MECNOSUD IM 5-8 Instruction Manual

IMPASTATRICE A SPIRALE SERIE IM

MANUALE DUSO E MANUTENZIONE

SPIRAL MIXER

MODEL IM

Operating manual

GB

SPIRALTEIGKNETMASCHINE

MODELL IM

Bedienungsanleitung

D

PÉTRIN À SPIRALE

MODÈLE IM

Manuel dutilisati n

F

SUMMARY

CHAPTER 1 GENERAL INFORMATION................................................................................ 24

CHAPTER 2 INSTALLATION................................................................................................. 31

CHAPTER 3 FUNCTIONING.................................................................................................. 33

CHAPTER 4 USAGE ............................................................................................................. 36

CHAPTER 5 MAINTENANCE ............................................................................................... 39

CHAPTER 6 DEMOLITION OF THE MACHINE...................................................................... 41

CHAPTER 7 AFTER SALE SERVICE ...................................................................................... 42

23

ENGLISH

Prefix

This man al is specifically for the installation, se and maintenance of spiral mixers. So yo are able to se the prod ct

in the best way. It is important that the man al is kept in good condition and sho ld stay with the machine at alltimes,

incl ding sale to another person, for sec rity in the se of the machine.

The man fact rer is not nder any obligation to notify of any f rther modification of the prod ct.

All rights of this doc ment are reserved and no alternation or reprod ctions can be made witho t permission of the

man fact rer.

The following symbols are incl ted to better stress some passages:

WARNING:

indi ates hazards that may ause serious damages; attention is required.

INFORMATION:

indi ates parti ularly important te hni al information.

24

SPIRAL MIXER - IM SERIES Operating manual

CHAPTER 1 GENERAL INFORMATION

1.1 Warranty

Guaranteed for 2 ears from date of purchase. The date must be stamped on the guarantee on

the date of purchase. Parts of the machine found to be a production defect exept electrical

components or parts worn out, will be changed and serviced free b us in our firm but onl ex our

factor within this period. Deliver expences and costs of labour are excluded from the warrant .

The warrant will not be valid when the damage is due to: transportation, mistaken or insufficient

maintenance, unskilled operators, damaging, repairs made b unauthorized personnel, non-

observance of the instructions of the manual.

All reimbursements from the manufacturer are excluded for direct or indirect damages caused in

the time the machine is inactive for the following reasons: breakdown, waiting to be repaired, or

an wa the nonpresence of the machine.

1.2 Characteristics of the machine

The mixers in the models with fixed top and bowl or with raising top and removable bowl were

made with the intention for food usage onl , to mix doughs made b cereal flours, for the prevalent

use in: pizza-restaurant, bread and baker shops.

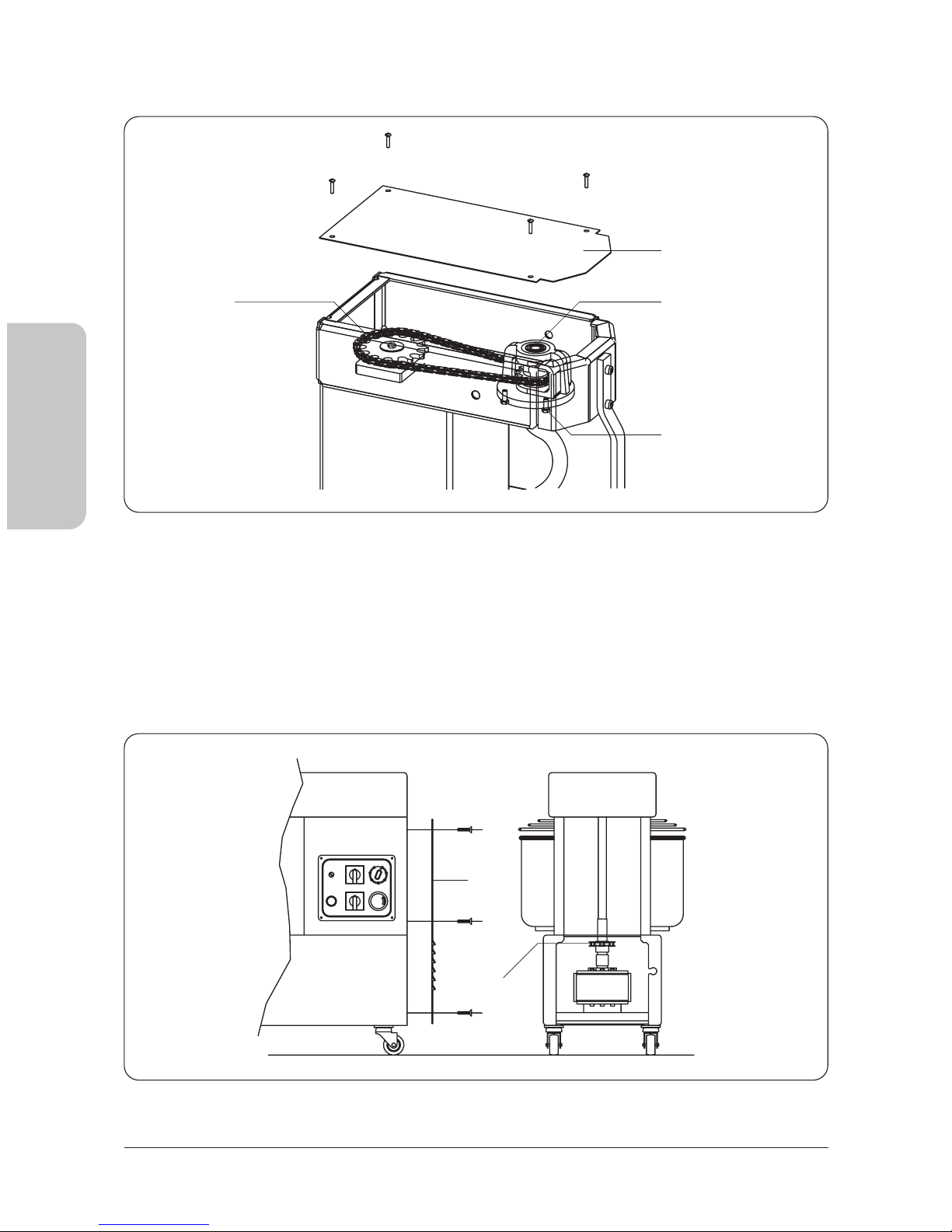

Ever mixer (PICT. 1) is composed of:

· A steel structure protected b a heat resistant varnish.

· The bowl, the spiral, the central doughbreaker and the protection grate are all in stainless steel.

· Chain drive with oilbath gearmotor.

