MEERSTETTER LTR-1200 User manual

User Manual

LTR-1200

Valid for SN:006 to SN:XYZ

LDD / TEC 19” Rack Enclosure

Suitable for:

TEC-1089

LDD-1124

TEC-1090

LDD-1121

TEC-1122

LDD-1125

TEC-1123

Third-Party Devices

Meerstetter Engineering GmbH

Schulhausgasse 12

3113 Rubigen, Switzerland

Phone: +41 31 712 01 01

Email: contact@meerstetter.ch

Website: www.meerstetter.ch

Meerstetter Engineering GmbH (ME) reserves the right to make changes without further notice to the product described herein. Information

furnished by ME is believed to be accurate and reliable. However typical parameters can vary depending on the application and actual performance

may vary over time. All operating parameters must be validated by the customer under actual application conditions.

SWISS MADE

User Manual

LTR-1200

31.07.13 TB

22.10.14 SK

Page 3 (18)

5171C

Table of Content

1Device Overview 4

2Functional Description 5

2.1 Device-specific Documentation 5

2.2 Getting Started 5

2.3 Menu Structure 6

2.3.1 Available Device Parameter 7

2.4 Communication Interfaces 8

2.4.1 LTR-1200 Communication Concept 8

2.4.2 Connecting LTR-1200 over Ethernet 8

2.4.3 Service Software Default Address 9

2.4.4 Access over Third Party Software 9

2.4.5 Communication Fault Management 9

3Technical Data 10

3.1 Elements and Configurations 10

3.2 Front Panel 10

3.2.1 LCD 10

3.2.2 Navigation 10

3.2.3 LED 11

3.2.4 Digital I/O 11

3.2.5 RS485 12

3.2.6 RS232 12

3.2.7 USB 13

3.2.8 Ethernet 13

3.3 Back Panel 14

3.3.1 TEC Sensors Pinout 14

3.3.2 LDD Sensors Pinout 15

3.3.3 AC Mains Supply 16

3.4 Error Numbers 16

3.4.1 RTOS Errors 16

3.4.2 Routing Errors 16

3.4.3 HMI Errors 16

3.5 Physical Dimensions 17

3.6 License Notice 17

4Quotation Request Form 18

Page 4 (18)

5171

31.07.13 TB

22.10.14 TB

LTR-1200

User Manual

1 Device Overview

Features

General Description

Rack Enclosure Size:

1U, 400mm in Depth

The LDD / TEC 19" rack enclosure LTR-1200 is a

highly configurable, ready-made carrier system

facilitating the integration of up to 4 devices

belonging to either the LDD-Family of laser diode

drivers or the TEC-Family of Peltier/TEC

controllers. The system caters for power, cooling

and communication.

The combination of built-in devices (models,

number) is freely selectable by the customer, their

application will dictate the choice (12V or 24V) and

number of internal primary DC power supplies.

Meerstetter Engineering will take care of the

integration and provide a fully configured turnkey

solution.

Up to 4 fans drag air sidewise through the rack

enclosure. Their speed is managed by intelligent

fan control on a dedicated PCB such that air-

cooling becomes effective upon prolonged use at

high ratings.

For table-top operation, the rack mounting brackets

can be removed.

The current status of the rack enclosure and of the

built-in devices are indicated on the front side

display (2x40 characters) and by dual color LEDs.

The most important settings (parameters of the

built-in devices and of the front side data interfaces)

can be adjusted over the 5-way navigation switch.

For advanced operation and configuration, all

internal devices can be addressed over one of the

electrically isolated interfaces; therefore the

originally supplied TEC and/or LDD Service

Software’s can be used.

For continuous monitoring and control by

customers' systems, the serial communication

protocol 'MeCom' can be used: on one hand, it

allows direct control of the each built-in LDD and

TEC device, on the other hand it allows polling

further information about the overall system status.

For fast signals (such as LDD pulse triggering)

three digital (electrically isolated) input lines are

available. Also, one digital output is available (e.g.

for error indication).

The integration of third party hardware (such as

fiber-coupled diode lasers) is possible if

dimensional requirements are met.

AC Input Voltage:

100..240V / 50..60Hz

Space for Devices:

Up to 4 LDD / TEC

Drivers; Third-Party

Devices (Max 8 Outputs)

Data Interfaces:

Electrically Isolated

(>1kV)

- Ethernet 10/100 MBit/s

- USB (Virtual Com Port)

- RS485

- RS232

Digital I/O Signals:

Electrically Isolated

(>1kV)

- 3 Digital Inputs

- 1 Digital Output

Human Machine

Interface (HMI):

Backlit 2x40 Character

Display and 5-Way

Navigation Switch for

Local Monitoring and

some Main Settings

Status Indication:

2 LED (Dual Color)

Forced Air Cooling:

Temperature-Dependent

Fan Speeds

Max Ambient

Temperature:

Full load up to 40°C

Half load up to 45°C

Advanced Operation

Remote Control:

LDD / TEC Service

Software and

'MeCom' Protocol

Applications

Optics (Laser Diodes, Crystals, …):

e.g. autonomous turn-key solutions for

comprehensive control (supply, cooling) of

ps lasers

Electronics (Detectors, RF References, …):

e.g. low-noise camera cooling

Instrumentation (Microscopy, Materials,

Biochemistry, …):

e.g. precision multi-temperature control

(thermal zones)

User Manual

LTR-1200

31.07.13 TB

22.10.14 SK

Page 5 (18)

5171C

2 Functional Description

2.1 Device-specific Documentation

The following devices can be installed into the LTR-1200. Some of these devices can be connected in

parallel to achieve higher output currents. Please contact Meerstetter Engineering if you have

requirements which currently are not covered by any of these devices.

LDD-Family (Laser Diode Drivers)

TEC-Family (Thermo Electric Cooling Controllers)

LDD-1121

LDD-1124

LDD-1125

TEC-1089

TEC-1090

TEC-1122

TEC-1123

The functional description and the technical data of these devices are documented in their own specific

Datasheets and User Manuals.

2.2 Getting Started

1. Connect the LTR-1200 to the mains power and switch it on.

The display shows the start screen

2. Wait until the LTR-1200 has finished startup.

The display now shows the main screen

No error is indicated (both LEDs are green)

3. Use the navigation switches to browse through the Menu. The Menu structure is documented in

chapter 2.3 Menu Structure

4. Connect to an internal device. (Chose one of the two options below):

(For more information about how to connect please refer to 2.4 Communication Interfaces)

Ethernet (preferred, if possible):

Remote Control over big distances.

Simultaneous connections (multiple applications) to several devices are possible.

Simultaneous connections (multiple PCs) to one device are possible.

oSet up the IP configuration (See chapter 2.4.2 Connecting LTR-1200 over

Ethernet)

oConnect the Ethernet cable.

USB:

Easy on-site connection.

Only one device at the same time.

oConnect the USB Cable.

5. Connect the corresponding (TEC or LDD) Service Software to a device

(Notice that you establish a connection to a device. “Device” and “Terminal” have different

meanings. See chapter 2.4.1 LTR-1200 Communication)

Set up the Service Software connection in the Maintenance Tab (See chapter 2.1

Device-specific Documentation)

When the Software is successfully connected it will show a green status “Connected” and

the Monitor tab will be updated periodically.

If you connect over Ethernet and wish to connect to multiple devices repeat this

procedure for all devices to connect.

6. Now the device(s) are connected. The device configuration and the various setting options are

described in the device-specific User Manuals. (See chapter 2.1 Device-specific Documentation)

Page 6 (18)

