1PRODUCT OVERVIEW......................................................................................................................................................... 3

1.1 SUPPLIED ITEMS ..................................................................................................................................................................... 3

1.2 DOCUMENT CONVENTIONS ...................................................................................................................................................... 4

1.3 PRODUCT SPECIFICATION ......................................................................................................................................................... 4

1.3.1 Current Inputs ............................................................................................................................................................ 4

1.3.2 Service Type ............................................................................................................................................................... 4

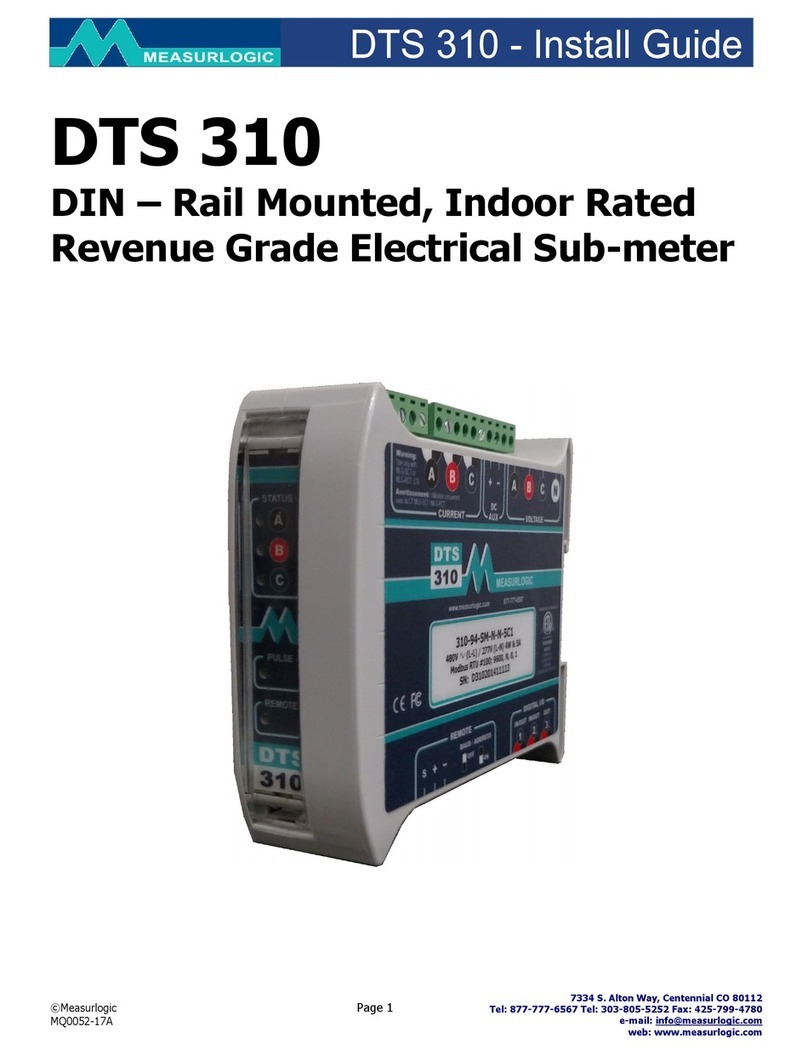

2INSTALLATION ................................................................................................................................................................... 5

2.1 SAFETY GUIDELINES ................................................................................................................................................................ 5

2.2 PRODUCT DIMENSIONS............................................................................................................................................................ 6

2.3 MOUNTING REQUIREMENTS AND GUIDELINES ............................................................................................................................. 6

3CONNECTING TO THE DTS 307 ........................................................................................................................................... 7