· The moving parts are on ball bearing.

· T pe feet (from models IM 5 and IM 8), set of wheels (for models from IM 12 to IM 44), t pe feet

in stainless steel and wheels in n lon (for IM 60)

· Operation with single-phase or threephase motor, one speed; on request: threephase motor with

two speeds and timer (apart from models IM 5 and IM 8).

· Electric circuit fed b a cable to the network to which are connected at low tension (24V) the

control devices to start, to stop, and of the safet devices. Among these l'internal blocking of the

moving parts activated b the movement of the mobile protection of the pan.

ENGLISH

25

ENGLISH

PICT. 1

IM 5; IM 8

B

AC

IM 12; IM 18; IM 25; IM 38; IM 44

B

AC

IM 12A; IM 18A; IM 25A;

IM 38A; IM 44A

AC

B

26

SPIRAL MIXER - IM SERIES Operating manual

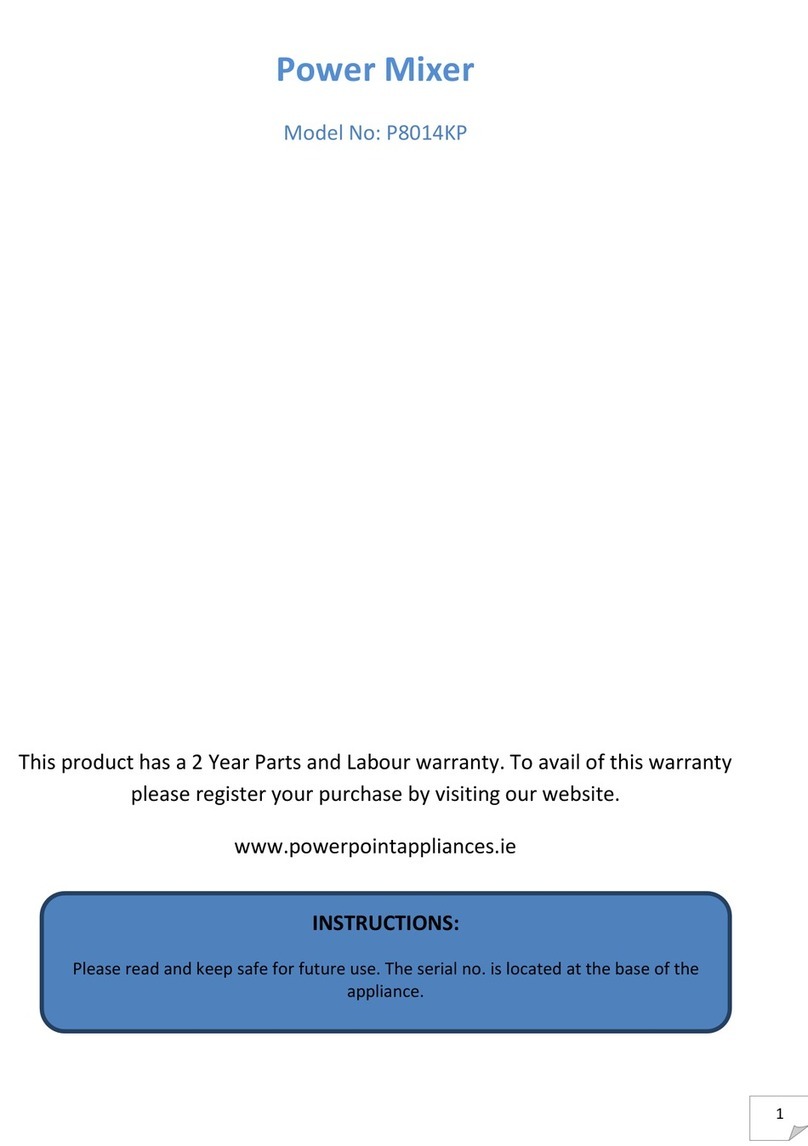

1.3 Technical characteristics

ENGLISH

LIFTABLE HEAD AND EXTRACTIBLE STEEL BOWL

g g Lt w A C B g

FIXED HEAD AND FIXED STEEL BOWL

mm

IM 5M

IM 5T

IM 8M

IM 8T

IM 12M

IM 12T

IM 12D

IM 18M

IM 18T

IM 18D

IM 25M

IM 25T

IM 25D

IM 38M

IM 38T

IM 38D

IM 44M

IM 44T

IM 44D

IM 60M

IM 60T

IM 60D

IM 12AM

IM 12AT

IM 12AD

IM 18AM

IM 18AT

IM 18AD

IM 25AM

IM 25AT

IM 25AD

IM 38AM

IM 38AT

IM 38AD

IM 44AM

IM 44AT

IM 44AD

5

5

8

8

12

12

12

18

18

18

25

25

25

38

38

38

44

44

44

60

60

60

12

12

12

18

18

18

25

25

25

38

38

38

44

44

44

3

3

5

5

8

8

8

12

12

12

17

17

17

25

25

25

30

30

30

40

40

40

8

8

8

12

12

12

17

17

17

25

25

25

30

30

30

7

7

10

10

15

15

15

20

20

20

33

33

33

40

40

40

50

50

50

75

75

75

15

15

15

20

20

20

33

33

33

40

40

40

50

50

50

0,37

0,37

0,37

0,37

0,9

0,75

0,6/0,8

0,9

0,75

0,6/0,8

1,1

1,1

1/1,4

1,5

1,5

1,5/2,2

1,5

1,5

1,5/2,2

2,6

2,6

2,6/3,4

0,9

0,75

0,6/0,8

0,9

0,75

0,6/0,8

1,1

1,1

1/1,4

1,5

1,5

1,5/2,2

1,5

1,5

1,5/2,2

230/50

400/50/3

230/50

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

230/50

400/50/3

400/50/3

540 x 260 x 527

540 x 260 x 527

550 x 280 x 555

550 x 280 x 555

675 x 350 x 690

675 x 350 x 690

675 x 350 x 690

697 x 390 x 690

697 x 390 x 690

697 x 390 x 690

762 x 430 x 770

762 x 430 x 770

762 x 430 x 770

818 x 480 x 770

818 x 480 x 770

818 x 480 x 770

842 x 530 x 770

842 x 530 x 770

842 x 530 x 770

1020 x 575 x 1010

1020 x 575 x 1010

1020 x 575 x 1010

690 x 350 x 690

690 x 350 x 690

690 x 350 x 690

715 x 390 x 690

715 x 390 x 690

715 x 390 x 690

780 x 430 x 770

780 x 430 x 770

780 x 430 x 770

838 x 480 x 770

838 x 480 x 770

838 x 480 x 770

878 x 530 x 770

878 x 530 x 770

878 x 530 x 770

33

33

36

36

60

60

60

65

65

65

95

95

95

105

105

105

110

110

110

250

250

250

80

80

80

85

85

85

115

115

115

130

130

130

140

140

140

237 x 160

237 x 160

260 x 200

260 x 200

317 x 210

317 x 210

317 x 210

360 x 210

360 x 210

360 x 210

400 x 260

400 x 260

400 x 260

452 x 260

452 x 260

452 x 260

500 x 270

500 x 270

500 x 270

550 x 370

550 x 370

550 x 370

317 x 210

317 x 210

317 x 210

360 x 210

360 x 210

360 x 210

400 x 260

400 x 260

400 x 260

452 x 260

452 x 260

452 x 260

500 x 270

500 x 270

500 x 270

M= Monophase Motor T= Threephase Motor D= Threephase Motor 2 speeds

Model neading capacity Flour capacity Bowl volume Motor power Volt Dimensions mm WeightBowl dimension