5171

31.07.13 TB

22.10.14 TB

LTR-1200

User Manual

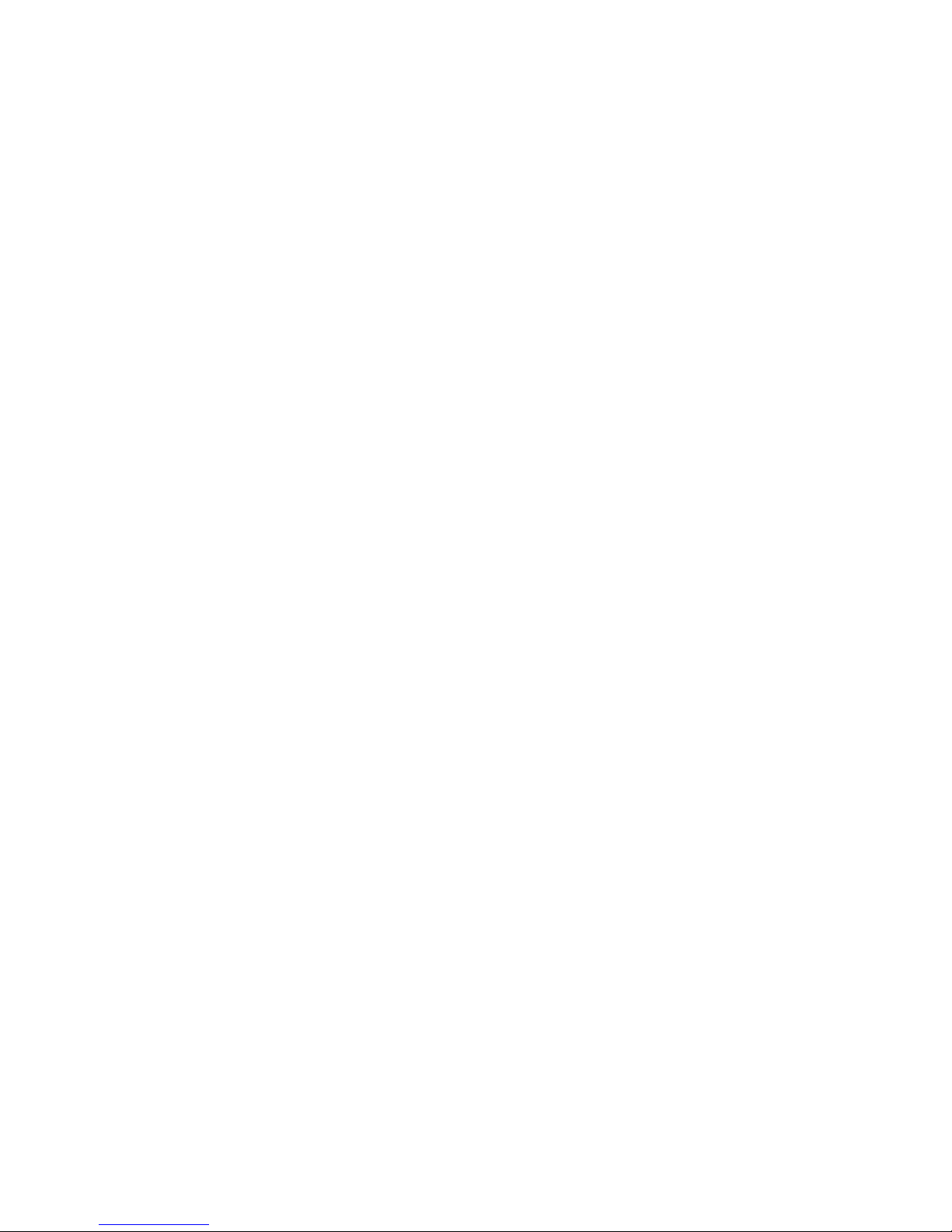

2.3 Menu Structure

The Menu is created dynamically depending on the installed devices. Only the Terminals to which a

device is connected are shown in the Menu. Each Terminal has its own Menu entry where the most

important settings of this Terminal can be adjusted. There is also a small overview for each Terminal.

Because there are so many parameters for each Terminal there is only a small selection of parameters

available through the display menu.

Below there is an example of the Menu structure with a TEC controller connected to Terminal 1 and an

LDD connected to Terminal 2.

Overview

T# 5-8

Manufacturer

Overview

LTR Settings &

IP Address

Type and S/N

T# 1-4

Device Status

IP Gateway

IP Network Mask

...

FANC Settings &

Device Status

T# 1 Detailed

T# 1 Settings &

Object Temperature

Device Overview

Device Status

Sink Temperature

Actual Output Current

...

T# 2 Detailed

T# 2 Settings &

Laser Diode I Act

Device Overview

Device Status

Laser Diode U Act.

Laser Diode Temp.

...

T# 3-8

T# 3-8 Settings &

...

Device Overview

Device Status

Legend:

T# -> Terminal

Status / Information

Settings

To navigate through the Menu use the 5-way navigation switch.

Settings marked with [-/R] have read only permissions.

Settings marked with [R/W] can be modified through the menu. Simply press the OK Button to switch to

the editing mode. Use left and right to switch between the digit positions. Use up and down to change the

digits value. Press OK to confirm the setting change.

Errors are shown on the overview screen with a symbol. For a description of the different Symbols see

3.2.1 LCD. A detailed Error Report will be shown on the device specific Menu screen.

User Manual

LTR-1200

31.07.13 TB

22.10.14 SK

Page 7 (18)

5171C

2.3.1 Available Device Parameter

Additional Parameters are available on request. Please contact Meerstetter Engineering for an inquiry.

2.3.1.1 LTR-1200

IPv4 Address

Gateway IPv4 Address

IPv4 Network Mask

Service Software Default Device

Interface RS232 Baud Rate

Interface RS485 Baud Rate

HMI Device Address

Internal Maximal Temperature

Internal Maximal Fan-Speed

2.3.1.2 LDD

Laser Diode Current Actual

Laser Diode Voltage Actual

Laser Diode Temperature

Laser Power Actual

Laser Diode Driver Enable

Laser Diode Current CW

Laser Diode Power CW

2.3.1.3 TEC

Object Temperature

Sink Temperature

Actual Output Current

Actual Output Voltage

Output Stage Enable

Target Object Temp

Page 8 (18)

