MECHAPRO Tiny-Step User manual

Assembly Instructions

Stepping Motor Board >Tiny-Step<

Rev. 1.0 (last updated 15.07.2008)

Functional description:Functional description:

Functional description:Functional description:

Functional description:

Tiny-Step is a 1 channel stepping motor driver, that can drive motors with up to 2.25 amperes

(peak) in full-, half-, fourth- or eighth-step mode. The board is based on the A3977 that

supports all features of microstep signal generation and includes the amplifier. The signal /

SLEEP can reduce motor current by 25%. The /e-STOP signal switches off the amplifier

directly. The HOME-LED signals every fourth full step for a simple signal in case steps are lost.

The board is delivered partially fitted with components (all SMD parts).

DisclaimerDisclaimer

DisclaimerDisclaimer

Disclaimer, EMC-compliance, EMC-compliance

, EMC-compliance, EMC-compliance

, EMC-compliance

Even though all parts of the circuitry have been thoroughly checked and tested, mechapro

does not give any warranty or other assurance as to the operation or functionality of the

circuitry or the documentation.

To the full extent permissible by law we disclaim all responsibility for any damages or losses

(including, without limitation, financial loss, damages for loss in business projects, loss of profits

or other consequential losses) arising from the use or reproduction and/or operation of the

presented circuitry.

The stepper motor driver card Tiny-Step is an OEM-product for further processing by industry

or other, in electronics specialized, personal. In line with §5 of the EMC-regulation the Tiny-

Step driver card does not have to carry a CE-Label. Wiring and the individual components

being used as well as the complete environment in which the controller card is operated will

influence its EMC behaviour. Therefore, if CE-compliance is required, a system in which one or

more Tiny-Step driver cards have been installed for operation has to be evaluated as a whole

unit. Of course, when developing the circuitry for the Tiny-Step all possible aspects for an

EMC-suitable design have been taken into account.

Fitting with ComponentsFitting with Components

Fitting with ComponentsFitting with Components

Fitting with Components

- Start with the small components (resistors, diodes, capacitors, ...)

- Be careful to assemble with correct polarity (diodes, electrolytic capacitors, ...)

- The ICs should be mounted on sockets as a precaution.

- A heat sink is not necessary. The amplifier is cooled by a thermal ground pad on the board. In

use, depending on the environment, it may be necessary to use an additional fan for cooling.

If the casing is already well ventilated, it may not be necessary to use an additional fan, if the

board is mounted in the air-stream.

Initial OperationInitial Operation

Initial OperationInitial Operation

Initial Operation

- Before first use, the assembly and all solder points should be carefully checked! Are all ICs

mounted in the correct direction? All cables on the NCS-BUS and the solder points should be

checked for short circuits.

ostermann@mechapro.de • www.mechapro.de

Adress: Theaterplatz 6-8 • 52062 Aachen • Germany

Layout diagramLayout diagram

Layout diagramLayout diagram

Layout diagram

DimensionsDimensions

DimensionsDimensions

Dimensions

• The jumpers should be set to the default values as described below.

• Start with only the 5V logic supply (via NCS-BUS) - without applying power to the motors

and with no other connections (PC, Motors).

• Set the reference voltage for the Motor current with the R16 trimmer. The voltage can be

measured between the TEST pins. The measured voltage V(ref) depends on the motor

current (effective value) in the following way:

V(ref)=2*Squareroot(2)*Ieff(Motor)=2,83*I(Motor) equals the nominal value for the line

current. The peak current Ipeak is greater by the factor of Squareroot(2) - (max. 2,25A). For

1,5Aeff for example you would set the system to 4,24 volts.

• When all of this has been tested and verified, the board can be tested with a motor.

To do this, connect the board to the PC or microcontroller board. Always start up the PC first,

then start the software and then switch on the power supply for the board!

During boot up the power levels of some signal levels can change, that can cause undesired

reactions. For tests a free demo (for example PCNC) or a small self written program is

recommended.

If possible, start by applying a small voltage to the motor (15-20V), from a current limiting

power supply.

JP1: Step DividerJP1: Step Divider

JP1: Step DividerJP1: Step Divider

JP1: Step Divider

Jumper JP1.2 JP1.1

Full Steps closed closed

Half Steps open closed

1/4 Steps closed open

1/8 Steps open open

JP2: External rectificationJP2: External rectification

JP2: External rectificationJP2: External rectification

JP2: External rectification

The default setting (jumper set to 2-3) disables the „synchronous rectification“, and so

reduces power dissipation in the device. When no external diodes are used, change jumper

setting to 1-2. Caution: The maximum current of the board will be lowered in this

configuration!

External ConnectionsExternal Connections

External ConnectionsExternal Connections

External Connections

• The motor is connected to the screw connectors X1 (1. Coil) and X2 (2. Coil). The rotational

direction of the motor can be changed by reversing the polarity of one coil.

Center pins of unipolar motors (with 5 or 6 pins) are not connected. The pins must be

insulated and may not be connected to the positive supply or ground in any case!

Bipolar motors with 8 pins provide the possibility to connect two coil pairs in series or in

parallel. In series will always work. Connecting the coils in parallel may allow faster revolutions,

however the current is doubled as well (in comparison with the serial setup). The coil

resistance is halved in this case and the coil resistance should not be below 0.8 Ohms.

•To connect the board to the PC an interface board with a seperate connection for End-

point- and Emergency-Off-Switches is available. Alternatively an adapter cable can be used.

• When no interface board is used, pull all inputs of the board to VCC/+5V (or to ground) with

pullup resistors (10-47k).