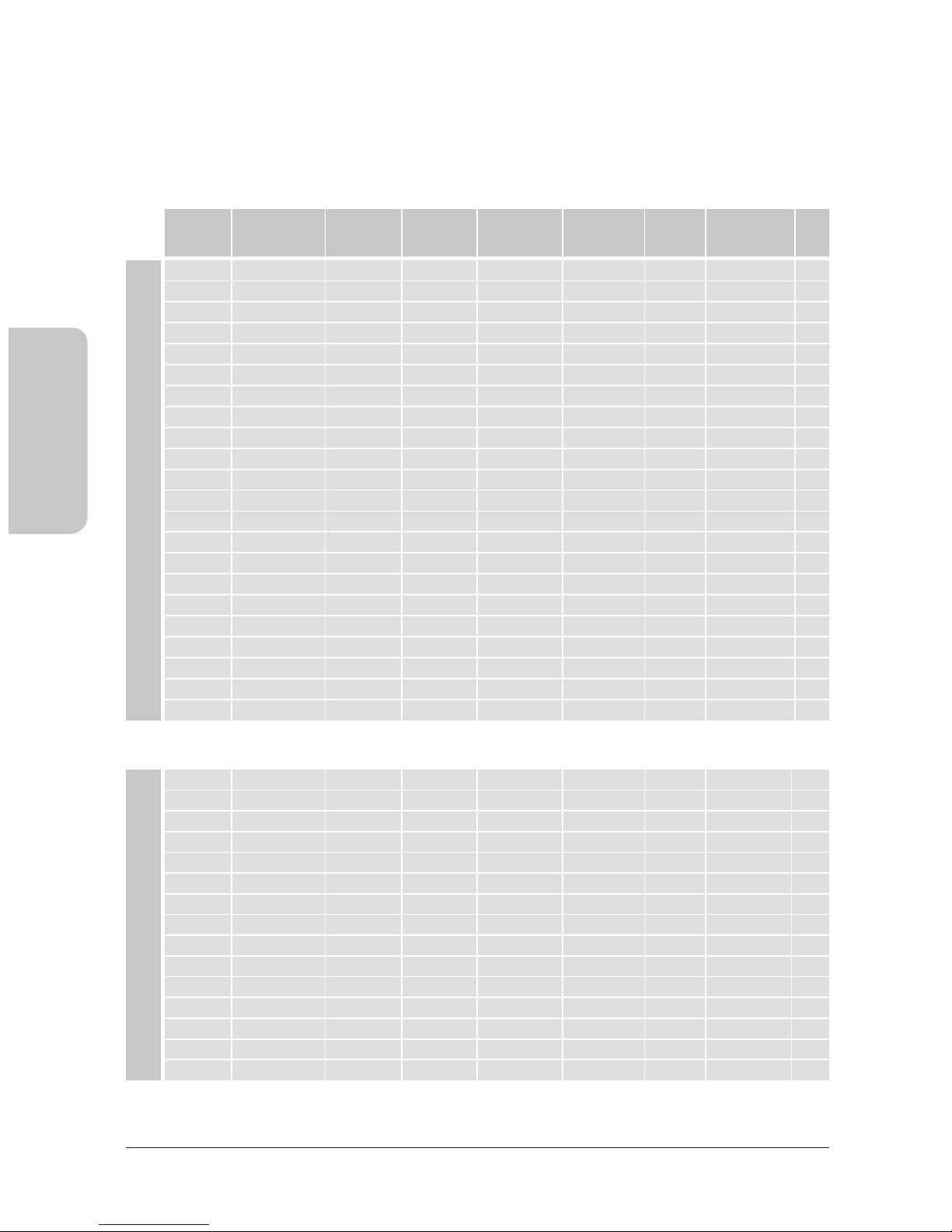

1.4 Electrical schemes

27

ENGLISH

SINGLE-PHASE CONNECTION IM 5- M

TM

N

L

F500mA

F

TM

2,5VA

START

RL1

1

M

RP1 RP2

+

-

B

Led

C

MC1

START

RL1 RP1 RP2

+

-

1

M

UV

L

1

L

2

LINE

GND

BRL2

STOP

CLED

RP1

RP2

F500mA

RL2

STOP

R2

MC2

SINGLE-PHASE CONNECTION IM 12-1 -25-3 -44 M

L

N

Q15

L2 L3

LINE

123

T1618M

1-

1-

PE

F500mA

M15

1

MC

T

14 9

PT

8 7 10 11

F17

START-

12

13

PE

N

L

Q15

1

M15

18M

L

N

1

3 2

230V

F500mA

F17

T16

8VA

24V

(14)

(13)

PT

(12)

(11)

T

MC (10)

(7)

STOP

START

(8)

13

14

18M

(9)

A1

A2

18M

28

SPIRAL MIXER - IM SERIES Operating manual

ENGLISH

THREE-PHASE CONNECTION IM 12-18-25-38-44-60 T

PE

L1

A2

K18M

A1

(9)

K18M

14

1

(1 )

(11)

(12)

(10)

(7)

(8)

START

STOP

MC

T

PT

(14)

F500mA

F17

MC

24V

8VA

T16

2 0V/400V

2

1

K18M

L1

PE

Q15

M15

K18M T16

1

12

START-

F17

111078

PT

914

T

M15

F500mA

1-

1- 21

LINE

LL2

Q15

L2

L

L1

L2

L L

L2

L1

THREE-PHASE CONNECTION 2 VEL. IM 12-18-25-38-44-60 D

2 0V/40

L1

L2

LL

L2

L1

L1

L1

L2

L

PE

LINE

Q15

L2 L 12

1-

1-

F500mA

M15

T

14 9

PT

8 7 10 11

F17

START-

12

1

T16K18M

Q15

PE

K18M

1

2

T16

8VA

24V

MC

F17

F500mA

(14)

