheirexpense.Downloaded from www.Manualslib.com manuals search engine

Page 12 MSI-6260CS Crane Scale™ • User Guide6260CSCraneScaleRFSCALEINSTRUMENTATIONSECTION3–THEEMBEDDEDCELLSCALEForacompleteguidetoallthefeaturesoftheembeddedCellScale,refertotheMSI-9000UserGuide.ACCESSINGTHECELLSCALEThe 6260CS Comm Port provides access to the embedded CellScale. To access the advanced features of the

CellScale a Comm Port is provided on the 6260CS front casting.

The CellScale offers Set Points, ID Codes, and other advanced features which are controlled either through a

remote Indicator such as the 3750CS or the 9750 Handheld. These features are also accessed by connecting a

terminal program in a PC to the Comm Port. Tested terminal programs that function well with the CellScale

include ProComm Plus, Qmodem, HyperTerm (shipped with many versions of Windows), WinTerm, and

ZTerm or Microphone (for Macintosh). Usually a VT102 emulation is used. All commands are single letter

except when entering data.

Settings for your terminal program are: 9600 baud, 8 bit, 1 start bit, 1 stop bit, no parity, Handshaking usually

not required, but you can turn on Xon/Xoff if you desire.

The CellScale Terminal Access Mode is used to set Network parameters, Scale parameters, Set Points, and

other various setup conditions. Refer to the MSI-9000 CellScale User Guide for detailed information.

CONNECTIONPROCEDURE1) Connect the PC to the 6260CS through the Comm Port.

2) Start your terminal program. Press any key on the terminal to refresh the screen. The CellScale menu

should appear.

3) If the menu does not appear, confirm baud rates. If baud rates match, and no menu appears, the embedded

CellScale might be in the “Host” mode. To start the terminal access program send:

;MSI9MSI9

followed by a CRLF (return on most terminals). All letters must be capitals.

4) Once in the Terminal Access Mode menus, commands are usually a single number or letter. Refer to the

9000 CellScale User Guide for further information.

SETPOINTSThe Internal CellScale can monitor up to 32 Set Points. Set Points are used for safety warnings and process

control. Set Points are programmed from a 3750CS, a 9750, or through the Terminal Access Mode. On special

order MSI can supply audible alarms, sirens, or other warning devices for Set Point outputs.

SCALECALIBRATIONUse the calibration procedure found in your indicator User Guide.

The 6260CS is best calibrated using a remote indicator such as the 3750CS, 9850, or the 9750A Handheld.

Calibration procedures using these devices are covered in their respective User Guides. You can also use the

Terminal Access Mode for calibration as covered in the MSI-9000 Users Guide. The CVM program can also be

used for calibration.

MSI recommends having test weights of at least 50% capacity to properly calibrate the Crane Scale. The

calibration procedures will operate with as little as 12.5% of capacity, though rated accuracy cannot be guar-

anteed. Very large capacity scales are often calibrated using transfer techniques. Weigh something on a truck

scale, then pick it up on the Crane scale and match the weight during the calibration procedure. The CellScale

software permits multi-point calibration (up to 9 span points + Zero), but multi-point calibration is not usually

necessary with our standard product line, being very linear from zero to capacity. The need for Multi-Point

calibration is left up to the Scale Technician.

MSI-6260CS Crane Scale™ • User Guide Page 13

MEASUREMENTSYSTEMSINTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

Calibration Tips1) Before calibration, exercise the load cell at least 5 times by lifting a test weight having a weight approxi-

mately equal to the system capacity.

2) Make sure that the scale and load are stable (not swinging or vibrating) for every calibration step.

3) Prevent off-center loading during calibration. The scale must be perpendicular to the earth to prevent

cosine theta errors. Adjust the rigging as necessary so that the pull is straight through the center of the

scale.

4) Calibration always starts with the zero load. Remove all rigging that is not always present on the scale.

However, it is sometimes best to calibrate zero with the rigging necessary for picking up the test weights

attached to the scale. It’s effect on dead load can be zeroed out later.

5) If the rigging has not been zeroed out, make sure you add its weight to the test weight when entering the

calibration weight.

6) Multi-point calibration can be done in any random order, as long as the zero step is first.

