MECNOSUD PowerRoll DL Series User manual

ROLLING MACHINE DL SERIES

OPERATING MANUAL

SUMMARY

CHAPTER 1 GENERAL INFORMATION ................................................................................ 20

CHAPTER 2 INSTALLATION................................................................................................. 25

CHAPTER 3 FUNCTIONING ................................................................................................. 27

CHAPTER 4 USAGE ............................................................................................................. 28

CHAPTER 5 MAINTENANCE .............................................................................................. 30

CHAPTER 6 AFTER SALE SERVICE ...................................................................................... 32

19

ENGLISH

Introduction

This manual as ritten by the Manufacturer in order to give all useful information for a correct installation,

use and maintenance of the machine, ith extreme caution to avoid risks for the operator during the utilization.

It is very important to keep this manual, an integral part of the machine, in good condition and in an accessible place

for all operators. The Manufacturer reserves the right to modify at any moment the product or the contents

of this manual ithout any notice.

Please be advise on the follo ing symbols to better evidence some passages:

WARNING indicates hazards for hich attention is required.

INFORMATION indicates particularly important technical information.

20

ROLLING MACHINE - DL SERIES Operating manual Edition 08-08

CHAPTER 1 GENERAL INFORMA ION

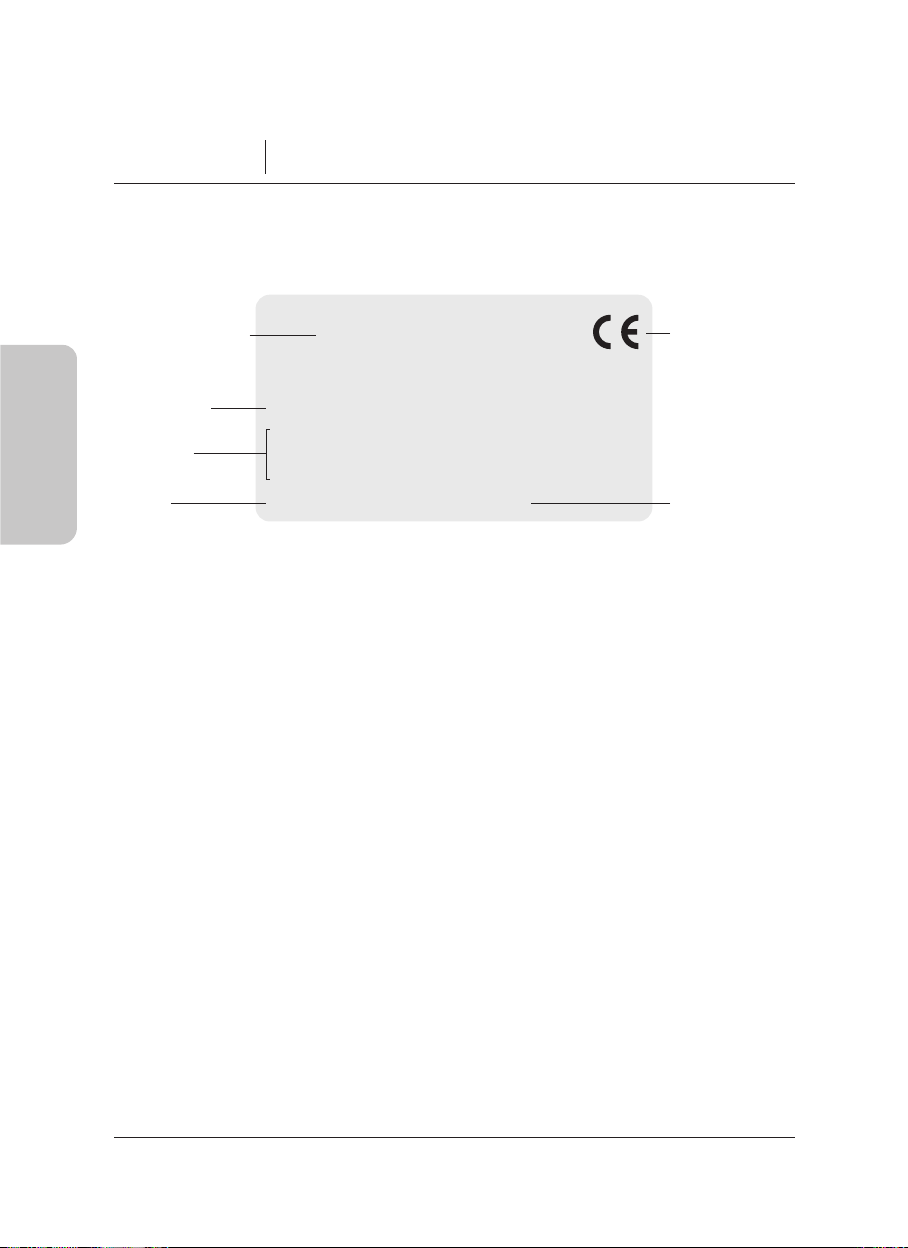

1.1 Identification Manufacturer and machine

ENGLISH

Identification manufacturer

echnical Data

