Table of contents

1 Notes on safety ..................................................................................................................... 6

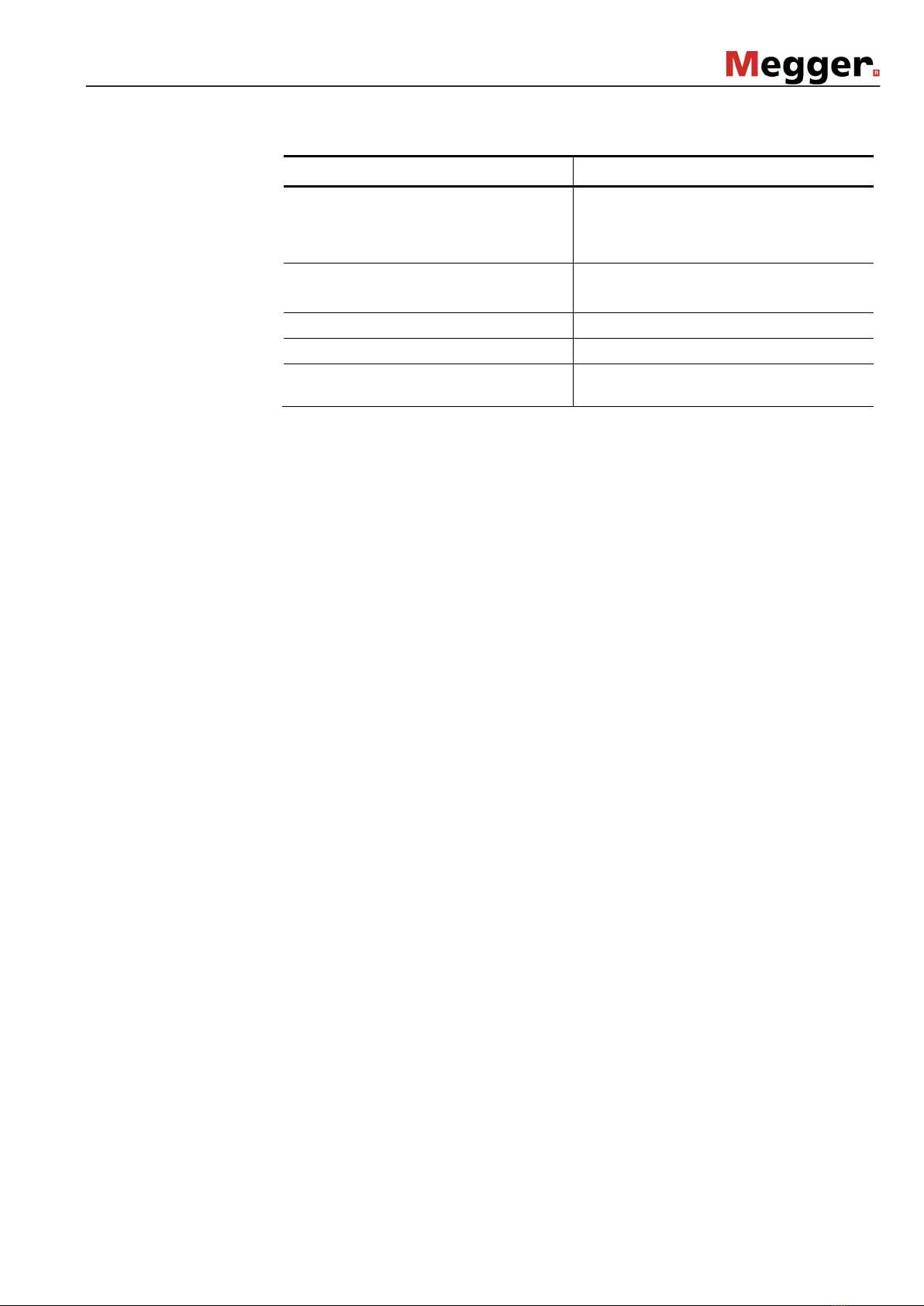

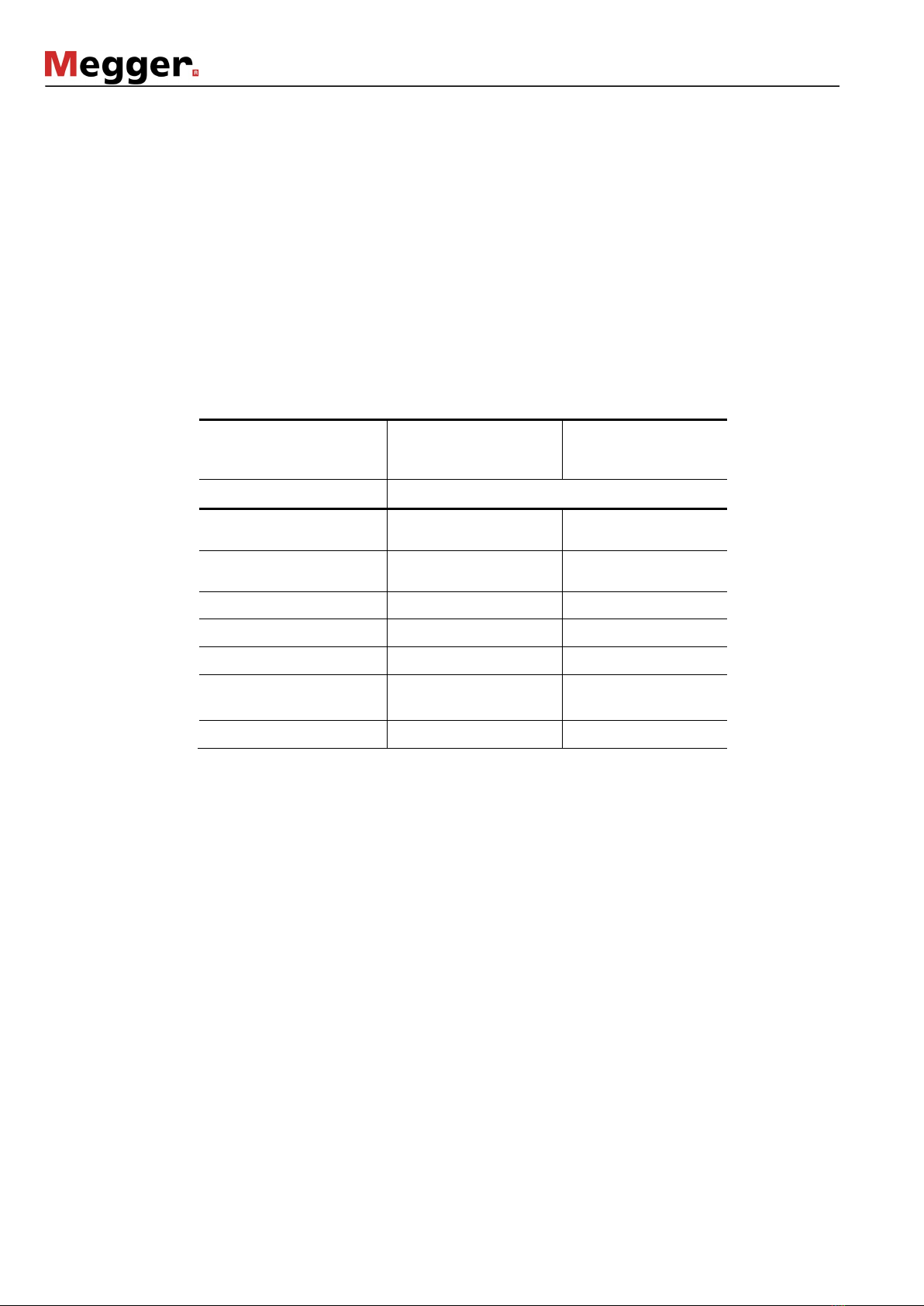

2 Technical data ...................................................................................................................... 7

3 System overview ................................................................................................................ 10

3.1 Easyloc Standard Rx receiver .............................................................................................. 11

3.2 Easyloc Standard Tx transmitter .......................................................................................... 13

4 Using the location system ................................................................................................. 14

4.1 Connection and initial use of the Easyloc Standard Tx transmitter ...................................... 14

4.1.1 Transmitter signals and modes of operation .................................................................. 14

4.1.2 Options for direct and inductive signal coupling ............................................................. 15

4.1.2.1

Direct coupling on cables and pipes .................................................................................... 15

4.1.2.2

Coupling using special connection accessories ................................................................... 17

4.1.2.3

Inductive signal coupling ...................................................................................................... 18

4.1.2.4

Signal coupling in non-metallic pipes ................................................................................... 19

4.1.3 Initial use of the transmitter ............................................................................................ 20

4.2 Locating lines with the Easyloc Standard Rx receiver .......................................................... 21

4.2.1 Changing the system settings ........................................................................................ 21

4.2.1.1

Depth measurement settings .............................................................................................. 21

4.2.1.2

Changing the receiving frequency ....................................................................................... 22

4.2.2 The basics of locating lines with the receiver ................................................................. 23

4.2.2.1

Modes of operation for the receiver ..................................................................................... 23

4.2.2.2

Regulating the sensitivity level to match the reception signal strength ................................ 24

4.2.2.3

Handling the receiver and locating the line .......................................................................... 25

4.2.3 General site surveying .................................................................................................... 26

4.2.4 Determining the direction of a line .................................................................................. 27

4.2.5 Determining the depth of a line ..................................................................................... 28

4.2.6 Masking-Out Lines ......................................................................................................... 31

4.2.7 Functional test of the receiver ........................................................................................ 32

5 Maintenance ........................................................................................................................ 34