MEDENUS SL 10 Manual

© 11.2016

Safety relief valve

SL 10

Operating and Maintenance Instructions

Subject to technical modifications! Reprint prohibited!

© 11.2016© 11.2016

Table of Contents

1 General Information 4

1.1 Warranty and Liability 4

1.2 Symbols, Notes 5

1.3 Terms, Abbreviations 5

2 Safety Instructions 6

2.1 Hazards of Handling the Device 6

2.2 Personnel Requirements 6

2.3 Country-Specific Requirements 6

2.4 Handover of the Operating and Maintenance Instructions 6

2.5 Safety in Operation 7

2.6 What To Do in Case of Danger 7

3 Responsibility of the Operator 7

4 Transport, Storage and Packaging 8

4.1 Transport 8

4.2 Storage 8

4.3 Packaging 8

5 Mounting and Commissioning 9

5.1 Safety Instructions and Preparation 9

5.2 Mounting 10

5.3 Leakage Test (Test for External Leakage) 11

5.4 Initial Commissioning / Recommissioning 12

5.5 Decommissioning 13

6 Maintenance 13

6.1 Maintenance Plan 13

6.2 Maintenance Procedure 14

6.3 Table of Screw Tightening Torques MA14

6.4 Lubricants Table 14

7 Troubleshooting 15

7.1 Safety Relief Valve 15

8 Replacement and Disposal 16

9 Spare Parts 16

9.1 Parts for Maintenance Work 16

O-Rings and Sealing Rings 16

Valve Plates / Diaphragms 16

9.2 Spare Parts Drawing SL10 17

10 Declaration of Conformity 18

11 Notes 19

4

© 11.2016

1 General Information

The personnel entrusted with installation, operation or maintenance of the safety relief valve must

have completely read and understood beforehand the following documents:

• Safety Relief Valve SL 10 Product Information

The product information contains technical data, dimensions and a description of the design and the mode of

operation.

• Safety Relief Valve SL 10 Operating and Maintenance Instructions

This document allows safe and efficient handling of the device and contains information on assembly,

commissioning, maintenance, troubleshooting, and repair according to regulations.

It is an integral part of the scope of delivery of the device, must be kept in close proximity of the device and

must be readily accessible to personnel at any time.

The basic requirement of safe operation is compliance with all safety instructions and guidelines specified in

these instructions. Accordingly, the information and instructions must be observed when working on the device

or on the gas line. In addition, the local occupational safety regulations and the general safety regulations for

the application range of the device shall apply.

The figures in these instructions are provided for basic understanding and may differ from the actual design.

The contents in these instructions are protected by copyright. They may be used as part of operating the

device. Any other use and / or reproduction is not permitted without prior authorization by the MEDENUS Gas-

Druckregeltechnik GmbH.

1.1 Warranty and Liability

Claims under warranty or liability for personal injury and material damage are generally void,

if one or several of the following conditions are not observed:

• Work on the device during the warranty period may only be performed in consultation with the manufacturer

• Designated use of the device in accordance with the established conditions of use

• Proper installation, commissioning, operation and maintenance of the device

• Operation of the device with properly installed and functioning safety devices only

• Operating and maintenance instructions of the device or of the system

• Observance of the maintenance instructions

• Properly performed repairs

• Supply lines without defects

• The use of original MEDENUS©spare parts and lubricants listed in these instructions or

• Force majeure

It is generally prohibited

• to perform constructive modifications on the device

• to keep using the device despite the detection of a defect

5© 11.2016

1.3 Terms, Abbreviations

Terms and abbreviations are explained below:

1.2 Symbols, Notes

The instructions contain safety instructions marked with symbols to indicate possible consequences in case of non-

observance:

DANGER

Note

NOTICE

This combination of symbol and signal word indicates a potentially hazardous

situation which may result in light injuries, damage to the device, the breakdown

of the system, and material or environmental damage if not avoided.

This combination of symbol and signal word indicates an imminent hazardous

situation, resulting in death or serious injuries if not avoided.

This signal word highlights useful tips, recommendations, and information for

efficient and trouble-free operation.