Serial No.

Conformity Mark

Year of construction

Mod.

Hp.

V.

Matr.

Kw.

A.

Hz.

Peso Kg.

Anno

Model of machine

1.2 Warranty

Guaranteed for two years from date of invoice or purchase ticket. Parts of the machine found to

be a production defect (except electrical components or parts worn out), will be changed or serviced

free by us in our establishments but only ex our factory, within this period.

Delivery expenses and costs of labour are excluded from the warranty.

he warranty will not be valid when the damage is due to : transportation, mistaken or insufficient

maintenance, unskilled operators, damaging, repairs made by unauthorized personnel, non-

observance of the instructions of the manual. All reimbursements from the manufacturer are

excluded for direct and indirect damages caused in the time the machine is inactive for the following

reasons: breakdown, waiting to be repaired or anyway the non-presence of the machine.

The machine is ideal for rolling pizza dough, flat

loaves, buns etc. into a round pie (Mod. DL 30 -

DL 30M - DL 0) or rectangular (DL 0P).

machine is composed of :

· Two pairs of regulating rollers to obtain the

thickness and diameters required;

· Separate safety covers for rollers;

· Gear box realized with special high

resistance resins;

· Digital control panel;

· Frame totally in stainless steel for an easy cleanliness;

· Electric system and safety devices are conform to European regulations.

The range is composed by the following models:

DL 30 Ideal for round pie pizza dough. Max diameter: 300 mm.

DL 30M Ideal for sheet of dough and round pie pizza dough. Max diameter: 300 mm.

DL 40 Ideal for round pie pizza dough. Max diameter: 00 mm.

DL 40P Ideal for sheet of dough. Max width: 00 mm.

