Medora GS-12-Air User manual

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

O&M_GS_12_Air_120V_10389_20191017

GS-12-Air

120V Owner's Manual

Table of Contents

About Medora Corporation

Medora Corporation combines knowledge and experience from across the water quality spectrum to help

solve real-world problems. Whether in Lakes, Stormwater Retention Ponds, Raw Drinking-Source Reservoirs,

Water Treatment Plants, Potable Storage Tanks, or Wastewater Treatment Processes, Medora Corporation

equipment continues to be at the forefront as the #1 world leader for in-situ water body treatment.

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Table of Contents

10014_20191001

GS-12-Air

120V Owner's Manual

Saftey Instructions 1

Package Contents 4

Machine Requirements 5

Installation and Operation 6

Final Checklist 10

Troubleshooting 11

Technical Specifications 12

Warranty 13

Customer Service 14

O&M_GS_12_Air_120V_10389_20191017

Carefully read safety information when you see

any safety symbols.

Be sure you have read all installation, operation, maintenance and safety instructions

before you install, service or begin to operate this unit.

Accidents occur every year because of careless use of industrial equipment. You can avoid

hazards by following these safety instructions, and applying some ordinary common sense

when operating or servicing this unit.

Keep in mind that full operator attention and alertness are required when operating or

servicing this unit.

USE COMMON SENSE!! Most accidents can be avoided by using common sense and

concentration on the job being done.

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Safety

Safety

1949_10036_20191001 O&M_GS_12_Air_120V_10389_20191017 - 1

IMPORTANT!!!

Follow all federal and state laws in regards

to safety regulations of working at heights,

conned spaces, rescue, etc. as required by

the U.S. Department of Labor, Occupational

Safety and Health Administration. Use

necessary PPE when placing and servicing

this unit.

Identify all possible hazards. Determine what

safeguards are needed and implement them.

Only you, the user, understand your product

and system characteristics fully. The ultimate

responsibility for safety is with you. Your

safety ultimately rests in your hands. Do

your part and you will enjoy safe, trouble free

operation for years to come. This instruction

manual is not intended to include a compre-

hensive listing of all details for all procedures

required for placement, operation and mainte-

nance. If you have a question about a proce-

dure or are uncertain about any detail, Do Not

Proceed. Please contact GridBee Customer

Service at 866-437-8076 to speak to a repre-

sentative.

ELECTRICAL HAZARD

WARNING: THIS EQUIPMENT CONTAINS HIGH

VOLTAGE! ELECTRICAL SHOCK CAN CAUSE

SERIOUS OR FATAL INJURY. ONLY QUALIFIED

PERSONNEL SHOULD ATTEMPT PLACEMENT,

OPERATION AND MAINTENANCE OF

ELECTRICAL EQUIPMENT. REMOVE ALL

SOURCES OF ELECTRICAL POWER BEFORE

PERFORMING ANY SERVICE WORK TO THE

MACHINE. USE PROPER LOCKOUT TAGOUT

(LOTO) PROCEDURES TO ENSURE A SAFE

WORK ENVIRONMENT.

Rotating Hazard

CAUTION: KEEP BODY APPENANDAGES OR

LOOSE CLOTHING AWAY FROM EQUIPMENT

WHILE OPERATING. ENSURE EQUIPMENT IS

OFF BEFORE ATTEMPTING SERVICE.

Crush Hazard

WARNING: DO NOT REMOVE ANY FLOAT

ASSEMBLY BOLTS OR PINS WHILE

EQUIPMENT IS FLOATING IN WATER.

EQUIPMENT MUST BE SECURELY

SUPPORTED BEFORE PERFORMING

SERVICE.

Laceration Hazard

CAUTION: EDGES MAY BE SHARP AND

CAUSE LACERATION IF PROPER CARE IS

NOT USED.

Entanglement Hazard

WARNING: ENSURE THAT PERSONNEL ARE

CLEAR OF THE ELECTRIC CORD AND CHAIN

TO AVOID ENTANGLEMENT.

Thin Ice Hazard

WARNING: ICE SURROUNDING MACHINE

MAY NOT SUPPORT WEIGHT, KEEP CLEAR OF

THIN ICE.

