SOMAS SKV Operating instructions

Mi-706 EN

Service and operating instruction

Ball valves

Type SKV/SKVT

Edition: 2020-10

Nominal pressure Nominal size NPS

Type SKV PN 40 Class 300 DN 25 - 50 1 - 2

Type SKV PN 25 Class 150 DN 80 - 400 3 - 16

Type SKVT PN 25 Class 150 DN 450 - 500 18 - 20

Material Stainless steel, Flanged design

2

Edition: 2020-10 Original document - Mi-706 EN

Introduction

This operating manual is intended for the operating, maintenance and

supervisory personnel.

This operating manual also describes components, equipment and ancillary units

which are not or only partially included in the scope of supply.

The operating personnel must have read, understood and must comply with this

operating manual.

We keep the right to do any technical changes which are necessary to improve the

product without prior notice.

Copyright

Copyright by SOMAS Instrument AB. No part of this publication may be

reproduced, stored in a retrieval system, or transmitted in any form or by any

means, graphic, electronic, mechanical, photocopying, recording, taping, or

otherwise without the prior permission of the copyright owner.

Valve supplier

SOMAS Instrument AB

Norrlandsvägen 26-28

SE-661 40 SÄFFLE

SWEDEN

Phone: +46 (0)533 167 00

E-mail: sales@somas.se

Website: www.somas.se

3

Original document - Mi-706 EN Edition: 2020-10

Table of contents

1 Preliminary remarks 6

1.1 Explanation of warnings, symbols and signs 6

1.1.1 Warnings 6

1.1.2 Symbols and signs 7

2 Safety 8

2.1 Safety instructions 8

2.1.1 General dangers 8

2.1.2 Hazards due to electrical equipment 8

2.1.3 Additional hazards 8

2.1.4 State of the art 9

2.1.5 Preconditions for using the valve 9

2.2 Designated use of the valve 9

2.2.1 Use 9

2.2.2 Liability for non-designated use 10

2.3 Organizational measures 10

2.3.1 Availability of operating manual 10

2.3.2 Additional regulations 10

2.3.3 Checks 10

2.3.4 Protective equipment 10

2.3.5 Rebuilds or modifications at the valve 10

2.3.6 Replacing damaged parts 10

2.4 Selection and qualification of personnel 10

2.5 Safety instructions for ball valves 11

3 Description 13

3.1 General information 13

3.2 Function and design 13

4

Edition: 2020-10 Original document - Mi-706 EN

4 Technical specifications 14

4.1 Tightening torque for bolts 14

4.1.1 Torques for flange boltings 14

4.1.2 Tightening torque for screws in valves 15

4.1.3 Tightening torque for stuffing box gland 15

4.1.4 Tightening torque for bearing blocks 15

5 Assembly 16

5.1 Unpacking and transportation 16

5.2 Installation of the valve in the pipeline 17

5.2.1 Important information for installation 17

5.3 Commissioning 18

5.4 Disassembly of the pneumatic actuator 18

5.5 Positioning of the shaft with disassembled actuator 20

5.6 Assembly of the pneumatic actuator 20

5.6.1 Actuator mounting alternatives 21

6 Maintenance 24

6.1 Disassembling the ball valve from pipeline 24

6.2 Maintenance 25

6.3 Installation and disassembly of the stuffing box 26

6.5 Replacing the seats and ball 28

6.5.1 Disassembly, DN 25–50 valves 28

6.5.2 Cleaning, lubricating and mounting 28

6.5.3 Disassembly, DN 80-400 valves 29

6.5.4 Cleaning, lubricating and mounting 30

6.5.5 Disassembly, DN 450-500 valves 31

6.5.6 Cleaning, lubricating and mounting 32

6.6 Replacing the shaft 33

5

Original document - Mi-706 EN Edition: 2020-10

6.6.1 Disassembly, DN 25–50 valves 34

6.6.2 Cleaning, lubricating and mounting 34

6.6.3 Disassembly, DN 80–400 valves 35

6.6.4 Cleaning, lubricating and mounting 35

6.6.5 Disassembly, DN 450–500 valves 36

6.6.6 Cleaning, lubricating and mounting 36

6.7 Adjustment of the end positions 37

6.7.1 Setting of the “closed” position with type SKV 37

6.7.2 Setting of the “open” position with type SKV 38

6.8 Leak test of the valve 39

6.9 Components 40

6.9.1 SKV, DN 25-50 40