LEGAL-FOR-TRADEThe 6260CS is designed to meet NTEP requirements (COC pending). The “STANDARD” setting in the

embedded CellScale must be set to NTEP. See the 9000 User Guide for details on NTEP operation and setting

the operating Standard.

Enabling the NTEP mode requires that you designate a control device for the crane scale. Only one control

device is allowed to change metrologically significant parameters such as Zero or Tare. All other remote

devices can display weight but cannot control the scale.

Unless you are actively involved in Legal-For-Trade activity, do not enable the NTEP mode due to the limi-

tations it causes in the use of peripheral equipment. The Industrial standard is just as accurate if calibrated

properly, and allows multiple controller/indicators.

SEALINGTHEMSI-6260CSCRANESCALEThe 6260CS is sealed with a standard lead-wire seal. The seal is used to prevent removal of the seal screw cov-

ering the calibration enable switch. The wire is passed through the seal screw and through two adjacent screws

in the front casting (figure 3-1). Use seal wire with a maximum diameter of .040” (1mm). 20 Gauge or smaller

wire is appropriate.

Once all channel parameters are set and calibrations completed replace the seal screw and tighten down

securely to ensure a water proof seal.

The rear casting assembly (Battery Well) must also be sealed to prevent access to the electronics (figure 3-2).

This seal does not need to be broken to calibrate the system. Only the front casting wire must be broken to

provide access to the calibration menus.

Page 14 MSI-6260CS Crane Scale™ • User Guide6260CSCraneScaleRFSCALEINSTRUMENTATION

Remove only this seal screw for access

to the calibration enable switch. Do not

remove the casting Cap Screws.

Pass 20-24 AWG wire through these

two casting Cap Screws and the Seal

Screw for Legal-For-Trade seal.

Figure 3-1

Calibration Switch Pushbutton

is behind Seal Screw

MSI-6260CS Crane Scale™ • User Guide Page 15

MEASUREMENTSYSTEMSINTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

The Battery Casting must be sealed to

prevent tampering. This seal does not

need to be removed for calibration.

Figure 3-2

Page 16 MSI-6260CS Crane Scale™ • User Guide6260CSCraneScaleRFSCALEINSTRUMENTATIONAPPENDIX–SPECIFICATIONS&DIMENSIONSHARDWAREOVERVIEWElectronics• µC Board: 6 layer SMD, AM186ESLV based w/ Flash Memory – 512kbytes of Flash Program Memory,

512kbytes of non-volatile RAM.

• Power Supply / I/O Board: power regulation and I/O for MM – Input range 10-16V. Optional direct AC

board 90-260VAC.

• 2 Channel A/D Board: 4 layer SMD, 24bit A/D.

• Highly integrated Radio Modem: 2.4GHz Spread Spectrum. Protected Antenna.

• Display Board: 4 Layer SMD with six 1.2” (30mm) digits and 14 backlit annunciators.

Housing• Cast Aluminum. Double O-ring gasketed. NEMA 4, IP66

Load Train• Load Cell: 4340 Aircraft Quality Steel

• Industry Standard Lifting Eyes and Bottom Hooks

GENERALFEATURESChannels 1-4 – Scale Input Channels• Internal Load Cell connected to Channel 1. Optional additional scale inputs by special order for multipoint

lift situations.

Channel 5• Channel 5 allows remote access to inputs on remote Slave CellScales

Channel 6• Channel 6 is math calculations. Up to 8 separate math channels can be used to combine conversions from

multiple scale channels. Supported functions are: multiply, divide, add, subtract, absolute value, square

root, and constants. Multiple levels of parentheses are available for any scaling or channel data manipula-

tion formulas.

Excitation• 5 V (+5V relative to ground). Current limited and over-voltage protected to Factory Mutual standards. AC

(switched DC) or DC excitation.

Radio Link• Frequency Hopping Spread Spectrum in 64 channels @ 2.4 GHz. Allows 64 collocated networks of scales

and peripheral devices.

Calibration• Via RF or Input Comm Port. Calibration is accomplished through a computer program residing on any

computer. The calibration program is user friendly, with menus that are easy to use on a full graphics

screen. Calibration is also available using the 3750CS, 9850 or 9750A Meters. Sealing the system is not

necessary due to password protected calibration routines. Seal can be provided on front panel in Legal-

For-Trade systems.