ATC Acceptance test certificate

DN Nominal width

GPR Gas pressure regulator

MOP Maximum operating pressure

in a system

SSV Safety shut-off valve

SRV Safety relief valve

6

© 11.2016

2 Safety Instructions

National accident prevention regulations and the system operator‘s safety regulations are not superseded by these

operating and maintenance instructions and must be taken into consideration with priority (in Germany, see, among

others, DVGW Code of Practice G 600, G 459/II, G 491 and G 495)

When performing work on the device, the current general and specific safety regulations must be observed.

The application limits of the device with respect to the medium, operating pressure and operating temperature can be

found on the type plate affixed to the device or on the acceptance test certificate.

Using the device under different operating conditions must be agreed upon in consultation with

MEDENUS Gas-Druckregeltechnik GmbH.

The mechanical components of the device do not have any potential ignition sources of their own nor any hot surfaces and

are thus not within the scope of 2014/34/EU (ATEX). The electronic accessories used comply with the ATEX requirements.

2.1 Hazards of Handling the Device

MEDENUS©devices conform with current standards and directives, the recognized technical rules and the recognized

safety rules.

However, improper use can result in hazards to the user or to third parties. This can also result in damage to the device

or to the system.

This is why the device may only be used:

• in accordance with its designated use

• in perfect condition

• while observing the notes given in these operating and maintenance instructions, and inspection and

maintenance regulations, which apply to the functioning and safety of the overall system.

Malfunctions or faults must be eliminated immediately.

2.2 Personnel Requirements

The device may only be mounted by qualified personnel.

Only authorised personnel in possession of the required qualification is allowed to perform settings or repairs on the

device.

2.3 Country-Specific Requirements

The rules and regulations applicable at the place of use with respect to:

• gas lines, installation of the gas system

• gas supply

• work on the gas system

• accident prevention must be observed and complied with.

2.4 Handover of the Operating and Maintenance Instructions

The supplier of the system shall hand over these operating and maintenance instructions to the operator of the system

no later than during commissioning and training of the operating personnel with the reminder to carefully store these

instructions.

7© 11.2016

2.5 Safety in Operation

The device may only be used when all protective devices on the device or in the system are fully

functional.

At least once a year, the device must be inspected for externally visible damage and for proper functioning

by a representative of the manufacturer or by a qualified person.

A more frequent inspection may become necessary, depending on the system conditions.

2.6 What To Do in Case of Danger

Information on what is to be done in case of danger and in case of accidents can be found in the respective operator's or

specialist company's work instructions.

3 Responsibility of the Operator

Operator An operator is a person who operates the device himself for commercial or economic purposes or hands

it over to a third party for use / application and is legally responsible for the safety of the user, personnel

or third parties.

The device is used in the industrial sector. Accordingly, the operator of the device is subject to the legal

obligations concerning occupational safety. In addition to the safety instructions contained in these

instructions, the established maintenance intervals must be observed, taking into account the respective

national standard (alarm and hazard prevention plan).

In particular, the following applies:

• The operator is obliged to perform work on MEDENUS©devices during the warranty period only

after consultation with the manufacturer. Otherwise the claims under warranty will become

void.

• The operator must obtain information on the current occupational safety regulations and

determine additional hazards resulting from the special work conditions at the place of use of

the device in a risk assessment. The operator must implement them in the form of operating

manuals for operating the device.

• During the entire time of use of the device, the operator must check whether the operating

manuals drawn up by him conform to the current state of the regulations and, if necessary,

adapt them.

• The operator must clearly regulate and define the responsibilities for installation, operation,

troubleshooting, maintenance, and cleaning.

• The operator must ensure that all persons handling the device have read and understood these

instructions. In addition to that, he must train the personnel at regular intervals and inform it

about the dangers.

• The operator must make available to the personnel the required protective equipment and

oblige them to wear the required protective equipment.

• Moreover, the operator is responsible for the device always being in technically perfect condition.

Therefore, the following applies:

• The operator must make sure that the maintenance intervals described in these instructions

are observed.

• The operator must have all safety devices checked regularly for functioning and completeness.

Operator's

obligations

8

© 11.2016

4 Transport, Storage and Packaging

4.1 Transport

The device must be handled carefully and secured against impact and shock.

In case of transport damage, we will require the following information from the type plate affixed to

the device:

• Type of device

• Device model

• Year of construction / fabrication number

Note

4.2 Storage

Equipment and spare parts must be stored under the following conditions:

• Do not store outdoors.

• Store in a dry and dust-free location.

• Store on a flat surface.

• Do not expose to aggressive media.