6.9.2 SKV, DN 80-400 41

6.9.3 SKVT, DN 450-500 42

6.10 Alternative seat design 43

6.10.1 Locked seats 43

6.10.2 Scraping seats 43

6

Edition: 2020-10 Original document - Mi-706 EN

1 Preliminary remarks

To enable you to find information quickly and reliably in the operation manual,

this chapter familiarises you with the structure of the operating manual.

This manual uses symbols and special characters which make it easier for you to

find information. Please read the explanations of the symbols given in the section

below.

Ensure that you read all the safety instructions in this operating manual very

carefully.

You will find safety instructions in section 2, in the foreword to the sections and

before any working instructions.

1.1 Explanation of warnings, symbols and signs

1.1.1 Warnings

Warnings are used in this operating manual to warn against injury and material

damage. Always read and observe these warnings! Warnings are identified by the

following symbols:

In this manual are used diverse types of safety and warning notices:

Danger!

International

Safety symbol

Type of danger.

Advise for imminent danger. Not attention of the advices could be mortal or cause severe

injuries as a consequence.

Explanation of the countermeasures.

Warning!

International

Safety symbol

Type of danger.

Advise for imminent danger. Not attention of the advices could cause severe injuries or property

damage as a consequence.

Explanation of the countermeasures.

Attention!

International

Safety symbol

Type of danger.

Advise for possible danger. Not attention of the advices could cause property damage as a

consequence.

Explanation of the countermeasures.

7

Original document - Mi-706 EN Edition: 2020-10

Note

i

Advices and give tips for better understanding of the manual or a better handling of the valve.

1.1.2 Symbols and signs

Symbols and signs are used in this operating manual to provide fast access to

information.

1.1.2.1 Symbols and signs in the text

Symbol Denotation Explanation

Operating instructions This means there is an action to be carried out.

1.

2.

Operating instructions,

multi-step

Work instructions must be carried out in the

sequence shown.

Deviations from the sequence shown may result in

damages to the valves and accidents.

•

–

Lists, two-stage No activities are linked with lists.

➔Cross-reference References to images, tables, other sections or other

instructions.

Tab.1-1 Symbols in the text

8

Edition: 2020-10 Original document - Mi-706 EN

2 Safety

2.1 Safety instructions

2.1.1 General dangers

Sources of danger resulting in general hazards:

• Mechanical hazards

• Electrical hazards

2.1.2 Hazards due to electrical equipment

Due to the permanent dampness, electrically-operated machine parts represent a

potential source of danger.

Comply with all regulations on electrical equipment in damp areas!

2.1.3 Additional hazards

2.1.3.1 Entanglement, crushing and cut/sever hazards

• by moving machine parts left exposed, by removing covers for inspection,

sampling, etc.

• by automatic operated valves

2.1.3.2 Burning or scalding hazards

• by opening or leaving open function-check and/or sampling openings on

systems operating at high temperatures (above 40°C)

• by operating temperature >= 70°C. Short contacts (approx. 1s) of the skin with

the surface of the valve may cause burns (pr EN 563).

• by operating temperature = 65°C. Longer contacts (approx. 3s) of the skin with

the surface of the valve may cause burns (pr EN 563)

• by operating temperature 55°C…65°C. Longer contacts (approx. 10 ... 3s) of the

skin with the surface of the valve may cause burns (pr EN 563)

2.1.3.3 Explosion hazards

A high surface temperature on a valve and actuator, constitutes (a risk for burn

injuries, and) a risk of ignition of explosive atmospheres in ATEX applications.

