Medionic IONIC-PULSER PRO User manual

COLLOIDAL SILVER

GENERATOR

IONIC-PULSER

PRO / Standard S

Manual

since 1997

Dear customer,

You have purchased a proprietary device that has been developed in cooperation with professional

users. Already in 1997, Medionic GmbH was the first company in the German-speaking countries

that made colloidal silver known to the public. In the meantime, almost all book authors work with

our e uipment and many silver solutions that are available in the mail-order business and in

pharmacies are produced with it. Studies of several independent laboratories confirm our

information about concentration and uality of the produced silver dispersions (model Standard S).

Ionic-Pulser is a protected trademark in Europe which is registered at the European Patent Office.

Attention: Similar designations do nothing have in common with our original e uipment. These

devices are also operating on the principle of electrolysis but not on the Ionic Pulser ® system that

makes possible exact concentrations as shown in the table below.

Please note that with conductance measuring instruments (TDS Meter) - even if they are calibrated

in ppm - it is possible to determine real solutions such as salt solutions but not the concentration of

metal dispersions, e.g. colloidal silver. The stated values in our table were determined and

confirmed using complex laboratory measurement procedures.

IONIC-PULSER® - best results even with bi-distilled water - there are no additional

measuring instruments required - The device is automatically set to different water

qualities and temperatures.

Preparation

The silver electrodes have to be inserted into the sockets having a slant. With a bit of sensitivity

they are inserted automatically in the correct angle.

1. Heat distilled water (demineralised) in a metal or heat-

resistant glass container until the boiling point, let it cool

down for about 3 minutes, and then put it into a glass. Insert

the silver electrodes into the sockets on the underside of the

device. Put the device onto the glass. Important: The

electrodes have to be covered almost completely with water

(0.5 - 1 cm below the glass edge).

2. Connect the connection cable of the power supply unit to the

device.

3. Plug in the power supply unit to a properly installed (100-240

volt) wall socket - the red indicator light lights up. The sensor

on the device (red light) only responds when the silver

electrodes are immersed in water. In order to terminate the

production, the device must be removed from the glass. The

time depends on the desired concentration (see table).

Higher concentrations of silver can make the water

yellow/brown. This colour is evidence of high purity of the

used water but not a measure for the concentration. Even at

the same preparation time the colour of every solution varies.

At higher concentrations, sometimes a black coating on the

electrodes and on the bottom of the container arises. At low

concentrations or short production time, these particles exist in

the same ratio but they are not visible. Milky white/gray

discolourations result from the use of tap or mineral water.

Do not drink!

A pure silver colloid can only be produced with highly demineralised (distilled) water. The purer the

water the longer and more difficult the process. Therefore, many vendors of conventional devices

recommend the additional usage of salt, mineral water, or tap water. Doing so, silver salts are

created during electrolysis (with every device). They are less effective and can be deposited

easier due to their larger particles (a granule of salt is already sufficient). Therefore, DO NOT USE

SALT - the Ionic-Pulser re uires no water additives! The production can also be done with cold

water but hot water achieves a better uality.

In order to prevent black deposits in the production container, the process should be briefly

interrupted at least after 15 minutes, just to wipe the silver electrodes. For a better dispersion of the

silver particles it is also possible to stir with a non-metallic object, but not before 15 minutes. No

metal or plastic containers can be used for production. High glasses with a volume of 0.1 -1 litre

are suitable. Please note that during and after the production process the silver clusters shall

continue dividing themselves (especially in hot water). Doing so, they reach their optimal size. In

smaller containers (200 ml) better results are achieved at higher concentrations. Normal drinking-

glasses are more suitable than unbreakable or heat-resistant glasses because the silver particles

are less able to deposit on the glass walls.

Concentration

The silver concentration is given in parts per million, abbreviated “ppm”.

ppm = ratio to determine the molecular presence of a particular substance (e.g. silver) per million

parts in relation to another one (e.g. water)

In conventional devices, the production time depends on temperature, conductivity, uality of the

used water, and the surface of the electrodes. The silver concentration is not regular and can

achieve the multiple value in only twice the time of production. Stirring during production also

changes the concentration.

The Ionic Pulser compensates these factors. The silver concentration is the same for each type of

water and proportional to the time of production, that is to say, doubled time = twice the

concentration.

Concentrations (ppm) can be determined according to the table.*

Choose the amount of water in the horizontal line (size of the production container), in the vertical

line below the desired ppm value, and read on the left side, on the same level, the production time.

Table for Ionic Pulser PRO: Table for Ionic Pulser STANDARD S:

* When using bi-distilled water, the production time has to be extended for 3 minutes.

Do not heat the silver dispersion during and after the preparation process!

Only stir after 15 minutes!

At low concentrations colloidal silver is colourless and tasteless. At higher values a discolouration

occurs. This discolouration may vary extensively at the same concentration. The higher the

concentration the more intense the bitter metallic taste, regardless of the colour or the uality of the

silver solution.

Storage of Colloidal Silver

The finished silver solution is usable for months but it is losing effect continuously. Colloidal silver

with a large amount of positively charged ions is particularly effective and should be used as fresh

as possible. In order to keep its optimal condition, the following advices have to be taken into

consideration:

Do not store in plastic or metal containers but in dark glass bottles.

Do not place in electromagnetic fields (next to electric cooker, TV, stereo system, etc.).

Do not refrigerate but store in a cool place.

Care and Maintenance of the Equipment

The generator is completely maintenance-free. Clean only with a damp cloth and when the power

supply unit is unplugged.