MSI-6260CS Crane Scale™ • User Guide Page 17

MEASUREMENTSYSTEMSINTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

GENERALSPECIFICATIONSCalibration Parameters (Programmed via Terminal Access Mode)• CAL – Zero then Span, up to 10 point calibration (counting 0)

• AZM – OFF, ON (.5d), 1d to 255d Programmable

• Motion Detect – OFF, ON (.5d), 1d to 255d (programmable in 1d steps)

• Software Filter – None, LOW, HIGH

• Zero – 100% of capacity, limited by Legal-for-trade settings.

• Units – lb, kg, Ton, Ton (metric), oz, g, daN, or user defined using the math channels through remote indi-

cators (3750CS or 9750).

• Standard Crane Scale Capacities – 500 lb / 250 kg, 2000 lb / 1000 kg, 5000 lb / 2500 kg, 10000 lb /

5000 kg, 20000 lb / 10000 kg, 30000 lb / 15000 kg, 50000 lb / 25000 kg, 70000 lb / 35000kg, 100000 lb /

50000kg. Larger capacities available on request. MSI can provide load cells to 500 tons. Any scale can be

calibrated to a smaller capacity. e.g. a 2000 lb scale could be calibrated to overload at 1800 lb.

• “d” Scale divisions – Any resolution from 10,000 divisions or less. Standard 6260CS resolution is 2000d

to 5000d. Having more resolution than needed can cause settling delay.

Power Consumption• Battery Life – 30-40 Hrs with new battery.

Approvals (pending)• NTEP, OIML, Factory Mutual, NEMA, FCC

Temperature • Operating NTEP/OIML

-40°C to 85°C (-40° to 185° F) -10°C to 40°C (14° to 104° F)

RFI/EMI Shielding• Exceeds NIST HB44 and European Standards.

Real Time Clock• Supports date/time stamping in US or European time and date. Backed up by a replaceable Lithium Bat-

tery (Typical life >5 years). Clock data available via RF interfaces (3750CS, 9750, 9020).

Data I/O• Any scale data is available via RF Modem or through the 3750CS or 9750 Indicators.

Totalization and Statistics• Push button or Automatic. Total weight up to 999,999,999. Weighments counter up to 65,535. Totals are

stored with each ID register. Min, Max, Average, Standard Deviation, and Coefficient of Variance com-

puted and stored for each ID.

Internal Set Points• 3 Contacts internal (SS Relays). Programmable for form A or form B (normally open or normally closed).

Relays rated for 60V @ 350mA. 2.5Ω maximum contact resistance. Accessible by special order.

Page 18 MSI-6260CS Crane Scale™ • User Guide6260CSCraneScaleRFSCALEINSTRUMENTATIONDIMENSIONSANDLOADTRAINSPECIFICATIONS

CONSULT FACTORY FOR HIGHER CAPACITIES – See MSI-9300HT Specification Sheet for applications that require powered rotation of lifted material.

CAPACITY RESOLUTION** A* B* C* D* E* F HOOK EYE NUT OR APPROX.

SHACKLE SHIP WT.