The surface temperature of the equipment is not dependent on the equipment

itself, but on the ambient conditions and the process conditions. The protection

from the surface temperature is the responsibility of the end user, and must be

effectuated before the equipment is put into service.

9

Original document - Mi-706 EN Edition: 2020-10

2.1.4 State of the art

This product has been built by SOMAS Instrument AB in accordance with state-

of-the-art standards and the recognized safety rules. Nevertheless, its use may

constitute a risk to life and limb of the user or of third parties, or cause damage to

the valve and to other material property, if:

• the product is not used as designated

• the product is operated or repaired by untrained personnel

• the product is modified or converted improperly and/or

• the safety instructions are not observed.

Therefore, every person involved in erecting, operating, inspecting, maintaining,

servicing and repairing the valve must read, understand and observe the complete

operating instructions, particularly the safety instructions.

2.1.5 Preconditions for using the valve

The valve only has to be used:

• in perfect technical condition

• as designated

• according to the instructions in the operating manual, and only by safety-

conscious persons who are fully aware of the risks involved in operating the

valve

• if all protective devices are installed and operative

Rectify immediately any functional disorders, especially those affecting the safety

of the valve!

2.2 Designated use of the valve

2.2.1 Use

The valves are appropriate to be used in pulp and paper industry, chemical

industry, shipbuilding industry, energy industry and offshore industry.

Particular data to the operation and limit values are specified on the data sheet

“Si-706EN”.

The operating values, limit values and setting data must not deviate from the

values specified in the operating manual and correspondig information sheet

without consulting the manufacturer! The manufacturer cannot be held liable for

any damages resulting from non-observance of the operating manual.

10

Edition: 2020-10 Original document - Mi-706 EN

2.2.2 Liability for non-designated use

Using the valve for other purposes than those mentioned previously is considered

contrary to its designated use. For resulting damages of this, SOMAS Instrument

AB is not liable! The user take the risk.

2.3 Organizational measures

2.3.1 Availability of operating manual

The operating manual has to be stored and be readily available!

2.3.2 Additional regulations

In addition to the operating manual, it have to be observed all other generally

applicable legal and other mandatory regulations relevant to accident prevention

and environmental protection! Direct the personnel to comply with them!

2.3.3 Checks

Periodically check that the personnel carry out the work in compliance with the

operating manual and that they pay attention to risks and safety factors.

2.3.4 Protective equipment

Use when necessary protective equipment.

2.3.5 Rebuilds or modifications at the valve

Do not make any rebuilds or modifications at the valve yourself, which can affect

the security of the valve.

2.3.6 Replacing damaged parts

Valve parts that are not in perfect condition must be replaced immediately

with original spare parts! Use only original spare and wear parts from SOMAS

Instrument AB.

On unauthorized parts is not guarantee that they have been designed and

manufactured according to the application.

2.4 Selection and qualification of personnel

Operation, maintenance and repairing works require special knowledge and

may only be carried out by trained technical specialists or qualified personnel

authorized by the user.

11

Original document - Mi-706 EN Edition: 2020-10

2.5 Safety instructions for ball valves

• Operation of the ball valve is always subject to the local safety and accident

prevention regulations.

Danger!

Risk of injury!

Observe movements of the ball.

Keep hands, tools and other objects away from the area where the ball moves when the actuator

is connected to compressed air system. Single action actuators may move to “open” or “closed”

position without being connected to the air system.

Warning!

Before carrying out maintenance or repair work on the ball valve with actuator or installation

and removal of the ball valve from the pipeline, always disconnect the compressed air supply to

the actuator.

Single action actuators may move to “open” or “closed” position without being connected to the

air system.

Warning!

Ensure that personnel who work with, install or repair the ball valve are appropriately trained.

This prevents unnecessary damage and accidents or injury to personnel.