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Safety

Safety

1949_10036_20191001 O&M_GS_12_Air_120V_10389_20191017 - 2

Permit-Required

Conned Spaces

A conned space has limited openings for

entry or exit, is large enough for entering and

working, and is not designed for continuous

worker occupancy. Conned spaces include

underground reservoirs, ground storage tanks,

elevated tanks, silos, manholes, and pipelines.

Conned Space Tips

• Do not enter permit-required conned spaces

without being trained and without having a

permit to enter.

• Review, understand and follow employer’s

procedures before entering permit-required

conned spaces and know how and when

to exit.

• Before entry, identify any physical hazards.

• Before and during entry, test and monitor for

oxygen content, ammability, toxicity or

explosive hazards as necessary.

• Use fall protection, rescue, air monitoring,

ventilation, lighting and communication

equipment according to entry procedures.

• Maintain contact at all times with a trained

attendant either visually, via phone, or by

two-way radio. This monitoring system

enables the attendant and entry supervisor

to order you to evacuate and to alert

appropriately trained rescue personnel to

rescue entrants when needed.

Refer to 29 CFR 1910.146 for complete

regulations set by OSHA. Refer to your state's

regulations if your state established and operates

their own safety and health programs approved

by OSHA.

Protect Yourself

Medora Corporation insists that you comply with

all relative OSHA and local regulations while

installing and performing any maintenance to the

mixer circulation equipment.

Key OSHA Compliance Standards that must

be followed (and not limited to) are:

• 1910.146 Permit-required conned spaces

• 1910.147 Lockout/Tagout

• 1926.500 Fall Protection

Fall Protection Tips

• Identify all potential tripping and fall hazards

before work starts.

• Look for fall hazards such as unprotected

oor openings/edges, shafts, open hatches,

stairwells, and roof openings/edges.

• Inspect fall protection and rescue equipment

for defects before use.

• Select, wear, and use fall protection and

rescue equipment appropriate for the task.

• Secure and stabilize all ladders before

climbing.

• Never stand on the top rung/step of a ladder.

• Use handrails when you go up or down stairs.

• Practice good housekeeping. Keep cords,

welding leads and air hoses out of walkways

or adjacent work areas.

Refer to 29 CFR 1926.500 for complete

regulations set by OSHA. Refer to your state's

regulations if your state established and operates

their own safety and health programs approved by

OSHA.

Lockout Tagout

When the On/Off switch is in the "ON" position,

the mixer may start up at any time if not already

operating. The mixer's On/Off switch can be

locked out by placing a pad lock thru the door latch

of the controller after the switch has been turned

to the "OFF" position. The On/Off switch is to be

used as the emergency stop.

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Safety

Safety

1949_10036_20191001 O&M_GS_12_Air_120V_10389_20191017 - 3

1 5/16” Hole Saw

Chain Grab Tools Lexel

Sealant Tube

Kellem Grip

Cord Strain Relief

100’

Stainless Steel

Chain

GS-12-Air SCADA Panel

(Optional Accessory Item)

GS-12-Air Mixer

Tank-roof junction box (Optional Ac-

cessory Item included with Heated

hose, mounts onto through-tank

tting, )

Through-tank tting

for air line; sup-

ports junction box

and retrieval chain

attach point

Interior Hose

(Optional Accessory Item)

Exterior Hose

(Optional Accessory Item)

AC655 1HP

Compressor Unit

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Package Contents

GS-12-Air

Package Contents

10401_20191001 O&M_GS_12_Air_120V_10389_20191017 - 4

Hatch Requirement

A 12 inch (305 mm) diameter hatch opening is required

to t the GS Mixer through.