5171

31.07.13 TB

22.10.14 TB

LTR-1200

User Manual

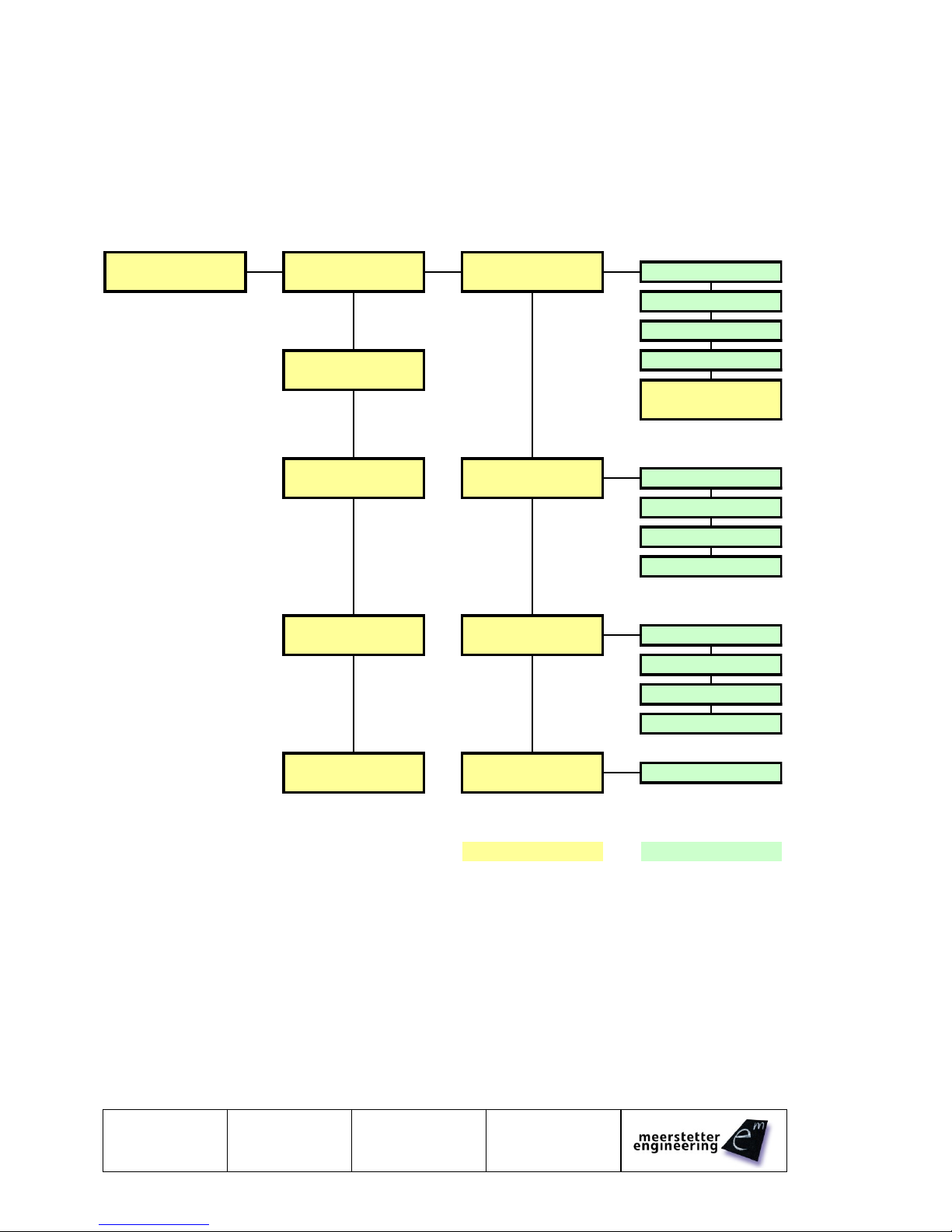

2.4 Communication Interfaces

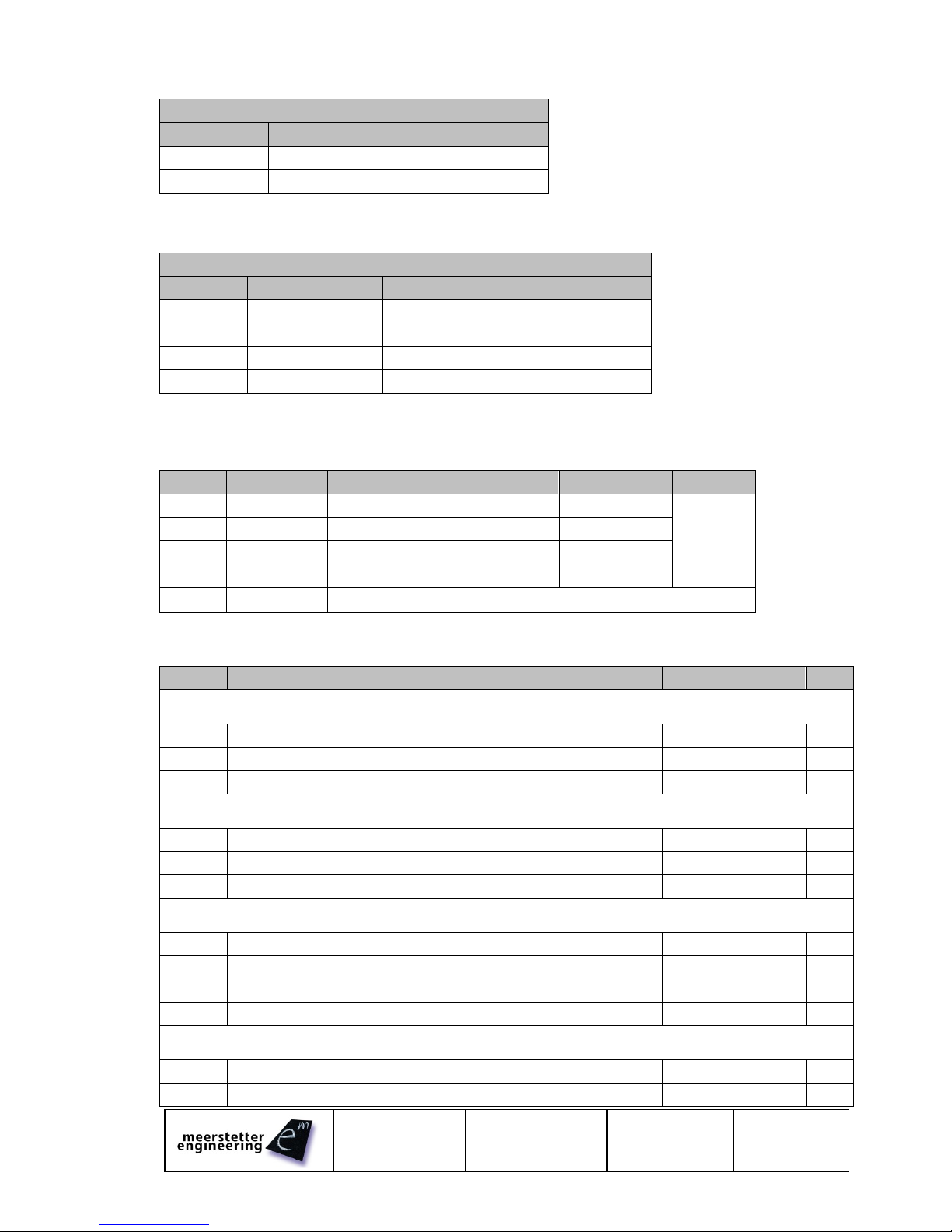

2.4.1 LTR-1200 Communication Concept

The LTR-1200 is equipped with several communication interfaces, which can be used simultaneously.

Every communication interface has its own receiving buffer.

The router will process every received message. The message is forwarded to the desired device. As

soon as the router task has received the responding message from the device, the message is forwarded

to the corresponding interface.

Every communication interface has the same priority. All messages are processed successively.

A connection is always between one control software and one device. The Terminal, device number and

Channel are not directly associated.

Terminal represents only the output on the Back-Plane of the LTR-1200. One device can be connected to

more than one Terminal.

Channel represents the output channel of one device (e.g. CH1 or CH2 in the case of TEC controllers.)

Please consult the “LTR-1200 Configuration Sheet” (which was supplied with the LTR-1200) to find out

which device channel is connected to which Terminal.

2.4.2 Connecting LTR-1200 over Ethernet

The LTR-1200 does not support DHCP. A fixed IP Address configuration must be set over the display

menu. Please set the following settings:

IP Address

Gateway Address (required for routing)

Network Mask

Please try to access to the built-in LTR-1200 web server by entering the previously configured IP Address

to your web browser.

Interface

Buffer

RS485

Interface

RS232

Interface

USB

Interface

Ethernet

Interface

Interface

Buffer

Interface

Buffer

Interface

Buffer

Router

TEC-1089

LDD-1121

TEC-1122

LDD-1125

HMI

FANC

LTR Internal BUS

Virtual Connection

User Manual

LTR-1200

31.07.13 TB

22.10.14 SK

Page 9 (18)

5171C

2.4.2.1 Ethernet Connection

Please refer to 2.1 Device-specific Documentation to connect the Service Software over Ethernet. The

Device Address (Device to be addressed) can be found on the LTR-1200 Menu or on the Built-in web

site. It usually is the same as the Terminal Number. The LTR-1200 provides a total of six connections

(TCP/IP, Port 50000, Timeout: 10s) to control the LDD/TEC Drivers over Ethernet. For Third Party

Software communication please refer to the MeCom communication protocol specifications (See chapter

2.1 Device-specific Documentation).

2.4.3 Service Software Default Address

In some cases it may be helpful to configure a default LDD/TED driver as standard device. This can be

done by setting the 'Service Software Default Device' parameter to a specific LDD/TEC Device Address in

the Display menu. In this case the Device Address 0 will be routed to the 'Service Software Default

Device'.

2.4.4 Access over Third Party Software

For Third Party Software communication please refer to the MeCom communication protocol

specifications (See chapter 2.1 Device-specific Documentation).

2.4.5 Communication Fault Management

2.4.5.1 For RS485, RS232 and USB Interfaces

A received MeCom-Package with a wrong CRC is not being processed, no error is generated.

If a MeCom-Package is being forwarded to a device (LDD/TEC) and no answer is received from the

device, no error is generated. The sending host must repeat the MeCom-Package.

2.4.5.2 For Ethernet Interface

A received MeCom-Package with a wrong CRC results in closing the corresponding TCP connection.

If a MeCom-Package is being forwarded to a device (LDD/TEC) and no answer is received from the

device, the MeCom-Package is being sent to the device two more times. If still no answer is received, the

TCP connection is closed by the LTR-1200.

Page 10 (18)

5171

31.07.13 TB

22.10.14 TB

LTR-1200

User Manual

3 Technical Data

3.1 Elements and Configurations

Each rack enclosure is equipped and configured to the customer's specifications:

Up to four LDD-Family or TEC-Family devices can be built in (See 4 Quotation Request Form).

The number of required power supplies and fans depends on types, numbers and applications of

the built-in devices. Meerstetter Engineering equips the LTR-1200 accordingly.

The LTR-1200 is back panel configurable, the standard panel offers 4 power output terminals and

4 sensors inputs connectors. (Up to 8 Terminals are possible)

It is also possible to install third party devices. Please contact Meerstetter Engineering with your

enquiry.

Important note concerning the integration of LDD-Family devices into LTR-1200 rack enclosures:

The internal wiring from an LDD device to its back panel terminal can measure several 10cm and

represents an inductive load. Therefore, fast pulsing performance will be impaired.