PT

T

MC

STOP

START

(8)

(7)

(10)

(12)

(11)

(1 )

1

14

K18M

(9)

A1

K18M

A2

COMM

M15

COMM

29

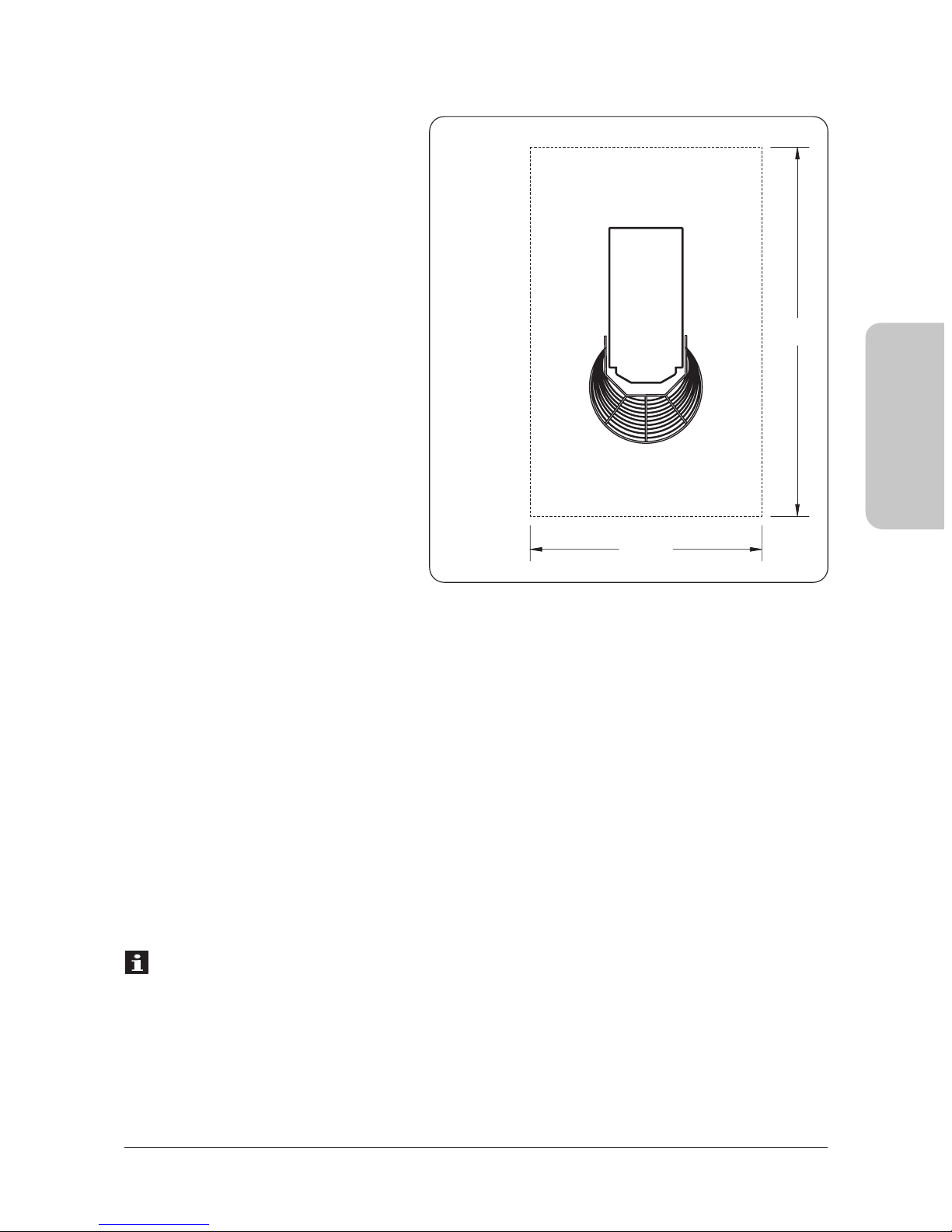

1.5 Operating area

In normal working conditions and to have the best exploration of the potentiality of the machine,

the operator needs the area represented in PICT. 2.

1.6 Security indications

Altho gh the machine is b ilt in conformity to the req ired sec rity r les regarding electrical,

mechanical and hygienic reg lation it can be dangero s if:

· Used in case and condition different to those described by the man fact rer.

· Manomission of the protection and of the safety devices.

· Innattention to the instr ction of: Installation - F nctioning - Usage - Maintenence.

INFORMATIONS

Insta ation and maintenence have to be done by qua ified personne authorized by the

manufacturer who is not responsab e for any mistaken insta ation or manomission.

