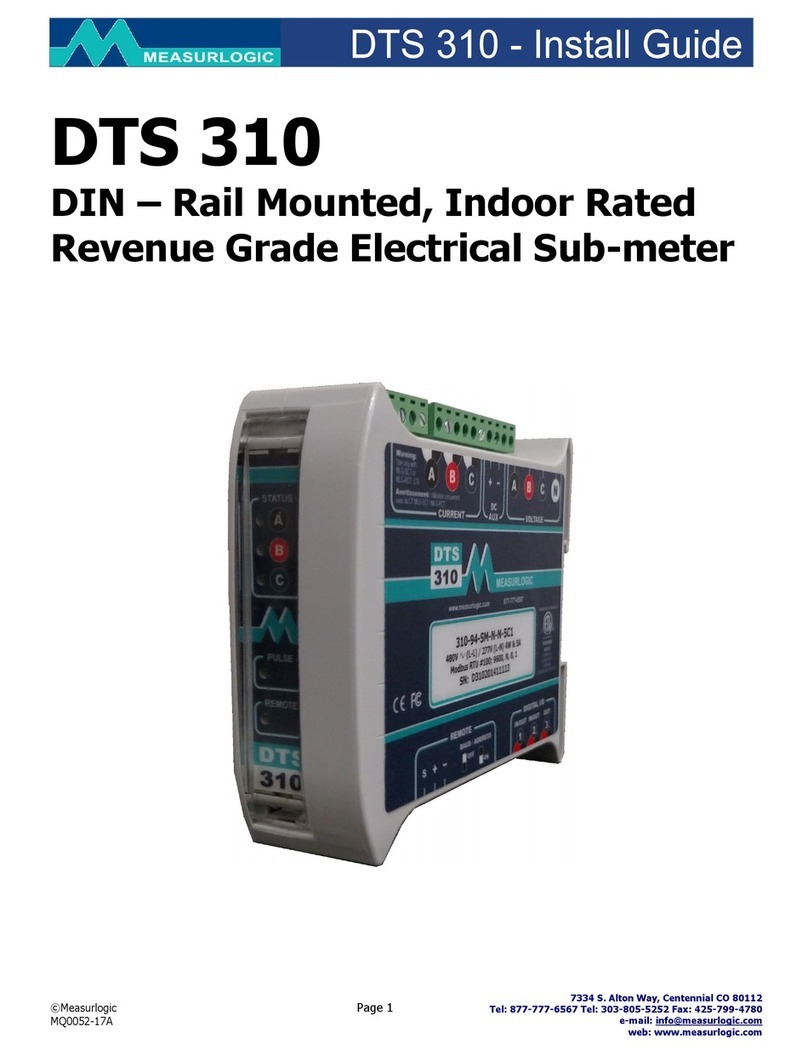

This Quick Start Guide is designed to familiarize the user with the connection and configuration of the DTS 310 DIN rail

mounted single / 3 phase power & energy meter with 333mV/Rogowski Coil current sensor inputs and RS-485 serial

Modbus RTU or BACnet MS/TP communications.

Supplied Items

Check that the meter and equipment matches your order specifications and has not been damaged during shipping. The following component(s)

are included in the package:

•The DTS 310 power meter.Check input ranges, output configuration and auxiliary power supply (if applicable) on the label of the unit.

For a more detailed explanation of the part number please download the latest version of the DTS 310 datasheet from:

https://www.measurlogic.com/product/dts-310/

•The necessary green terminal plugs are fitted to the DTS meter.