• Do not expose to ozone or ionizing radiation.

• Do not store adjacent to direct heat sources.

• Avoid mechanical vibrations.

• Storage temperature: 0 to 25°C.

• Relative humidity: < 55 %.

Spare parts:

• Components susceptible to corrosion must be provided with a suitable preservative.

• Do not store O-rings and seals for more than 7 years even if stored properly.

• Spare parts must be stored in their original packaging until use.

Storage period for devices:

• Storage of the device for up to one year:

Store the safety relief valve in its original packaging and original condition at the time of supply. All protective

caps of the device must remain mounted.

• Storage of the device for more than 1 year (e.g. as a spare device):

Store the device in its original packaging and original condition at the time of supply and check it for damage

once a year. Check the housing surface for dirt, damage and corrosion. If necessary, clean all external parts.

After 7 years, all O-rings and seals must be replaced.

4.3 Packaging

• The individual packaged items have been packaged in view of the transport conditions to be expected.

• The symbols on the packaging must be observed during transport and storage.

• Only environmentally-friendly materials have been used for packaging.

• The packaging is designed for protecting the individual components from transport damage, corrosion and

other damage until mounting. This is why the packaging must not be destroyed and only be removed just prior

to mounting.

9© 11.2016

5 Mounting and Commissioning

5.1 Safety Instructions and Preparation

Prior to starting work on pressurised components:

• Close all connections to the gas line.

• Depressurise all pressurised components. Also discharge residual energies.

• Defective components that are subject to pressure in operation must be replaced

immediately by a suitable qualified person.

Prior to starting work, ensure sufficient clearance for mounting.

Before installing the device, check whether the performance data (type plate) and the scope of

delivery coincide with the order or the system data, i.e., make sure that the provided devices are

suitable for their intended purpose. In particular, the inlet pressure of the system must be lower

than the maximum allowable pressure of the device or the system must be declared to be differential

pressure-resistant.

A direct contact of gas valves and fittings, i.e., the control system, with hardening masonry, concrete

walls or floors is not allowed. Provide suitable supports, working materials, and protective equipment.

Take into account the minimum clearances for maintenance as stated in the product information.

Before installing the device in the pipeline, check whether a shut-off device that interrupts the gas

flow supply to the device has been mounted upstream of the device to be installed.

Prior to commissioning, make sure that all installation work has been carried out and completed

in accordance with the data and information given in these instructions and that no unauthorised

persons stay in the danger zone.

DANGER

Note

Note

DANGER

10

© 11.2016

5.01 5.02

5.04

5.10

5.09

5.13

5.12

5.11

5.2 Mounting

• Install the safety relief valve (item 5.09) without twisting the pipeline.

Make sure to observe the direction of flow, i.e., the arrow on

the housing must point in the direction of flow.

• All breather lines (item 5.04) must be vented to the outside atmosphere.

• Breather lines (item 5.04) may not be required

if breather valves are being used.

Note

Note

11 © 11.2016

U

S

G

a

s

-

D

r

u

c

k

r

e

g

e

l

g

e

r

ä

t

D

E

N

U

S

G

a

s

-

D

r

u

c

k

r

e

g

e

l

g

e

r

ä

t

5.10

5.09

5.10

5.09

For Germany:

According to DVGW Code of Practice G 491, the fully assembled system must be subjected to a leakage test with air or

an inert gas at the installation site, using 1.1 times the maximum operating pressure of the system (MOP).

An exception is the room between the actuator installed in the gas pressure regulator and the first shut-off valve on the

outlet side. This room must be checked using the a test pressure corresponding to the maximum permissible pressure

in the system in case of a malfunction (1.1 MOPd). In this test, all detachable connections must be checked using a

foaming agent.

For other countries:

The relevant national and international standards shall apply.

Procedure

• Close the ball valves upstream of the valves and fittings (item

5.01).

• Close the downstream shut-off devices (item 5.13) (ball valves,

solenoid or pneumatic valve).

• Depressurise the system (item 5.11).

• Connect the testing device to measuring points upstream and

downstream of the gas pressure regulator (items 5.02 / 5.12).

• Test the tightness of the safety relief valve (item 5.09) until the

response pressure is reached and then close the line upstream of

5.3 Leakage Test (Test for External Leakage)

The devices are subjected to a strength and leakage test ex works at MEDENUS Gas-Druckregeltechnik GmbH.