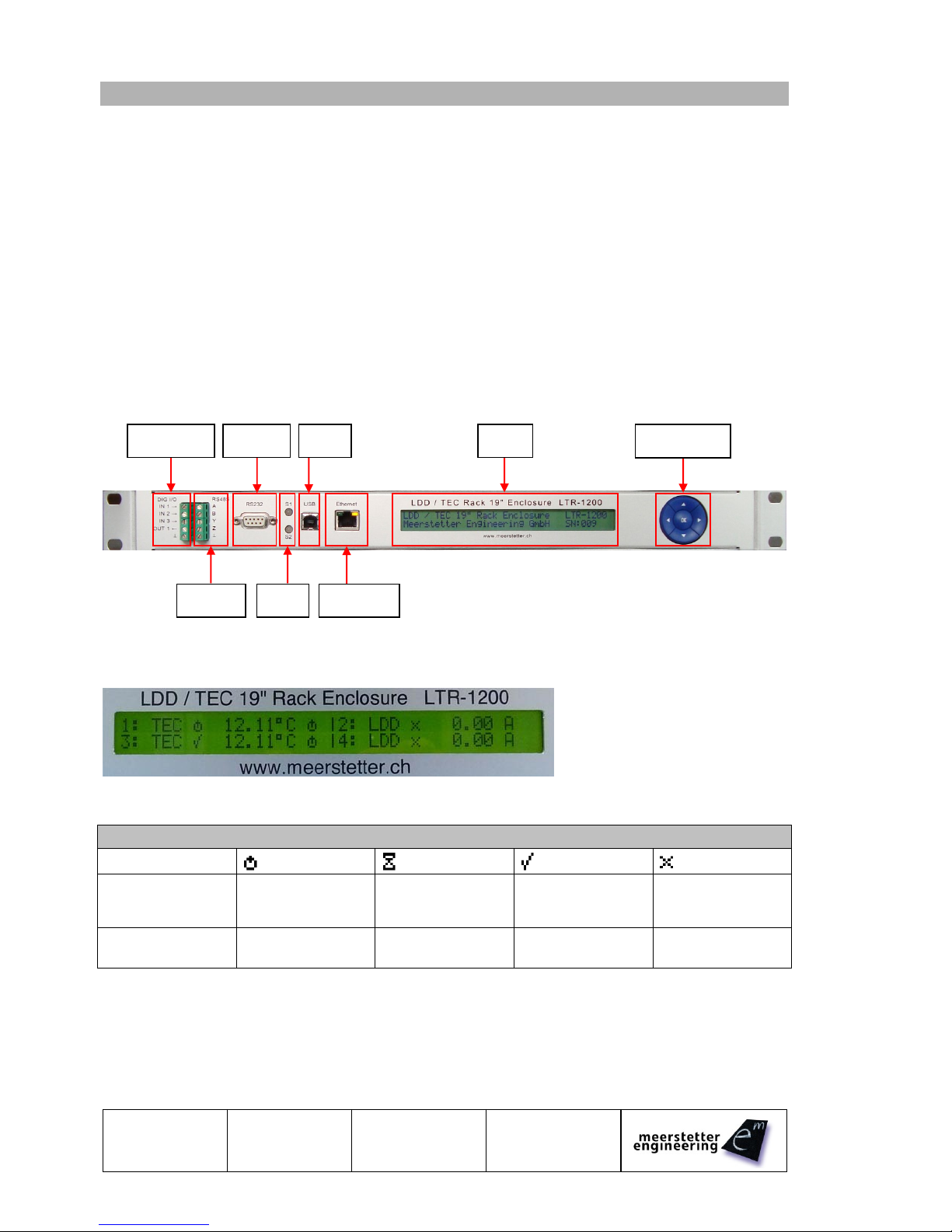

3.2 Front Panel

3.2.1 LCD

The picture shows the LCD display of an LTR-1200 with 4 devices built-in.

Symbols on the LCD Display

First Symbol

(next to TEC/LDD)

Device is 'Ready'

Other

(Reset, Restart,

Bootloader, …)

Device is 'Running'

Device has an

Error

Second Symbol

(if type is TEC)

Not in Temperature

Control Mode

'Wait'

(not stable, yet)

Stability Reached

-

3.2.2 Navigation

There is a five-point navigation switch available to browse through the Menu. This can be used to change

the most important settings of the internal devices.

Digital I/O

RS232

RS485

LED

USB

Ethernet

Navigation

LCD

User Manual

LTR-1200

31.07.13 TB

22.10.14 SK

Page 11 (18)

5171C

3.2.3 LED

Dual Color Status LEDs

LED

Sources (grouped)

S1 (top)

LTR Components (HMI, Fan Controller)

S2 (bottom)

Built-in Devices (LDDs, TECs)

Grouped status code is prioritized, i.e. if one output stage is running, the grouped LED shows 'Run', if one

device has an error, the grouped LED shows 'Error'.

LED Status Description (S1, S2)

Color

Pattern

Signification

Green

Slowly blinking

'Ready' status (no Error)

Green

Blinking fast

'Run' status (no Error)

Red

Static on

'Error' status, output stages disabled

Red

Slowly blinking

Unknown Device Status, but no Error

3.2.4 Digital I/O

3.2.4.1 Pinout

Type

DIG IO Label

LDD-112x

TEC-1122/1123

TEC-1089/1090

LTR-1200

Input 1

IN1

RES8

RES8

RES1

Special

Function

available

on request

Input 2

IN2

RES7

RES7

RES2

Input 3

IN3

RES6

RES6

RES3

Output 1

OUT

RES5

RES5

RES4

GND

Digital IO Ground

All digital I/Os are ESD-protected and have a series and pull-down resistor.

3.2.4.2 Characteristic

Symbol

Parameter

Comments

Min

Typ

Max

Units

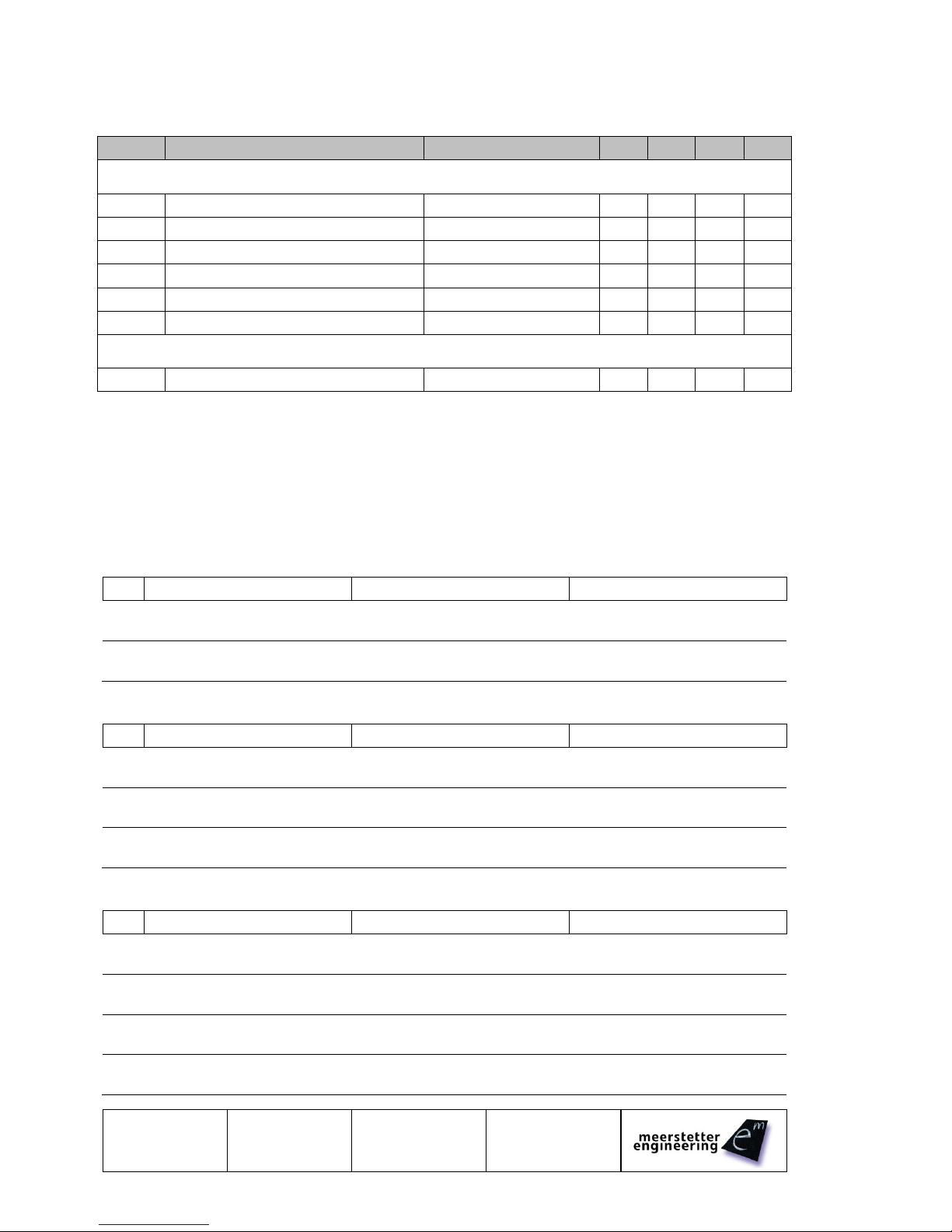

Digital Isolator Characteristics

VISO

Isolation Voltage

1

-

2.5

kV

fTRANSFER

Transfer Frequency

NRZ (No Return to Zero)