The maintenace and assembly personnel must be familiar with the process of installing and

disassembling the ball valve in a process line, the special and possible risks of the process and

the most important safety regulations.

The repair and assembly personnel must be familiar with the risks when handling pressurised

equipment, hot and cold surfaces, dangerous substances and substances which represent a

hazard to health.

Warning!

Do not exceed the design data of the ball valve!

Exceeding the design data marked on the ball valve may lead to damage and uncontrolled

escape of the pressurised medium.

Both the damage as such and the pressurised medium may lead to injuries to personnel.

Warning!

Do not remove the ball valve from the line as long as it is pressurised!

Dismantling or disassembly of a pressurised ball valve leads to an uncontrolled loss of pressure.

Always isolate the relevant ball valve in the pipe system; despressurise the ball valve and remove

the medium before working on the ball valve.

12

Edition: 2020-10 Original document - Mi-706 EN

Warning!

Before assembling or disassembling the pneumatic actuator of a ball valve installed in the

pipeline depressurise the relevant valve in the pipeline system, isolate the valve and remove the

medium before working on the valve.

The pressurised medium may lead to injuries to personnel.

Warning!

Inform yourself of the properties of the medium. Protect yourself and your environment from

hazardous or poisonous substances.

Observe the safety instructions in the safety data sheets of the manufacturers. Ensure that no

medium can enter the pipeline during maintenance work.

Warning!

Before replacing the stuffing box of a ball valve installed in the pipeline depressurise the

relevant valve in the pipeline system, isolate the valve and remove the medium before working

on the valve.

The pressurised medium may lead to injuries to personnel.

Danger!

Risk of injury!

Observe movements of the ball.

Keep hands, tools and other objects away from the area where the ball moves. The valve with

ball installed may work as a cutting tool. Do not leave any foreign objects in the valve body. The

ball of the ball valve always works as a separate device.

There is no difference whether an actuator is installed or not. The position of the ball

may change during transport or handling of the ball valve.

Warning!

Protect yourself against noise - use the relevant safety equipment.

The ball valve may cause noise in the pipeline. The noise level depends on the type of

application and can be determined with the SOMAS software SomSize.

Additional noise sources in the vicinity of the ball valve may increase the noise level.

Warning!

Beware of very cold or hot surfaces!

The body of the ball valve may become very cold or very hot during operation. Protect yourself

against frostbite and burns.

Warning!

When transporting and handling the ball valve, observe its weight.

Never lift the valve by its positioner, limit switch, solenoid valve or piping. Place the hoisting

ropes securely according to lift instruction.

The ball valve or parts thereof may injure persons if dropped.

Do not walk under suspended loads.

13

Original document - Mi-706 EN Edition: 2020-10

3 Description

3.1 General information

The SOMAS ball valves were developed to meet the requirements of industrial production for

control, on/off and hand operated valves. An unhindered flow is particularly advantageous for

substances containing dirt and the design enables a tight shut off function in closed position.

The valves of type SKV and SKVT are suitable for liquids, pulp slurry, muddy media, vapours,

gases and acids.

Two types of internal design are used: SKV and SKVT. SKV with “floating ball” design or “seat

supported ball” design, used for DN25 to DN400. SKVT with trunnion supported ball design, used

for DN450 and DN500.

Two types of seats are available PTFE 53 and HiCo (High Cobalt alloy)

3.2 Function and design

The SOMAS ball valve type SKV and SKVT is a full bore valve with a cylindrical bore for maximum

capacity. The pressure rating for DN25 - 50 is PN50 and for DN80 - 500 it is PN25. The flanges comply

with various standards and can be drilled according to the EN, ISO and ASME standards.

Spring loaded seats for excellent tightness at low differential pressures.

The valve is also available with “locked seats”. This design is used when there is a risk of media

penetrating behind the seats, a condition that forces the seats towards the ball and blocks the ball’s

rotary motion.

As standard the ball is hard chrome plated. As an option it can be coated with High Cobalt alloy

(HiCo).