The leakage test in the fully assembled system must be performed prior to commissioning and following maintenance

work.

For the external leakage test in the fully assembled system, the following applies:

the SRV (item 5.10).

• Always increase the test pressure slowly and steadily.

While doing so, you must ensure:

Pressure in outlet chamber (item 5.12) ≤Pressure in inlet chamber (item 5.02)

Pressure build-up always from the inlet side (inlet chamber)

Pressure reduction always from the outlet side (outlet chamber)

• After leakage test:

Open the ball valve in the SRV line (item 5.10) again.

Note

NOTICE

12

© 11.2016

5.21

M

E

D

E

N

U

S

G

a

s

-

D

r

u

c

k

r

e

g

e

l

g

e

r

t

M

E

D

E

N

U

S

G

a

s

-

D

r

u

c

k

r

e

g

e

l

g

e

r

t

5.22

5.25

5.4 Initial Commissioning / Recommissioning

Initial commissioning of the system components shall be carried out by the operator. For commissioning, please refer to

the documents listed under item 1 "General Information" and the system operator's work instruction.

The devices delivered by MEDENUS Gas-Druckregeltechnik GmbH are factory-set to the operating data specified by the

customer. This data is listed on the Acceptance Test Certificate (ATC)* and the type plate.

• For a functional test of the SRV, increase the gas pressure with the controller

until the SRV reacts and read the set regulating pressure on the outlet

pressure gauge (item 5.12).

• If necessary, correct the response pressure.

This is done by turning the SRV setpoint setting screw (item 5.22) to the right

or left, in order to increase and decrease the setpoint, respectively, after

removal of the GPR sealing cap (item 5.21).

• Screw on the SRV sealing cap (item 5.21) again.

Changing the control range

Switching to the control range of a different setpoint spring can be done for the SRV

while the device is pressurised.

• Take off the sealing cap (item 5.21) and unscrew the setting screw (item 5.22),

• Pull out the spring (item 5.25) and replace the spring with one that fits.

• Screw in the setting screw (item 5.22) again.

• Set the desired setpoint and screw on the sealing cap (item 5.21) again.

*) Acceptance Test Certificate (ATC) available optionally

13 © 11.2016

6 Maintenance

6.1 Maintenance Plan

The maintenance regulations of the system manufacturer must be observed. The following sections describe the

maintenance work required for optimal and trouble-free operation of the device.

If increased wear is detected during regular inspections, the required

maintenance intervals must be shortened in accordance with the actual wear.

For any questions on maintenance work and intervals, please contact the manufacturer.

The intervals for monitoring and maintenance work are strongly dependent on the

operating situation and the condition of the gas. This is why no fixed intervals

can be given. For Germany, it is recommended to initially observe the maintenance periods according to

the data given in DVGW Code of Practice G 495. For each system, this must be followed by

determining the maintenance interval independently on a medium-term basis.

During maintenance work, the components must be cleaned and subjected to a thorough visual inspection. This is

also necessary if irregularities in the operating behaviour have been detected during operation

or during functional tests. The check must cover the elastomers in particular.

Damaged parts and O-rings dismounted during dismantling must be replaced with new ones.

It is recommended to stock the parts listed in chapter 9.1 on page 16 for maintenance work.

Interval Maintenance activities Personnel

When required

Replacing O-rings

Qualified person

Replacing diaphragms

Replacing the valve plate

Replacing sealing rings for the connections of the breather lines

5.5 Decommissioning

For decommissioning, please refer to the documents listed under item 1 "General Information"

and the system operator's work instruction.

Procedure

• Slowly close the outlet shut-off valve (item 5.13) or

• Slowly lower the outlet pressure via the setpoint setting screw until the reserve rail takes over the gas supply

or

• Slowly raise the setpoint of the reserve rail until the operating rail is disabled.

• Close the ball valves upstream of the valves and fittings (item 5.01).

• Depressurise the system (item 5.11).

• Close venting ball valve (item 5.11).

14

© 11.2016

51

50

6.2 Maintenance Procedure

The maintenance procedure is described in detail step-by-step in our video tutorial and our pictorial descriptions.

Instructions for our products can be found in the download area of our website. Should you have any problems, please

feel free to contact us directly.

If components have been removed, make sure they are mounted correctly, reinstall all fastening

elements and observe the screw tightening torques.