Chapter 1

21

ENGLISH

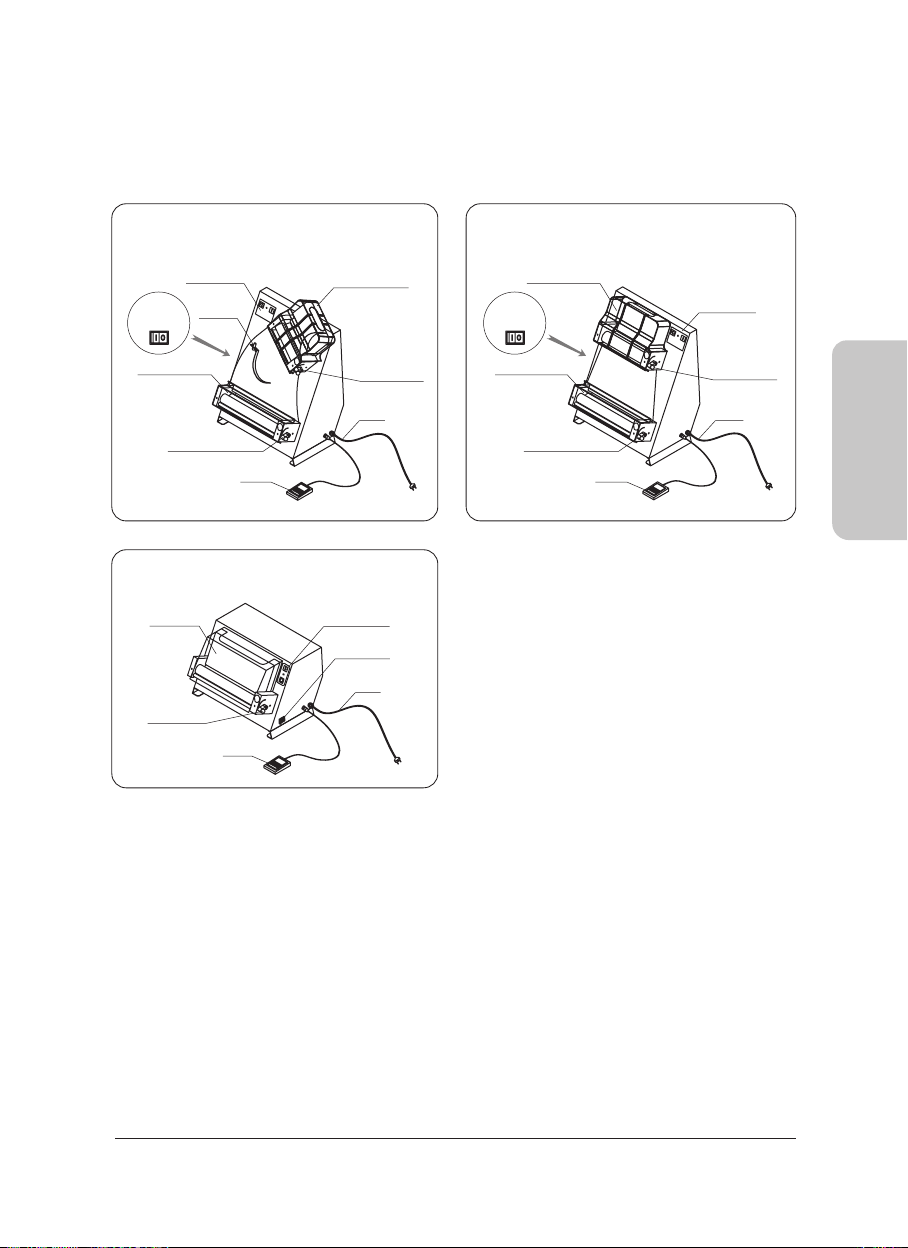

1.3 Description and specifications of the machine

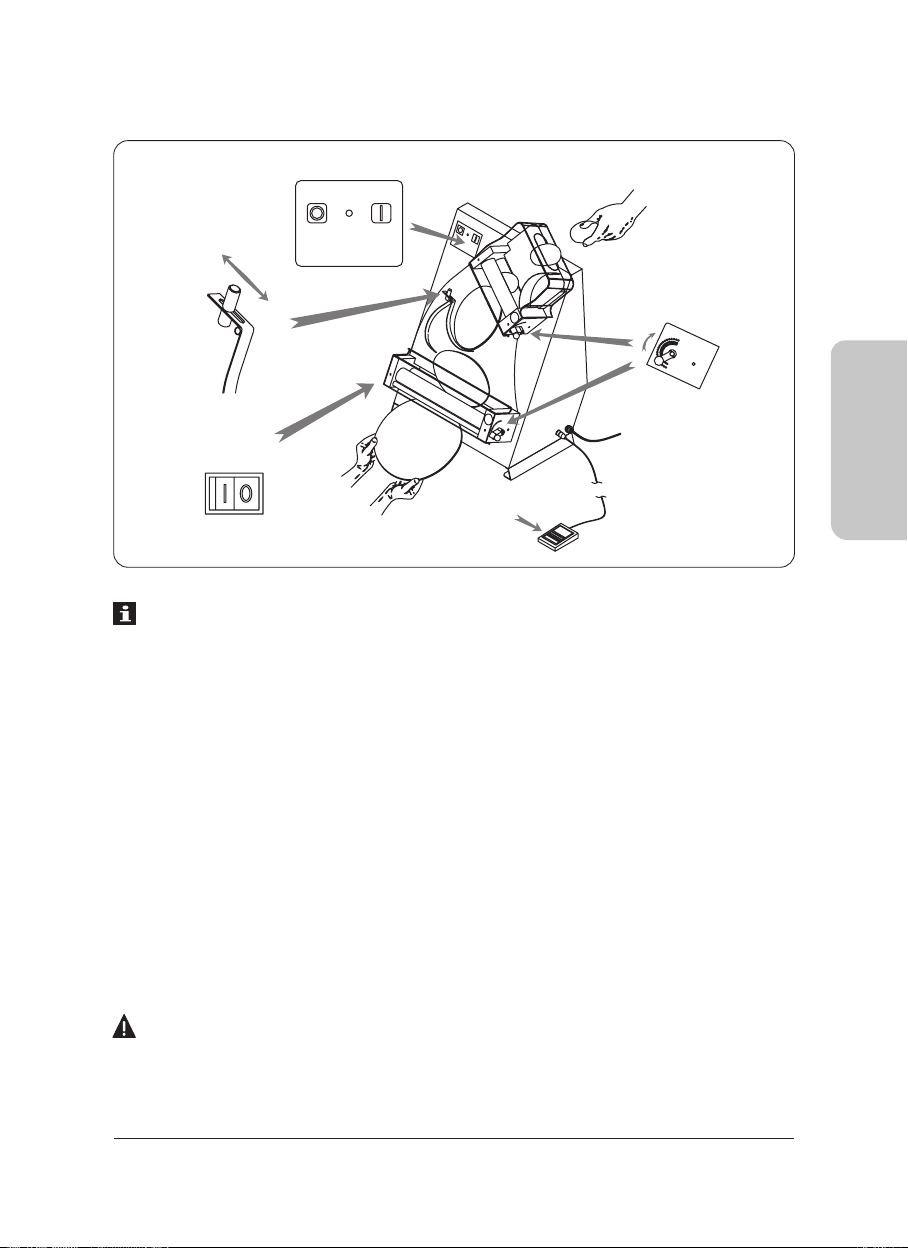

PICT. 1

MOD. DL 30 - DL 40

Roller protection

Control panel

Roller protection

Balance

Cable

Roller

distance regulator

Roller distance

regulator

Pedal

Main

switch

MOD. DL 40P

Control panel

Roller protection

Roller protection

Cable

Roller

distance regulator

Pedal

Main

switch

Roller distance

regulator

Control panel

Main switch

Cable

Roller

protection

Roller

distance

regulator

Pedal

MOD. DL 30M

22

ROLLING MACHINE - DL SERIES Operating manual Edition 08-08

ENGLISH

