Medionic Ionic-Pulser PRO3 User manual

Manual

Ionic-Pulser®PRO3

Detailed instruction manual for

preparation of colloidal silver solution

- 2 -

Contents

Suitable water types 2

Reduction of deposits 2

Concentration & silver release 2

Production 3

Determining the silver release 3

Colour of silver solution 4

Measurement of concentration 4

Storage of colloidal silver 4

Care and maintenance of the device 4

Care and replacement of silver electrodes 4

Trouble-shooting 5

Safety instructions 5

Disposal 5

Customer service 5

Scope of delivery 5

Declaration of Conformity 6

Dear customer,

you have purchased a branded device developed in cooperation with professional users. In 1997, the former

Medionic GmbH was the first company in German-speaking countries to promote colloidal silver. Authors

work with our devices, and many silver solutions, which are available through mail order and pharmacies,

are produced by the Ionic-Pulser®system.

Ionic-Pulser®is a trademark registered in the European Patent Office and protected throughout Europe.

Attention, similar sounding designations have nothing in common with our original devices! These devices

also operate on the principle of electrolysis, but not in association with the lonic-Pulser®system developed

by Wolfgang Jenkner which allows accurate silver releases.

Suitable water types

A pure silver solution can only be made with highly demineralised (distilled) water. The purer the water the

longer and more difficult the process. Therefore, many vendors of conventional devices recommend the

additional usage of salt, mineral water, or tap water. Please ignore such recommendations! By doing so,

silver salts are produced during electrolysis (with every device) which develop undesirable effects and can

be deposited easier due to their larger particles (a single salt granule is already sufficient).

Therefore, do not use salt or similar - the lonic-Pulser®does not require any water additives!

The preparation can also be done with cold water but with hot water a much better quality can be achieved.

For optimal results we recommend using hot distilled water aquaionic®.

Reduction of deposits

In order to reduce black deposits in the production container, you should not use ultrapure water such as

Aqua bidest. The production process should be interrupted briefly after 15-30 minutes to wipe off the silver

electrodes. For a better dispersion of the silver particles, stir occasionally with a non-metallic object (the

earliest 15 minutes after start of production). Do not use metal or plastic containers for the production. Tall

glass containers with a volume of 0.1 - 0.25 litres are best suited. Normal water glasses are preferred to

heat-resistant glasses as the silver particles on the glass walls can deposit less strongly here.

Please note that the silver clusters continue to change during and after the production process (especially in

hot water) to reach their optimal size and quantity.

Concentration & silver release

The silver concentration is given in parts per million, abbreviated ppm, and describes the amount of silver in

water. One ppm is equivalent to 1 milligram of silver per litre of water (mg/l). Due to adhesion of the silver to

- 3 -

glass and electrode surfaces as well as electrochemical processes the silver concentration is always lower

than the silver release.

The lonic-Pulser®compensates changes in temperature, conductivity, the quality of the water used and the

electrode surface. The silver release is the same for each type of water and proportional to the time of

production. To double the time means to double the silver release. The production time for the desired silver

