AEMC instruments FlexProbe 24-3001 User manual

Other AEMC instruments Measuring Instrument manuals

AEMC instruments

AEMC instruments PowerPad IV 8345 User manual

AEMC instruments

AEMC instruments 6536 User manual

AEMC instruments

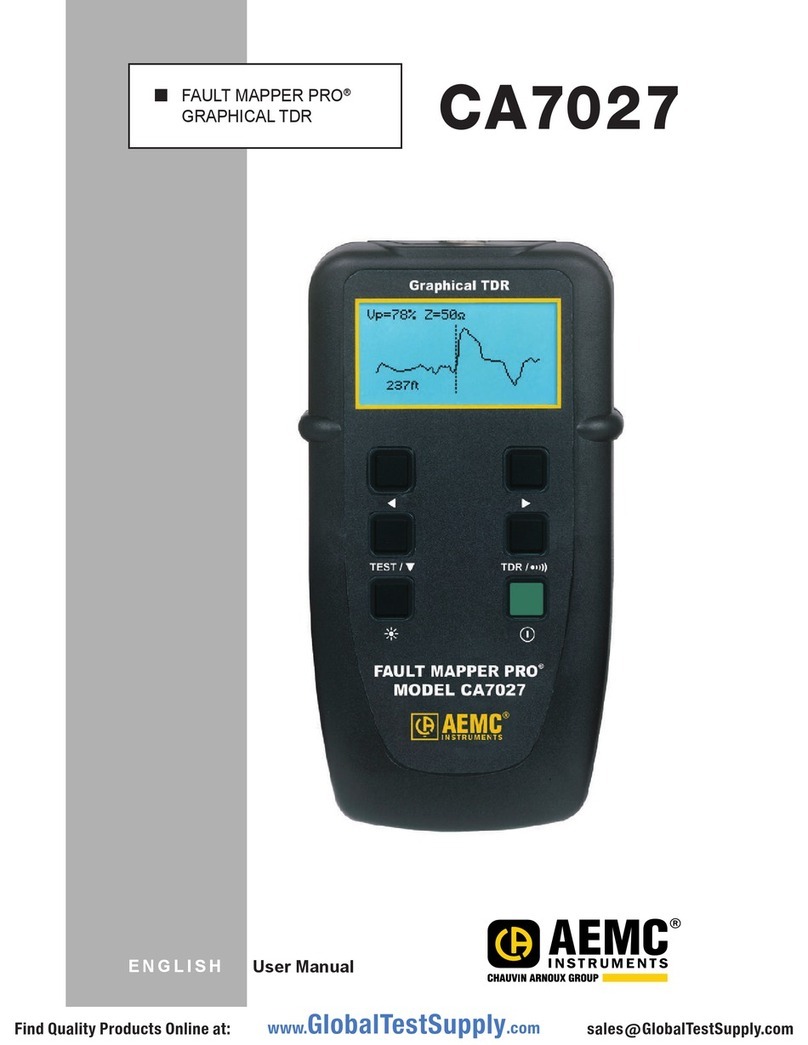

AEMC instruments CA7027 User manual

AEMC instruments

AEMC instruments 6505 User manual

AEMC instruments

AEMC instruments MR6292 User manual

AEMC instruments

AEMC instruments JM865A User manual

AEMC instruments

AEMC instruments MN02 User manual

AEMC instruments

AEMC instruments Chauvin Arnoux 6412 User manual

AEMC instruments

AEMC instruments MR525 User manual

AEMC instruments

AEMC instruments MR525 User manual

AEMC instruments

AEMC instruments JM840A User manual

AEMC instruments

AEMC instruments MN213 User manual

AEMC instruments

AEMC instruments A196-24-BK User manual

AEMC instruments

AEMC instruments 300-24-2-10 User manual

AEMC instruments

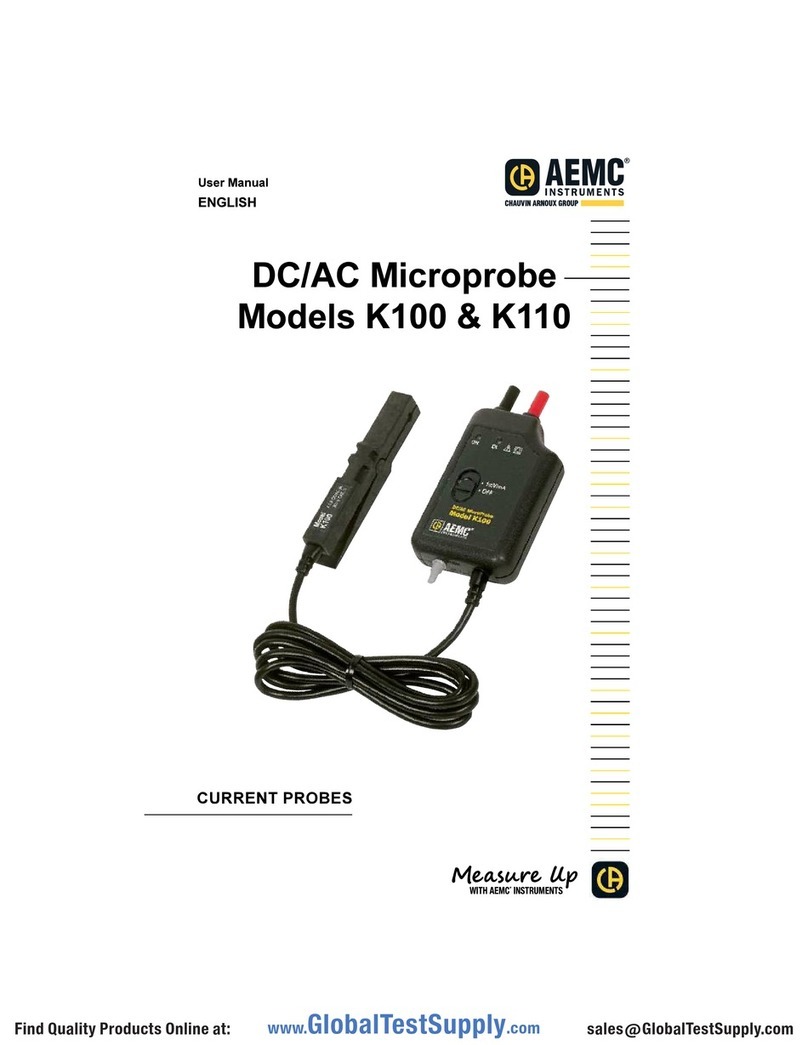

AEMC instruments K100 User manual

AEMC instruments

AEMC instruments MN312 User manual

AEMC instruments

AEMC instruments 1035 User manual

AEMC instruments

AEMC instruments AmpFlex User manual

AEMC instruments

AEMC instruments DIGITAL FLEXPROBE 400D-6 User manual

AEMC instruments

AEMC instruments MN09 User manual