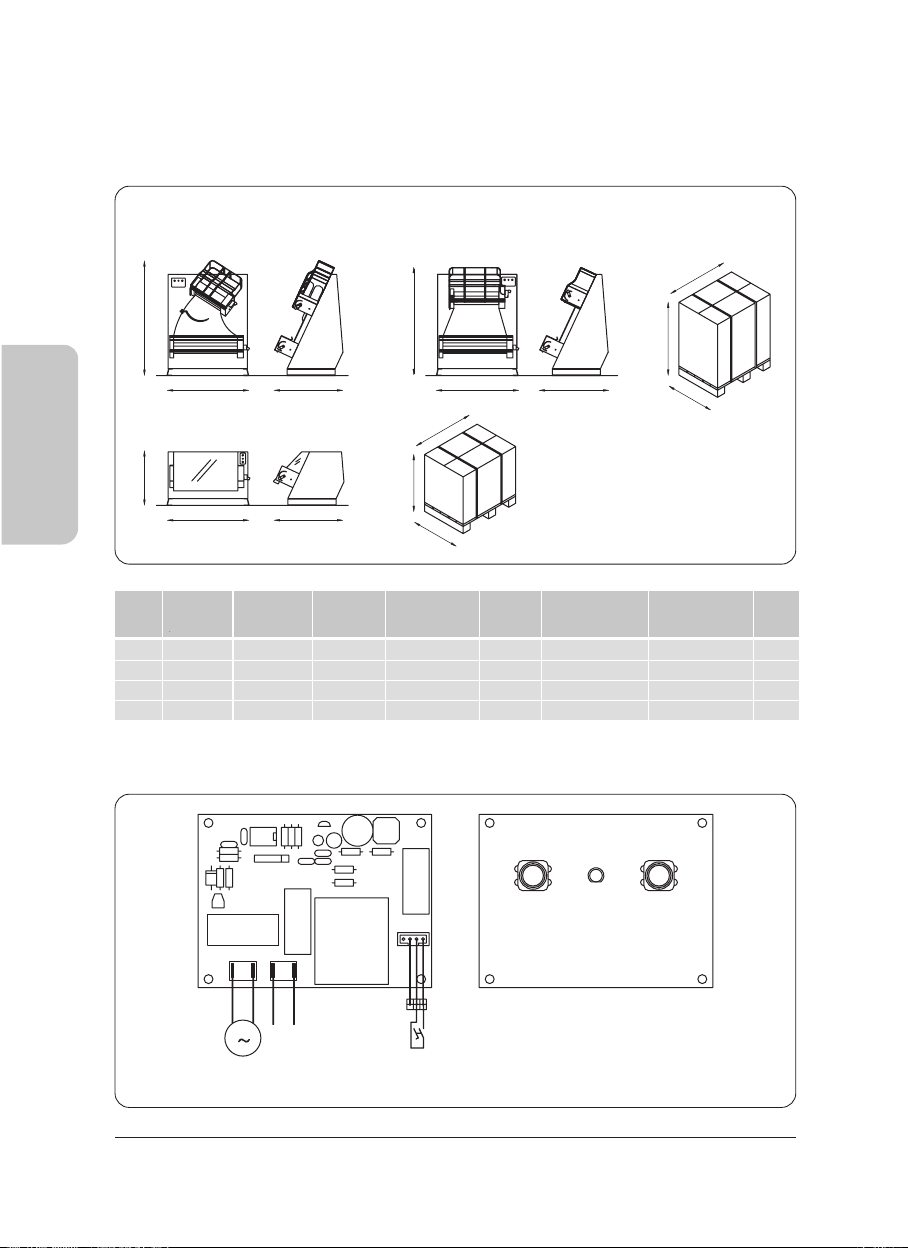

1.5 Electrical Diagram

1.4 Technical specifications

DL 30

Model

DL 0

DL 0P

Dough weight

80/210

Gr

80/ 00

100/700

Pizza diametre

1 /30

Cm

1 / 0

1 / 0

Motor power

0,5

Hp

0,5

0,5

230/50/1

Volt

230/50/1

230/50/1

Pack dimensions

510 x 75 x 675 mm

A C B

620 x 75 x 830 mm

620 x 75 x 830 mm

Weight

35

Kg

5

5

Absorbed power

375

W

375

375

20 x 50 x 650 mm

Dimensions

520 x 50 x 712 mm

520 x 50 x 750 mm

A C B

DL 30 - DL 40 DL 40P

AC

B

AC

B

B

C

A

PICT. 2

T1

F5A

12VDC

UVN

L

230V/12V

2VA

F5A

LINE

MOTOR

230V

M

3

STARTSTOP LINE

LV

PEDAL

AC

B

B

C

A

DL 30

PICT. 3

DL 30M 80/210 1 /30 0,5 230/50/1 510 x 75 x 375 mm 26375 20 x 50 x 350 mm

Chapter 1

23

ENGLISH

1.6 Operating area

In order to have the best exploitation of the potentiality of the machine, the operator need the

area represented in PICT. 4.

PICT. 4

mt 1

mt 2

1.7 General security indications

Althou h the machine is built in conformity to the required security rules re ardin electrical,

mechanical, and hy ienic re ulations it can be dan erous in followin cases:

· Used in cases and conditions different to those described by the manufacturer.

· Modifications of the protections and/or safety devices.

· Inattention to the instructions of: installation, functionin , usa e, maintenance.

