Contents

23A4558F Repair, Parts

Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

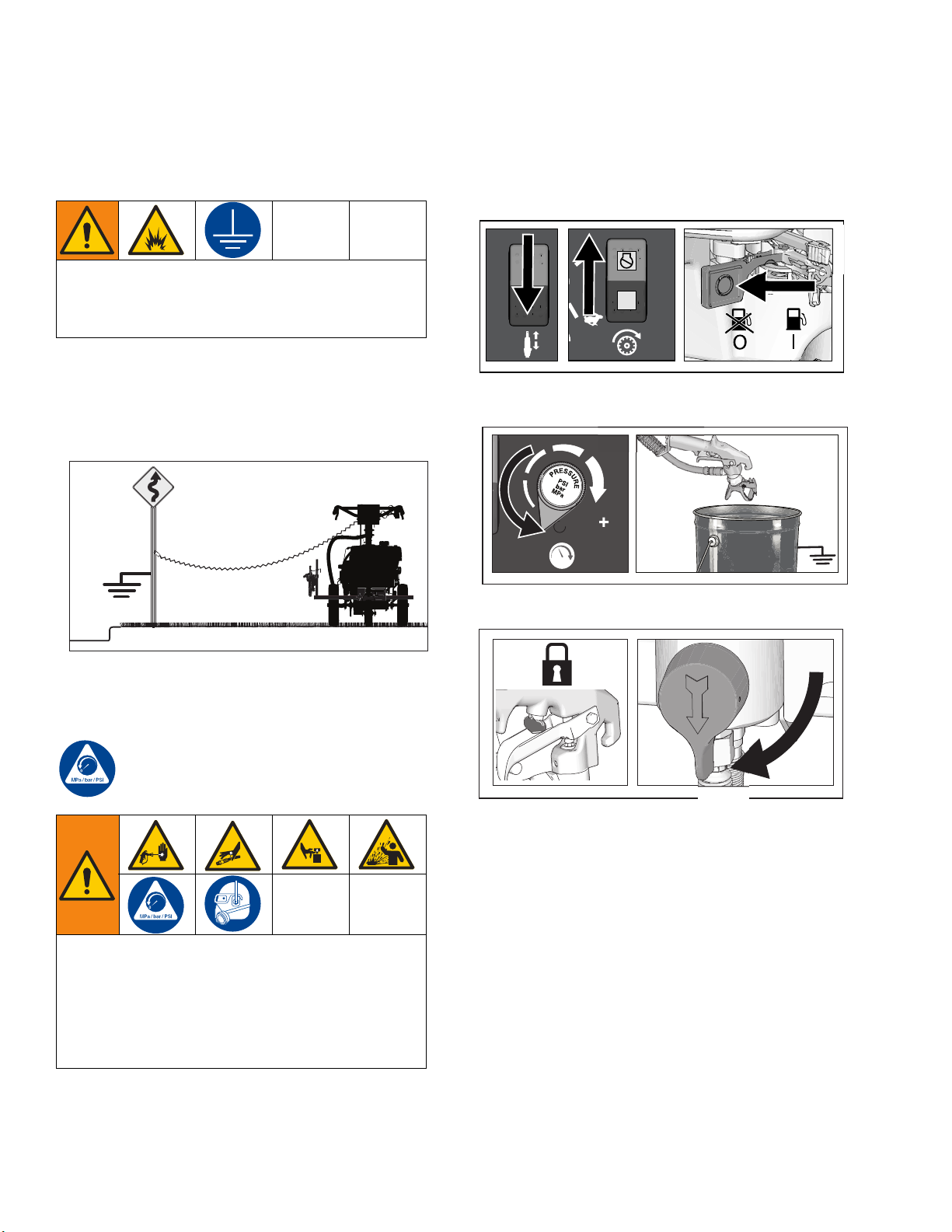

Grounding Procedure (For Flammable Materials

Only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Pressure Relief Procedure . . . . . . . . . . . . . . . . . . . 6