Remove deposits between the sockets occasionally.

Care of Silver Electrodes

Rub the silver electrodes with paper towels or a linen-cloth after every preparation process. Do not

use silver cleaners or scouring pads! If possible, insert the electrodes always with the same end.

Once the electrodes have the diameter of a pencil lead and could break off soon, they should be

replaced. One pair of silver electrodes is sufficient for the production of about 600 litres 5 ppm or

120 litres 25 ppm colloidal silver.

Beware of replacement silver electrodes! Our standard size 2.5 x 75 mm or 2.7 x 82 mm has

been copied several times by other manufacturers and imitations are offered as supposed original

or universal electrodes. These products rarely meet the high purity and NEVER the hardness of

the original. In order to produce accurate concentrations dense silver electrodes have to be used

(hardness in accordance with specifications of the manufacturer). The ends need to be rounded

and sanded.

Exact concentrations and optimum particle sizes can only be achieved with the original

electrodes!

Repair Malfunctions

INDICATOR LIGHT OF POWER SUPPLY UNIT DOES NOT WORK - power plug

has no contact, house fuse has gone.

DISPLAY OF THE GENERATOR DOES NOT WORK - The silver electrodes or the power supply

unit are not plugged in correctly. The electrodes are not immersed in water.

SILVER SOLUTION HAS DISCOLOURATION AT SAME PREPARATION TIME - A different kind of

water or different water temperature was used. The electrodes have been cleaned in another way.

The preparation was made at different lighting conditions. There are slight residues of detergent or

fat in the production container.

BUBBLES ARE ASCENDING ONLY ON ONE ELECTRODE - A SILVER CLOUD IS FORMING

ONLY ON ONE ELECTRODE - ONLY ONE ELECTRODE IS BECOMING BLACK - This is

completely normal in the electrolysis process.

WHITE OR GREY COLOURATION OF THE WATER - Mineral water or tap water has been used or

salt has been added. Use water with the designation “distilled” or “demineralised”. Do not add

water additives.

Safety Indications

The device may only be operated with the original 30 volt IONIC PULSER power supply unit. Do

not immerse the device in water. Therefore, use containers that have a substantially smaller

diameter than the Ionic-Pulser. Persons with pacemakers should avoid direct contact with the

electrodes or leave the operation to another person. Avoid contact between the active electrodes

and the mucous membrane like it is done in the "tongue test" for batteries. Do not work on

conductive surfaces (metal sinks, hotplates, etc.). The connected device must not be placed on

such or wet surfaces. Do not operate the device unattended. After completion unplug the power

supply unit. Keep out of reach of children.

Pure colloidal silver can only be produced with water that has the designation “distilled” or

“demineralised”. When using other types of water, also from household osmosis equipment,

undesirable chemical compounds can be produced. Only the user is responsible for quality and

purity. The field of application is also the e clusive responsibility of the user.

Disposal

Do not dispose the device with the normal household refuse.

Information about environmentally suitable disposal

may be obtained from the relevant department in your community.

Medionic Gerätebau, Radibor WEEE -Reg.-Nr. DE 60236950

Customer Service

Before you send a unit back to us, please check whether the malfunction can be repaired by your

own, according to the information given in “Repair Malfunctions”, or call us. Important: Always

enclose the power supply unit in your consignment. Defective power supply units will be

repaired. In case of replacement of a power supply unit a nominal fee of EUR 65.00 will be

charged, since it is a customized design.

Unstamped repair consignments will not be accepted.

Warranty repairs only on presentation of proof of purchase.

24 months defects liability guarantee from date of invoice.

Included:

1 x Generator IONIC-PULSER

Model PRO or Standard S (5-58 volts)

1 x 30 Volt power supply unit

Special model for Ionic-Pulser

For connecting to 100-240 volts mains voltage

1 x 2 pieces of silver electrodes 2.7 x 82 mm

Degree of purity min. 99.99%

1 x Manual

1 x Storage tube for electrodes

This manual suits for next models

1

Table of contents

Other Medionic Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Sakamoto Model

Sakamoto Model M193 user manual

epredia

epredia STP120 Operator's guide

Universal Medical

Universal Medical ISOLED XII Service manual

Neurotech

Neurotech AvivaTens XP Instructions for use & warranty

Zeiss

Zeiss VISULAS YAG III user manual

Howard Industries

Howard Industries PHACOJACK Operator's manual

Life Smart

Life Smart M70C Operator's manual

Agilent Technologies

Agilent Technologies 7100 Technical note

I-care

I-care ic100 instruction manual

Lowenstein Medical

Lowenstein Medical prisma CHECK Instructions for use

Spectrum Healthcare

Spectrum Healthcare AlbacMat user guide

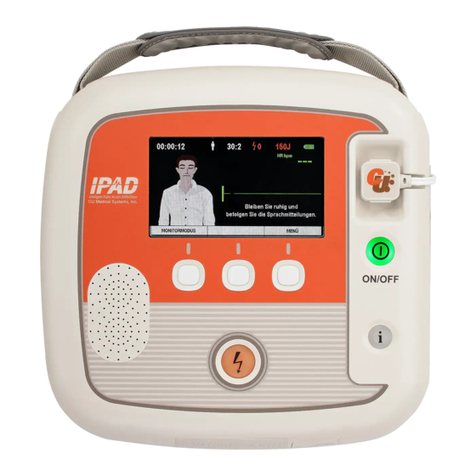

CU Medical Systems

CU Medical Systems i-PAD CU-SP2 Instructions for use