release can be determined according to the table.*

Production

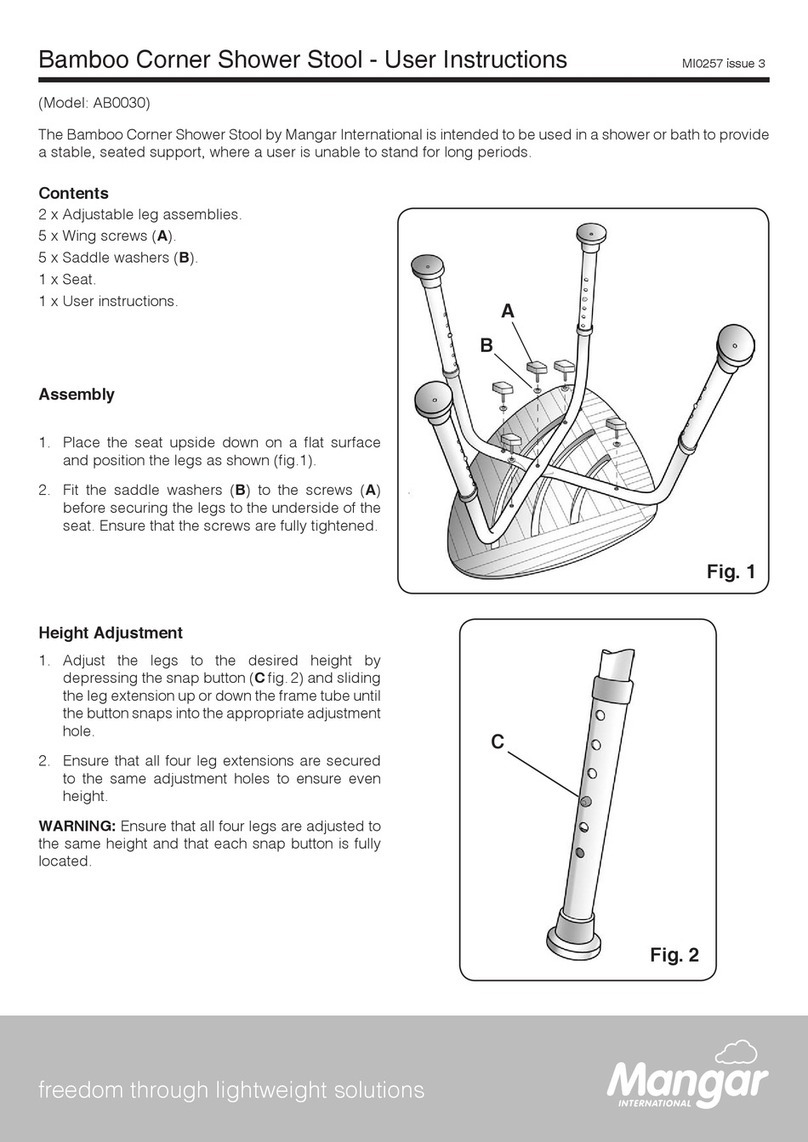

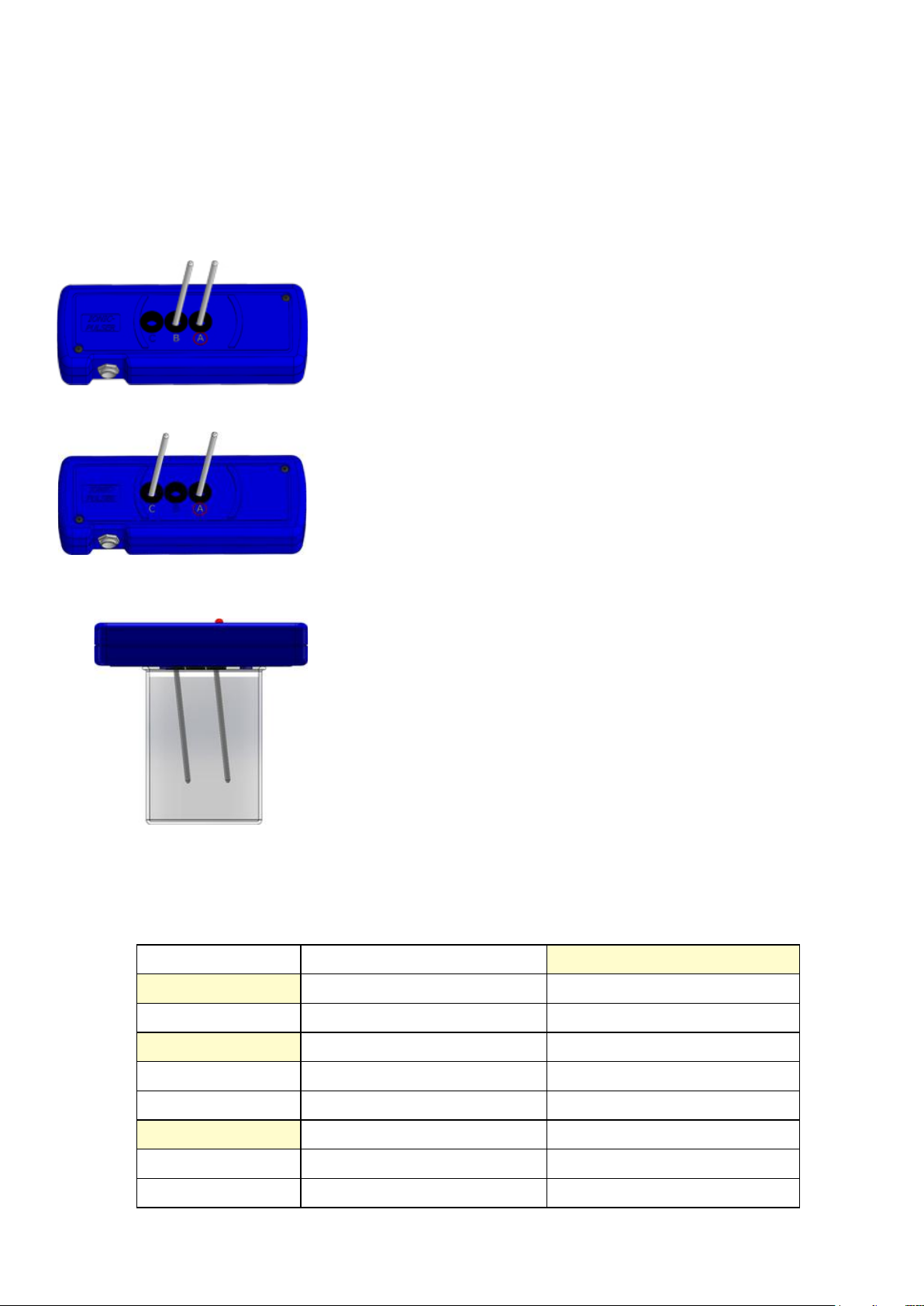

The small electrode distance (A-B) leads to a slightly faster production

process.

The recommended large electrode distance (A-C) leads to a slower

production process creating a better quality, since bridging between the

electrodes are excluded.

Attention: The labeled anode socket (A) must always be equipped with

an electrode!

The silver electrodes must be inserted obliquely into the sockets. With

little sensitivity they can be inserted automatically at the correct angle.

1. Boil distilled water (demineralised) in a suitable container, allow

to cool for about 3 minutes and then pour into a glass. Do not continue to

heat!

Insert silver electrodes into the appropriate sockets on the underside of

the device. Put the device on the glass.

Important: The electrodes must be completely covered with water (0.5 -

1 cm below the edge of the glass).

2. Connect the cable for the power supply unit to the device.

3. Plug the power supply unit into a properly installed (100-240

volts) socket - the red power indicator will light up. The sensor on the

device (red indicator light) only reacts when the silver electrodes are

immersed in the water. To stop the production, the device must be

removed from the glass. The time depends on the desired silver release

(see table).

Determining the silver release

The value in the bracket applies to the large electrode distance A-C.

Silver release Time at 200 ml Time at 250 ml

10 mg/l (ppm) 6 (9) minutes 8 (11) minutes

20 mg/l (ppm) 12 (15) minutes 15 (18) minutes

25 mg/l (ppm) 15 (18) minutes 19 (22) minutes

30 mg/l (ppm) 18 (21) minutes 23 (26) minutes

40 mg/l (ppm) 24 (27) minutes 30 (33) minutes

50 mg/l (ppm) 30 (33) minutes 38 (41) minutes

75 mg/l (ppm) 45 (48) minutes 56 (59) minutes