Power Requirement

120 VAC, 20 amp GFCI protected service and means

of quick power disconnect recommended

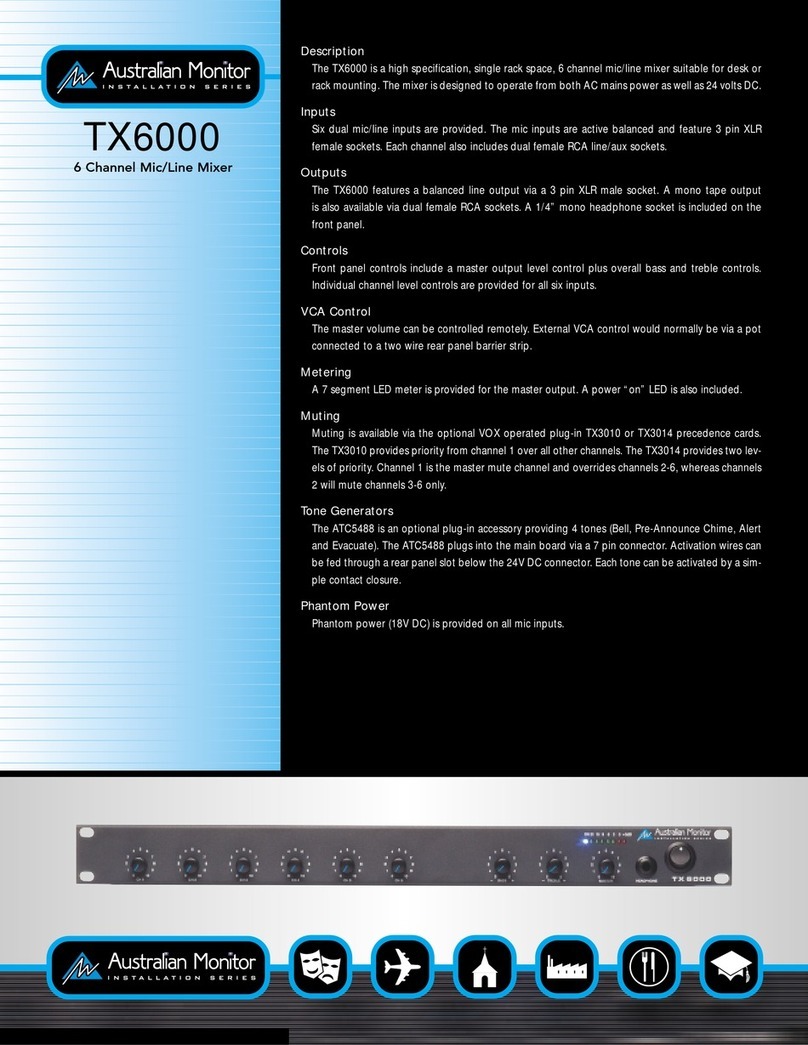

Figure 1: Typical GS Placement

Optional

Mixer Control Panel

Roof Mount Hose Fixture

Supplied with GS Mixer and located

within arms reach of the hatch.

Exterior Hose

120vAC, 20Amp

GFCI Circuit Breaker

Condensate Drain Located at the

lowest point of the hose.

Locate power source ex conduit termination at customer

preferred location of Mixer Control Panel

RATING FULL

LOAD LOCKED

ROTOR

AMPS

HP KW VOLTS HZ S.F. (2)

AMPS WATTS

1 0.655 115 60 1.6 6.0 655 18

Weather-Resistant, Ventilated

Enclosure

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Requirements

Requirements

GS-12-Air

10403_20191001 O&M_GS_12_Air_120V_10389_20191017 - 5

INSTALL THROUGH TANK FITTING:

STEP 1: Locate the hatch where the GS-12-Air mixer will be installed through and mark a penetration

point on the roof for the penetration tting. When selecting a penetration location be sure to conrm

the following:

A. The penetration is not going to hit an internal structure.

B. The penetration is centered within a clear footprint of approximately 8-inch X 8-inch (20cmX20cm)

C. The penetration is within arms reach of the hatch.

STEP 2: Use a cordless drill with the 1-5/16 inch (33mm) hole saw and begin drilling a hole through

the tank roof. A small amount of food grade vegetable oil or water works well for lubrication of the

hole saw. Prior to completing the penetration, position a catch bucket below the penetration point to

catch lings and the hole cut out. If a catch bucket is not readily available, use the cardboard box the

hole saw and ttings came in to catch the lings and disc cut out from falling into the tank.

STEP 3: Thoroughly clean all surfaces around the penetration of any lings before removing

the catch bucket. The penetration is now ready for a sealant application and installation of the

penetration tting.

STEP 4: Apply a healthy amount of sealant on all the surrounding surfaces of the penetration (interior,

exterior, and inner wall). This will prevent future corrosion of the roof around the xture.