Prior to recommissioning, observe the following:

• Make sure that all maintenance work has been carried out and completed in accordance

with the data and information given in these instructions.

• Make sure there are no unauthorised persons in the danger zone.

• Make sure that all covers and safety devices have been installed and are working properly.

For recommissioning, please refer to the relevant manufacturer's documentation of the

gas pressure regulator installed in the system, the work instructions of the system operator, and the other

safety regulations of the system in which the safety relief valve has been installed.

To guarantee smooth operation, we recommend always keeping a maintenance set in reserve.

NOTICE

DANGER

Note

6.3 Table of Screw Tightening Torques MA

Item

No.

SL10 / Rp 1“

SL10 / Rp 1 1/2“

SL10 / Rp 2“

50 M6 / 8 Nm

51 M6 / 8 Nm

6.4 Lubricants Table

Components (apply a thin layer) Lubricants Article number

All O-rings Syntheso Proba 270 SYNTHESO-PROBA-270

All fastening and locking screws Anti Seize AS 450 AS-450

15 © 11.2016

7 Troubleshooting

7.1 Safety Relief Valve

Description of the error Possible cause Elimination

SRV vents during

operation

Actuator dirty or damaged Check valve plate (seal) and valve seat for damage

and dirt, replace valve plate, if necessary

Static sealing elements defective Replace O-rings

Valve plate has become disconnected

from the valve stem Tighten nut under the valve plate

Wrong SRV settings Check SRV settings

SRV set too low Check SRV settings

Sluggishness of the device due to dirt Subject device to maintenance

SSV frequently shuts

off

Stopcock upstream of SRV is closed Open stopcock

SSV set too low or SRV set too high Check SSV and SRV settings

Gas escapes through

breather line

Fastening of the main diaphragm has

come off

Main diaphragm is damaged or has

been mounted incorrectly

Check diaphragm for fastening, damage and correct

fit

16

© 11.2016

9.1 Parts for Maintenance Work

O-Rings and Sealing Rings

Item

no.

Name Quantity

pcs.

Exception SL10 / Rp 1“

SL10 / Rp 1 1/2“

SL10 / Rp 2“

4 O-ring 1 O-013

7 O-ring 1 O-007

11 O-ring 1 O-007

14 NBR-ring 2 N-001

20 O-ring 1 O-013

2 HD2 O-013

O-ring set

order number: OS-081

Example:

Safety relief valve: SL10 / Rp1“

Spare parts according to tables in 9.1

Valve plate SRV: VT-212

Diaphragm SRV: M-111

O-ring and sealing ring set: OS-081

Info: The allocation of individual parts is done according to the item no. in the tables in 9.1, conforming to the spare

parts drawings in 9.2.

Valve Plates / Diaphragms

Item

no.

Name Number SL10 / Rp 1“

SL10 / Rp 1 1/2“

SL10 / Rp 2“

6 Valve plate 1 VT-213

16 Diaphragm 1M-111

8 Replacement and Disposal

After the device has reached the end of its useful life, it must be dismounted and disposed of in an

environmentally compatible manner.

During dismounting, components that may present a risk of injury by contamination,

depending on the medium are removed. Depending on the processed medium, the

components must be properly decontaminated. Components capable

of diffusion (diaphragm, O-ring, etc.) may have to be taken to a special disposal unit,

depending on the material used. If no return or disposal agreement

has been reached, dismantled components should be recycled:

• Metals should be scrapped

• The remaining components should be disposed of after sorting according to material.

For technical information, please contact our customer service:

MEDENUS Gas-Druckregeltechnik GmbH

Saßmicker Hammer 40

D-57462 Olpe

Phone +49 (0) 2761 / 82788-0

Fax +49 (0) 2761 / 82788-9

In addition, we are always interested in information and experience resulting from the application and

which can be valuable for improving our products.