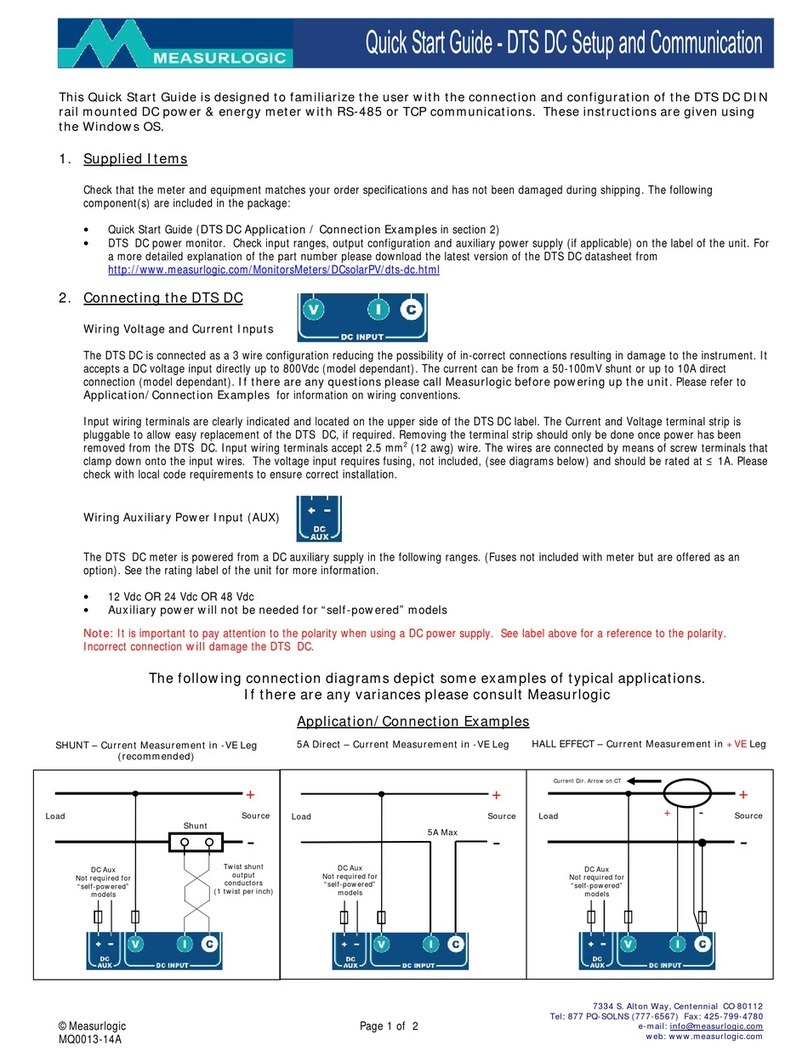

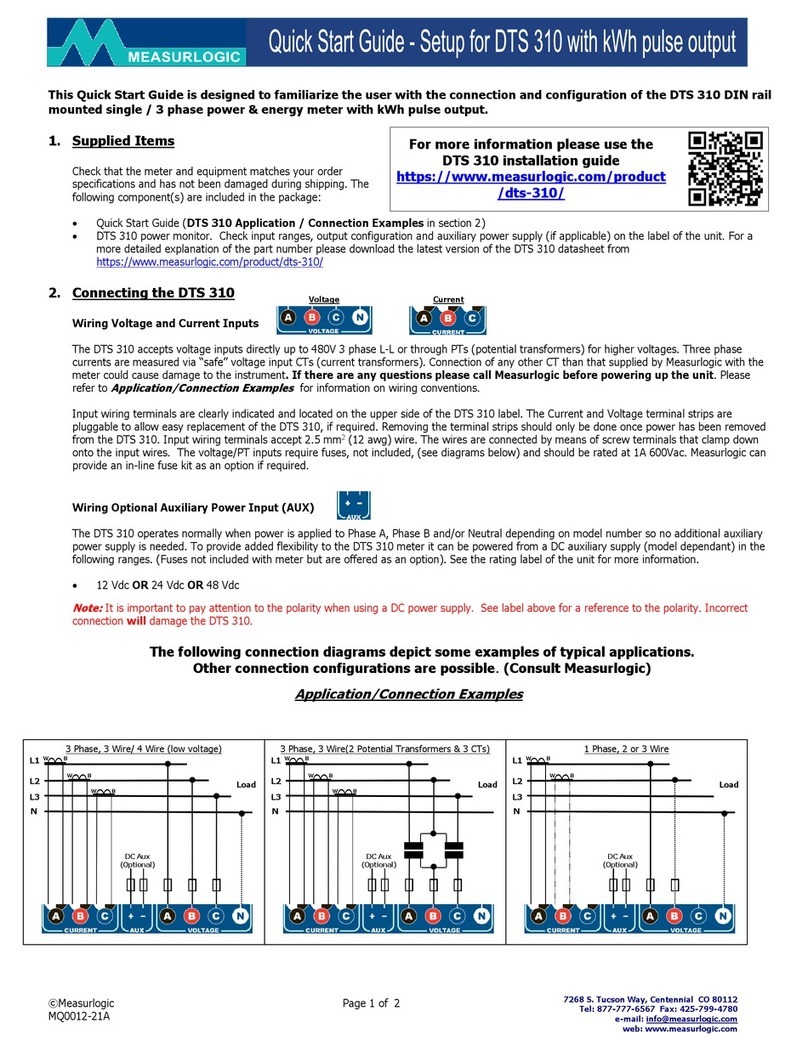

3.1 WIRING VOLTAGE AND CURRENT INPUTS .................................................................................................................................... 7

3.1.1 Wiring Examples ........................................................................................................................................................ 7

3.2 CONNECTING MULTIPLE LOADS................................................................................................................................................. 8

4MAINTENANCE AND SERVICE............................................................................................................................................. 9

5DTS 307 COMMUNICATIONS INTERFACE............................................................................................................................ 9

5.1 RS-485 2-WIRE COMMUNICATIONS ......................................................................................................................................... 9