STEP 5: Install the penetration tting as shown below so that there is an interior and exterior nut and

gasket in place prior to tightening the xture to the roof. Adjust the height of the xture so the top is

approximately 3-1/2 inches (9cm) above tank roof. Tighten jam nut to rmly secure the xture to the

roof using a large channel lock and pipe wrench.

Penetration Fitting

THE

INFORMATION

CONTAINED

IN

THIS

DRAWING

IS

THE

SOLE

PROPERTY

OF

MEDORA

CORPORATION

.

ANY

REPRODUCTION

IN

PART

OR

AS A WHOLE

WITHOUT

THE WRITTEN PERMISSION

OF SOLARBEE

,

INC

.

IS

PROHIBITED

.

PART

NO

.

REV

TITLE:

PROPRIETARY

AND

CONFIDENTIAL

Fixture

Bolt:

Steel

Tank

Mount

FILE

NAME

FixtureBolt_20161130

1 CORD BOLT PER

SOLARBEE:

N

UT/GASKET

OD:

2.250"THREADED FIXTURE OD: 1.250"BORE REQUIRED:1.250"METAL TANK ROOF

INSIDE TANKOUTSIDE TANKBRASS NUTHDPE WASHER

SEAL

HDPE WASHER

SEAL

BRASS NUT316SS CORD BOLT

(3/4"

NPT INTERNALTHREADS FOR PV STAND

CONNECTION

POINT)

316SS CORD BOLTASSEMBLEDVIEWEXPLODEDVIEW

CROSS-SECTIONAL

VIEW

T316

SS

FIXTURE

BOLT:

TANK

PENETRATION

ASSEMBLY

TANK

PENETRATION

IS

SEALED WITH

HDPE

WASHERS

ACCOMPANIED

BY

LEXEL®

CO-POLYMER

RUBBER-BASED

SEALANT

Penetration Fitting

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Installation and Operation

GS-12-Air

10390_20191001 O&M_GS_12_Air_120V_10389_20191017 - 6

INSTALL GS-12-Air MIXER:

STEP 1: Plan out a safe procedure and hoist the GS-12-Air mixer to the top of the tank near the

hatch opening. Use the chain attached to the GS-12-Air mixer for lifting and supporting the weight.

Keep clear of chain and air hose to avoid entanglement.

STEP 2: Slide the required kellem grip over the air hose that will attach to the machine. Make sure

kellem grip is 6-8ft from the end and eye loop is towards the machine end of the hose. Attach the

kellem grip using a quick link to the center of the suspension chain attached to the machine. Attach

air hose to hose barb on the machine with supplied hose clamp and tighten.

STEP 3: Attach one end of the retrieval chain to the bottom of the penetration tting with a quick link.

Attach opposite end of the retrieval chain to the quick link located on the mixer chain. Tighten both

quick links with a pliers.

STEP 4: Slowly and carefully lower the GS-12-Air mixer down to the tank oor until it is resting on

the bottom. The proper position is when the at edge of the GS-12-Air mixer ends are resting on the

oor.

For suspended conguration pick the unit up so it is just above the tank oor, but is as low as

Medora Corporation

3225 Hwy 22, Dickinson, ND 58601

+1 866.437.8076 • +1 701.225.4495 • Fax +1 701.225.0002

www.medoraco.com

GS_SuspensionKit_Spec_20150918 © 2015 Medora Corporation • Dickinson, ND

Entanglement Hazard

WARNING: WHEN LOWERING OR RAISING THE GS-12-Air

MIXER, BE SURE THAT YOU AND OTHERS ARE CLEAR OF THE

ELECTRIC CORD AND CHAIN TO AVOID ENTANGLEMENT!

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Installation and Operation

GS-12-Air

10390_20191001 O&M_GS_12_Air_120V_10389_20191017 - 7

INSTALL AIR HOSE

STEP 1: Secure interior hose barb to bottom of penetration tting. Secure interior hose (cut to length)

to the interior hose barb with the provided hose clamp as shown below.

STEP 2: Secure exterior hose barb and elbow to the penetration tting. Secure exterior hose to the

exterior hose barb using provided hose clamp as shown below.