100 mg/l (ppm) 60 (63) minutes 75 (78) minutes

- 4 -

* If bidistilled water is used, the specified production time must be extended by 5 minutes.

Do not heat the silver solution during and after the process!

At low concentrations, colloidal silver is colourless and tasteless. At higher values, a discolouration may

occur. The higher the concentration, the more intense the metallic-bitter taste, regardless of the colour or

quality of the silver solution.

Recommended concentration for nearly all applications:

25 ppm or 50 ppm (even more effective).

Optimal production: drinking glass with 200 ml (250 ml)

Production time: 25 ppm = 15 min (19 min at 250 ml)

50 ppm = 30 min (38 min at 250 ml)

Colour of silver solution

Higher concentrations of silver can stain the water (yellow/brown).

This colour shows high purity of the water used, but is not a measure of the concentration. Even with the

same production time, each solution can discolour differently. At higher concentrations, a black coating

sometimes forms on the electrodes and on the bottom of the glass. At low concentrations or short production

time, these particles are also present in the same ratio, but hardly visible.

Milky white/gray discolouration is caused by contamination or the use of tap or mineral water. Do not drink!

Measurement of concentration

Please note: With conductivity meters (TDS meters) it is possible to determine real solutions such as saline

solutions, but not the concentration of metal dispersions, e.g. colloidal silver (even if the TDS meter is

calibrated in ppm). The values given in our table were determined and confirmed by means of complex

laboratory tests.

Storage of colloidal silver

The finished silver solution can be used for several months, but gradually diminishes in its effect. Colloidal

silver with a large amount of positively charged ions is particularly effective and should therefore be used

fresh.