ENGLISH

E ectrica schemes

SINGLE-PHASE

AND THREE-PHASE CONNECTION

IG = General switch

T16 = Transformer

F17 = F se

PT = Thermoproction of the engine

FC = Safety photocell

MC = Safety limit switch

STOP = Stop b tton

START = Operating b tton

K18M = Contactor

LI = Operating light

M = Engine

PICT. 2

mt 1,5

mt 2

30

SPIRAL MIXER - IM SERIES Operating manual

ENGLISH

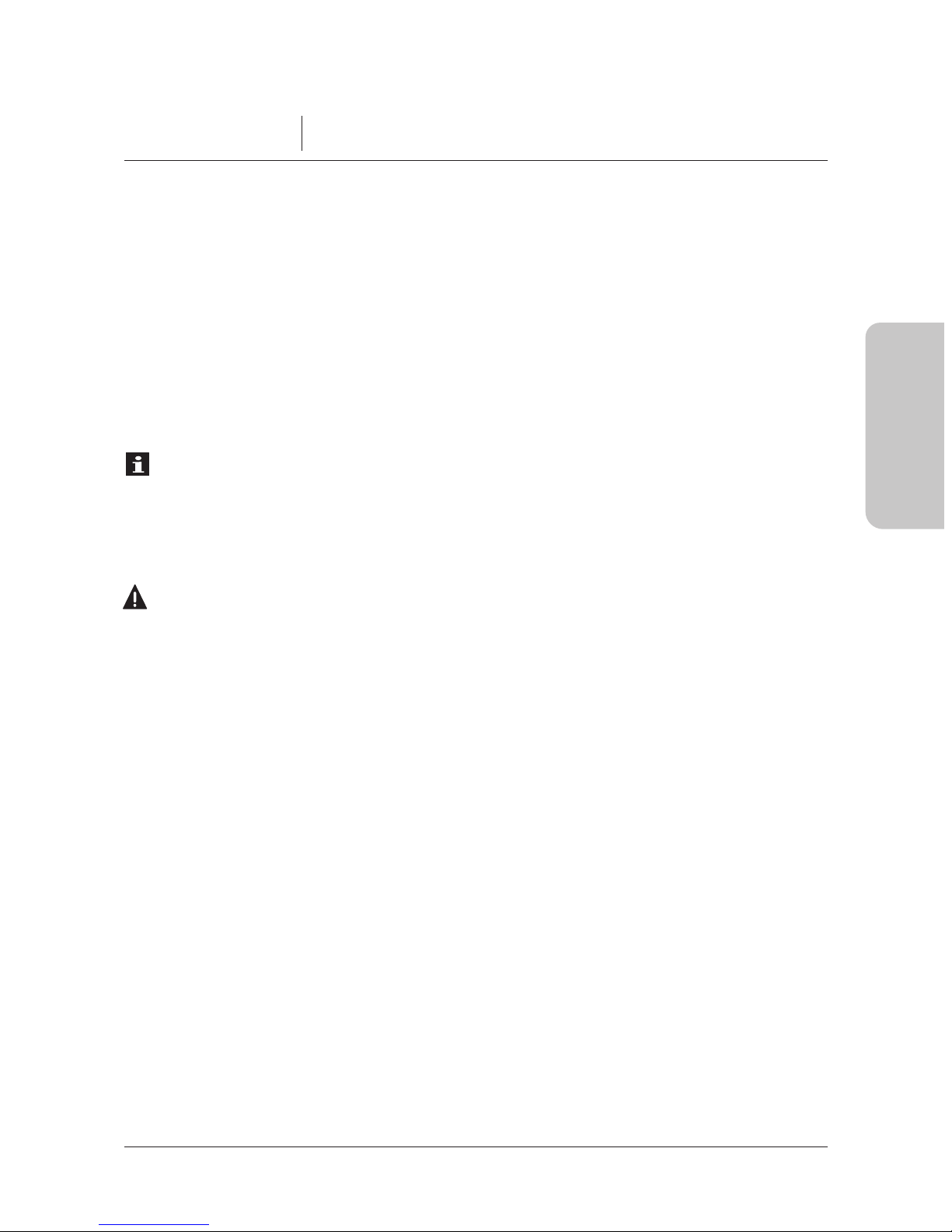

1.7 Security indications

INFORMATION

Carefully read the instruction efore using the machine.

WARNING

The avoid dangerous condition and/or possi le injuries caused from: electric current, mechanical

parts, fire or hygienical pro lems, you must follow the security indications step y step.

A) Keep in order your working area. Disorder can cause dangerous accidents.

B) Consider environmental conditions. Do not use the machine in humid, wet or nadly

lit environments, close to inflama le liquids or gas.

C) Keep away from children and non authorized personnel. Do not permit them to go

near the machine or the working area.

D) Only utilize the machine with the correct voltage. Normal usage gives etter results.

E) Dress in adequate way. Do not wear hanging clothes or any items which can e caught

in the machine. Use non-slip shoes. For hygiene and safety keep your hair tied ack and

wear protective gloves.

F) Protect the ca le. Do not pull the ca le to extract the plug. Do not leave the ca le

near high temperatures, sharp o jects, water or solvents.

G) Avoid insecure positions. Find the est surface to ensure the machine is alanced.

F) Always pay maximum attention. Do not e distracted when using the machine.

I) Take the plug out. When the machine is not in use, efore cleaning, maintenance

and moving it.

L) Do not use further extensions.

M) Check that the machine is not damaged. Before using the machine carefully check

that all security devices are working. Check that: the mo ile parts are not locked,

there are not any parts damaged, all the parts have een set up correctly and all the

conditions that could influence the regular functioning of the machine

are in working order.

N) Repairing the machine y qualified personnel. The repairs can only e done y qualified

people, using original spare parts. The non- compliance with these rules can represent

danger for the user.

31

2.1 Instructions for the user

The environmental conditions in which the machine must be installed must follow these characteristics:

· Be dry

· The machine is constructed to have IPXI protection level.

· Water and heat sources at safe distance

· Adequate ventilation and li htin correspondin to hy iene and security re ulations followin

the existin laws.The surface should be flat and compact for easier cleanin . For normal ventilation

of the machine no objects should obstruct.

INFORMATION

The electric network must be pro ided with an automatic differential switch ha ing characte

ristics suitable to those of the machine, in which the opening distance between the contacts

must be of at least 3 mm. Most of all it is necessary a good grould system.

WARNING

Verify that the electrical set-up corresponds with the numbers of the technical characteristics

(1.3) found and on the small plate at the back of the machine.

2.2 Installation methods

The machine is supplied in a closed packa e and fixed with metal straps on wood. Inside the

packa in with the machine you will find the instructions and the declaration of conformity

accordin to the machines re ulation. The machine must be unloaded and lifted out at the part

indicated on the packa in by proper equipment. For the transportation of the machine to the

place of installation, use a fork lift.

After cuttin the metal straps take out of the packa in and the plastic cover, then with the help

of a proper belt put under the machine (PICT. 3) and a fork lift (manual or motor) lift the machine

and take away the bottom pallet, position the machine makin sure you leave a space around it

of 50 cm to make usa e, cleanin and maintenance easier. If the machine is unstable put under

the feet or wheels pieces of hard rubber. If the machine has wheels make sure they have been

blocked by pushin the lever A downwards till it blocks (PICT. 4).

Note: All packa in must be disposed of in a lawful way.

CHAPTER 2 INSTALLATION

ENGLISH

32

SPIRAL MIXER - IM SERIES Operating manual

2.3 Electrical connections

The connections type Y of the machine ith the electric net ork is made by means of an operation

cable, hich is provided ith a plug only in the singlephase model. As far as the three-phase

machines are concerned it is necessary to put together the cable and a normalized and polarized

plug (the distinction bet een phase and neutral must be unequivocal), and verify that the rotation

ay of the bo l is the same indicated by the arro on the bo l.

2.4 Positioning of the machine

The plug must be easily accessible, must not require any kind of movement. The cable from the

machine to the all plug must not be pulled tightly, also do not rest the machine on the cable.