500 lb 0.2 lb 18.3 in 2.25 3.06 1.44 1.41 – 5 ton alloy CR # 7 53 lb

250 kg 0.1 kg 465 mm 57.1 77.7 37.0 36.0 – swivel eye nut 24 kg

2,000 lb 1 lb 18.3 in 2.25 3.06 1.44 1.41 – 5 ton alloy CR # 7 53 lb

1,000 kg 0.5 kg 465 mm 57.1 77.7 37.0 36.0 – swivel eye nut 24 kg

5,000 lb 1 lb 20.5 in 2.50 3.50 1.81 1.69 – 7 ton alloy CR #8 62 lb

2,500 kg 0.5 kg 521 mm 64.0 89.0 46.0 42.9 – swivel eye nut 28 kg

10,000 lb 2 lb 20.5 in 2.50 3.50 1.81 1.69 – 7 ton alloy CR # 8 62 lb

5,000 kg 1 kg 521 mm 64.0 89.0 46.0 42.9 – swivel eye nut 28 kg

20,000 lb 5 lb 28.5 in 4.00 6.25 2.62 2.41 – 15 ton alloy CR # 11 105 lb

10,000 kg 2 kg 724 mm 101.6 159 66.5 61.2 – swivel eye nut 47 kg

30,000 lb 10 lb 30.0 in 4.00 6.25 3.00 3.19 – 22 ton alloy CR # 11 125 lb

15,000 kg 5 kg 762 mm 101.6 159 76.2 81.0 – swivel eye nut 55 kg

50,000 lb 10 lb 41.0 in 5.00 6.00 3.62 3.63 15.0 30 ton alloy CR 25 ton 235 lb

25,000 kg 5 kg 1041 mm 127 152 92.0 92.0 381 swivel *** shackle # 2130 106 kg

70,000 lb 20 lb 43.2 in 5.00 6.00 4.56 3.75 15.0 37 ton alloy CR 40 ton 270 lb

35,000 kg 10 kg 1097 mm 127 152 116 95.0 381 swivel **** shackle # 2140 121 kg

100,000 lb 20 lb 52.1 in 5.75 6.65 5.06 4.25 16.25 CR 45 ton CR 55 ton 420 lb

50,000 kg 10 kg 1324 mm 146 169 129 108 413 S1 swivel ***** shackle # 2140 189 kg

EDB9.4in239mmFRONT VIEWSIDE VIEWFRONT VIEW50/70/100,000 Lb. ModelF13.2in335mm9.1in231mmCAContact factory for higher capacitiesCR = Crosby or equivalent*These dimensions also apply to 50/70/100,000 lb units withhook and shackle.**Resolution subject to change for NIST approved units***Ultimate overload: 490% of kg capacity****Ultimate overload: 475% of lb capacity / 430% of kg capacity*****Ultimate overload: 450% of kg capacity

OPTIONSANDACCESSORIES• Substitute Shackle for bottom swivel hook

• Oversized top lifting eye or shackle

• Direct wired input power, AC or DC, (specify required voltage)

• Audible Alarm or Very Loud Siren

• Heat Shield for Foundry Operations

• Slave Load Cell Input – RF 9300 or 6260CS units can function as slave Crane Scale inputs to a 6260CS or

other CellScale based products. Up to three RF connected slaves are possible.

• Fast SLA Battery Charger (Included) – Cordsets available for Europe, UK, Australia, and USA/Japan.

• Serial Input Cable 4m (Included) – MSI P/N 501705-0001. Used for addressing the embedded CellScale

for Setup and/or Calibration.

• Spare 12V SLA Battery – MSI P/N D00599-0004

MSI-6260CS Crane Scale™ • User Guide Page 19

MEASUREMENTSYSTEMSINTERNATIONAL

Rev 1 4/14/06 for SW Ver 5-xx

THEMSILIMITEDWARRANTYMEASUREMENT SYSTEMS INTERNATIONAL, INC., WARRANTS load sensing elements and meters

against defects in workmanship and materials for a period of one year from date of purchase and warrants

electrical cables and batteries against the same defects for a period of ninety (90) days from date of purchase.

Any device which proves defective during the warranty period will be replaced or repaired at no charge;

provided that the defective device is returned to the Company freight pre-paid.

In no event shall the Company be liable for the cost of any repairs or alterations made by others except those

repairs or alterations made with its specific written consent, nor shall the Company be liable for any damages or

delays whether caused by defective workmanship, materials or otherwise.

The Company shall not be liable for any personal injury or property damage resulting from the handling,

possession or use of the equipment by the customer.

The warranty set forth herein is exclusive and is expressly in lieu of all other warranties, express or implied,

including without limitation any implied warranties of merchantability or fitness, or of any other obligations

or liability on the part of the Company.

The liability of the Company under this warranty is limited solely to repairing or replacing its products during

the warranty periods; and the final judgment and disposition of all claims will be made by MEASUREMENT

SYSTEMS INTERNATIONAL, INC.

A RICE LAKE WEIGHING SYSTEMS COMPANY

Measurement Systems

International

TM

14240 Interurban Avenue South Suite 200 ƔSeattle, WA 98168-4661 ƔUSA

Phone: 206-433-0199 ƔFax: 206-244-8470

www.msiscales.com

©

2012 Rice Lake Weighing Systems

Table of contents