0

25

MHz

tPHL, tPLH

Propagation Delay

45

60

ns

Input Characteristics (Digital Isolator)

VIH

Logic High Input Threshold

2.31

V

VIL

Logic Low Input Threshold

0.99

V

VIMAX

Max Input Voltage

-0.5

5.5

V

Output Characteristics (Digital Isolator)

VOH

Logic High Output Voltage

Output Current 20uA

3

3.3

V

VOL

Logic Low Output Voltage

Input Current 20uA

0

0.1

V

VOHL

Logic High Output Voltage (Hi Load)

Output Current 4mA

2.8

3.1

V

VOLL

Logic Low Output Voltage (Hi Load)

Input Current 4mA

0

0.4

V

ESD Protection (between Digital Isolator and Connector)

VPP

ESD Discharge

IEC61000−4−2

100

kV

RA

Series Resistance

170

200

230

Ω

Page 12 (18)

5171

31.07.13 TB

22.10.14 TB

LTR-1200

User Manual

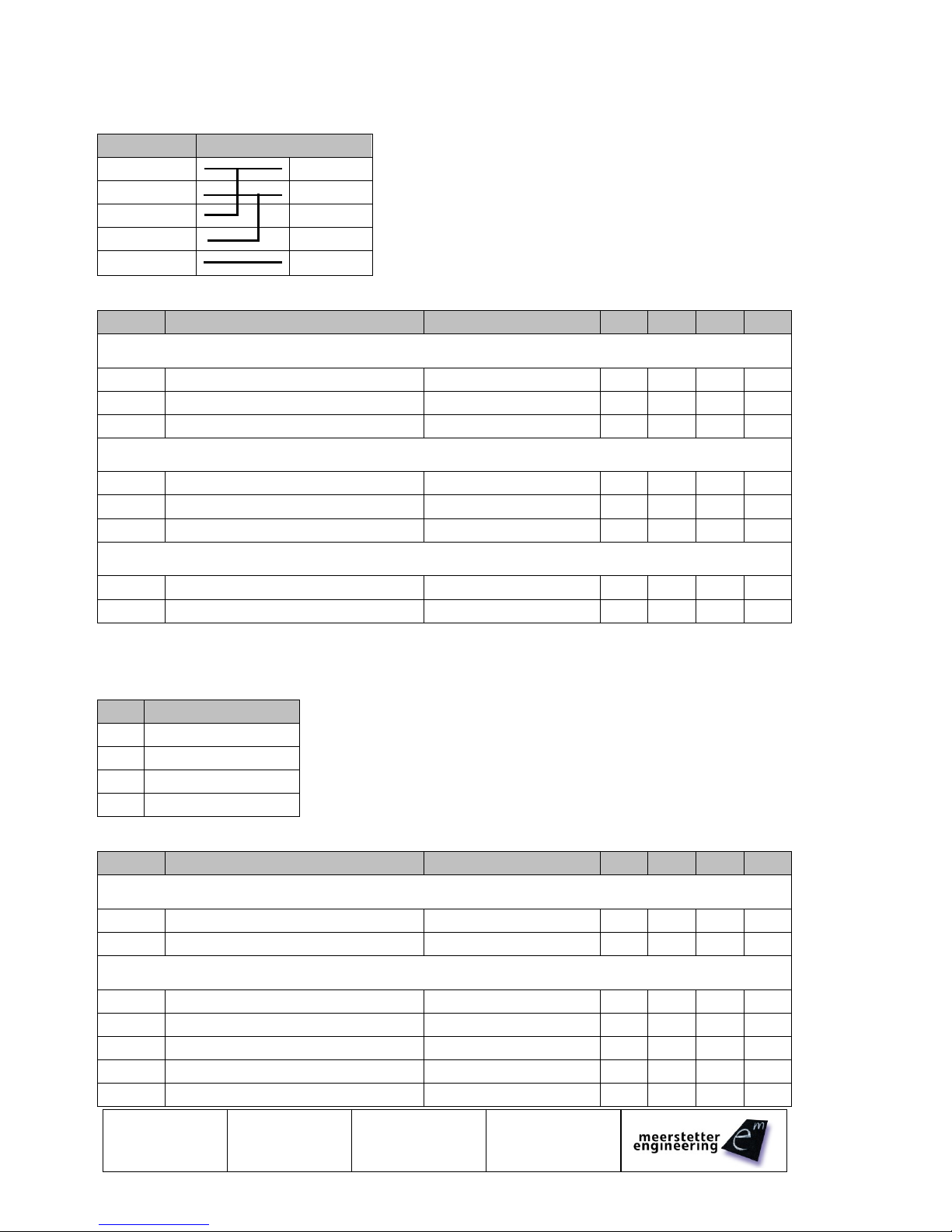

3.2.5 RS485

3.2.5.1 Pinout

RS485 Label

Half-Duplex Connection

A

A

B

B

Y

Z

GND

3.2.5.2 Characteristic

Symbol

Parameter

Comments

Min

Typ

Max

Units

Digital Isolator Characteristics

VISO

Isolation Voltage

1

-

2.5

kV

Speed

Communication Speed (Baud Rate)

Software Setting

4800

1M

bps

VPP

ESD Protection

Human Body Model

+-15

kV

Input Characteristics (Receiver)

VTH

Differential Input Threshold Voltage

-200

-125

-30

mV

VHYS

Input Voltage Hysteresis

15

mV

RIN

Line Input Resistance

96

kΩ

Output Characteristics (Driver)

VOD1

Differential Output Voltage, Loaded

RL= 100Ω (RS422)

2.0

3.6

V

VOD2

Differential Output Voltage, Loaded

RL= 54Ω (RS485)

1.5

3.6

V

3.2.6 RS232

3.2.6.1 Pinout

Pin

Function

2

TxD (Data from LTR)

3

RxD (Data to LTR)

5

Signal Ground (GND)

other

Not Connected

3.2.6.2 Characteristic

Symbol

Parameter

Comments

Min

Typ

Max

Units

Protection Characteristics

VISO

Isolation Voltage

1

-

2.5

kV

VPP

ESD Protection

Human Body Model

+/-15

kV

Electrical Characteristics

Speed

Communication Speed (Baud Rate)

Software Setting

4800

1M

bps

VOH

High-level Output Voltage

TxD at RL= 3kΩ to GND

5

5.5

V

VOL

Low-level Output voltage

TxD at RL= 3kΩ to GND

-5

-5.4

V

VIT+

Positive Input Threshold Voltage

1.5

2.4

V

VIT-

Negative Input Threshold Voltage

0.6

1.2

V

User Manual

LTR-1200

31.07.13 TB

22.10.14 SK

Page 13 (18)

5171C

3.2.7 USB

The USB interface is electrically isolated. A virtual COM Port is provided for communication with a host

PC. The drivers are the same as the ones already required / installed for the individual internal devices.

(Used chip: FTDI FT232RQ)

3.2.7.1 Characteristic

Symbol

Parameter

Comments

Min

Typ

Max

Units

Protection Characteristics

VISO

Isolation Voltage

1

-

2.5

kV

VPP

ESD Protection

Human Body Model

+/-15

kV

Electrical Characteristics

Speed

Communication Speed (Baud Rate)

Software Setting

4800

1M

bps

3.2.8 Ethernet

3.2.8.1 Specifications

The Ethernet meets the following specifications:

IEEE 802.3 compliance

100BASE-TX and 10BASE-T compliance

Auto Negotiation (Automatically switch between 10Mbit/s / 100Mbit/s, Half -/ Full-Duplex)

Auto MDIX (Auto crossover)

Optional VLAN (available on request)

Optional IEEE 1588: Precision Time Protocol (available on request)

3.2.8.2 LED Description

Green

Orange

Off

Not connected

10Mbit/s

Blink

Activity

-

On

Connected

100Mbit/s

3.2.8.3 Available Features

Small embedded website

Service Software communication

MeCom protocol

Page 14 (18)