ENGLISH

A

PICT. 3 PICT. 4

33

ENGLISH

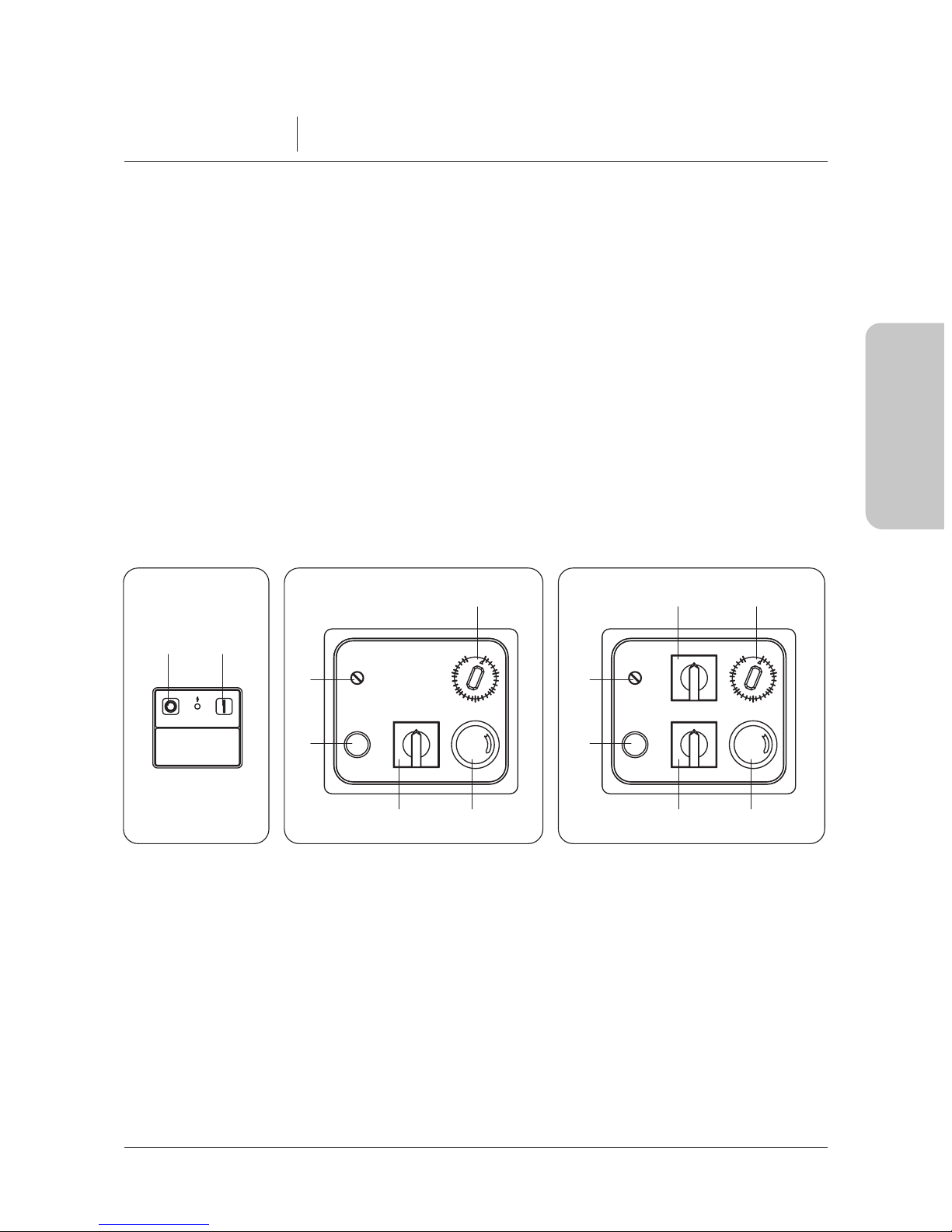

The machines are provided with the following operating and safety devices:

3.1 Operating devices

Single-phase or Threephase machines (IM 5 - IM 8) (PICT. 5):

A - reen button 1 operating

B - Red button 2 Stop

Single-phase or Three-phase machines (the rest of the models) (PICT. 6-7):

C - eneral switch

D - reen button: Operating

E - Red button: Emergency stop

F - Timer

- Fuse

H - Speed commutator

HAPTER 3 FUNCTIONIN

3.2 Safety devices

I - Moving protection grate (PICT. 8)

L - Device proving that the top and the protection cover are up or down

M,M1- Check pin of the top (down position)

N - Device proving that the bowl is in or out

O -Blocking disk of the bowl

Note:

The safety devices M,M1-N-O can be found only in the machines wih raising top and

removable bowl (A models). The device proving that the protection cover is up or down is located

inside the head of the machine on the models with fixed top.

1

0

2

0

1

RETESTOP START

BA

PI T. 5 PI T. 6 PI T. 7

0

5

10

15

20

25

30

1

0

0

5

10

15

20

25

30

F

G

D

CE

F

G

D

H E

C

34

SPIRAL MIXER - IM SERIES Operating manual

ENGLISH

WARNING

The single safety device are efficient when:

· On raising the protetion I PICT. 8) the machine stops.

· On raising the top by means of the check pin M and/or taking off bowl the machine does not start.

· On softly pulling either the bowl or the top they do not move.

Before operating the machine, the protection I PICT. 9) must be completely lowered. In the A models

it must be checked that the bowl is correctly inserted and blocked by the disk O and that the top is

down and blocked by the check pin M this must be completely inserted). After inserting the plug the

machine is ready for use.

PICT. 8

M

M1

I

O

PICT. 9

P

35

ENGLISH

3.3 Working test machine

Single-phase or three-phase machine (mod. IM 5 - IM 8):

OPERATING: push the green button A to start the bowl and the spiral.

STOP: push the red button to stop the bowl and the spiral.

Single-phase or three-phase machine (1-2 el.) (from mod. IM 12 to mod. IM 60)

OPERATING: rotate the knob of the swit h C in position 1, set the time of mixing by the timer F,

push the green button D to start the bowl and the spiral.

STOP: rotate the knob of the swit h C in position 0, or push the red button E to stop the bowl and

the spiral. In order to operate the ma hine again after the stop due to the raising of the prote tion

I or to the a tivating of the emergen y button E it is ne essary to pro eed as follows: lower again

and ompletely the prote tion I; release the button E by rotating in lo kwise, as shown by the

arrow, and push the operating button D.

Note:

In a ma hine fed ele tri ally by three-phase, if the rotation of the bowl is opposite the way

shown by the arrow it is ne essary to follow these indi ations for the fun tioning and every time you

hange the ele tri plug:

· Stop the ma hine.

· Take the plug out.

· Reverse on the plug the position of two phases (example: L1 with L2 and vi e versa).

· Restart the ma hine and verify if the bowl is rotating the right way.

Start the ma hine without using it, let it on for about one minute and verify that it is fun tioning perfe tly.

Before starting work make sure that the machine is perfectly clean in particular, the surfaces of

bowl, the spiral and of the central column that have contact with the food products. If necessary

clean them following indications at 5.1.