The valve seats are available in two different materials:

PTFE 53 (which is PTFE reinforced with stainless steel powder) or HiCo (High Cobalt alloy).

PTFE 53 consists of 50% stainless steel powder and 50% virgin PTFE. PTFE 53 can be used up a

temperature of 200° C. To minimize deformation at high differential pressure and high temperature

the PTFE 53 material is mounted into a support ring made of stainless steel. (➔Fig.3-1).

Seat in HiCo material (➔Fig.3-2) is used for higher temperatures and for fluids containing

impurities which mechanically can destroy a PTFE 53 seat.

Fig.3-1 PTFE 53 Fig.3-2 HiCo (High Cobalt alloy)

14

Edition: 2020-10 Original document - Mi-706 EN

4 Technical specifications

4.1 Tightening torque for bolts

4.1.1 Torques for flange boltings

Use washers and greased bolts to ensure that the joints function properly. Tighten the bolts

alternately with a torque wrench.

Suitable torque varies according to the size of the bolt.

Tab.4-1 Torque for flange boltings

1The information in the table refers to lubricated bolts. The correction factor for new, unlubricated bolts is 1.5.

Tighten the bolts alternately until the correct tightening torque is reached.

Tightening torque applies to flat gaskets corresponding to non-reinforced and reinforced graphite according to EN 12516-2: 2014 with

m-factor according to ASME 2.0 to 2.5. Maximum thickness for gasket: 2.0 mm. Tightening torque must not be exceeded, because then

the functionality of the valve can be compromised. Tightening torques in Nm are designed for gaskets according to EN 1514-1, ASME

B16.21 and counter flanges according to EN 1092-1, EN 1759-1, ASME B16.47.

DN PN/Class Bolt Torque

(Nm) 1

DN PN/Class Bult Torque

(Nm) 1

Dim. Qty. Dim. Qty.

25 10, 16, 25

40

/150

/300

M12

M12

1/2"

5/8"

4

4

4

4

32

48

35

60

200 10

16

25

/150

M20

M20

M24

3/4"

8

12

12

8

175

120

140

180

40 10,16, 25

40

/150

/300

M16

M16

1/2"

3/4"

4

4

4

4

65

95

65

75

250 10

16

25

/150

M20

M24

M27

7/8"

12

12

12

12

140

135

200

170

50 10,16, 25

40

/150

/300

M16

M16

5/8“

5/8“

4

4

4

8

80

120

60

45

300 10

16

25

/150

M20

M24

M27

7/8"

12

12

16

12

160

180

205

230

80 10,16, 25

Class 150

M20

5/8"

8

4

65

105

350 10

16

25

/150

M20

M24

M30

1"

16

16

16

12

215

235

340

280

100 10,16

25

/150

M16

M20

5/8"

8

8

8

80

95

70

400 10

16

25

/150

M24

M27

M33

1"

16

16

16

16

240

300

445

270

125 10,16

25

/150

M16

M24

3/4"

8

8

8

90

110

110

450 10

16

25

/150

M24

M27

M33

1 1/8"

20

20

20

16

210

300

395

405

150 10,16

25

/150

M20

M24

3/4"

8

8

8

120

140

130

500 10

16

25

/150

M24

M30

M33

1 1/8"

20

20

20

20

245

410

480

355

600 10

16

25

/150

M27

M33

M36

1 1/4"

20

20

20

20

310

615

630

510

15

M6 M8 M10 M12 M16 M20 M24 M27

10 25 47 57 140 273 472 682

M6 M8 M10 M12 M16 M20 M24

7 15 25 50 80 125 185

7 10 15 25 50 80 125

Original document - Mi-706 EN Edition: 2020-10

4.1.2 Tightening torque for screws in valves

Screw dim./class

Tightening torque MV 1) (Nm)

1) Mv-recommendations refer to flat burr-free surfaces lubricated with a good quality lubricant.

