5

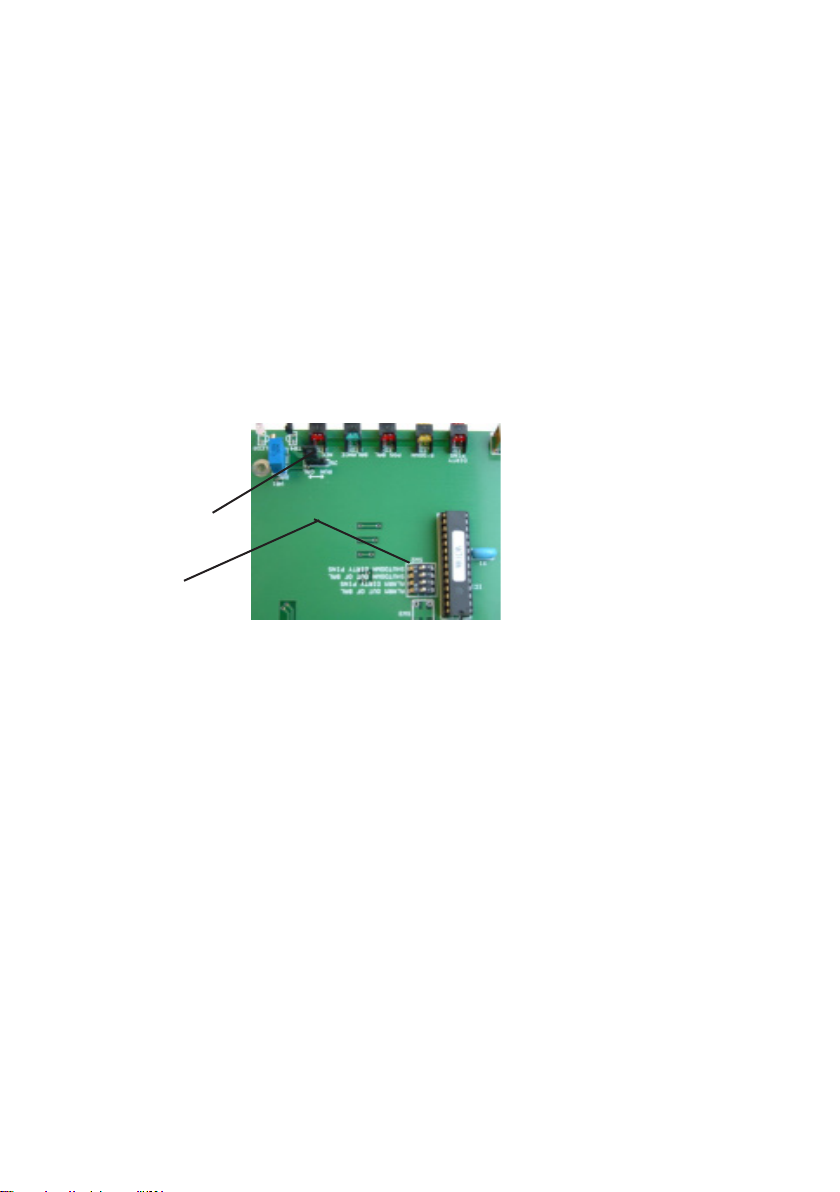

Indicator LED’s

1. Power On LED (Green)

This illuminates when the unit is switched ON and indicates that an electrical supply is

present within the Ioniser.

2. (a, 2b, 2c) Ion Balance Indicator LED’s ( Red, Green,

Red)

This array of three lamps indicates the ion balance state. Under normal operating

conditions only the middle (Green) lamp will be illuminated. This indicates that the ion

output from the ioniser is balanced. If the ion emission becomes imbalanced and the

imbalance exceeds the alarm limits (standard factory setting +/- 25V) then the green

lamp will dim or extinguish and either the positive (+ve) red LED or the negative (-ve)

red LED will illuminate dependant upon the polarity of the out of balance condition (

see “Fault Finding” later).

3. Inspect Pins (Red)

This lamp only illuminates when the emitter pins of the ioniser have become dirty and

the ion output has fallen below a factory pre-set level. i.e. when insucient ionisation is

being created to fully maintain optimum performance.

4. Auto Shutdown (Orange)

In normal operation this lamp will not be illuminated. The lamp will only illuminate when

the unit has detected a fault and the appropriate Selectable Diagnostic Functions have

been selected ( see “Alarm Function” later). When the lamp is illuminated, the HV

supply to the emitter pins will have been automatically switched o by the control circuit

of the ioniser. The ioniser fans and other indicator lamps will remain ON. Ion Balance

Adjustment