E-Mail [email protected]

Internet www.medenus.de

NOTICE

9 Spare Parts

17 © 11.2016

20

16

11

14

6

7

4

20

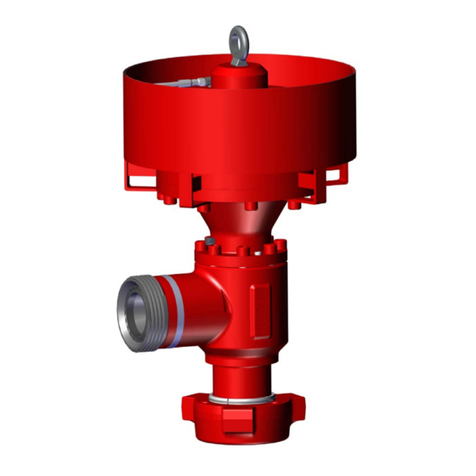

SL10 shown with

high-pressure spindle HD2

9.2 Spare Parts Drawing SL10

18

© 11.2016

Konformitätserklärung

(Zusammenfassung)

Hersteller: Medenus Gas-Druckregeltechnik GmbH

Anschrift: Saßmicker Hammer 40

D-57462 Olpe-Saßmicke

bescheinigt hiermit, dass das Produkt:

SL 10 Sicherheits-Abblaseventil

einer EG-Baumusterprüfung unterzogen wurde und den

grundsätzlichen Anforderungen der Richtlinien GAD 2009/142/EG

EG-Gasgeräterichtlinie in der gültigen Fassung entspricht.

Für Geräte, die zusätzlich mit dem CE-Kennzeichen gekennzeichnet

sind, liegt eine EG-Baumusterprüfbescheinigung vor nach:

EU/97/23/EG A III B EG-Druckgeräterichtlinie

Prüfbericht: CE-0085 / AZ 12/009/4305/116 (SL10)

Grundlage der EG-Baumusterprüfung sind die harmonisierten

europäischen Normen und/oder nationalen Normen:

DIN 33821 (01.03.2009)

Kennzeichnung (PIN) nach Gasgeräterichtlinie

CE-0085AQ0879 Modell SL 10

Kennzeichnung nach Druckgeräterichtline

Die Überwachung des Qualitätssicherungssystems (Modul D) erfolgt

durch den DVGW.

Olpe-Saßmicke,

30.09.2016

Martin Clemens

Geschäftsführer

Declaration of Conformity

(Summary)

Manufacturer: Medenus Gas-Druckregeltechnik GmbH

Address: Saßmicker Hammer 40

D-57462 Olpe-Saßmicke

herewith declares that the product:

SL 10 Safety Relief Valve

has been subjected to an EC type examination and conforms to

the basic requirements of the directives GAD 2009/142/EC

EC Gas Appliances Directive in the respective current version.

For devices that additionally carry the CE mark,

an EC-type-examination certificate has been issued according to:

EU/97/23/EC A III B EC Pressure Equipment Directive

Test report: CE-0085 / AZ 12/009/4305/116 (SL10)

The EC type-examination is based on the harmonised

European Standards and/or national standards:

DIN 33821 (2009-03-01)

Marking (PIN) according to Gas Appliances Directive

CE-0085AQ0879 model SL 10

Marking according to Pressure Equipment Directive

The quality assurance system (module D) is monitored

by the DVGW.

Olpe-Saßmicke,

2016-09-30

Martin Clemens

Managing Director

19 © 11.2016

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

..............................................................................

11 Notes

German:

http://medenus.de/files/upload/

downloads/SL10/BWA_SL10_de.pdf

In the download area of our homepage, this document is available in different languages. You can use the following

QR codes and links to go directly to this document in your language.

MEDENUS Gas-Druckregeltechnik GmbH

Fon +49 (0)2761 82788-0

Fax +49 (0)2761 82788-9

Saßmicker Hammer 40 / D-57462 Olpe

www.medenus.de

Other manuals for SL 10

1

Table of contents

Other MEDENUS Control Unit manuals

Popular Control Unit manuals by other brands

MADDALENA

MADDALENA Arrow WAN 2 Instructions for installation, use and maintenance

Resol

Resol HKM3 manual

Macnaught

Macnaught HG 55 Series instruction manual

Metso

Metso D Series Installation, maintenance and operation instructions

Dewetron

Dewetron XR-RTD8 Technical reference manual

Harvia

Harvia C150 manual

Samson

Samson 3321 Mounting and operating instructions

resideo

resideo Braukmann D05FT installation instructions

Teletek electronics

Teletek electronics TTE Combo manual

SOMAS

SOMAS SKV Service and operating instruction

Vexve

Vexve Hydrox HCU Remote Installation, operation and maintenance instructions

Weir

Weir SPM Operating and maintenance instructions