IN ORMATION

All operations for installation and maintenance have to be done by qualified personnel

authorized by the manufacturer who is not responsible for any mistaken installation or

manumission.

24

ROLLING MACHINE - DL SERIES Operating manual Edition 08-08

ENGLISH

1.8 Security indications

INFORMATION

Carefully read this anual before installation and using the achine.

WARNING

To avoid dangerous conditions and/or possible injuries caused by: electric current, echanical

parts, fire or hygiene proble s, you ust follow the safety warnings step by step:

· Keep in order your working area.

· Do not use the achine in hu id, wet or badly lit environ ents.

· Keep the children and/or non authorized personnel away

fro the achine when functioning.

· Do not anu it for any reason the safety devices

· Do not re ove the protection covers when functioning.

· Only utilize the achine with the correct voltage: an i proper use is dangerous.

· Do not put hands or objects through dangerous parts.

· Dress with adequate clothes, in accordance to the regulations against all risks.

· Protect the cable. (Do not use extension cables).

· Disconnect the plug fro the current point when the in achine

is not functioning or before operations of aintenance or oving.

· Cleaning of the parts in contact with dough ust always be carried out

when the achine is off and disconnected. (Do not use high pressured water).

· Do not operate or anu it the achine if alfunctioning,

and contact the qualified personnel only.

Chapter 2

24

ENGLISH

2.1 Instructions for the user

The environment in which the machine must be installed must have the following characteristic:

· Be dry

· Water and heat sources at safe distance

· Adequate ventilation and lighting (corresponding to hygiene and security

rules following the e isting laws.

The surface must be horizontal and smooth for the best cleanliness.

INFORMATION

The electric net must be provided ith an automatic differential s itch and this has to

be suitable to the machine. It is particularly important to have a good ground system and

that the electric tension and the frequency of the system correspond ith the numbers

of the technical specifications described on the small plate at the back of the machine.