STEP 3: Run external air hose to air compressor. Place water drain assembly at the lowest part of the

hose length to allow water condensation to collect. Secure hose using stainless steel zip ties, magnet

pads, or adhesive pads attaching hose to structure at a recommended spacing of every 4’. Best

attaching method depends on specic tanks.

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Installation and Operation

GS-12-Air

10390_20191001 O&M_GS_12_Air_120V_10389_20191017 - 8

GS-12-Air Flow Pattern

The GS-12-Air is designed to circulate water by bringing water from along the tank oor and sending

it upward and out across the water surface in layers causing direct and induced mixing effects. The

air diffuser creates thousands of tiny bubbles which produces a "Low Pressure Zone" that creates an

uplift suction ow through the intake draft tube, and a slight mound at the water surface, producing

gentle ow radially outward from the AP Unit.

The near laminar layers ow outward radially, in diverging stream lines directly above the GS-12-

Air. As ow leaves the Unit, vertical ow is induced in between the water being drawn below and the

water above. At the level of the ow intake, water is drawn from all inner walls and along the oor

of the tank. As this lower layer of uid makes its way inward with converging streamlines to the GS-

12-Air, the water is forced upward, toward the surface, providing gentle mixing, de-stratication, and

surface renewal.

The GS-12-Air Unit requires a minimal amount of supplied air. The air is supplied to the GS-12-Air

Unit with the provided air feed hose that connects to air manifold.

It is acceptable to use the Unit on an as needed or required basis. This will allow for reduced power

consumption and will benet in energy savings. This will require the Unit to run on a timer or local

SCADA system.

Refer to air supply manufacturer for recommended duty cycle and other operational

recommendations and constraints.

LOW PRESSURE

ZONE

WATER PULLED HORIZONTAL TOWARD INTAKE

DIRECT

UPLIFT FLOW

WATER PULLED HORIZONTAL TOWARD INTAKE

INDUCED FLOW PATTERN

INDUCED FLOW PATTERN

SURFACE FLOW

SURFACE FLOW

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Installation and Operation

GS-12-Air

10390_20191001 O&M_GS_12_Air_120V_10389_20191017 - 9

Installation Checks

Before starting the GS Series mixer a few checklist

items are recommended to conrm the installation is

correct.

Installation Checks Check

Is the mixer placed correctly with slots facing up? (Placement)

Is the mixer retrieval chain connected securely? (Placement)

Is the kellum grip supporting the weight of the cord/hose? (Placement)

Is the cord/hose ran through the cord seal in the top of tank junction box? (Placement)

Is the Tank Penetration tting sealed with Lexel? (Top of Tank Junction Box)

Are the top of tank junction box splices correct and each splice individually sealed to protect from

corrosion? (Top of tank Junction Box) (Not applicable for GS-12-Air)

Is the eld wiring correct? (Requirements)

Is The Mixer submerged in at least 2’ (0.75m) of water?

Pre Operation Checks Reading

Continuity Check Line to Neutral:

Line to Ground:

Neutral to Ground:

Source Voltage Reading

Operation Check (While Mixer is Running) Reading / Observation

Source Voltage Reading

Amperage Reading

Flow Check Auditory

Flow Check Visual

Operation Checks

The following checklist items are recommended to

conrm proper operation.

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Final Checklist

Final Checklist

1931_10003_20191001 O&M_GS_12_Air_120V_10389_20191017 - 10

Voltage (ṽ)

To measure the voltage follow these steps.

1. Set the voltmeter on Volts AC.

2. Place the positive probe on the black wire and the negative

probe on the white wire on the top of the contactor (source side).

3. Record the reading.

Amperage (Ã)

To Measure the Amperage follow these steps.

1. Use a clamp type ammeter, set to Amps AC.

2. Clamp around the black wire on the bottom of the contactor

(load side). Marked Load 1 (L1).

3. Record the reading with mixer turned on.

Ohms (Ω)

To Measure the Ohms follow these steps.

1. Turn off the circuit breaker feeding the control panel and follow

lock out tag out procedures.

2. Measure the Voltage to conrm that the power is removed.

3. Disconnect the black and white wires from the bottom of the

contactor (load side). Marked Load 1 (L1) and Neutral (N).