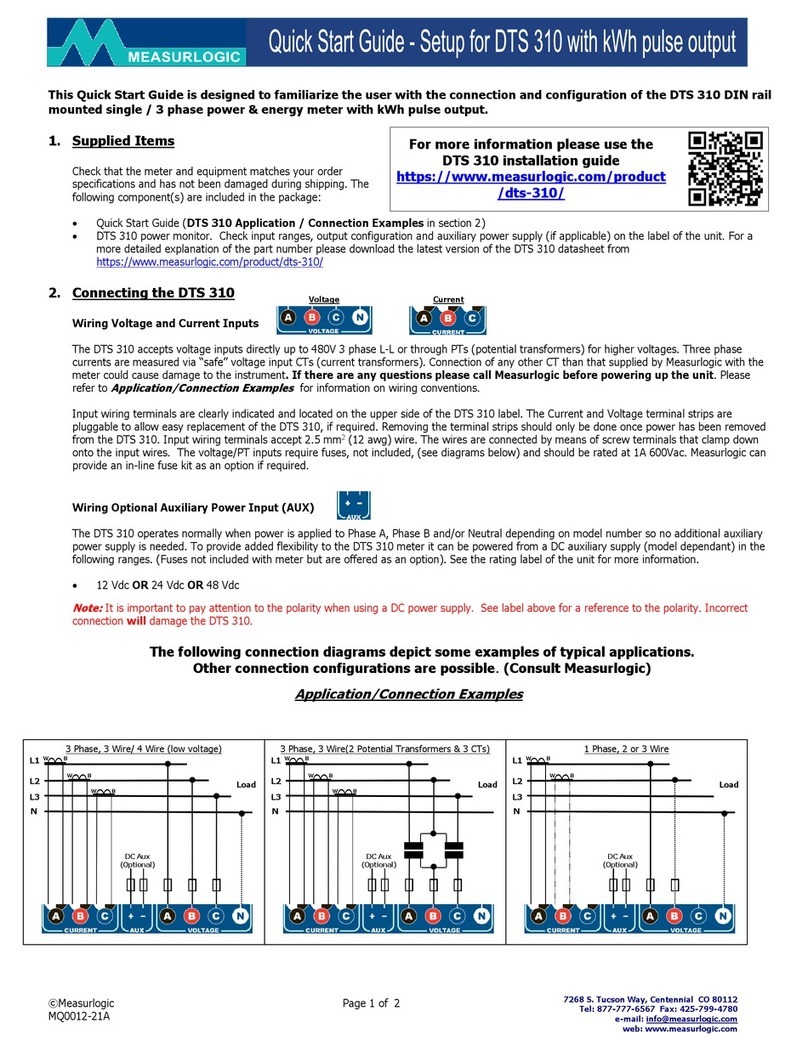

Connecting the DTS 310

Wiring Voltage and Current Inputs

The DTS 310 accepts voltage inputs directly up to 480V or 600V 3 phase L-L (model dependent) or through PTs (potential transformers) for higher

voltages. Three phase currents are measured via “safe” 333mV or Flexible Rogowski CTs (current transformers). Connection of any other CT

than these outputs could cause damage to the instrument. If there are any questions, please call Measurlogic before powering up the

unit. Please refer to

Application/Connection Examples

for information on wiring conventions.

Input wiring terminals are clearly indicated and located on the upper side of the DTS 310 label. The Current and Voltage terminal strips are

pluggable to allow easy replacement of the DTS 310, if required. Removing the terminal strips should only be done once power has been removed

from the DTS 310. Input wiring terminals accept 2.5 mm2(12 awg) wire. The wires are connected by means of screw terminals that clamp down

onto the input wires. The voltage/PT inputs require fuses, not included, (see diagrams below) and should be rated at 1A 600Vac. Measurlogic can

provide an in-line fuse kit as an option if required.

Wiring Optional Auxiliary Power Input (AUX)

The DTS 310 operates normally when power is applied to Phase A, Phase B and/or Neutral depending on model number so no additional auxiliary

power supply is needed. To provide added flexibility to the DTS 310 meter it can be powered from a DC auxiliary supply (model dependant) in the

following ranges. (Fuses not included with meter but are offered as an option). See the rating label of the unit for more information.

•12 Vdc OR 24 Vdc OR 48 Vdc

Note:

It is important to pay attention to the polarity when using a DC power supply. See label above for a reference to the polarity. Incorrect

connection will damage the DTS 310.

The following connection diagrams depict some examples of typical applications.

Other connection configurations are possible. (Consult Measurlogic)

Application/Connection Examples