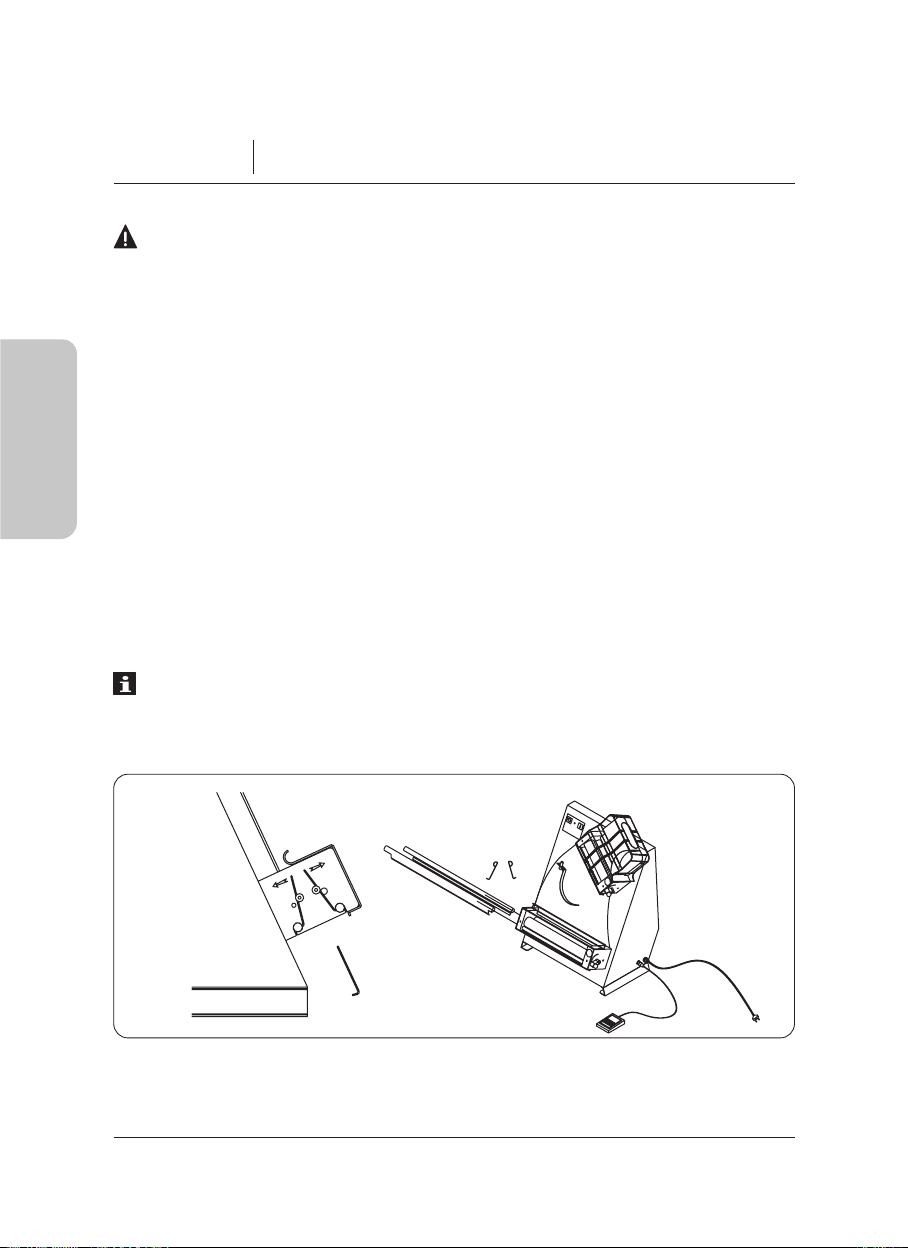

2.2 Installation methods

The machine is supplied in a closed package on wood pallet. Inside the package, in addition to

the machine, there are the protection covers for the rollers with a tool for assembling, the instruction

book and the declaration of conformity according to the directives of the machine.

The machine must be unloaded lifting it with an adequate equipment.

Use a trolley with wheels, to move the machine to the installing area.

Take out the machine from the package by adequate belts under the machine, take off the pallet,

and position the machine in the corresponding location, leaving a space of 50 cm. all around for

the usage, cleanliness and maintenance of the machine.

Assemble the protection covers with the included screws (PICT. 5).

WARNING

Before using the machine obligatory apply the protection covers supplied inside the

package. The manufacturer declines all responsibility for damages caused to things or

persons if these instructions are not follo ed.

CHAPTER 2 INSTALLATION

26

ROLLING MACHINE - DL SERIES Operating manual Edition 08-08

2.3 Electrical connections

T e connection of t e mac ine to t e electrical network is made t roug a cable provided wit a plug.

2.4 Positioning of the machine

T e plug must be accessible, does not ave to require any kind of movement. T e cable from t e

mac ine to t e wall plug must not be pulled tig tly, also do not rest t e mac ine on t e cable.

ENGLISH

PICT. 5

Chapter 3

27

ENGLISH

3.1 Control devices (PICT. 6)

A) Main Switch 0 - 1

B) Green button (START)

C) Red button O (STOP)

D) Line signalling

CHAPTER 3 FUNCTIONING

STARTSTOP LINE

CBD

A

P CT. 6

3.2 Functional verification

· Connect the achine to the current point inserting the line cord into the socket.

· Turn on the ain switch (A) (PICT. 6) on position (1). The line signalling (D) will light up.

· Press the green button START (B) to turn on the achine (PICT. 6).

· Press the red button STOP (C) to turn off the achine (PICT. 6).

· Start the achine without using it, let it run for a few inutes

and ake sure it is functioning perfectly.

28

ROLLING MACHINE - DL SERIES Operating manual Edition 08-08

ENGLISH

Be ore every work-cycle always make sure the machine is per ectly clean. I necessary clean the

machine ollowing point 5.1.

4.1 Usage of the machine

· Use the speci ic levers to adjust thickness on both roller units.

· The upper rollers must be adjusted to a airly wide opening while the lower rollers must have

an opening as wide as the required thickness (run a ew tests to correctly per orm this operation).

· Adjust the position o the scale counter-weight according to the size and weight o the dough

to be rolled (run a ew tests to correctly per orm this operation).