Pinout of CON1 (NCS-BUS)Pinout of CON1 (NCS-BUS)

Pinout of CON1 (NCS-BUS)Pinout of CON1 (NCS-BUS)

Pinout of CON1 (NCS-BUS)

1not connected (n.c.)

2/Clock (Clock signal, falling edge generates a step)

3not connected (n.c.)

4/CCW (rotational direction, counterclockwise at low-level)

5/Emergency Off (at low-level)

6/Sleep (current reduction to 25% of the nominal current at low-level)

7,8 VCC (+5 Volts)

9,10 Ground

Meaning of LEDsMeaning of LEDs

Meaning of LEDsMeaning of LEDs

Meaning of LEDs

POWER: Turns on as soon as 5 Volts are applied to CON1

HOME: Lights up at every fourth full step position (Home position)

Hints for THints for T

Hints for THints for T

Hints for Troubleshootingroubleshooting

roubleshootingroubleshooting

roubleshooting

- If any part of the circuit does not work after first assembly, or when a failure occurs, find

and fix the error, before connecting or running a motor with the circuit! These additional hints

may be of help:

If these hints and the additional help at www.NC-Step.de don’t answer all your questions,

contact me for further help, by email. Please provide a detailed description of the problem

and your configuration. (Power supply, used Software a.s.o.) -> E-Mail: Ostermann@NC-

Step.de

Component List (without SMD-Parts)Component List (without SMD-Parts)

Component List (without SMD-Parts)Component List (without SMD-Parts)

Component List (without SMD-Parts)

Qty.Value Package Parts

81R R-EU_0207/10 R1, R2, R3, R4, R5, R6, R7, R8

8BYV27 BYV27 D1, D2, D3, D4, D5, D6, D7, D8

11K R-TRIMMT18 R16

1BC557B BC557B Q1

1lcLED yellow - home LED3MM LED1

1lcLED green - power LED3MM LED2

110µF/35V CPOL-EUE2.5-5 C10

1100µF/63V CPOL-EUE5-10.5 C11

1Pinh. 1*2 JP1E TEST

1Pinh. 1*3 JP2E JP2

1Pinh. 2*2 JP2QE JP1

1Connector-ML 10pol. ML10 CONTROL

2Pinhead 10pol.

3Screw Connector W237-02P X1, X2, X3

1DIL8 IC-Sockel

1DIL14 IC-Sockel

3Jumper

1TLV272IP TLV272IP IC3

174HCT14N 74HC14N IC1

0,5m ribbon cable 10pol.

Additional NotesAdditional Notes

Additional NotesAdditional Notes

Additional Notes

- A well stabilized motor voltage saves time and work, when searching for errors and reduces

noise levels. (Rule of thumb: 10.000µF for 3 motors (a lot helps a lot ;-)

- The 1 kOhm SMD resistors (R20, R21) should be adjusted according to the used LEDs if low

current LEDs are not used (Approximation: (5V - U_Diode)/I_Diode = R, e.g. (5V-1V) / 15mA =

270 Ohm).

notesnotes

notesnotes

notes

TT

TT

Technical Dataechnical Data

echnical Dataechnical Data

echnical Data

Power Supply (Logic): 5 Volts +/- 5%

Power Drain (Logic): typical 75mA, maximum 100mA

Power Supply (Power Element):15-35 Volts

Power Drain (Power Element): dependent on Power Supply Voltage, Motor current and

used Motor. Maximum Continuous Current: 2 Amperes.

Control: Clock- and Direction signals, CMOS-compatible.

Step Resolution: Full-, Half-, 1/4th and 1/8th-Steps

Outputs: 1 stepping motor channel up to 1.6/2.25A (effective/peak)

per coil, not short circuit protected

Popular Carrier Board manuals by other brands

Diamond Systems

Diamond Systems Jackson JAX-BB01 user manual

ICM Controls

ICM Controls ICM2920 Installation, operation & application guide

IBM

IBM Power System 5105-22E manual

Arbor Technology

Arbor Technology PBN-9007 Quick installation guide

Seco

Seco COM-Express CCOMe-C79 user manual

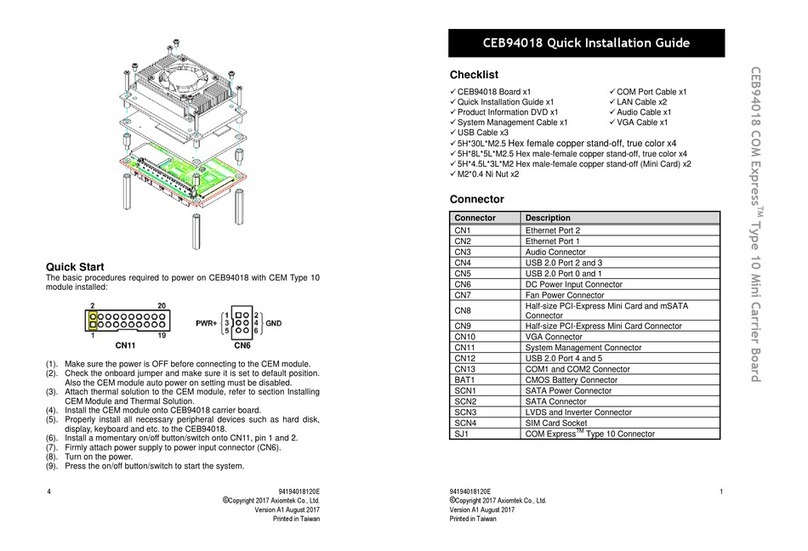

AXIOMTEK

AXIOMTEK CEB94018 Quick installation guide