5171

31.07.13 TB

22.10.14 TB

LTR-1200

User Manual

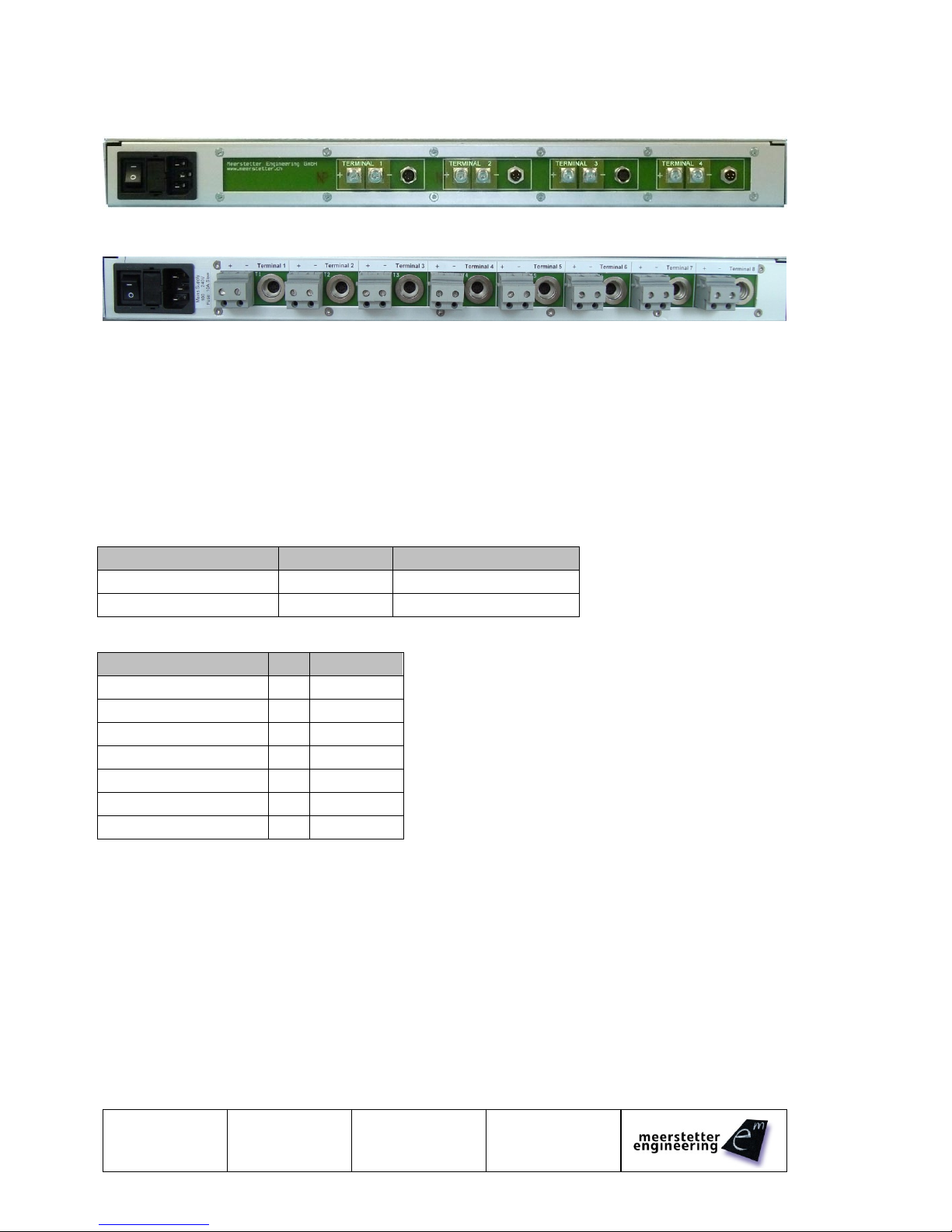

3.3 Back Panel

Picture of 4 Terminal Version. (Only approx, the Sensor connectors are wrong)

Picture of the 8 Terminal Version:

By standard, the GND potentials of all built-in TEC and LDD devices are interconnected. Consequently,

all external loads and sensors to be attached to the back panel should be potential-free. At the most, only

one single potential (e.g. GND of one laser diode) may be tied to a given potential; it is however

recommended to keep all loads and sensors potential-free.

Upon customer request, individual outputs can be equipped such that they are potential-free (i.e.

independent of other built-in devices). Please contact Meerstetter Engineering with your enquiry

3.3.1 TEC Sensors Pinout

Fully pre-confectioned cables are available from Meerstetter Engineering at request.

3.3.1.1 Part List

Description

Manufacturer

Manufacturer Part Nr.

Connector Solder 7-Way

Binder

99-4925-00-07

Cable 6-Way, Shielded

Kabeltronik

2-LifYCY TP (820600800)

3.3.1.2 Pinout

Function

Pin

Cable Color

Object Voltage Sense +

1

White

Object Voltage Sense -

2

Brown

Object Current Output

3

Green

Object Current Return

4

Yellow

Sink Sense A

5

Grey

Sink Sense B

6

Pink

NC

7

-

Please connect “Current Output” and “Voltage Sense +” together to one side of the thermistor,

and “Current Return” and “Voltage Sense –“ together to the other side of the thermistor.

User Manual

LTR-1200

31.07.13 TB

22.10.14 SK

Page 15 (18)

5171C

3.3.2 LDD Sensors Pinout

Fully pre-confectioned cables are available from Meerstetter Engineering at request.

3.3.2.1 Part List

Description

Manufacturer

Manufacturer Part Nr.

Connector Solder 4-Way

Binder

99-4909-00-04

Cable 4-Way, Shielded

Kabeltronik

2-LifYCY TP (820400800)

3.3.2.2 Pinout

Function

Pin

Cable Color

Temperature Sense A

1

White

Temperature Sense B

2

Brown

Photodiode Cathode

3

Green

Photodiode Anode

4

Yellow

Page 16 (18)

5171

31.07.13 TB

22.10.14 TB

LTR-1200

User Manual

3.3.3 AC Mains Supply

The main power connector is a 3-pol Connector for IEC C13 Cables

Symbol

Parameter

Comments

Min

Typ

Max

Units

Electrical Characteristics

VACnom

Nominal Input Voltage

Single Phase

100

240

V

VAC

Input Voltage

Continuous

90

264

V

VACtrans

Input Transients

60ms

300

V

fAC

Input Frequency

47

50/60

63

Hz

PIN

Input Power*

1 - 4 Power Supplies

400

1600*

W

PIN110

Input Power (110VAC)

1 - 4 Power Supplies

400

1100

W

Protection Characteristics

Fuse

Slow Fuse

Integrated into Connector

10

A

* When operated on 110VAC mains supply, the max input power is derated to 1100W due to the 10A fuse

built into the standard IEC C13 housing. Please contact Meerstetter Engineering if you require an

alternative connector.

3.4 Error Numbers

Error Numbers 1 to 99 are universal error numbers, which are identically on each device. For all other

universal error numbers please refer to the LDD-Family or TEC-Family User Manuals.

Error Numbers 100 and above are HMI (LTR)-specific.

3.4.1 RTOS Errors

#

Code

Description

Error Condition, Remedy

80

RTOS_STACKOVERFLOW

One task has a stack overflow

Please contact Meerstetter

Engineering

81

RTOS_MALLOCFAIL

Can not allocate memory

Please contact Meerstetter

Engineering

3.4.2 Routing Errors

#

Code

Description

Error Condition, Remedy

100

ROUTING_LOSTFRAME

The routing task has lost a

frame

Lost frame on internal bus

101

COM_TIMEOUT

Communication timeout to an

internal device occurred

No answer for 3x100 ms

102

ADDRESS_CONFLICT

Two internal devices use the

same address on the bus

Two identically addresses

detected

3.4.3 HMI Errors

#

Code

Description

Error Condition, Remedy

110

DEVICE_VERSION

HMI and device firmware

versions not compatible

Update all device firmware to

the actual version.