·

Make sure the roller blades are in the correct position and their springs are well-tensioned (PICT. 8).

CHAPTER 4 USAGE

START

STOP

LINE

Control panel

Dough

thickness

regulation

Main

switch

Pedal

·Turn on the main switch (PICT. 7)

on position (1).

· Press the green button START (PICT. 7)

or press down the pedal control

(optional), to turn on the machine.

· Introduce the small ball o dough made

with lour and le t to rise or at least 5

hours, through the opening o the

highest cover (PICT. 7). It is

recommended to squash the sides

slightly so the ball o dough can easily

go through the highest rollers.

·When inished, stop the machine

pressing the button STOP (PICT. 7)

· At the end o the work-cycle, disconnect

the power supply turning the main

switch (PICT. 7) on position (0).

PICT. 7

Chapter 4

29

ENGLISH

4.3 Pedal control (Optional)

· When the machine is off, insert the pedal control plug in the socket on the side of the appliance.

· Press the start button to power the pedal.

· Start the machine pressing down on the pedal control. Release the pedal to stop the machine.

· The machine will restart each time the pedal is pressed down.

· When finished, turn off the pedal control by pressing the stop button.

WARNING

To prevent the appliance rom accidentally restarting, always turn o the pedal by pressing

the stop button. Only remove the pedal plug rom the socket a ter pressing the stop button.

INFORMATION

Do not insert balls o dough that are more heavy provided than the weight or each

machine. (see technical speci ications pag. 22)

4.2 Recommendations or use

lways use the machine with a wide opening between the upper rollers to prevent excessively

straining the transmission components.

ST RTSTOP LINE

Control panel

Balance

regulation

Dough thickness

regulation

Pedal

Main

switch

30

ROLLING MACHINE - DL SERIES Operating manual Edition 08-08

ENGLISH

WARNING

Before doing any kind of maintenance or cleaning you must take out the plug. In any

case of malfunctioning or damages of the machine you must apply for authorized

assistance from the manufacturer.

.1 Cleaning

· Remove t e plug from t e electrical socket.

· Accurately clean using neutral products.

· Clean external mac ine parts wit a damp sponge.

· Do not use metallic pads and abrasive detergents.

.2 Roller blade cleaning

· Un ook t e springs on t e lower rollers by pus ing t em outwards (PICT. 8).

· Rotate t e pins inwards and clean t e roller blades wit a damp clot .

· To return t e roller blades to t eir initially position, follow t e above directions in reverse order.

INFORMATION

Before each work cycle make sure the roller blades are correctly fastened (PICT. 8).

CHAPTER MAINTENANCE - TROUBLE SHOOTING - DEMOLITION

PICT. 8

Chapter 5

31

ENGLISH

5.3 Extended periods of disuse

Extended periods of disuse, turn off the main wall switch, clean the machine and cover it with a

cloth to protect it from dust.

5.4. Possible anomalies and breakdown

In the event of breakdown or malfunctioning, turn off the wall fuse and contact your dealers

service center. void dismantling internal machine parts. The manufacturer is not liable for any

machine tampering.

PROBLEM AUSE SOLUTION

The machine does not start

·

Main switch off

·

No voltage

on the power supply

·

Safety fuse burnt out

·

Transmission parts broken

·

Turn on the main switch

on position I

·

Contact your dealers

service center

·

Contact your dealers

service center

·

Contact your dealers

service center

Rollers malfunctioning

5.5 Disposal and recycling

The machine was designed and constructed to work for an average of 10.000 hours.

When finished using the machine, follow national laws for disposal and recycling.

32

ROLLING MACHINE - DL SERIES Operating manual Edition 08-08

ENGLISH

6.1 Spare parts

For a demand o spare parts, indicate the numbers on the small plate on positioned on the back

side o the machine (Model, year o construction, etc.) and the number corresponding to the part

on the drawings PICT. 9-10-11.

WARNING

Original spare parts are recommended.

CHAP ER 6 AFTER SALE SERVICE

This manual suits for next models

4

Other MECNOSUD Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use