4. Set the Voltmeter to Ohms.

5. Place the positive probe on the black wire and the negative

probe on the white wire that were disconnected.

6. Record the reading.

Depending on the length and gauge of wires to the mixer the ohms

should be approximately:

1-4 Ohms, 120V.

Figure 1: SCADA Control Panel

Problem Possible Cause

Compressor Intermittently

Tripping Circuit Breaker

Multiple GFCI on Circuit

Source Power Fluctuation

Compressor Quickly Tripping

Circuit Breaker

Short to Ground

Locked Rotor on Motor

Compressor Not Operating but

Circuit Breaker not tripped

Loose or Loss of Connection

Compressor Making Loud Noise Motor Bearing Failure

Compressor Gasket Failure

Figure 2: Disconnect Control Panel

Contactor

Contactor

Incoming

Power

Incoming

Power

Troubleshooting Information

Serial Number

Location Name

Tank Name

Distributor Name

(if applicable)

Voltage Reading

Amperage Reading

Ohm Reading

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Troubleshooting

Troubleshooting

GS-12-Air

10409_20191017 O&M_GS_12_Air_120V_10389_20191017 - 11

Figure 1: GS-12-Air

Technology Description- GridBee® electric submersible water circulation equipment, designed for continuous operation.

Constructed with T316 stainless steel shell and safe materials for contact with potable drinking water. Designed to be

placed into service through roof hatch without tank entry.

Electrical Requirements - 120VAC motor requires 120VAC/1PH power source outlet (minimum 20 Amp service).

Certications - Medora Corporation's potable water products are certied to ANSI/NSF Standard 61, and 372 for lead-free

content. Learn more at: www.medoraco.com/std61

Life / Maintenance / Warranty - 25-year design life, limited maintenance. Limited 5-year parts and labor warranty.

See Warranty Statement for details.

Optional Accessories - Additional standard hose available in 100’ length.

Minimum Water Depth - Machine requires 20 in (0.5 m) of

water to effectively circulate. No damage to machine when

run dry in shallow water or drained condition.

1 HP Compressor Unit - AC655 - 1 HP (655 Watt) rated compressor capable of producing 4.3 standard cubic

feet per minute (0.13 standard cubic meters per minute) @ 15 psi (105 kiloPascal). Mounted to steel skid, in-

cludes brass ttings, air inlet lter, 0-60psi pressure gauge, and pressure relief. Maximum Pressure of 40 psi (275

kiloPascal). Continuous duty-cycle. Requires 120vAC, 20 Amp Service. Current range: 2.5 amps (open dis-

charge) - 5.3 (dead head). Connection: 3/8” FNPT with 3/4” hose barb. Size: 18” L x 10.5” W x 15.5” H.

High Pressure unit for specic application requirements is available upon request. For self-supplied air source,

please contact Medora Corporation.

Materials of Construction - T316 stainless steel shell and

hardware construction. UHMW-PE end plates for worry-free

safe contact with all tank surfaces. See certications

section below.

100 ft (30 m) of T316 stainless steel retrieval chain included

for machine installation and retrieval without requiring tank

entry.

Minimum Access Opening - Machine can be placed

through 12 inch (30 cm) diameter opening.

Maximum Operating Depth - Maximum air discharge depth is limited by the air supply pressure available.

Machine Size / Weight

• 37 in (93.98 cm) long x 10 in (25.4 cm) height x 9 in (22.9 cm) width / 50 lbs (23 kg)

Patent Pending Subject to change without notice.

Recommended Air Supply - Machine is provided with a 1/2 inch air hose connection point.

Enclosed Area Warning - Air powered mixers should not be used in enclosed areas where methane or other explosive

gases could build up. Some gases can explode when combined with air. Please verify that you have proper ventilation to

prevent a buildup of methane gas or other gases in the headspace above the explosion limit.

