Introduction

The Model 935 Ionising Blower provides effective long range ionisation over a large

area. Its versatility makes it suitable for a wide range of industrial applications.

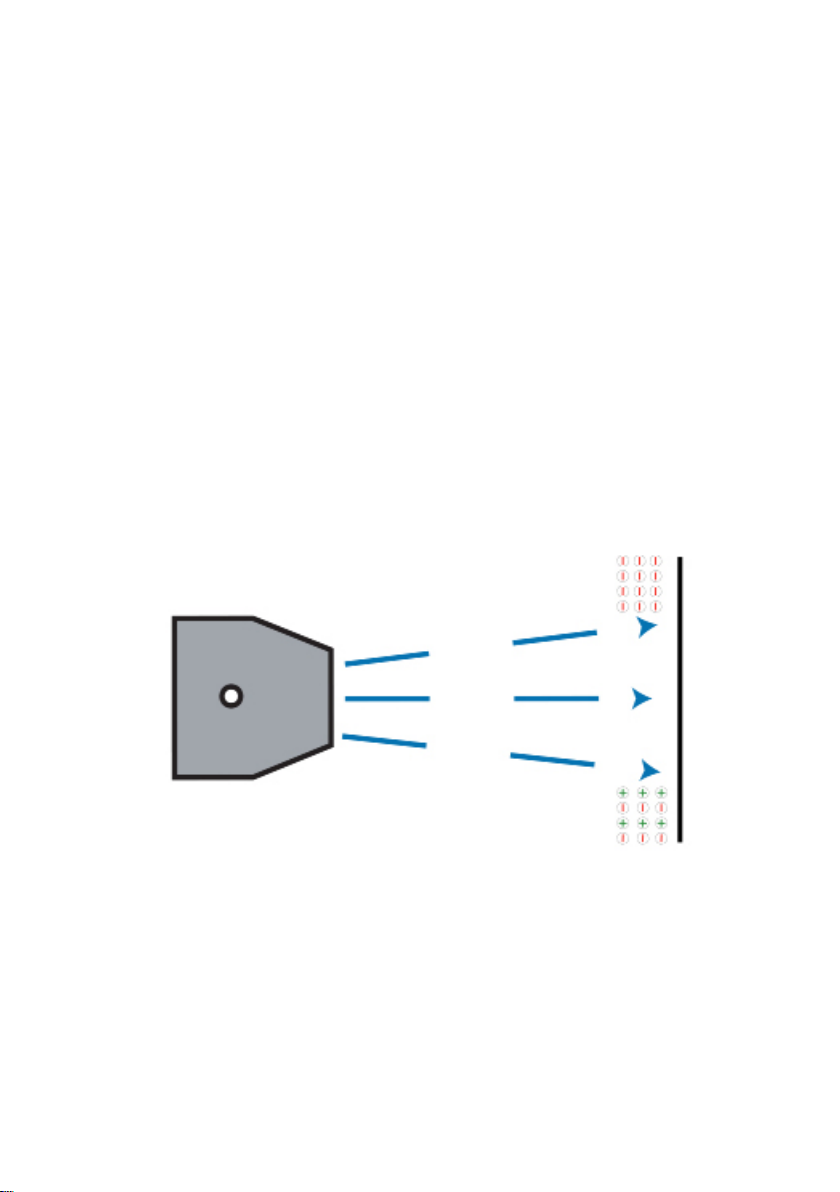

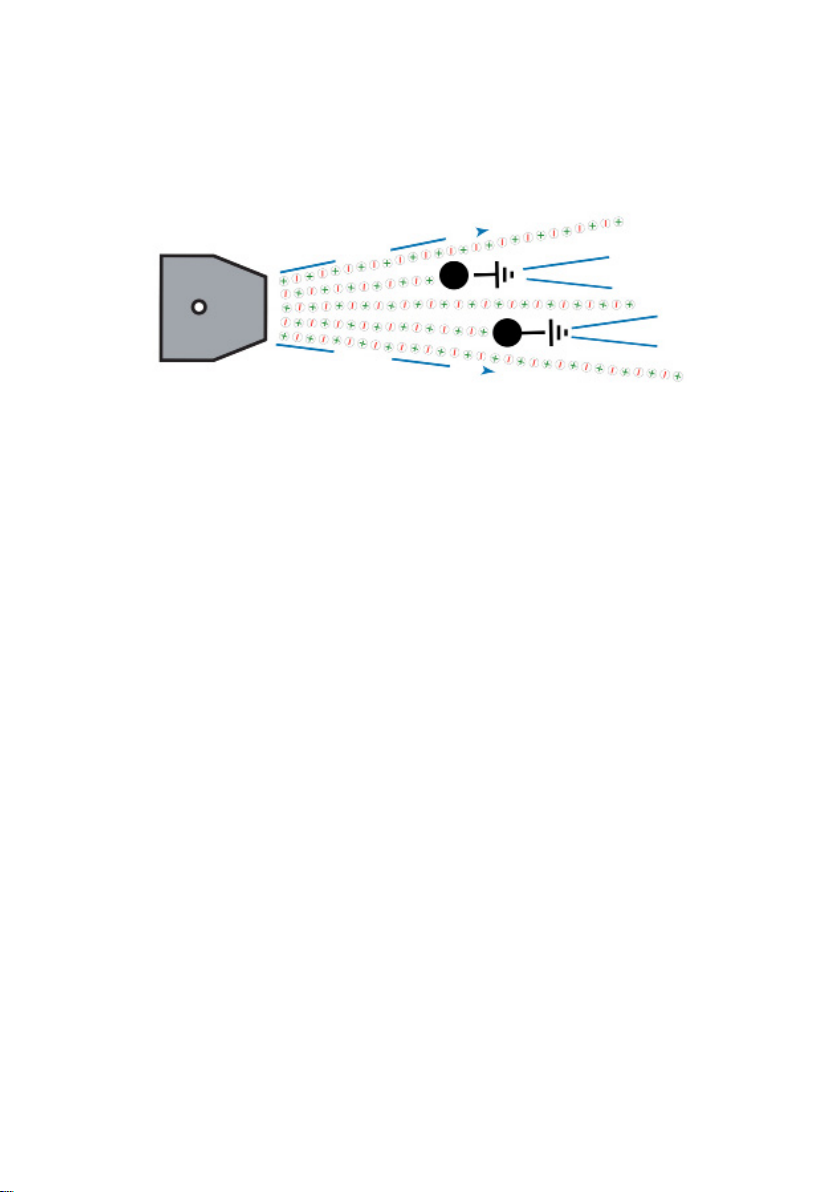

The Model 935 comprises an ionisation head and an integrated fan system. A high

volume flow of ionised air is generated by blowing air through the ionisation head

at the mouth of the unit. Ionisation is provided by powerful 915 bars, generating an

ionised field to a depth of up to 2000mm. The 935 unit is powered by the Model 904

and is available in both 110V and 240V versions.

There are many benefits to the Model 935, such as shockless operation due to a

resistively couples ionisation head. As the ionisation is provided by the 915 bars it

allows for powerful ionisation and very fast decay times. As it has a high volume air

flow it provides highly effective long range ionisation.

The 935 is flexible in a number of industries and also allows for simple installation and

mounting to suit any application. As it is made to suit any application, the model has a

variable fan speed and the air flow can be adjusted.

Due to the removable grill, it allows for easy access for maintenance of the ionisation

head.

Meech blowers are powerful static eliminators which give many years of excellent

service, provided that the following instructions are observed closely. 3