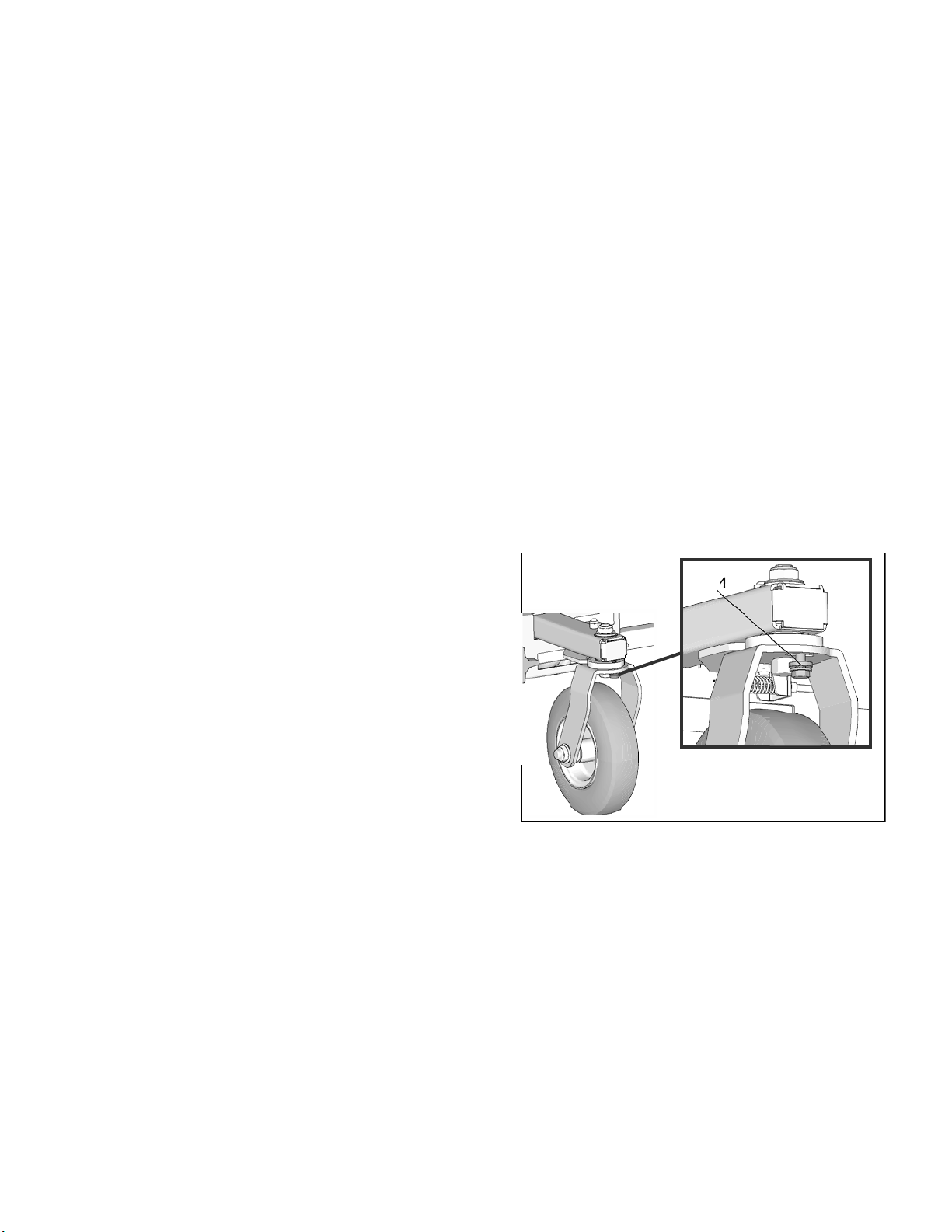

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Front Wheel Alignment: . . . . . . . . . . . . . . . . . . . 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