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Technical Data Sheet

GS-12-Air

2130_10400_20191001 O&M_GS_12_Air_120V_10389_20191017 - 12

GridBee GS Mixers. The GridBee Series GS mixers are warranted to be free of defective parts, materials, and

workmanship for a period of ve years from the date of purchase. This warranty is valid only for use of the equip-

ment in accordance with the owner’s manual and any initial and ongoing factory recommendations. This war-

ranty is limited to the repair or replacement of defective components only and does not apply to normal wear and

tear. If the factory’s service crews performed the original on-site placement and startup, then this warranty also

includes labor. Where labor is included, in lieu of sending a factory service crew to the site for minor repairs, Me-

dora Corporation may choose to send the replacement parts to the owner postage-paid and may pay the owner a

reasonable labor allowance, as determined solely by Medora, to install the parts. There is no liability for conse-

quential damages of any type. The warranty that is submitted and provided with the purchased equipment is the

valid warranty.

GridBee control panels, cold weather hose kits, air compressors and any optional accessories. These

items are considered “buyout” items for Medora Corporation, and as such include a warranty against defects in

material and workmanship for one year from the date of purchase. This warranty covers parts only, not labor.

Parts that are determined by Medora Corporation to be defective in material or workmanship under normal use

during the one year warranty period will be repaired or replaced. Shipping charges are the responsibility of the

customer.

Terms applicable to all equipment. There is no liability for any consequential damages of any type, or to re-

place items that wear out from “normal use” in Medora’s sole determination. Equipment warranties are valid only

for equipment that is used in accordance with the owner’s manual, and consistent with any initial and ongoing

factory recommendations. Medora Corp.’s warranties change from time to time; only the exact warranty in effect

when the equipment was purchased, as provided with the equipment, is valid.

EXCEPT AS STATED ABOVE, MEDORA CORPORATION AND ITS AFFILIATES EXPRESSLYDISCLAIM ANY

AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES ON PRODUCTS

FURNISHED HEREUNDER, INCLUDING WITHOUT LIMITATION ALL IMPLIED WARRANTIES OF MERCHANT-

ABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

Please consult your state law regarding this warranty as certain states may have legal provisions affecting the

scope of this warranty.

IN NO EVENT WILL MEDORA CORP. OR ITS AFFILIATES BE LIABLE FOR ANY DAMAGES CAUSED BY

FAILURE OF BUYER TO PERFORM BUYER’S RESPONSIBILITIES OR FOR FOLLOWING MEDORA CORP.

ADVICE. IN NO EVENT WILL MEDORA CORP. OR ITS AFFILIATES BE LIABLE FOR ANY LOST PROFITS OR

USE OR OTHER PUNITIVE, SPECIAL, EXEMPLARY, CONSEQUENTIAL, INCIDENTAL OR INDIRECT DAMAG-

ES, HOWEVER CAUSED, ON ANY THEORY OF LIABILITY, WHETHER OR NOT MEDORA CORP. HAS BEEN

ADVISED OF SUCH DAMAGES, OR REASONABLY COULD HAVE FORESEEN THE POSSIBILITY OF SUCH

DAMAGES, OR FOR ANY CLAIM AGAINST BUYER BY ANOTHER PARTY.

GridBee GS Submersible Mixer Limited Replacement Warranty:

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Warranty

1684_10018_20191017 O&M_GS_12_Air_120V_10389_20191017 - 13

© 2019 Medora Corporation | www.medoraco.com | 866 - 437 - 8076 | [email protected]

Service & Support

Medora Corporation employs qualied highly trained Service and Placement Technicians certied

to perform the necessary tasks required to install or remove SolarBee and GridBee circulation

equipment.

Medora's specialized Service and Placement Technicians are trained in Conned Space, Fall

Protection, and other related subjects as required by OSHA to perform the necessary work to install

or remove SolarBee and GridBee equipment, and are knowlegeable in the regulations and standards

of OSHA.

If you feel the need to service your SolarBee or GridBee circulation equipment, please contact

Medora's Customer Service Department at:

+1 866 437 8076

Medora Corporation Service & Support

1928_10001_20191017 O&M_GS_12_Air_120V_10389_20191017 - 14

Other Medora Mixer manuals

Popular Mixer manuals by other brands

Giani

Giani Cucina GCKF106 instruction manual

Electrolux

Electrolux Dito Ditomix 5 instruction manual

Fargo

Fargo CE-3401XG Installation operation and care

AUSTRALIAN MONITOR

AUSTRALIAN MONITOR TX6000 Specifications

Electrolux

Electrolux BMXE80 Brochure & specs

Healthy Choice

Healthy Choice MMX1000 instruction manual