111

DEVICE_MISSING

Unassigned rack output

terminal detected

Try to reboot the LTR-1200

112

MENU_OWERFLOW

Menu memory overflow

Please contact Meerstetter

Engineering

113

UNKNOWN_DEVICE

Unknown internal device

recognized

Please contact Meerstetter

Engineering

User Manual

LTR-1200

31.07.13 TB

22.10.14 SK

Page 17 (18)

5171C

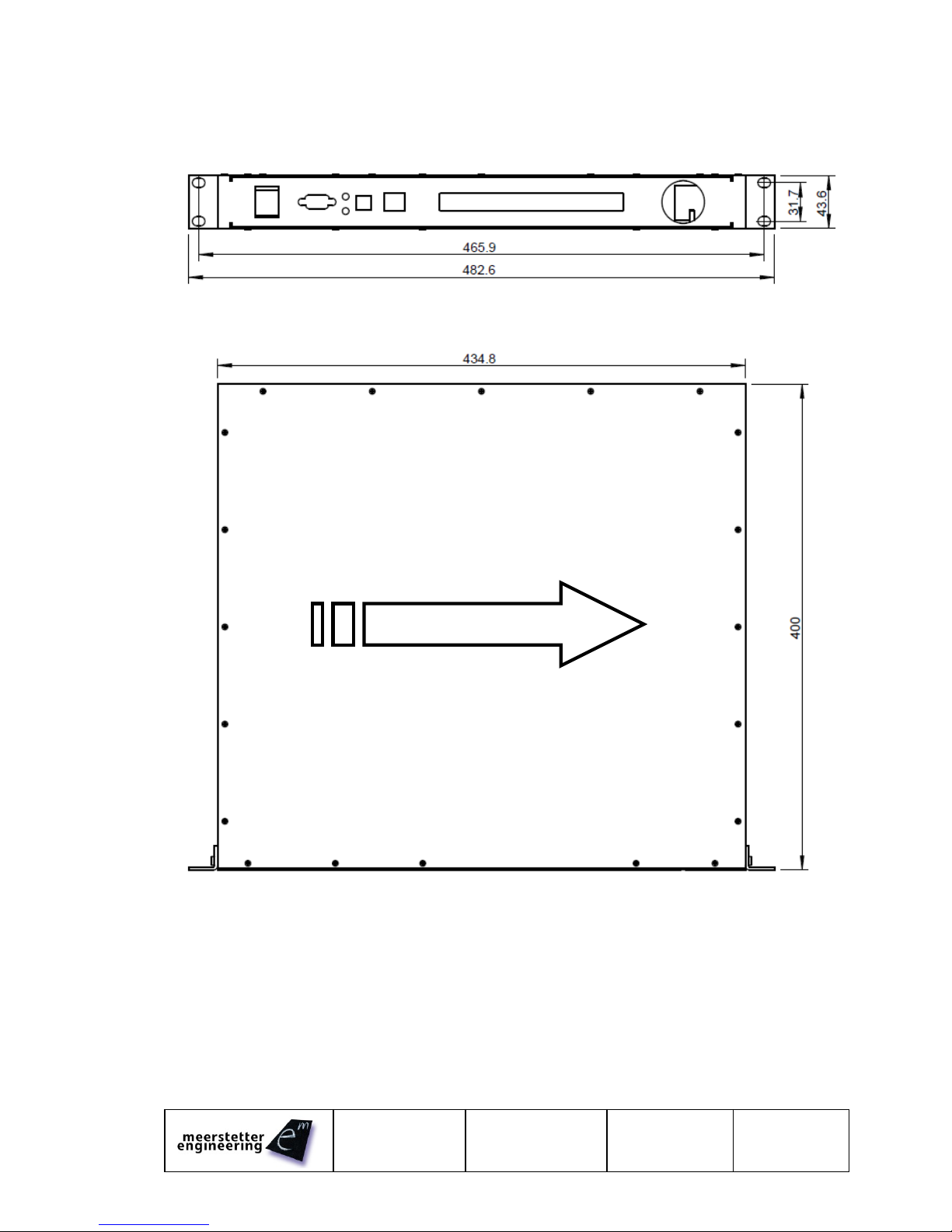

3.5 Physical Dimensions

All dimensions are in mm

Rack mounting brackets are removable

3.6 License Notice

The LTR-1200 Software is built on FreeRTOS (http://www.freertos.org).

Air-Flow

Page 18 (18)

5171

31.07.13 TB

22.10.14 TB

LTR-1200

User Manual

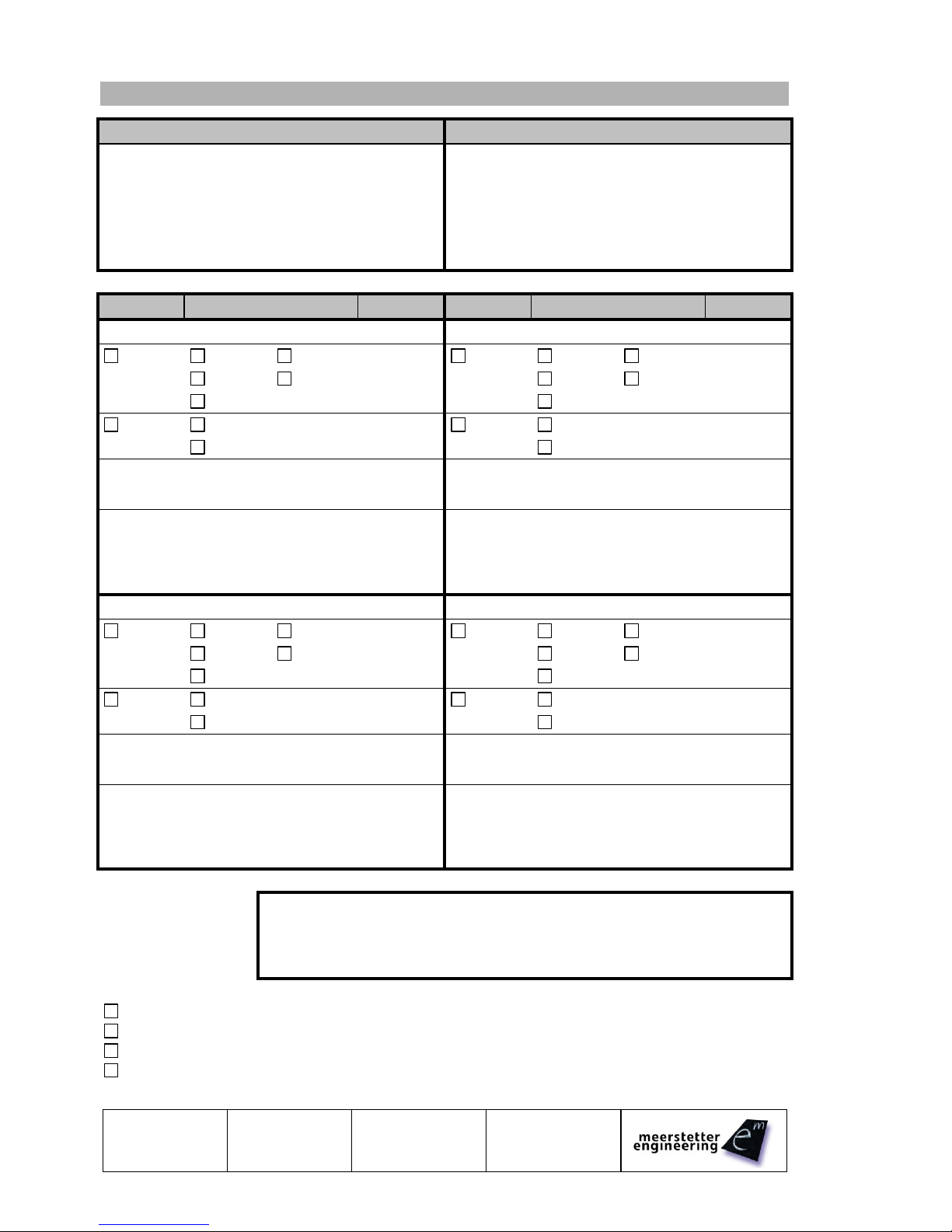

4 Quotation Request Form

Contact Information (Address)

Please Describe your Application

Type

Sensor Type

Power

Type

Sensor Type

Power

Output 1

Output 2

TEC

PT100

4 Wire

_____A

TEC

PT100

4 Wire

_____A

PT1000

2 Wire

_____V

PT1000

2 Wire

_____V

NTC

NTC

LDD

No LPC

_____A

LDD

No LPC

_____A

LPC

_____mA

_____V

LPC

_____mA

_____V

Laser Diode / Peltier Module (Manufacturer; Model)

Laser Diode / Peltier Module (Manufacturer; Model)

Comments / Special Requirements

Comments / Special Requirements

Output 3

Output 4

TEC

PT100

4 Wire

_____A

TEC

PT100

4 Wire

_____A

PT1000

2 Wire

_____V

PT1000

2 Wire

_____V

NTC

NTC

LDD

No LPC

_____A

LDD

No LPC

_____A

LPC

_____mA

_____V

LPC

_____mA

_____V

Laser Diode / Peltier Module (Manufacturer; Model)

Laser Diode / Peltier Module (Manufacturer; Model)

Comments / Special Requirements

Comments / Special Requirements

Special Requirements:

More than 4 Outputs are needed (up to 8 TEC outputs are possible)

The TEC outputs need to be independent. (If an Error occurs on one output, the others continue)

Pre-confectioned Sensor Cables are required. Cable Length: _____m

Third-party devices need to be installed: Please send us more information about this device

Table of contents

Popular Enclosure manuals by other brands

SilverStone

SilverStone Lascala LC11 manual

ZALMAN

ZALMAN Z5 U3 user guide

Macpower & Tytech

Macpower & Tytech Hydra S2 user manual

BE QUIET!