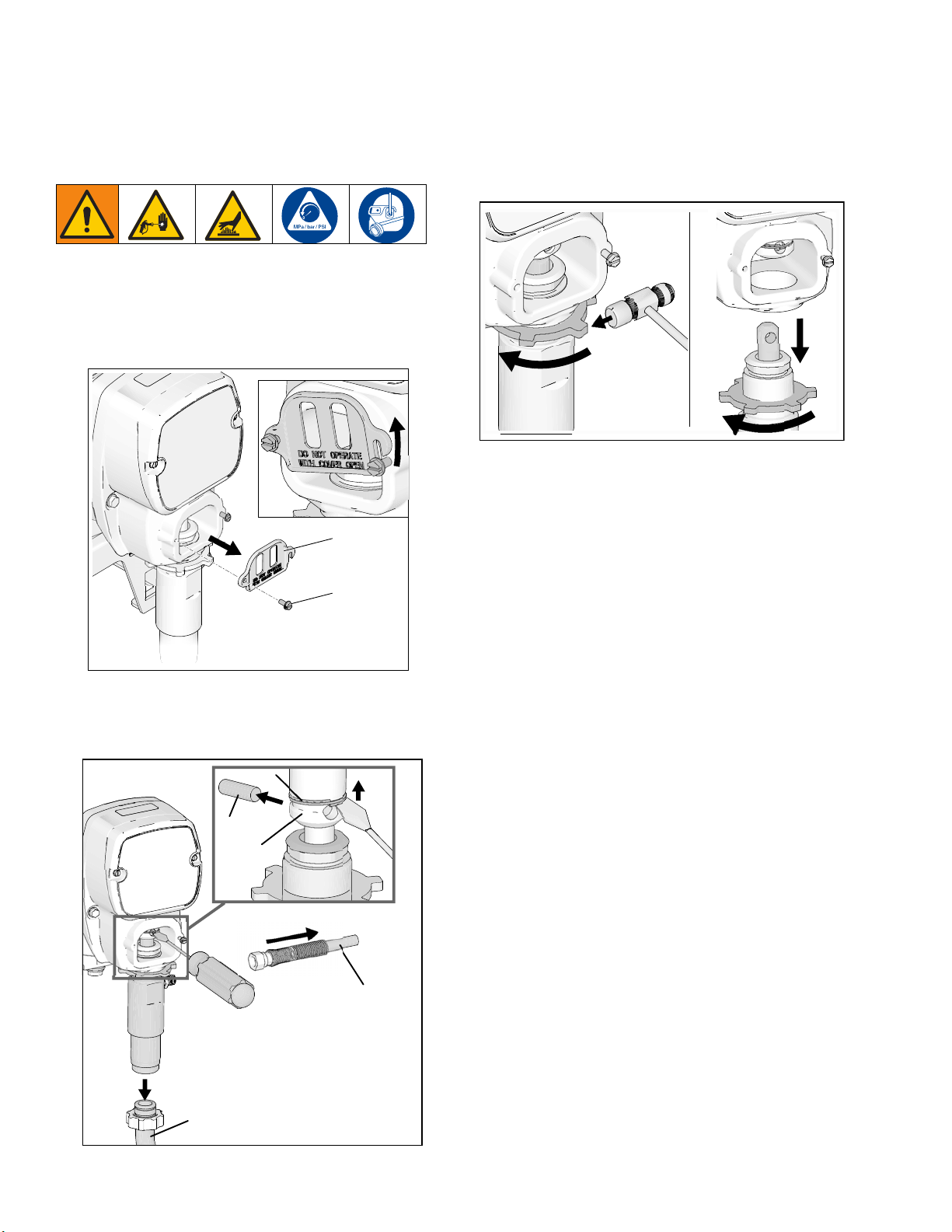

Displacement Pump . . . . . . . . . . . . . . . . . . . . . . . 10

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drive Housing and Connecting Rod . . . . . . . . . . 12

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Pinion Assembly/Clutch Armature/Clamp . . . . . 13

Pinion Assembly/Clutch Armature Removal . . . 13

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Clamp Removal . . . . . . . . . . . . . . . . . . . . . . . . 15

Clamp Installation . . . . . . . . . . . . . . . . . . . . . . . 15

Clutch Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Pressure Control Transducer . . . . . . . . . . . . . . . . 18

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pressure Control (On/Off Switch) . . . . . . . . . . . . 19

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Pressure Adjust Potentiometer . . . . . . . . . . . . . . 20

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Drive Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Drive Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Drive Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Drive/Axle Bearings . . . . . . . . . . . . . . . . . . . . . . . . 29

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Drive Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Motor Control Board . . . . . . . . . . . . . . . . . . . . . . . 33

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Speed Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Fluid Pump Runs Constantly . . . . . . . . . . . . . . . 38

Control Board Malfunction . . . . . . . . . . . . . . . . . 39

Control Board Malfunction (Steps) . . . . . . . . . . 40

Digital Display Messages . . . . . . . . . . . . . . . . . 41

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

25M230 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Parts List - 25M230 . . . . . . . . . . . . . . . . . . . . . . . . 43

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Self-Propelled Drive - Series A . . . . . . . . . . . . . 44

Parts List - Self-Propelled Drive - Series A . . . . . 45

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Self-Propelled Drive - Series B . . . . . . . . . . . . . 46

Parts List - Self-Propelled Drive - Series B . . . . . 47

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Parts List - 25M230 . . . . . . . . . . . . . . . . . . . . . . . . 49

Parts Drawing and List - Pinion Housing . . . . . . 50

Gun Arm Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Pressure Control/Filter Assembly . . . . . . . . . . . . 52

Parts List - Pressure Control/Filter Assembly . . 53

Pressure Control Wiring Diagram . . . . . . . . . . . . 54

Drive Control Wiring Diagram . . . . . . . . . . . . . . . . 55

PIONEER LIMITED WARRANTY . . . . . . . . . . . . . . 56