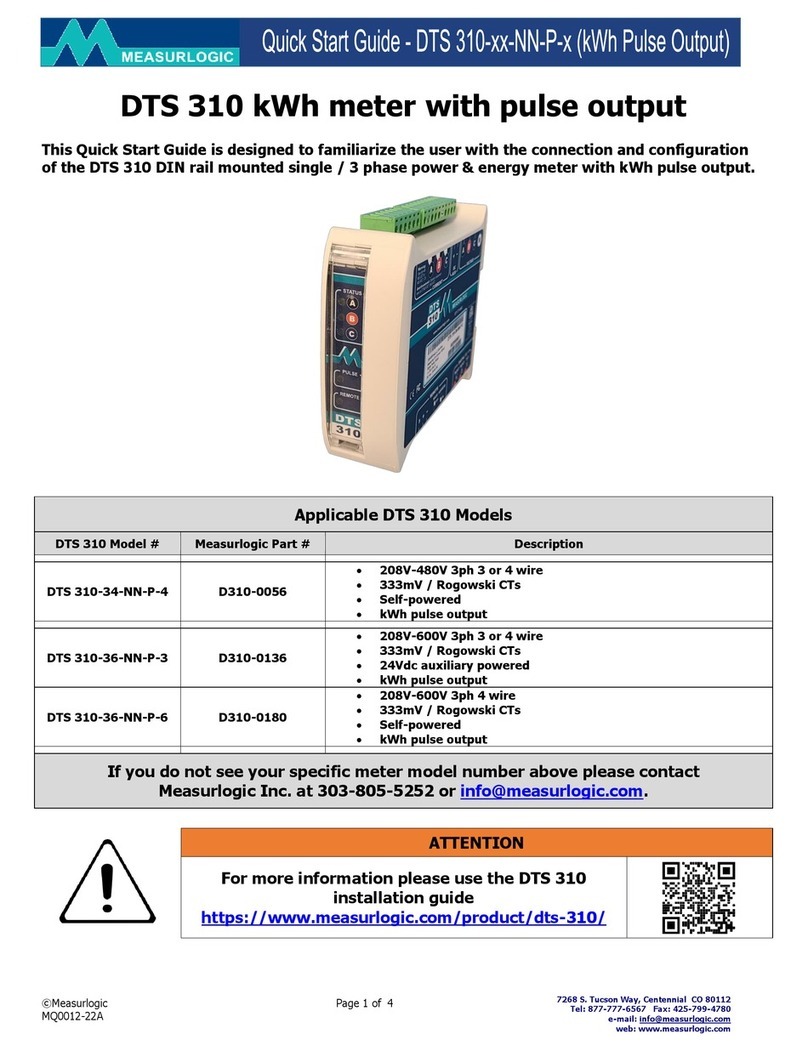

5.2 KWH PULSE OUTPUT (MODEL DEPENDENT).............................................................................................................................. 10

6LED DEFINITIONS ............................................................................................................................................................. 10

6.1 STATUS LED........................................................................................................................................................................ 10

6.2 REMOTE LED....................................................................................................................................................................... 11

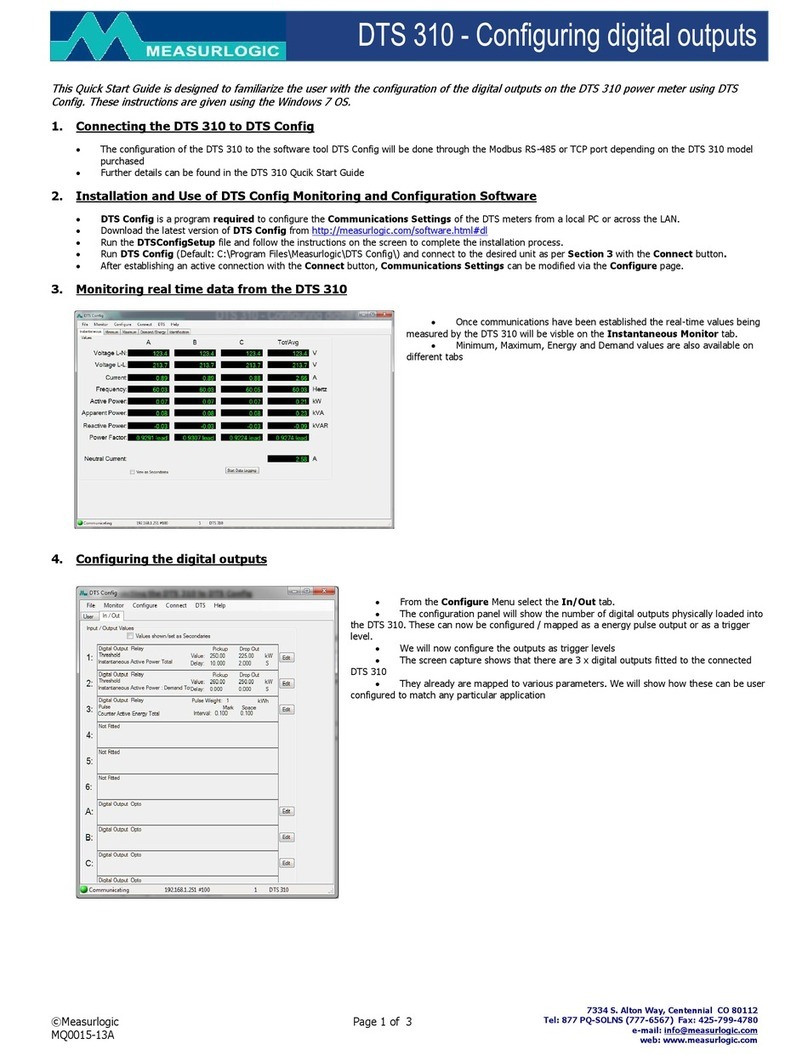

7INSTALLATION OF DTS CONFIG AND MONITORING SOFTWARE ....................................................................................... 11