4.1 Usage of the machine with fixed top and bowl

After lifted up the protection I, pour in the bowl all the required ingredients, push down the

protection, press the button to start A or . The movement made by the spiral, which is sincronized

with the rotation of the bowl, gives an amalgamation of, flour, water, salt, yeast and other eventual

ingredients till you obtain a mixture of the consistance required. If necessary, in order to modify

the characteristics and/or the consistence of the initial dough, pour the ingredients through the

protection grate I. When work cycle is completed, leave machine on hold, lift up the mobile

protection to maximum opening, take mixture out of the bowl, proceed with cleaning of the machine

following the indications at 5.1.

4.2 Usage of the machine with raising top and removable bowl

The machine with raising top and removable bowl, is functionally identical to the machine with

fixed top and bowl.

It differentiates from the other only for the following advatages, that it can offer at the end of

each work cycle:

· The facility in the collection of the dough.

· The facility in the cleaning phase.

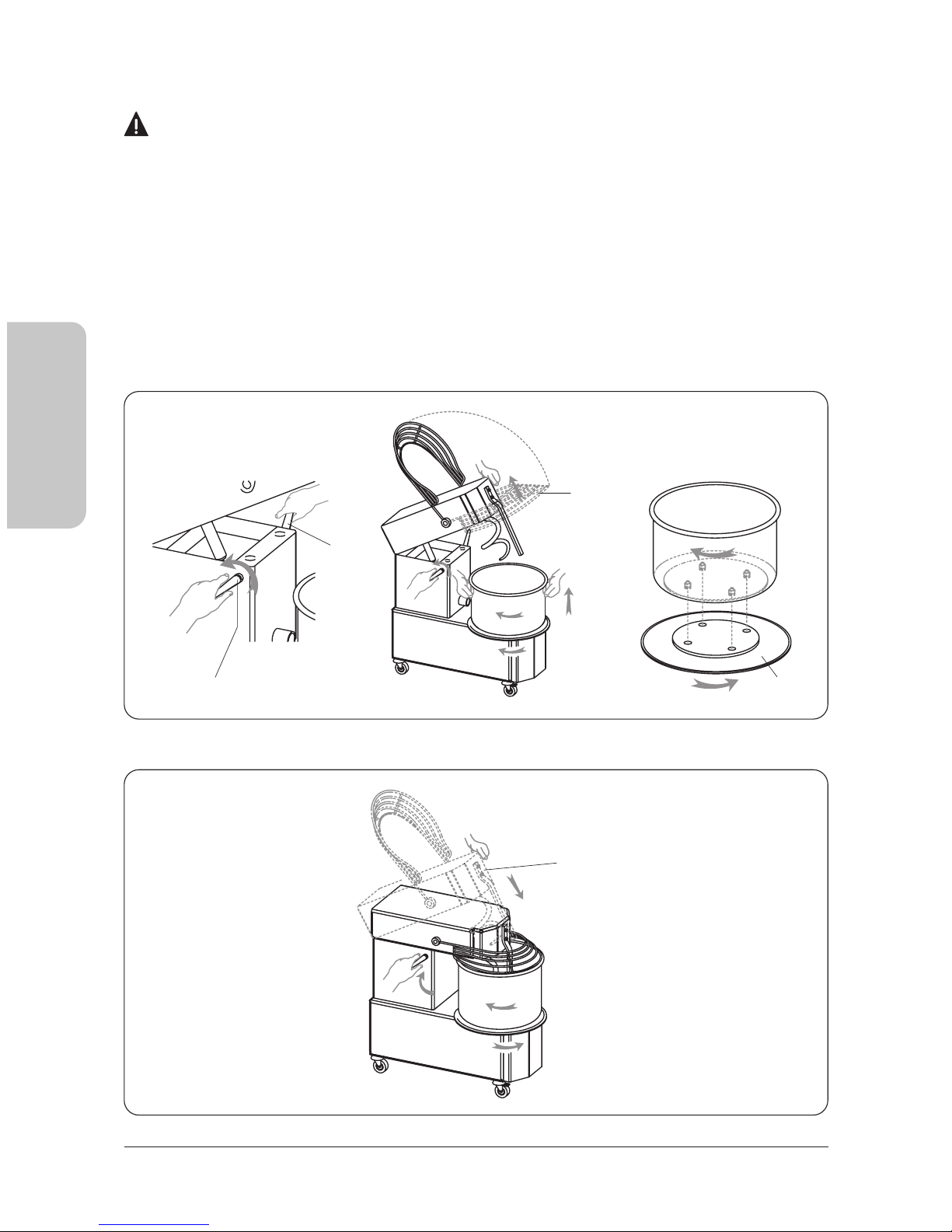

4.2.1 Raising of the top and taking off of the bowl

In order to raise the top and to take off the bowl proceed ad follows: stop the machine, unplug

the machine, raise the protection I completely (PICT. 10), pull the pin M as far as the top is blocked,

raise the top by means of the little piston underneath, rotate clockwise the disk O as far as the

bowl is unlocked, raise the bowl and take it off, take off the dough.

CH PTER 4 USAGE

36

SPIRAL MIXER - IM SERIES Operating manual

ENGLISH

4.2.2 Repositioning of the bowl and top

Once the cleaning is done, put the bowl back on, and make sure that the four pins underneath

(PICT. 11) are correctl fixed in the four holes K of the machine; then block the bowl rotating

clockwise the disk O. Put the top down pushing it downwards (PICT. 9) as far as it is blocked b

the pin M.

4.3 Usage of the machine with two speeds

OPERATING: Rotate the knob of the switch C in position 1 (PICT. 7), select speed 1 or 2 b rotating

the knob of the selector H, push the green button D to operate both the bowl and the spiral. In

order to change the speed of rotation of the machine, rotate te knob H from position 1 to 2 or vice

versa. After each change of speed push the button D.

STOP: Rotate the knob of the switch C in position 0, or push the red button E to stop both the bowl

and the spiral.

PICT. 10-11

3

ENGLISH

M1

I

O

K

4.4 Usage of the machine provided with timer

The timer is an electromechanical device that allows to program from 1 to 30 minutes.

· The work-time of the machine by rotating the knob 0 in the desired position (P CT. 13).

· Operate the machine following the instructions of par. 3.1 or 3.2 or 4.3.

· Once the set time is over, the timer stops the machine.

INFORMATION

Before ta ing off the dough beware of following the stop procedure of par 3.1 or 3.2.

38

SP RAL M XER - M SER ES Operating manual

ENGLISH

39

ENGLISH

WARNING

Before effecting any kind of maintenance or cleaning you must take out the plug. In any case

of malfunctioning or damage of the machine you must apply for authorized assistance from the

manufacturer see Chapter 7).