4.1.3 Tightening torque for stuffing box gland

Screw dim./class

Torques Graphite box (Nm)

Torques PTFE box (Nm)

Valve DN450 DN500

Number of bolts / Diameter 12X M16 8X M20

First mounting torque 50 (Nm) 50 (Nm)

Second mounting torque 220 (Nm) 220 (Nm)

Final tightening torque 280 (Nm) 547 (Nm)

4.1.4 Tightening Torque Bearing Blocks

16

Edition: 2020-10 Original document - Mi-706 EN

5 Assembly

5.1 Unpacking and transportation

Inspect the ball valve for transport damage when unpacking. The protective caps

must only be removed immediately before assembly. The valve must be stored on a

suitable base and protected against dirt until installed.

The valve must be stored in a cool, dry, clean place, not in direct contact with

the floor. The valve must always be protected against dirt during storage and

assembly.

Warning!

When transporting and handling the valve, observe the weight of the valve or of the whole unit.

Do not walk under suspended loads.

Transportation must be carried out with suitable hoisting equipment as shown in

(➔ Fig.5-1). The picture shows a standard situation. Please note that all possible

situations that can occur cannot be covered in this lift instruction.

Fig.5-1 Lifting

17

Original document - Mi-706 EN Edition: 2020-10

5.2 Installation of the valve in the pipeline

Attention!

The valve is normally installed in the pipeline complete with mounted actuator.

Mounting in horizontal pipes

How SOMAS valves are mounted in a horizontal pipe can depend on a variety of factors

like the media, the application as such and available space.

SOMAS valves (ball valves, segmented valves and butterfly valves) should generally be

mounted:

• In the first place with the shaft horizontally

• If it is necessary to deviate from above, the spindle should point upwards in the upper

half plane

• For media that has a thick ”bottom fraction” that can accumulate in the lower shaft

bearing, avoid mounting with the shaft straight up or near straight up

• Mounting with the shaft pointing down in the lower half plane should be avoided,

and especially mounting with the shaft straight down

• If there are strong reasons for choosing the mountings that contradict the

instructions above, SOMAS should be contacted to evaluate the risks associated with

these mountings

The direction of flow is indicated with arrows on the valve body. Fix the pipeline correctly

to prevent the exertion of external forces on the valve.

Warning!

Before carrying out maintenance or repair work on the ball valve with actuator or installation

and removal of the ball valve from the pipeline, always disconnect the compressed air supply to

the actuator.

Single action actuators may move to “open” or “closed” position without being connected to the

air system.

5.2.1 Important information for installation

• Only remove protective devices immediately before installation of the valve

• Mating flanges must be in accordance to the European or ASME standards

• Ensure that the valve is not dirty and the pipeline is cleanly purged. Dirt damages the

seat and the ball segment and leads to leakages

• Ensure that the sealing areas of the mating flanges are clean and parallel

• Ensure that the valve and the gaskets are correctly centred and gaskets of the correct

quality are used

• Tighten the flange bolt carefully. The tightening torque depends on the bolt size (➔

Tab.4-1). Keep the valve closed when it is not put into operation

18

Edition: 2020-10 Original document - Mi-706 EN

5.3 Commissioning

1. Ensure that the valve is cleaned well before commissioning. Dirt damages the

ball and/or seat and leads to leakages.

2. Open the valve completely.

3. Check the stuffing box when the pipe system is pressuerized and retighten the

nuts of the stuffing box gland in the event of leakage.

5.4 Disassembly of the pneumatic actuator

Note

i

Observe also the detailed information in the operating manual of the actuator Mi-503 EN.

Warning!

Before assembling or disassembling the pneumatic actuator of a ball valve installed in the

pipeline depressurise the relevant valve in the pipeline system, isolate the valve and remove the

medium before working on the valve.

The pressurised medium may lead to injuries to personnel.

Warning!

Before carrying out maintenance or repair work on the ball valve with actuator or installation

and removal of the ball valve from the pipeline, always disconnect the compressed air supply to

the actuator.

