MEFE—Mitchell Engineering Food Equipment Pty Ltd

23 Storie Street Clontarf QLD 4019 Australia

Page 3

+617 3283 4536

Free AU 1800 669 006

1. General Warning

• This machine should be operated by professionals familiar with the safety measures.

• If the operator is a beginner, they should be trained before operang.

• Please cut o the power before cleaning or performing maintenance on the machine.

• If the protecon measures are to be taken o because of cleaning and maintenance, the risks must be eval-

uated carefully.

• Aenon must be highly focused for cleaning and maintenance.

• Protecng the machines power cables is necessary. Damaged power cable may can results in an electric

shock.

• Please contact us if malfuncons occur or the machine needs to be adjusted or maintained. Operators are

not recommended to repair damages.

• The machine should not be used to cut bone, frozen meat or sh and non-food substances.

• When the machine is working, please do not put your hands into it.

• Under the following circumstances, the producer will not take charge:

1. The machine is operated by an unprofessional.

2. Components of the machine have been replaced with parts produced by dierent factories.

3 . The operator has not obeyed rules.

4. The machine has not been maintained properly.

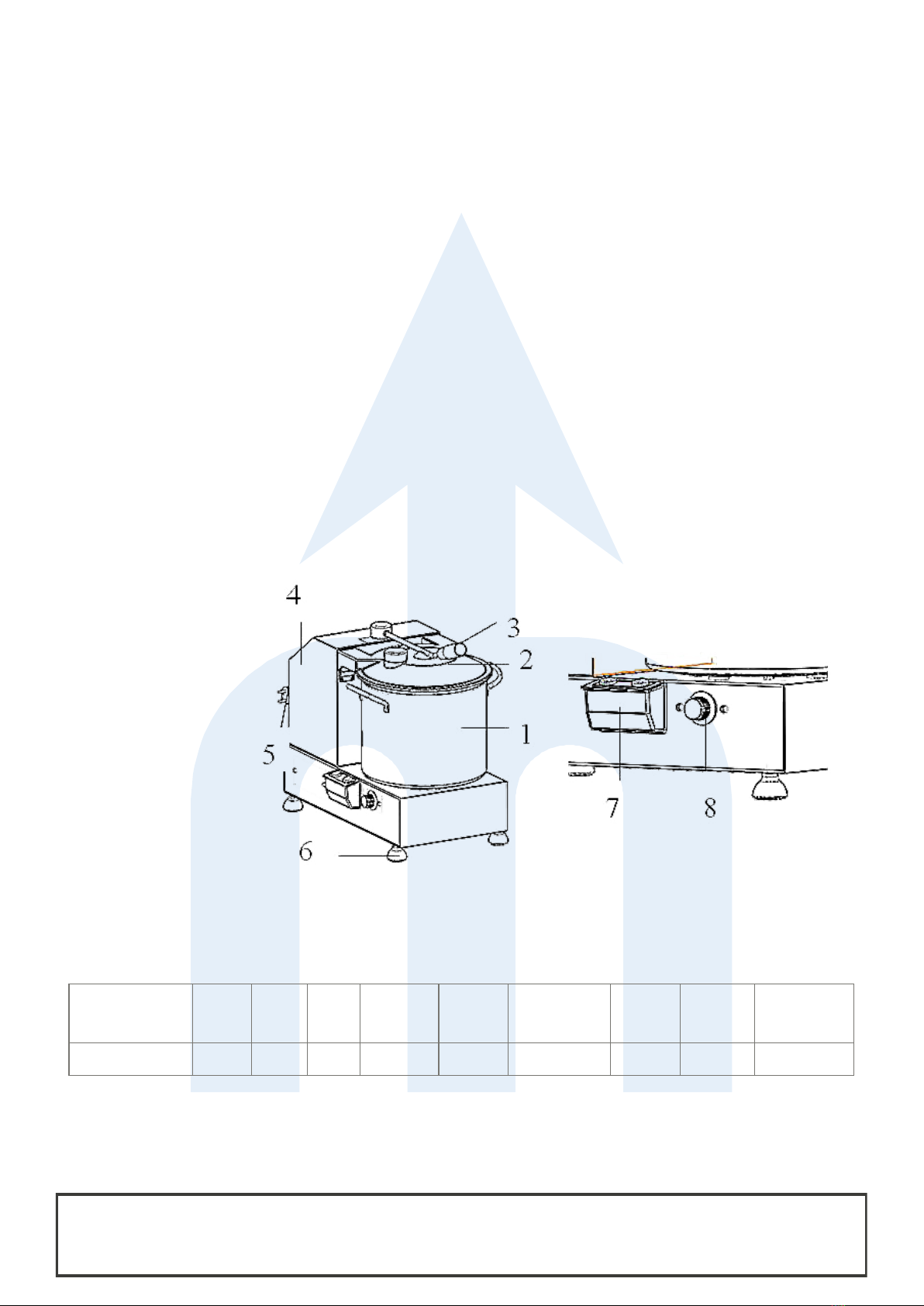

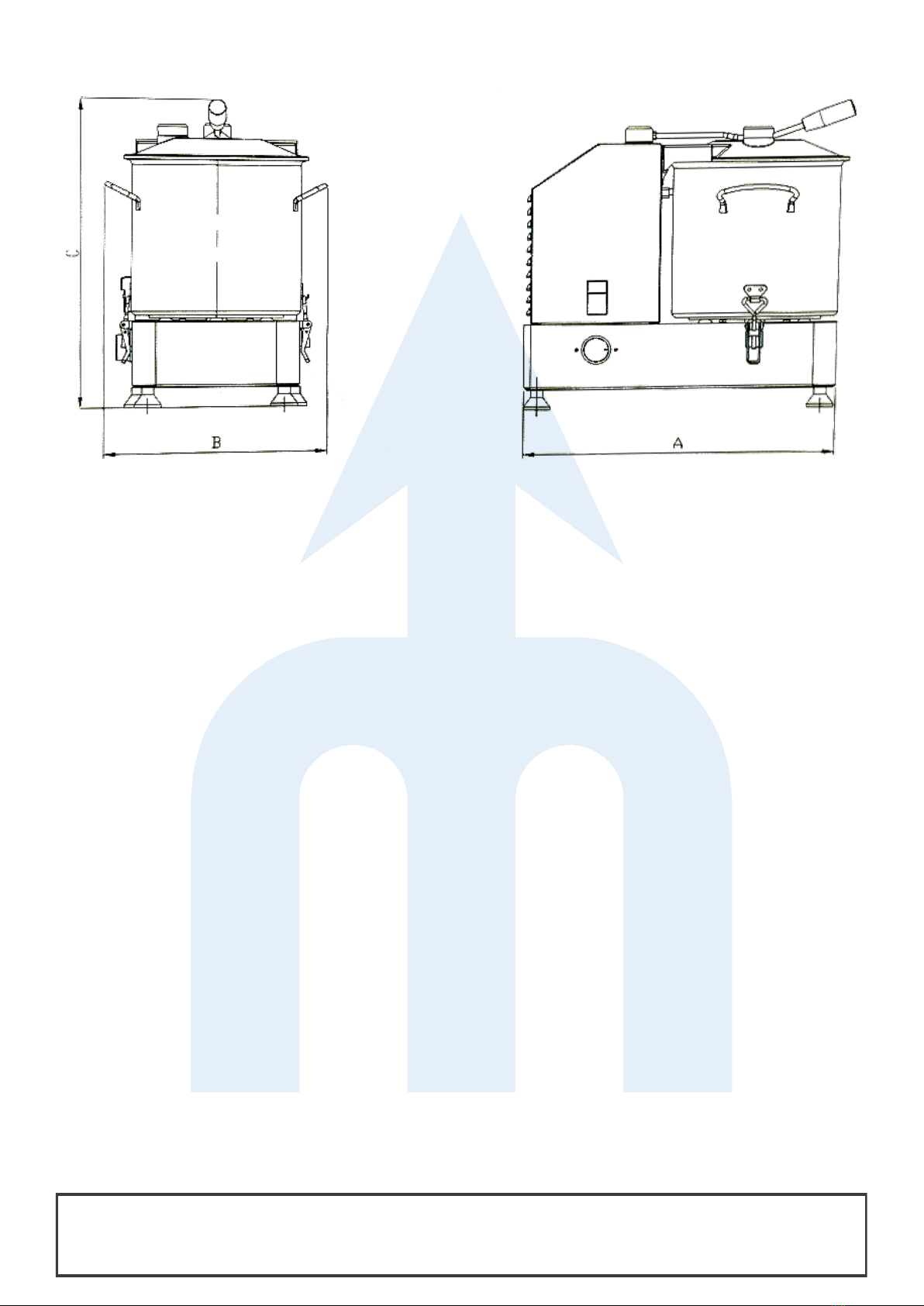

2. Product Design and Features

2.1 Safety Features

• The cover plays an important role in protecon. The cover can be moved away if arm lock is up.

• Micro mechanical device—The machine will stop working if the arm lock is up or the cover is not on proper-

ly.

• Relay—If the power cuts o, the machine should be restarted.

• Motor—The motor contains PTC thermal protecon: When the machine works for a long me, the motor

temperature can exceed a set temperature and the machine will automacally turn o. In the event of over-

heang remove the plug and restart the machine aer 10 minutes.

• Even though this machine is equipped with electrical and mechanical safety features (for working, mainte-

nance and cleaning), some risks cannot be avoided that may happen while feeding food and performing

maintenance (hands may be hurt by blades) so please always take extreme cauon.