5.1 Cleaning

The cleaning must be done every time the machine has been used following all the rules to prevent

malfunctioning of the machine and for hygienic purposes. Using a wooden or plastic palate first

clean the residue of dough, then with a soft sponge and warm water accurately clean the pan, the

spiral the dough breaker and the mobile protection, dry with kitchen paper, then pass over the

parts just mentioned then all the machine with a smooth and cleaned cloth with a specific cleaning

product for food machines.

WARNING

We recommend not to use any kind of chemical product abrasive or corrosive. Absolutely avoid

using running water, different tools, rough or abrasive objects, metal wool, sponges etc. which

can damage the surfaces and be dangerous from an hygienic point of view. To maintain the

efficiency and security of the machine it is necessary to proceed with periodical maintenance

every 6 months) of the following indications:

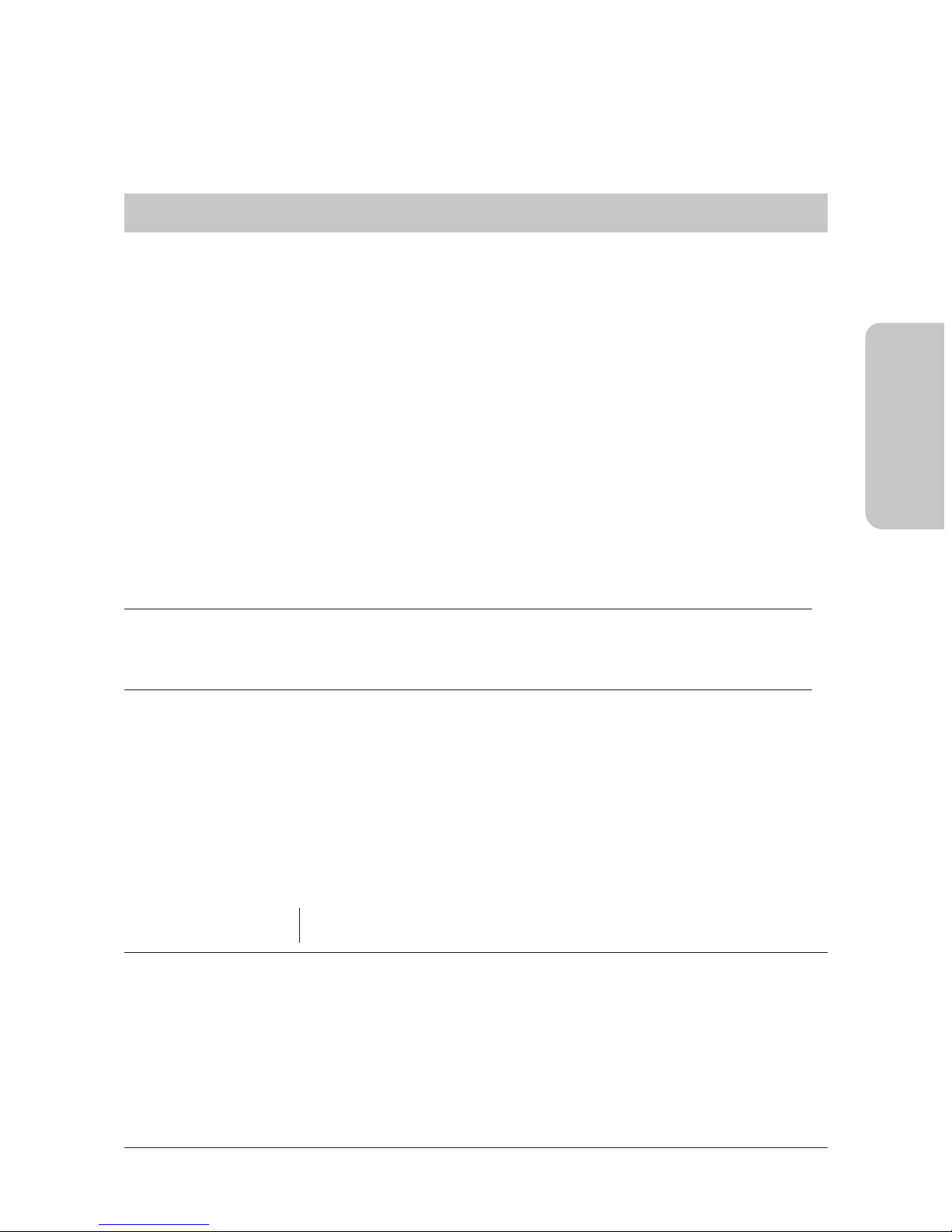

5.2 Tensioning of the upper chain

The chain must be tensioned if, by checking it, it becomes loose or if the rotation of the spiral is

not constant. Unscrew the panel P, (PI T. 14) loosen the screws Q, pull the support of the spiral

R as far as the tension of the chain is optimzed, lock the support R with the screws Q, put the

panel P on once more and fix it.

CHAPTER 5 MAINTENAN E

5.3 Lubrificating the chains

After unscrewing the fixing screws, take away the upper P and the back V panels, put on the

ichains S-T (PI T. 15-16) a reasonable amount of proper grease, sufficient to lubricate all the links

of the chain. Once this is done, mount the two panels and secure again with screws.

40

SPIRAL MIXER - IM SERIES Operating manual

ENGLISH

PICT. 16

V

T

PICT. 14-15

P

R

Q

S

5.4 Possible anomalies

In case of dismantelling and demolition of the machine, the pieces which the machine is made

of, do not present any kind of danger that necessitates any particular caution.

To facilitate the recycling process of the materials, you must separate all electrical components.

CHAPTER 6 DEMOLITION O THE MACHINE

41

ENGLISH

ANOMALY CAUSE SOLUTION

La macc ina non si avvia ·Lack of energy in the

power grid

·The Emergency stop button

in blocked

·The protection grid

and/or the top are up

·The knob of the general switch

is in position 0

·The knob of the speed selector

is in position 0

·The timer is in position 0

·Check the general switch,

the plug, the tap and the

feeding cable

·Rotate the button following

the direction of the arrow

·Put down correctly both

the grid and the top

·Rotate the knob in position 1

·Rotate the knob in position

1 or 2

·Rotate the knob of the timer

from 1 to 30 minutes

T e spiral turns incostantly

T e mac ine stops w ile

working

·The chain is loose

·Stop of the fuse

·Stretch the chain following

the instructions at par. 5.2

·Change the fuse with another

on which has the same

characteristics

This manual suits for next models

2

Other MECNOSUD Mixer manuals