In order to keep the silver solution in its optimum condition for a long period of time, the following must be

observed:

Do not store in plastic or metal containers, store in dark glass bottles.

Do not place in electromagnetic fields (next to electric stove, TV, stereo, etc.).

Do not refrigerate, store in a cool place.

Care and maintenance of the device

The generator is maintenance free. Clean with a damp cloth when the power supply is unplugged.

Occasionally remove deposits between the sockets.

Care and replacement of silver electrodes

Wipe the silver electrodes vigorously with kitchen paper or cloth after each operation. Do not use silver

cleaner or scourer! Always insert the electrodes with the same end. If the electrodes have reached the

diameter of a pencil lead and could break, it is time to replace them. A pair of silver electrodes is enough to

produce about 400 litres of 10 ppm or 150 litres of 25 ppm colloidal silver.

Beware of replacement silver electrodes!

Original electrodes are chamfered to a certain angle, to avoid damage to the sockets. Our former standard

size of 2.7 (2.5) x 82 mm has been copied several times by other manufacturers. Imitations are offered as

original or universal electrodes. These products rarely match the high degree of purity and can lead to a loss

of warranty if the sockets are damaged.

Accurate silver release with the best quality can only be achieved with original electrodes!

- 5 -

Trouble-shooting

• Control lamp on the power supply unit does not light up

Main plug has no contact, house fuse has triggered.

• Indicator light on the device does not light up

The silver electrodes or power supply unit are not plugged in properly, the silver electrodes are not

immersed in the water.

• Silver solution has discolouration at same production time

Another type of water or water temperature was used, the electrodes were cleaned in a different way, the

production was carried out under different lighting conditions, there are small amounts of detergent or

grease in the production container.

• Bubbles only rise at one electrode - only one electrode forms a silver cloud - only one electrode

turns black

This is completely normal during the electrolysis process.

• White or gray haze of water

Mineral water or tap water was used or salt added. Use distilled or demineralized water. Do not add any

water additives.

Safety instructions

The device may only be operated with the original 30 Volt Ionic-Pulser®power supply unit. Never immerse

the device in water. Therefore, use containers that are much smaller in diameter than the lonic-Pulser®.

People with pacemakers should avoid direct contact with the electrodes or leave the operation to another

person. Do not associate the active electrodes with the mucosa, such as the "tongue test" for batteries. Do

not operate on conductive surfaces (metal sinks, hobs, etc.). Never place the plugged device on a wet

surface. Do not operate the device unattended. After completing the process unplug the power supply unit.

Keep out of reach of children.

Pure colloidal silver can only be made with demineralized or distilled water.

When using other types of water, including household osmosis devices, undesirable chemical compounds

can be produced. The user is solely responsible for the quality and purity. Likewise, the scope of application

is up to you.

Disposal

Do not dispose the device with normal household waste. Information about environmental

disposal is provided by the responsible department of your municipality.

Customer service

Before you send a device to us, check whether you can fix the fault yourself according to the information

"Trouble-shooting" or call us.

Important: Always send in the power supply unit. Defective power supplies are replaced.

Non-free repair shipments will not be accepted.

Warranty repairs only on presentation of proof of purchase.

24 months warranty from date of invoice for private customers.

Scope of delivery

1x electrolysis device Ionic-Pulser®, model PRO 3 (5-58 volts DC)

1x power supply unit 30 volts for Ionic-Pulser®, for connection to 100-240 volts mains voltage

1x 2 pieces of silver electrodes 3 x 82 mm, purity over 99.99%

1x storage tube for electrodes

1x user manual

1x storage case

- 6 -

Declaration of Conformity

Manufacturer: Medionic GmbH & Co. KG

Großbrösern 1

02627 Radibor

Germany

Hereby the manufacturer declares that the devices comply with the following directives, standards

and regulations:

EMV guideline 2004/108/EG

EN 61000-6-3: 2007

EN 61000-6-1: 2007

The devices were manufactured according to the RoHS guidelines 2001/65 / EU.

The declaration applies to the following products marked with

Designation Ionic-Pulser®Standard S

Designation Ionic-Pulser®PRO

Designation Ionic-Pulser®PRO 3

Radibor, 1st September 2018 _______________________

Managing Director

© 2019 Medionic – all rights reserved.

Medionic GmbH & Co. KG | Großbrösern 1 | D-02627 Radibor

Other languages: www.medionic.de/documents19/

Table of contents

Other Medionic Medical Equipment manuals