BE QUIET! SILENT BASE 801 user manual

HP

HP 418800-B21 - StorageWorks Modular Smart Array 70 Storage... Maintenance and service guide

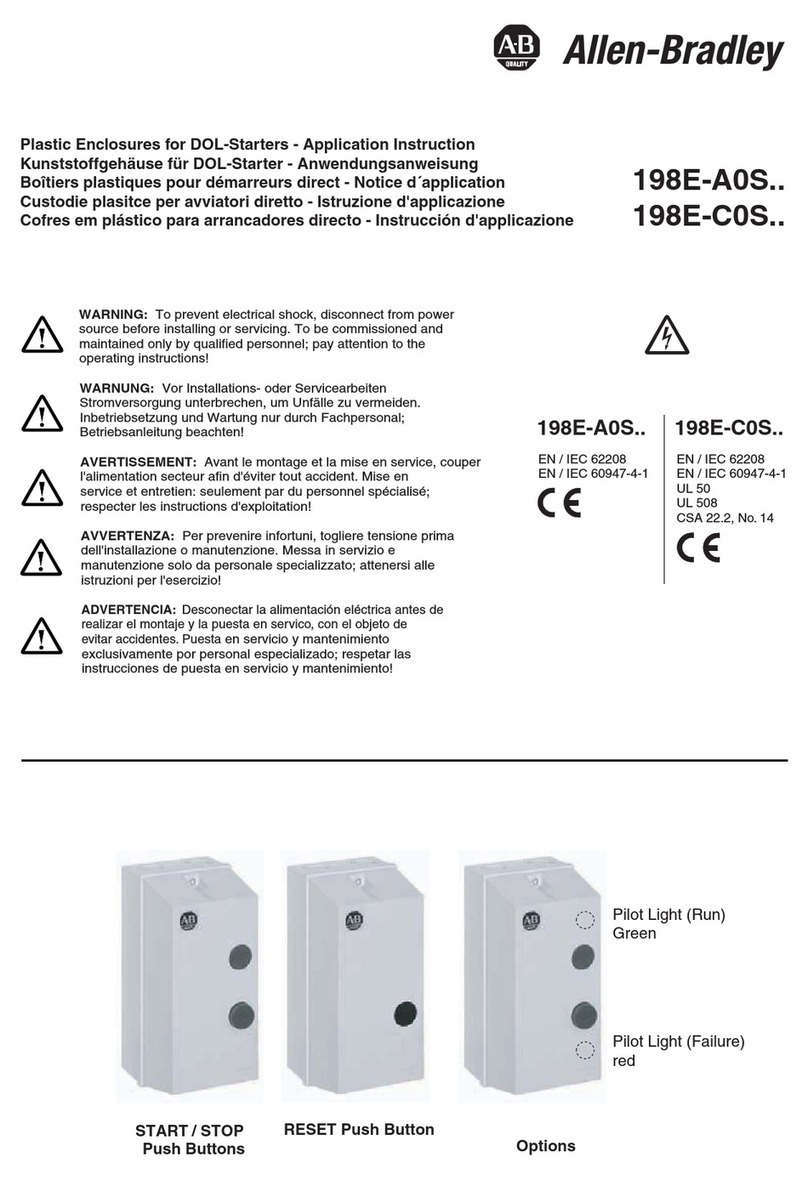

Allen-Bradley

Allen-Bradley 198E-A0S Series Application Instruction

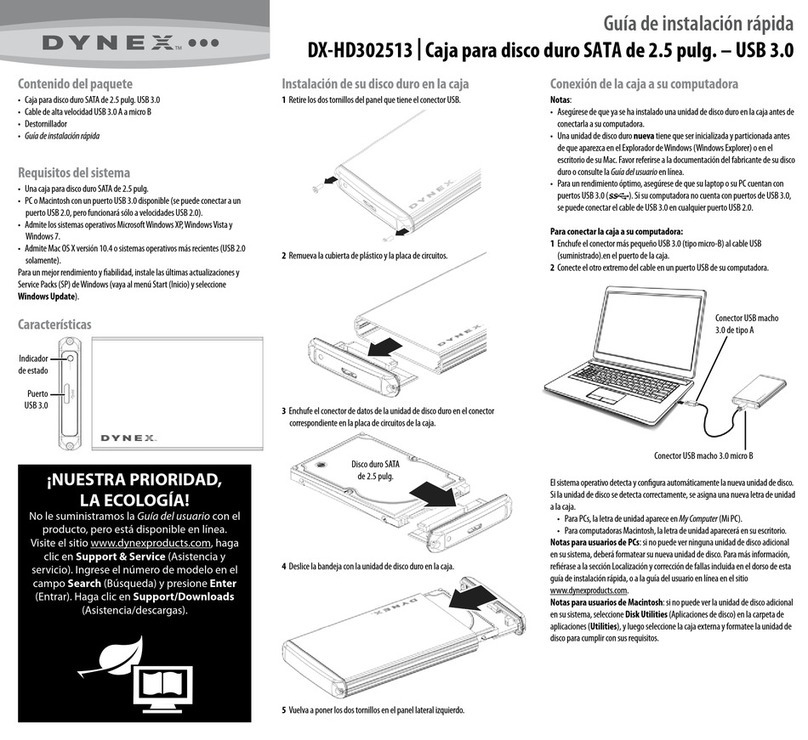

Dynex

Dynex DX-HD302513 Guía De Instalación Rápida

Agilent Technologies

Agilent Technologies G6012A User information

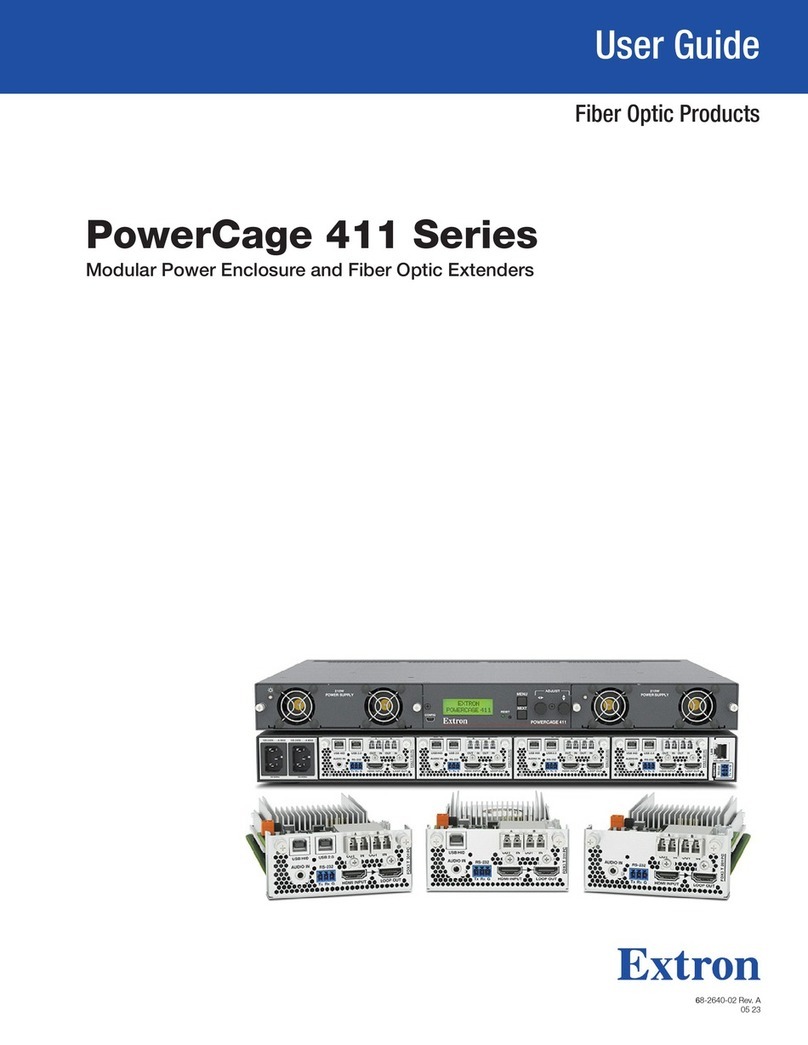

Extron electronics

Extron electronics PowerCage 411 Series user guide

Avid Technology

Avid Technology Unity LANshare LP Replacement procedure

Rosewill

Rosewill SPECTRA D100 Quick user guide

Rittal

Rittal SK 3185.330 Assembly and operating instructions