Single action actuators may move to “open” or “closed” position without being connected to the

air system.

19

3

2

1

4

5

6

Original document - Mi-706 EN Edition: 2020-10

A11 A13 A21 A22 A23 A24 A31 A32

34786 34786 34786 34786 34786 34786 34787 34787

A33 A34 A41 A42 A43 A44 A51 A52

34787 34787 34788 34788 34788 34788 34788 34788

1 Puller 3 Screw 5 Bolt

2 Driver 4 Clamping ring bolts 6 Bracket

Fig.5-2 Disassembly of the actuator (schematic diagram)

Use a puller to remove the actuator from the valve. This prevents damage to the

seat and ball of the valve.

Pullers

Actuator size

Article no.

Actuator size

Article no.

1. Undo the clamping ring bolts (➔Fig.5-2/4).

2. Remove the accessory parts such as positioners and end position limit

switches.

3. Remove the screws (➔Fig.5-2/3), to remove the driver (➔Fig.5-2/2).

4. Remove the bracket (➔Fig.5-2/6) from the valve by removing the bolts

(➔Fig.5-2/5).

5. Press the actuator off the valve with the puller (➔Fig.5-2/1). Turn the puller in

until the actuator can be removed from the valve shaft.

6. Lift the actuator off and turn the puller out again.

20

Edition: 2020-10 Original document - Mi-706 EN

5.5 Positioning of the shaft with disassembled actuator

The shaft of DN 25-50 valves has one key while the shaft of DN 80-400 valves has

two keys placed 180° from each other.

The valve is closed when each key is 90° from the flow direction.

Fig.5-3 Location of the keyway. DN 80-400

5.6 Assembly of the pneumatic actuator

Note

i

Observe also the detailed information in the operating manual of the actuator Mi-503 EN.

Warning!

Before assembling or disassembling the pneumatic actuator of a ball valve installed in the

pipeline depressurise the relevant valve in the pipeline system, isolate the valve and remove the

medium before working on the valve.

The pressurised medium may lead to injuries to personnel.

Warning!

Before carrying out maintenance or repair work on the ball valve with actuator or installation

and removal of the ball valve from the pipeline, always disconnect the compressed air supply to

the actuator.

Single action actuators may move to “open” or “closed” position without being connected to the

air system.

Danger!

Risk of injury!

Observe movements of the ball.

Keep hands, tools and other objects away from the area where the ball moves. The valve with

ball mounted may work as a cutting tool. Do not leave any foreign objects in the valve body. The

ball of the ball valve always works as a separate device.

There is no difference whether an actuator is installed or not. The position of the ball may

change during transport or handling of the ball valve.

This manual suits for next models

1

Table of contents

Other SOMAS Control Unit manuals

Popular Control Unit manuals by other brands

DynaQuip

DynaQuip WaterCop LEAK STOP+ Owner's manual and installation guide

Bosch

Bosch Conettix DX4020 installation guide

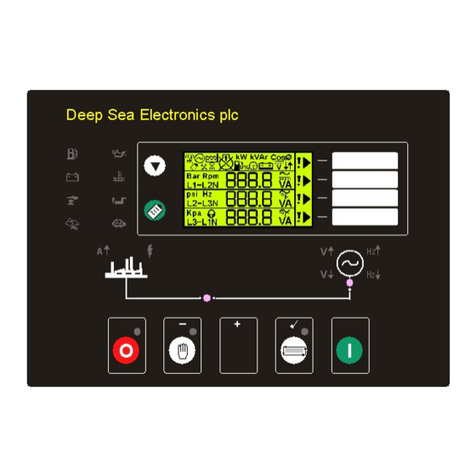

DSE

DSE 5210 operating manual

Equinox Systems

Equinox Systems SuperSerial PM16-RJ/422 Hardware manual addendum

Mercury Racing

Mercury Racing VesselView Installation, Calibration & Operation Manual

ICP DAS USA

ICP DAS USA PETL-7060 quick start guide